InSinkErator Model WX-300 User manual

Other InSinkErator Garbage Disposal manuals

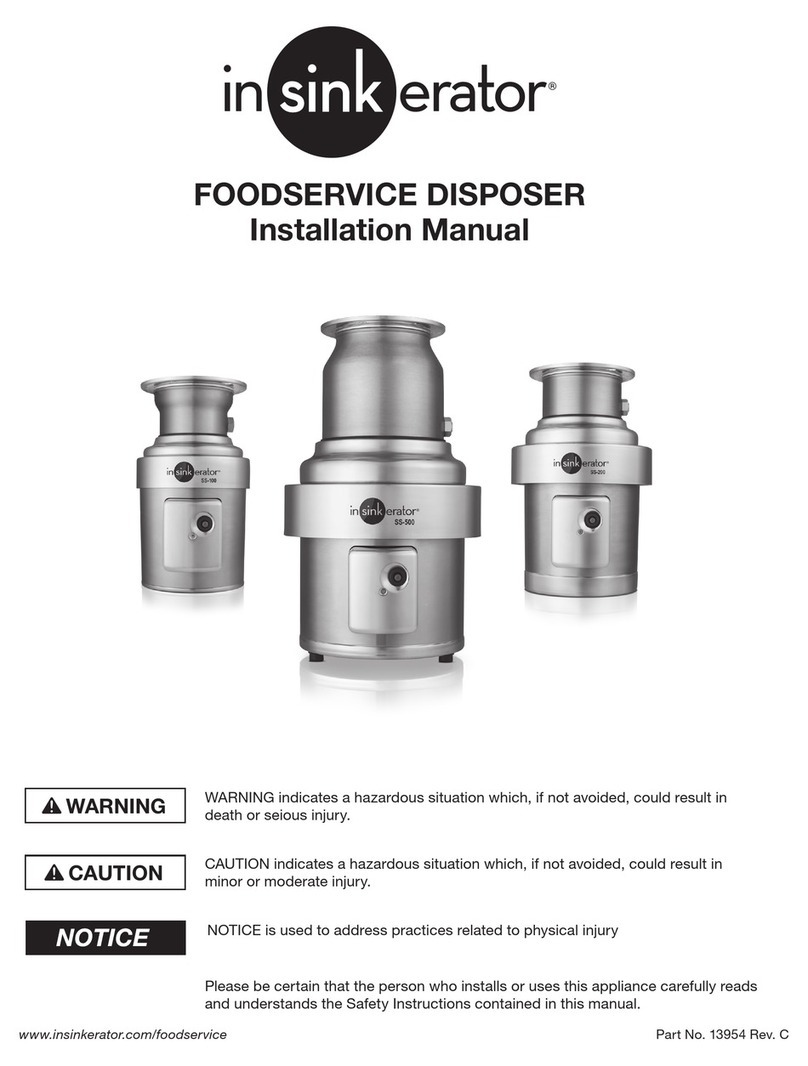

InSinkErator

InSinkErator EVOLUTION COVER CONTROL User manual

InSinkErator

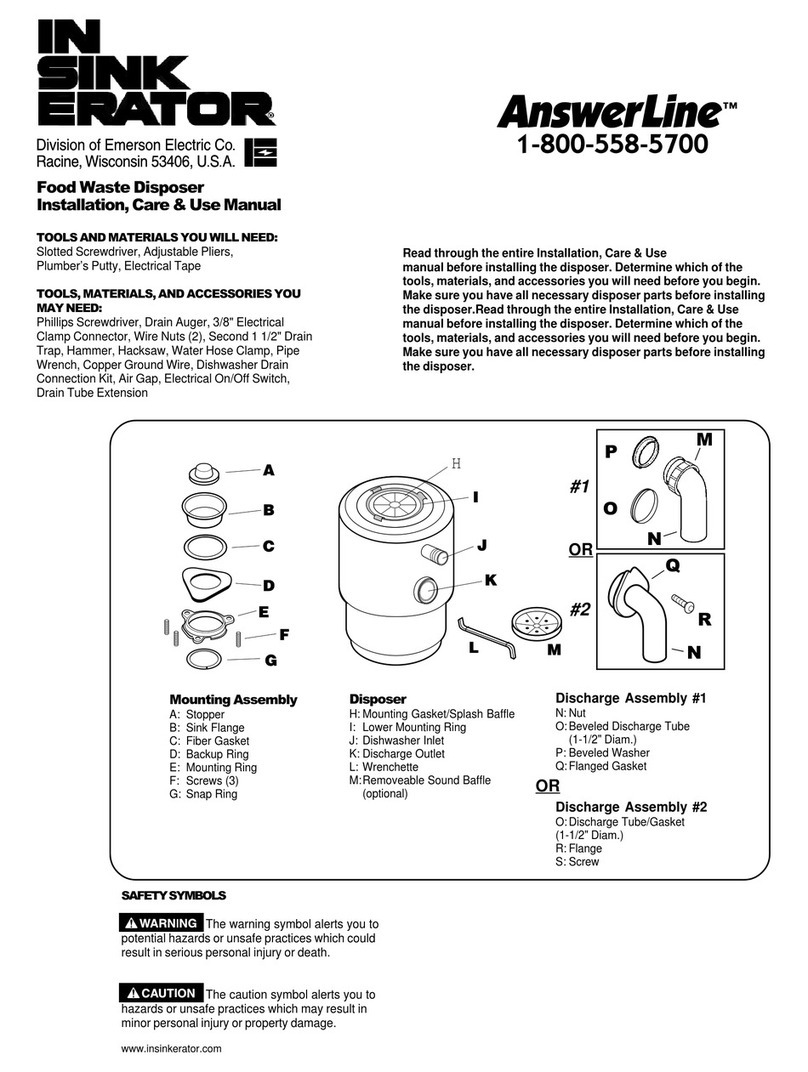

InSinkErator PRO Series User manual

InSinkErator

InSinkErator Model SS-50 User manual

InSinkErator

InSinkErator Model SS-100 User manual

InSinkErator

InSinkErator Badger 1 User manual

InSinkErator

