INSTROTECH 4001 User manual

Universal Process /

Counter / Frequency /

Integrator / Totaliser

Indicator

Operating Manual for Models :

4001 / 4011 / 5001 / 5011 / 5600 /

8001 / 5001-T / 8001-T

Cleaning

Do not clean the instrument while the instrument is on.

Harsh abrasives, solvents, scouring cleaners and alkaline

cleaning solutions, such as washing soda, should not be

used especially on the display window. The outside of the

instrument may be wiped down with a slightly damp clean

cloth (lightly moistened with water only).

Under no circumstances should you attempt to wipe the

inside of the instrument.

Safety

This equipment is supplied by a mains voltage which can

cause an electric shock injury. Before removing the circuit

board from its housing, switch the instrument off, isolate it

from the mains power supply and make sure that it cannot

be connected inadvertently by other persons.

If the circuit board is removed from its housing, do not

apply power to the instrument unless specifically instructed

to do so in these instructions. When working on live

equipment, exercise great care, use insulated tools and test

equipment, and do not work alone.

When fitting option boards, always put the circuit boards

back in the housing with the back-plate securely fastened

before powering up the instrument.

When handling circuit boards, ensure that full anti-static

precautions are observed.

Replace external mains fuse with one of an equivalent type.

Contents

Introduction ....................................................................... Page 3

Electrical specifications ..................................................... Page 3

Input ranges ...................................................................... Page 3

Sensor excitation................................................................Page 3

Power supply .....................................................................Page 4

Programmable specifications ............................................ Page 4

Other specifications ...........................................................Page 4

Installation (panel cutout) .................................................. Page 5

Installation (fastening) ....................................................... Page 5

Display & keypad (during normal display mode) ...............Page 5

Display & keypad (during programming mode) .................Page 5

Connections & links ...........................................................Page 6

Process inputs ..............................................................Page 6

Frequency / count inputs ..............................................Page 6

Hardware link selection for J5 ...................................... Page 6

Potentiometer input ......................................................Page 7

Option connections & links, Power supply links ........... Page 7

Programming chart ............................................................Page 8

Display codes explained ................................................... Page 10

Programming example ...................................................... Page 11

Asciibus protocol ............................................................... Page 12

Setting up Model 5001-T totaliser / integrator ................... Page 13

Option 3000, 3001-P / M, 3002, 3003, 3004-P / M ........... Page 15

Option 3006,3008,3009,3010,3011,3012, 3013.................Page 16

Option 3014, 3017-P / M, 3018-P / M.................................Page 17

Option 3021, 3022, 3023, 3024..........................................Page 18

Option 3025, 3026, 3028 ...................................................Page 19

Diagram “P” .......................................................................Page 20

Diagram “M” ...................................................................... Page 20

Declaration of conformity .................................................. Page 20

Guarantee ......................................................................... Page 20

Page 2

0 - 20 mA, 4 - 20 mA, 0 - 200mV, 0 - 2 V, 0 - 10 V, 0 - 20 V, Special

(pot input), 0.2Hz - 40kHz (24V max, up to 0.01 Hz resolution).

Electrical Specifications

Sensor Excitation

Accuracy & linearity : 0.05% of F.S., or 1 count

Option 3011/15/27 accuracy : 0.5% of F.S., or 1 count

Internal resolution : 20000 counts (bi-polar)

Temperature coefficient : 20 ppm / °C typical

Settling time for process inputs : 0.5 seconds

Settling time for frequency input : 5 milliseconds (with no filter)

Operating temperature range : -10 to +50°C

Storage temperature range: -40 to +80°C

Humidity : < 85% non-condensing

Warm-up time : None required

Electro-mechanical relays : 250V AC, 30V DC, 2A, PF=1

Solid state relays : 400 V AC/DC, 0.5A, PF=1

Analogue output accuracy : 0.1% of full scale, 12 bits

Current analogue output load : 500 Wmaximum

Voltage analogue output load : 1 kWminimum

Memory retention : Full non-volatile operation

Option 3006 isolation rating : 1500 V

Declaration of conformity : See last page

24V DC: (17-26V), current limited. For 2-wire transmitters,

proximity switches or encoders. With option 3010,

current capability increases to 100mA

5V DC: ± 1%, maximum 25mA

2.5V DC: Precision reference, 2mA max for pot (2 kWmin)

Input Ranges

The Models 4001, 4011, 5001, 5011, 5600, 8001, 5001-T, 8001-T

indicators are universal LED process indicators that can be

applied to most process variables with analog & digital inputs.

These high accuracy panel meters are designed for accurate

measurement & display of pressure, level, flow, freq, up & down

counting, DC voltages or currents & revolutions / min. Selected

models offer integration / totalisation of the input signal. The built-

in sensor excitation supply is link selectable for 2-wire / 3-wire

transmitters, encoders & potentiometer input.

Model 4001 is a 4 digit (-1999 to 9999) indicator offering process

inputs of type mA, mV, V, pot and frequency.

Model 5001 is a 5 ½ digit (-199999 to 199999) indicator offering all

the features of Model 4001 but with process x frequency functions

as well as count rate & totaliser.

Model 5600 is a 6 digit (-199999 to 999999) indicator offering all

the features of Model 5001. Set points and other options are

however limits to 5 ½ digits.

Model 5001-T is a 5 ½ digit (-199999 to 199999) indicator offering

all the features of Model 5001 but with process integration /

totalisation included.

Model 8001 is a 5 ½ digit rate display indicator with an 8 digit count

display, while the Model 8001-T has process integration /

totalisation included.

Model 4011 & Model 5011 offer Asciibus serial input for remote

display of serial information.

Introduction

Page 3

Programmable Specifications

5½ / 6 / 8 Digit Models

Zero & full scale setting : -199999 to 199999

Decimal point : Adjustable on all digits

Process filtering : 0.0 to 10.0 seconds

Freq / counter scaler : 0.05 to 1999.99

Frequency units : Selectable Hz or RPM

Frequency filtering : None, 0.5, 1.1 or 4.5 seconds

Counter features : Reset (count up) / Preset (count down),

: Counter rate & totaliser

Options :

Analog output zero & span : -199999 to 199999

Alarm setpoint values : -199999 to 199999

Alarm hysteresis : 0 to 255 (default 1)

Alarm delay : 0 to 255 seconds (default 0)

Alarm relay settings : Selectable HIGH or LOW alarm

Alarm relay state : Selectable NO or NC

Unit address : 0 to 99

Baud rate : 2400, 4800, 9600, 19200

Standard

115 / 230 VAC ± 10%, link selectable, 50/60Hz, 5VAtyp

Optional

8 - 30VDC isolated power supply (Option 3008), 5VA typ

8 - 30VDC non-isolated, 5VA typ

95V-265V AC/DC isolated power supply (Option 3010), 5VA typ

Power Supply

4 Digit Models

Zero & full scale setting : -1999 to 9999

Decimal point : Adjustable on all digits

Freq / counter scaler : 00.01 to 99.99

Frequency units : Selectable Hz or RPM

Frequency filtering : None, 0.5, 1.1 or 4.5 seconds

Counter features : Reset (count up) / Preset (count down)

Options :

Analog output zero & span : -1999 to 9999

Alarm setpoint values : -1999 to 9999

Alarm hysteresis : 0 to 255 (default 1)

Alarm delay : 0 to 255 seconds (default 0)

Alarm relay settings : Selectable HIGH or LOW alarm

Alarm relay state : Selectable NO or NC

Unit address : 0 to 99

Baud rate : 2400, 4800, 9600, 19200

Other Specifications

DIN 48 x 96 housing, 147mm depth

Industrial strength single piece housing

Housing is flame retardant ABS plastic that meets UL94 V-0

Circuit board is flame retardant material that meets UL94 V-0

Front facia rating : IP65 (with o-ring seal supplied as standard)

Page 4

Fastening

The supplied fastening

clips may be fitted on

the side or the top /

bottom of the housing.

Ensure that the clip &

screw is mounted as

shown here.

Caution : Do not

overtighen the screws.

Min

12

45

92

Installation

To gain access to the

circuit boards, switch

power off and remove

terminals from the

back of the housing.

Observe safety

precautions. Use a

screwdriver to clip the

back-plate off.

During programming mode Display & Keypad

147

Panel Cutout

Installation

48

96

Enter

Programming menu

Move to next digit

Increment digit / change selection

Total

LED

(display

shows

totalised

value)

48

96

2341

Reset peak value (option 3012 only) /

Auto-zero (option 3014 only)

Print on demand (comms option only)

Show normal value (option 3012 only)

Show peak / valley hold value

(option 3012 only)

2341

kPa

All dimensions in mm

During normal display mode Display & Keypad

Page 5

Min

12

DIN 1/8 cutout

O-ring sealing

gasket supplied

as standard

Rate LED

(display shows rate)

Alarm LEDs

(illuminated whenever

relays are energised)

Hardware Link Selection For J5

mA XX

X

200 mV

2 V

10 V

20 V

Special*

X

X

X

X

X

Analog Output

+5VDC X

+24VDC, current limited X

+2.5V Vref X

X

Terminal 3 Voltage Output

0 - 20 / 4 - 20mA (option)

0 - 10V (option)

X

Input

J5

S

+

-

+

-

L

N

Namur

Circuit board

Frequency:

Display Hold (Option 3026)

Potential free contact

Namur

PNP / Volts

J8

P

CCounts /

Process

input

selector

1. In Lo

3. + Vout

4. Dig In

2. In Hi

J7

J5

NPN

Select sensor type

Connections & Links

Excitation select:

NPN / PNP

Generated frequency

(24V maximum)

2-wire NAMUR sensor

(must work with

5V excitation)

Line / mains frequency

measurement option

(Option 3021)

3-wire proximity switch /

encoder (NPN or PNP type)

Counter : Reset

Circuit board

True RMS AC (Option 3005)

Ohm / Tap input (Option 3011)

Process inputs of type

200mV, 2V, 10V, 20V,

0/4-20mA. (Select J5 link !)