InSinkErator Evolution Series User manual

InSinkErator

InSinkErator Evolution Essential User manual

InSinkErator

InSinkErator Badger 1 User manual

InSinkErator

InSinkErator Badger 1 Installation manual

InSinkErator

InSinkErator Model SS-100 User manual

InSinkErator

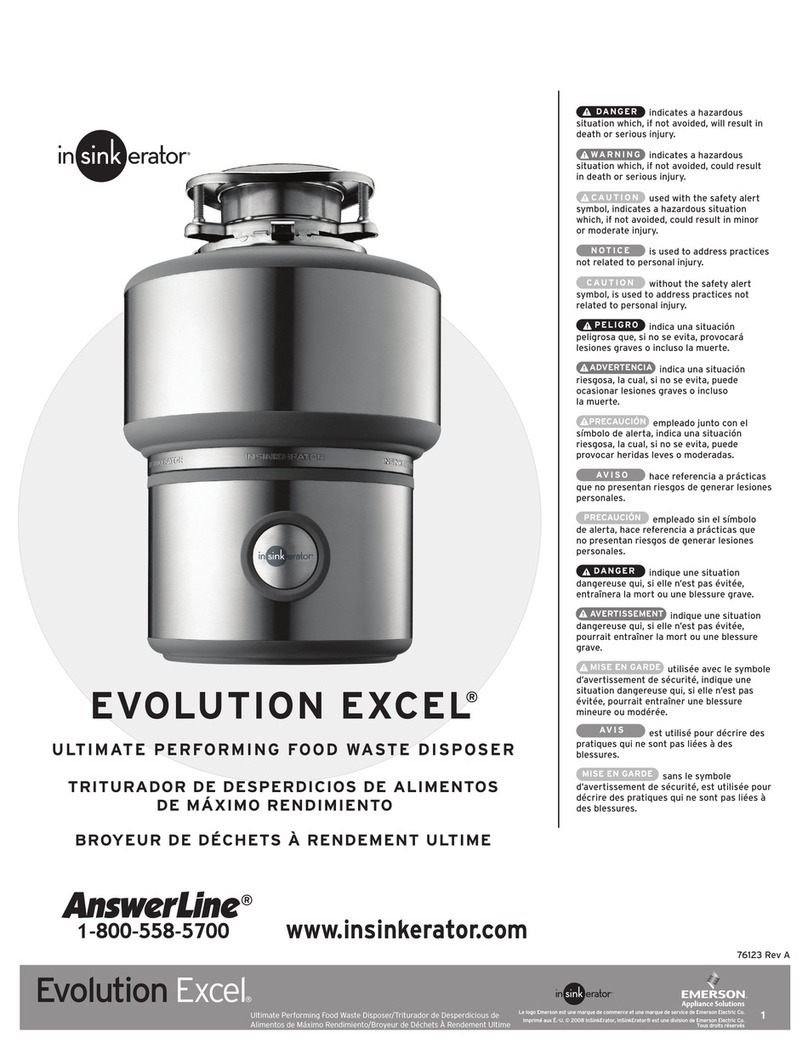

InSinkErator Evolution Excel User manual

InSinkErator

InSinkErator Model LC-50 User manual

InSinkErator

InSinkErator Evolution Excel User manual