+

-

Namur

PNP / Volts

J8

P

C

Counts /

Process

input

selector

1. In Lo

3. + Vout

4. Dig In

2. In Hi

J7

J5

Digital

sensor

selection

NPN

S

+

-

Select input link

(see J5 link table)

Process Inputs

4 - 20 mA, 2-wire

transmitter

0 - 20 mA, 3-wire

transmitter

Freq / Count Inputs

-

+

Totaliser reset OR

Rate vs Total select OR

Reset peak / valley hold (Option 3012) OR

Remote auto-zero (Option 3014) OR

Display hold (Option 3026)

Note : Counter or totaliser reset may also be achieved by pressing the 'Enter' key (press for 3 seconds). External reset is almost instantaneous.

Note : The "special" (SP) input is normally configured for potentiometer input. It can however be configured to order as per customer's requirements.

Note : For 2- wire NAMUR sensors, the proximity switch must be able to operate from 5V supply.

Place hardware links as shown in the diagrams.

Remember : Configuring this instrument requires two steps. (1)

Select the correct hardware links as shown. (2) Program the

instrument with the programming chart on page 8 & 9.

Page 6

For 230V

operation

For 115V

operation

DC supply

AC supply

-

+

NL

J2

Neut (+)

Power

supply

selector

Live (-)

*** External 0.5A fuse recommended ***

AC supply

-

+

NL

J2

Neut (+)

Power

supply

selector

Live (-)

DC supply

Power Supply Links

S

+

-

Circuit board

Display hold (Option 3026)

Potentiometer input

(Link as shown)

Namur

PNP / Volts

J8

P

C

Counts /

Process

input

selector

1. In Lo

3. + Vout

4. Dig In

2. In Hi

J7

J5

Digital

sensor

selection

NPN

Link as shown

Analogue

output

option

(see links

on J5)

RS232/

RS485

option

Alarm 1

Alarm 2

Alarm com

-

+

1. In Lo

3. + Vout

4. Dig In

7. +D (Rx)

5. -An out

2. In Hi

8. -D (Tx)

9. DGND

10

6. +An out

Neut (+)

11

12

Live (-)

Circuit board

J5

Link here for

voltage output

Alarm connections

for 3001/4-P only.

Solid state relays,

400V AC/DC,

0.5 A max, PF=1

Interposing relays

recommended for

heavy duty applications

Pulse output

(Option 3023)

Option Connections & Links

Linked for

current output

Page 7

J2 link positions do not matter for DC supply

or for Option 3008 or Option 3010.

Place hardware links as shown in the diagrams.

Remember : Configuring this instrument requires two steps. (1)

Select the correct hardware links as shown. (2) Program the

Potentiometer Input

RS485 / 232

only (Option

3002 / 3013)

,, ,,,, ,,

,, ,, ,

,, ,, ,, ,, ,, ,,

,

,,

,

,, ,

,

READ ME FIRST !

,

,,

to toggle the

following options

,

to accept

new value

,for menu

to accept

new value,for menu

,

If ‘pro.f’ is chosen in

input menu, then

If ‘d.tot’ or ‘p.int’ is chosen

in input menu, then

,, , , for menu

(Similarly for alarm 2, 3 & 4)

SEE NEXT PAGE for input type selection

“END”. Instrument returns to normal display mode.