InSinkErator

InSinkErator Badger 15ss User manual

InSinkErator

InSinkErator Badger 5 User manual

InSinkErator

InSinkErator Badger 444 Installation manual

InSinkErator

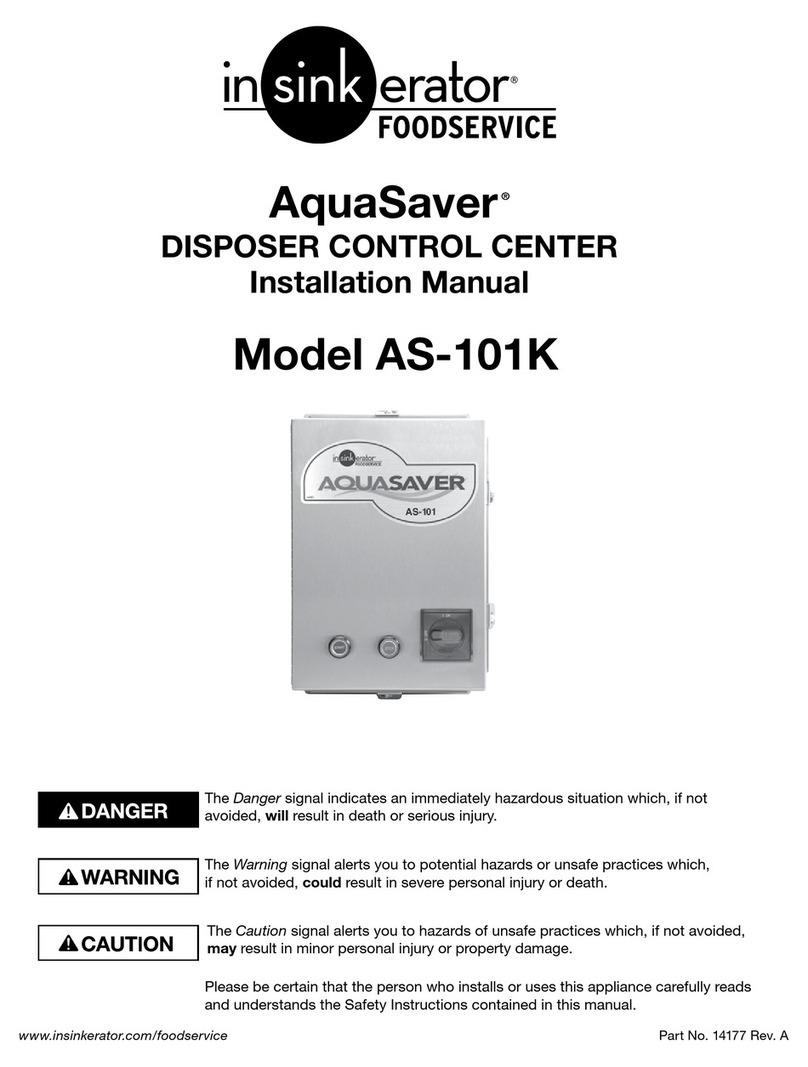

InSinkErator AQUASAVER AS-101K User manual

InSinkErator

InSinkErator EVOLUTION COVER CONTROL User manual

InSinkErator

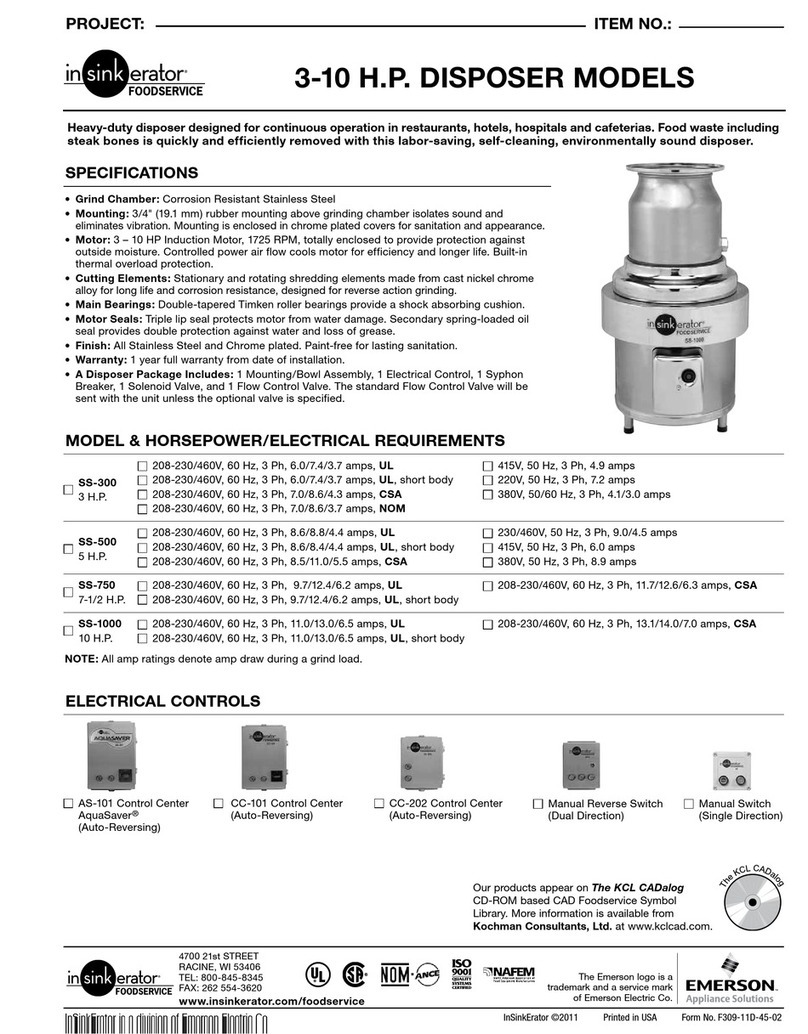

InSinkErator Model SS-1000 User manual

InSinkErator

InSinkErator Evolution PRO Series User manual

Popular Garbage Disposal manuals by other brands

Scheppach

Scheppach HP3000S Translation from the original instruction manual

Haigh

Haigh Quattro Vanguard Original manual

Maxmatic

Maxmatic 5000 OPERATING AND INSTALLATION Manual

Toro

Toro FP-2200 Operator's manual

Elephants Foot

Elephants Foot eDiverter Photo step by step instruction booklet

Zanussi

Zanussi DU 4400 Instruction booklet