to accept

new value

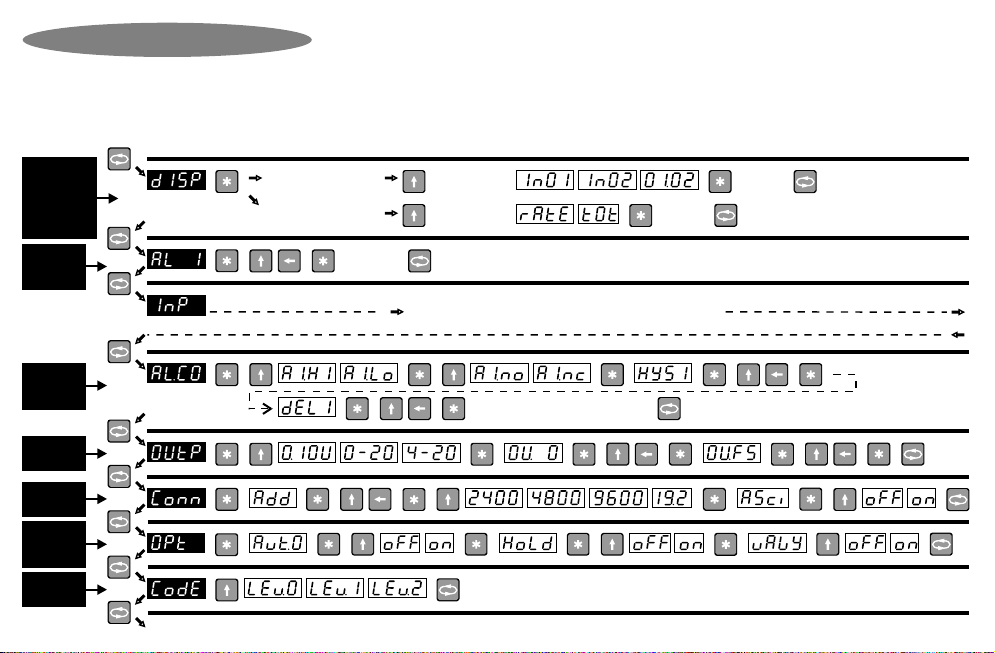

Note 1 : This programming chart is a simplified flowchart for users that have previous experience with this instrument. A programming example is

available in the next few pages to assist new users in understanding this programming chart.

Note 2 : Because this instrument has many options, all possible option menus are shown. Options that are not ordered will not appear in the

programming sequence.

Note 3 : Configuring this instrument requires two steps. (A) Select the correct hardware links (page 6 & 7). (B) Program the instrument with this chart.

Note 4 : To enter programming mode, press the menu key for a few seconds (unless the optional keypad lock has been set). Programming mode timeout

is about 20 seconds. If no key is pressed for 20 seconds during programming, the instrument returns to normal display mode.

, ,, , ,,

Analog output

only (Option

3003 / 3007)

Alarms /

setpoints /

only (Option

3001/4/17/18)

Keypad lock

only

(Option 3025)

START

HERE

Model 5001 /

5001-T / 5600 /

8001 / 8001-T

only, & if ‘pro.f’

or ‘d.tot’ or ‘p.int’

is chosen in

input menu

Programming Chart

(Similarly for alarm 2, 3 & 4)

to toggle the

following options

Alarms /

setpoints /

only (Option

3001/4/17/18)

,,

,,,,, ,,,,,

Auto-zero,

Peak / Valley

hold only

(3012 / 3014)

Page 8

,,

Menu identical

to 'Pro' menu,

followed by :

Special Note :

If Model 4011/

5011 is ordered,

then refer to the

supplemental

page supplied

with this manual.

0.2V, 2V, 10V, 20V, Pot (SP),

0 / 4 - 20mA input selection

Lineariser only

(Option 3000).

Manual setpoint

station only

(Option 3024)

Model 5001 /

5001-T / 5600 /

8001 / 8001-T

only.

See Note

On ‘incr’

Feature

Model 5001 /

5001-T / 5600 /

8001 / 8001-T

only

Model

5001-T / 8001-T

only

Menu identical

to 'Pro' menu,

followed by

'Freq' menu.

Model 5001 /

5001-T / 5600 /

8001 / 8001-T

only

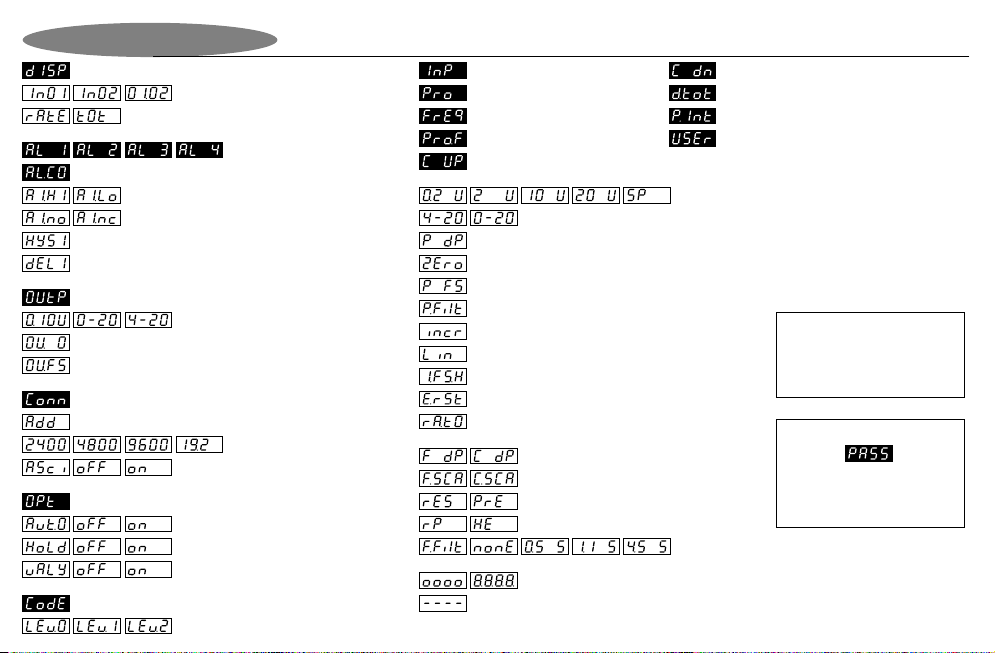

Please Read Me !

This page represents the input configuration

menus, and this chart must be read from top to

bottom. Only program the menu column

corresponding to the operation you require

(for example, for process integration, program

the “P.Int” menu column only. There is no need

to program the “Pro” menu as well.)

Incr Feature

"incr" is for display increment, and

specifies the display increment

steps. e.g. an increment of 10 will

cause the least significant digit to

function as a 'dummy' zero.

Page 9

Hardware overrange. Reduce input signal to reduce saturation.

Process input selection (0-20mA, 4-20mA)

Process input selection

(200mV, 2V, 10V, 20V, Special (potentiometer input)

Process decimal point selection (non-floating point)

Process zero display configuration

Process filter - analog inputs (factor 0.0 to 9.9 secs)

Frequency / counter decimal point selection

Frequency / counter scaler (multiplier)

RPM or Hz selection

Filter for frequency input (none, 0.5, 1.1, 4.5 seconds)

Output selection (0-10V, 0-20mA, 4-20mA)

Analogue output menu

Protocol selection. On = AsciiBus. Off =

DigiBus.

Process overscale. Input has exceeded full scale value. / Display test mode.

Display value selection menu

Process, freq, or process x freq input

Rate or totaliser display

Process input

Frequency input

Process x frequency input

Up counter input

Digital input rate & totaliser

Input selection menu

Output zero selection

Output full scale selection

Unit address (default 0)

Counter reset / preset

Display Codes Explained

1st, 2nd, 3rd, 4th setpoint value

Alarm configuration menu (shown for 1st alarm only)

1st alarm setpoint select HIGH / LOW alarm

1st alarm setpoint normally OPEN / CLOSED contact

1st alarm setpoint hysteresis

1st alarm setpoint delay

Communications menu (RS232 / RS485)

Peak OR valley hold. “off” = peak. “on” = valley

Available baud rate values

Process input integration / totaliser

User input for Option 3024 manual setpoint station

Configure digital input as external totaliser reset

Process integration full scale rate hour setting

Display increment. e.g. '10' would give dummy zero.

Configure digital input as external display rate / total selector

Linearisation menu (on/off) select (optional)

Process full scale display configuration

Auto-zero option turned off or on

Down counter input

Please Note :

If the front keypad has been

locked, then the word “PASS” will

appear. See option 3025 for more

information.

Peak / valley hold option turned off or on

Option menu for Auto-zero feature and Peak / Valley Hold feature

Keypad lock security level. Level 0 = none, Level 1 = alarm value changes, Level 2 = full

Keypad lock security menu. See Option 3025 for more information.

Page 10

Please Note :

Display screens shown in black

are to indicate the beginning of

sub-menus.

Remember, the symbols on the keypad have the following

definitions during programming.

Press “Menu” for

3 seconds

Next Menu

Item Increment digit Next Digit Enter /

Accept value

Press “Next digit” to

amend the next digit

Press “Increment digit”

to increase value

Press “Enter” to see

Alarm / Trip 1 value.

Amend the other digits in the same way until the desired trip

value is entered.

The entire programming menu operates in a manner

similar to the example described above.

Press “Menu” to

proceed to next

trip value.

Press “Enter” to accept

Alarm 1 value.

Setting Up Alarm Values (Option)

Programming Example

Use the same menu steps above to change trip levels

for trip 2, 3 and 4.

Page 11

IGNORE THIS PAGE unless communications option has been ordered. When the RS232 (option 3013) or RS485 (option 3002) is

ordered, two protocols are made available, namely ASCIIbus & DIGIbus protocols. DIGIbus is the default protocol which is used for

the calibration and configuration of the instruments, and whenever the instrument is connected to master-slave systems. DIGIbus

protocol is therefore used in complex bus systems, and is NOT described here. Please contact factory for the DIGIbus protocol.

ASCIIbus, which is described here, is much easier to use as it can easily interface to third party systems with very little engineering

work required. It is a purely ASCII based (7 bit) protocol. The protocol is essentially designed for one way communications

(instrument to PC). Under the "Conn" (connection) programming menu, ASCIIbus is enabled by selecting "ASCI" to "ON". If "OFF" is

selected, the DIGIbus protocol will be active. Although designed for one way communications only, the ASCIIbus protocol contains an

address. The address range is "00" to "99".

Using address "00" : If this address is selected, the instrument will only transmit data on demand by either momentarily pressing the

'menu' key, or by transmitting a byte (any ASCII character) to the DPM. This mode is useful for interfacing to printers. In addition, field

' AA ' will contain the ASCII character "blank/space". Field ' P ' will also contain the ASCII character "blank/space".

Using address "01" to "99". If any of these addresses are used, the meter continuously transmits information at approximately 5 times

a second.

The data format string output from the indicator is (7 bit ASCII code is used):

Line Settings : 7 Data Bits, 1 Parity bit, Odd Parity, 1 Stop Bit.

Baud Rate : Selectable 2400, 4800, 9600, 19200.

Data Bits : Numerical ASCII characters : 0, 1, 2, 3, 4, 5, 6, 7, 8, 9

Other ASCII characters : #, blank/space, +, -, CR, LF

Protocol format is : # AA S D D D D D D D D P CR LF

where : # = indicates start of message

: AA = Instrument address. ASCII 00 to 99. 00 is default.

: S = sign (polarity) ( ASCII "+" or "-" ).

: D = data bits (data for 8 numerals). See Note (1).

: P = decimal point position. ASCII 0 to 8.

: CR = ASCII carriage return.

: LF = ASCII line feed.

The output will follow the display reading. This

means that if the peak-hold option has been

ordered and activated, the communications output

will peak-hold as well.

Note 1 : This protocol allows for future expansion.

Therefore if Model 4001 is used for example, the

first four digit data will contain the ASCII character

"blank/space" and the last four digits will contain

the display reading. Similarly, if the Model 5001 is

used for example, the first 2 digit data will contain

the ASCII character "blank/space" and the last six

digits will contain the display reading.

Asciibus Protocol (for Option 3002 / 3013)Communications

Page 12

Page 13

Example 1:

Formula: I.FS.H value without decimal points = (Desired value on display after 1 hour * 14062.5)

-----------------------------------------------------------------------

(Total value accumulated after 1 hour/256)

Example: A 4-20mAinput signal must correspond to a 0-2500 rate display. This input must also be integrated (totalised) over an hour.

The totaliser must show 1250 after 1 hour if the input is 12mA for that hour. For calculation purposes, calculate the totalised value at

20mA, which in this case will be 2500.

According to the above formula,

A = Desired value on display after 1 hour

B = I.FS.H Value without decimal points

C = Total value accumulated after 1 hour (i.e. max value on rate (2500) * 3600 seconds = 9 000 000 )

B = (A * 14062.5)

--------------------

(C/256)

Therefore B = (2500 * 14062.5)

------------------------

(9000000/256)

I.FS.H = 1.000

After 1 hour at 12mA the display should show 1250. After 1 hour at 20mA, the display should show 2500.

Under the P.Int sub-menu in the instrument, set the following: select 4-20; P dP = oooooo; ZEro = 000000; P FS = 002500;

P.Filt = 00.5; incr = 000; C dP = oooooo; I.FS.H = 1.000

How to calculate the I.FS.H (integrated full scale hour) value for Model 5001-TModel 5001-T

Page 14

Example 2:

Formula: I.FS.H value without decimal points = (Desired value on display after 1 hour * 14062.5)

-----------------------------------------------------------------------

(Total value accumulated after 1 hour/256)

Example: A 4-20mAinput signal must corresponds to a 0-100 displayed rate value. The input signal must be totalised over an hour.

The reading at 20mA must be 360 after an hour.

According to the formula:

A = Desired value on display after 1 hour

B = I.FS.H Value without decimal points

C = Total value accumulated after 1 hour (i.e Max value on rate (100) * 3600 seconds = 360 000 )

B = (A * 14062.5 )

-----------------------

(C/256)

Therefore B = ( 360 * 14062.5 )

-------------------------

(360 000/256)

I.FS.H .= 3.600

After 1 hour at 20mA, the display should show 360.

Under the P.Int sub-menu in the instrument, set as follows: select: 4-20; P dP = oooooo; ZEro = 000000; P FS = 000100; P.Filt = 00.5;

incr = 000; C dP = oooooo; I.FS.H = 3.600

How to calculate the I.FS.H (integrated full scale hour) value for Model 5001-TModel 5001-T (cont.)

This option is similar to Option 3001-P but with a single alarm only. See page 7 for connection details. Wire for AL1 only.

This option is similar to Option 3001-M but with a one alarm set point only. See diagram “M” on page 20 for connections. Wire for AL1

only.

See page 7 for connection details.

See page 7 for connection details. Wire for AL1 & AL2 only.

If fitted, this option will accurately linearise signals for flow applications (square root extraction), s-curve (cylinder applications) and

other non-linear signals. The type of linearisation required is specified at time of order and cannot be user selectable. However, the

user has the option of toggling the lineariser feature 'ON' or 'OFF' in the process ('PRo') menu. See page 9 for programming details.

See page 7 for connection details. Select DIGIbus or ASCIIbus protocol from the program menu. See additional protocol documents.

One Set Point (Electro-Mechanical Relay)Option 3004-M

One Set Point (Solid-State Relay)Option 3004-P

0 - 20mA / 4 - 20mA / 0 - 10V Analogue Output OptionOption 3003

RS485 Serial Interface OptionOption 3002

Two Set Point (Electro-Mechanical Relays)Option 3001-M

Two Set Point (Solid-State Relays)Option 3001-P

Lineariser (Square Root / Cylinder / Sphere etc)Option 3000

This option provides two alarm set points with electro-mechanical relays. This option board slots into the upper slot of the panel meter

box. The upper terminals are clearly numbered 13-28 to differentiate them from the lower terminals. Both normally open and normally

closed contacts are provides with each relay. The relays are rated at 250VAC / 30VDC @ 2A. Visual LED alarm indication is provided

on the panel meter front. For connection wiring details, see diagram “M” on page 20. Connect wires for AL1 & AL2 only.

Page 15

Parallel BCD Output OptionOption 3009

This option displays and holds the max or min value (not both) of an input signal. This option is activated in the programming menu

“Opt” by selecting whether “Hold” should be “On” or “Off”, and selecting valley (”valy” = “On”) or peak (”valy” = “Off”) mode.

To show peak / valley value, press the “up” arrow for 3 seconds. To show normal display value, press the “side” arrow key for 3

seconds. To reset the peak / valley hold value, press the “star” key for 3 seconds, or use an external potential free contact (see page

6 for connection details). If analog output option is fitted, the output will hold as well. This option cannot be used with option 3014.

This option provides an 8 - 30VDC galvanically isolated power supply. See page 7 for connection details. This option also provides

excitation of up to four load cells.

This option is supplied as an additional slot in card in the top part of the instrument housing. See additional documentation.

This options allows the instrument to operate from a wide range of AC & DC power supplies. The supply connections are on page 7.

This option measures resistance & tap positions on transformers. See “Process Inputs” diagram on page 6 for connection details.

Peak Or Valley (Max or Min) Hold OptionOption 3012

Ohms / Tap Input OptionOption 3011

95V-265V AC / DC Power Supply OptionOption 3010

This is ordered with option 3002, 3003, 3007 or 3013. It provides a minimum of 1500V isolation between input and output signal.

Wiring connections are different for these isolated options. Use diagram “P” or diagram “M” on page 20 for wiring connections.

Galvanic Isolation (8 - 30V Supply) OptionOption 3008

Isolated Options (Analogue Output / RS232 / RS485)Option 3006

Page 16

See the additional pages supplied for protocol details & page 7 for connection details. Ensure that maximum cable length from

instrument to PC is less than 15 metres.

RS232 Serial Interface OptionOption 3013

Auto-zero OptionOption 3014

Three Set Points (Electro-Mechanical Relays)Option 3017-M

Three Set Points (Solid-State Relays)

Option 3017-P

This option provides three alarm set points with solid state relays. This option board slots into the upper slot of the panel meter box.

The upper terminals are clearly numbered 13-28 to differentiate them from the lower terminals. Only normally open contacts are

provided, which means that should the contacts be closed and the power fails, they will revert to a normally open condition. The

relays are rated at 400V AC /DC @ 0.5A. Visual LED alarm indication is provided on the panel meter front. For connection wiring

details, see diagram “P” on page 20. Connect wires for AL1, AL2 & AL3 only.

This option provides three alarm set points with electro-mechanical relays. This option board slots into the upper slot of the panel

meter box. The upper terminals are clearly numbered 13-28 to differentiate them from the lower terminals. Both normally open and

normally closed contacts are provides with each relay. The relays are rated at 250VAC / 30VDC @ 2A. Visual LED alarm indication is

provided on the panel meter front. For connection wiring details, see diagram “M” on page 20. Connect wires for AL1, AL2 & AL3 only.

This option allows the operator to zero the display at any time and continue the measurement from that zero point. This option is

activated "ON" or "OFF" in the "Opt” menu during programming (see page 8).

During normal operations, pressing the “star key” for 3 seconds will zero the display. The display can also be zeroed via an external

potential free contact (see page 6 for connection details). The display can be zeroed at any time over and over again. If the analog

output option is fitted, the output will follow the display. Note that this option cannot be used in conjunction with option 3012, nor will

this option be available if ‘d.tot’ or ‘p.int’ is selected in the input menu.

Page 17

This option is similar to option 3017-P, but contains four relays (see option 3017-P). For connection wiring details, see diagram “P” on

page 20. Connect wires for AL1, AL2, AL3 & AL4.

Four Set Points (Solid-State Relays)Option 3018-P

This option is similar to option 3017-M, but contains four relays (see option 3017-M). For connection wiring details, see diagram “M”

on page 20. Connect wires for AL1, AL2, AL3 & AL4.

Four Set Points (Electro-Mechanical Relays)Option 3018-M

This option is used with the optional totalising features of selected meters. With this option, the relay of alarm #1 pulses whenever the

totalising display changes by one count (alarm #1 relay will no longer function as an alarm setpoint). The maximum pulse rate is two

pulses per second, and it is therefore critical that the totalising display is configured not to change by more than two counts per

second. See the programming menu page 9 for more information on setting up the totalising parameters.

Pulse Output OptionOption 3023

The vertical bar-graph display option provides a graphic linear representation of the process variable being measured. The bar

graph’s zero and full scale setting is programmed by the ‘Outp’ sub-menu of the programming menu, which also controls the analog

output option. The ‘Out.O’ controls the zero point of the graph, and the ‘Ou.Fs’ controls the full scale value of the graph. See the

programming menu page 8 for more information. The instrument must be mounted vertically.

Vertical Bar Graph Display OptionOption 3022

This option is for applications where the main power supply frequency needs to be accurately measured (0.00 to 99.99 Hz). Note that

the input terminal are pins 1 and 2, NOT 1 and 4 in this application. See page 6 for wiring information.

Line / Mains Frequency Measurement OptionOption 3021

Page 18

When this option is ordered, a new sub-menu appears in the ‘Input’ menu. See the diagram on the right. This option is used to

simulate an input value. No physical analog input is required. The display value is edited on the display with the front keys. If the

analog output option is also ordered, the analog output will follow the display. e.g. If a value of 50% is entered on the display, the

output will give a value of 50% (12 mA for 4-20 mA output).

CONFIGURATION

In the main input menu, select the last option "User". Select the decimal place required. Press the menu button to proceed to the

output menu. Select the output type required : 0 - 20 mA, 4 - 20 mA, 0 - 10 V. Note that the PCB link must be set to the same output.

Enter the display value for zero output. Enter the display value for full scale output. Press the menu button to save and exit.

Manual Set Point Station OptionOption 3024

This option an 8 - 30 VDC non-isolated galvanic power supply. See page 7 for connection details.

Galvanic non Isolation (8 - 30V Supply) OptionOption 3028

Keypad Lock OptionOption 3025

The keypad lock option is used to prevent un-authorised access to the programming menu. When this option is ordered, a new sub-

menu called “CODE” appears at the end of the programming sequence. See programming page 8. Three levels of keypad lockout are

available: Level 0 - Full access to programming menu. Level 1 - User only has access to alarm set point values. Level 2 - Total

programming menu lockout.

If this option is ordered, the factory default is “Lev 0”. If the keypad has been locked with either level 1 or 2, then the word “PASS” will

appear on the display if the user attempts to enter programming mode. Pressing the menu key will return the instrument to normal

display mode. However, if the user wishes to enter the programming menu, then when the word “PASS” appears, press in

succession, 1 second apart, all four keys from right to left.

Page 19

APPLICATION

The display will continually show the present value. To change the value, press the enter key. The first digit on the

display will flash. Use the left and up keys to change to a new value. Press enter to accept or leave for 10 seconds

to exit without saving. The new value will now be displayed continuously.

Manual Set Point Station Option (Continued)Option 3024

Input type for

manual setpoint

Station

The option is at no-extra charge and allows the user to freeze the display via an external potential-free contact. Closing the switch will

freeze the display. This option is NOT available for 5001-T & 8001-T. The connections to the instrument for the external potential free

contact vary depending on input type. See page 6 for wiring connections.

Display Hold OptionOption 3026

Diagram “P”

+ Voltage output

-Output

+ Current output

NO

AL4

NCNO

AL3

NCNO

AL2

NC

AL1

NC NO

Diagram “M”

Universal process / counter / frequency

/ integrator / totaliser indicator

Lower Terminals

(Mother board)

Upper Terminals

(Option boards)

19 20 25 26 27 2813 14 15 16 17 18 21 22 23 24

N(+) L(-)

123456789101112

AL2 AL3

AL1 AL4

+ Voltage output

- Output

+D (Rx)

-D (Tx)

Comms GND

+ Current output

NO NO NONO

Lower Terminals

(Mother board)

Upper Terminals

(Option boards)

19 20 25 26 27 2813 14 15 16 17 18 21 22 23 24

N(+) L(-)

123456789101112

Declaration of Conformity

Type : 4001,4011,5001,5011,5600,8001,5001-T,8001-T

Options : 3000 to 3028

Corresponds to the requirements of the following EC directives:

EMC directive : 89/336/EEC

Low voltage directive : 73/23/EEC

The applicable harmonised standards are : EN 50081-1

: EN 50082-1

: EN 61010

The manufacturer reserves the right to alter any specification

without notice.

Guarantee

Page 20

Manufacturer : Calog

The manufacturer undertakes to replace without charge all

defective equipment which is returned to it (transportation costs

prepaid) during the period of guarantee, provided there is no

evidence that the equipment has been abused or mishandled in any

way.

This product is guaranteed against faulty workmanship or defective

material,foraperiodof 2(two)yearsfromdateofdelivery.

This manual suits for next models

7

Table of contents