InstroTek ValiDator User manual

innovators in instrumentation technology

OPERATING MANUAL

Nuclear Gauge Calibration and

Verication System

www.InstroTek.com

®

© 2018 InstroTek, Inc.

ValiDator Nuclear Gauge Moisture/Density Verification and

Calibration System

Manual Revision 6

InstroTek

1

1. Table of Contents

****************************************

1. INTRODUCTION 2

2. ACCESSORIES AND APPLICATION 13

3. SOFTWARE INSTALLATION 15

4. SYSTEM OPERATION 17

5. THEORY OF OPERATION 36

6. INDEX 38

7. WARRANTY 40

InstroTek

2

1. Introduction

We are happy and proud to share this Nuclear Moisture/Density Gauge

verification and calibration technology with you. ValiDator is the first and the

only traceable portable verification and calibration system in the industry.

InstroTek, Inc. would like to thank you for selecting the ValiDator as your field

verification and calibration device. The ValiDator Technology is covered by US

Patent numbers 5,923,726 and 6,050,725 including International patents.

We value your input and would like to hear from you with comments and

suggestions on how we can better serve you with this or other products.

This guide is designed as a reference for the operation of the Verification and

Calibration System. A thorough understanding of the operation and application

of Nuclear Moisture/Density gauges is necessary.

Please follow the nuclear gauge manufacturer recommendations with regard to

operation and safety concerns of these devices. All ValiDator operations should

be done from the end opposite the gauge source, stepping away three feet

while the source rod is in the measure position.

Why the ValiDator?

The American Society for Testing and Materials (ASTM) standards and American

Association of State Highway and Transportation Officials (AASHTO)

specifications require nuclear density gauges to be calibrated or verified every

12 months. In the absence of a field portable validation device, this commonly

would require returning a gauge to the manufacturer or other calibration

facilities. Strict shipping formalities, weeks without a gauge and expensive

calibration fees create a burden on gauge availability for field use.

Gauge owners have never had the option before of performing the verification

and re-calibration in the field. The ValiDator from InstroTek, Inc. is designed to

optimize the management of your gauge resources and help reduce

inconsistencies when multiple gauges are on-site. Multiple gauges calibrated

on the same device will reduce conflicts between results.

How to use the validator?

As easy as taking a field measurement, just place your CPN, Humboldt, InstroTek

or Troxler gauge on the ValiDator device and take a reading. Compare the

gauge wet density and moisture (M pcf) to the pass/fail range on the ValiDator

Calibration Sheet and your verification is complete. Even if the gauge

Verification fails, the optional Calibration Software would allow you to eliminate

the delays in calibration turn-around-time. Calibrate one or all depths in minutes.

InstroTek

3

Supported Nuclear Gauges

It is important when you verify or calibrate your gauge that the correct chart

and values are selected. If there are gauges in your fleet that are not supported

on this list, you may establish guidelines for Verification of these gauges.

(Reference Verification Procedures for Gauges Not Supported page 20)

CPN

MC3 New, MC1 DR New: Gauges manufactured with two GM detectors.

Standard counts are generally between 30000 & 40000 counts.

MC3, MC1 DR: Gauges manufactured before approximately 1996 with one GM

detector. InstroTek currently does not support these gauges. Standard counts

are generally between 10000 & 20000. Please contact InstroTek for more

information on these gauge models or reference Verification Procedures for

Gauges Not Supported page 20.

MC1: InstroTek currently does not support verification of this gauge. Please

contact InstroTek for more information on this gauge model or reference

Verification Procedures for Gauges Not Supported page 20.

MC2: InstroTek currently does not support verification of this gauge. Please

contact InstroTek for more information on this gauge model or refer to manual

section Verification Procedures for Gauges Not Supported page 20.

MC3 and MC1 Elite:

These gauges are supported.

Humboldt

5001 B, 5001C, 5001P, 5001 EZ and 5001 SD are supported.

InstroTek

Model 3500 Xplorer and 3500 Xplorer 2 are supported.

Troxler

3401 & 3411: These gauges are only different in electronic functionality. Both

these gauges are supported by the ValiDator.

3430 & 3440: These gauges are only different in electronic functionality. Both

these gauges are supported by the ValiDator.

3411 New: (Very few gauges were produced, serial numbers greater than 17000)

InstroTek

4

3450: Please contact InstroTek for instructions on how to calibrate these gauges.

These gauges, like 4640, operate with two independent measurement systems.

A special optional software application is required for these gauges.

4640: Not supported by the ValiDator I. The ValiDator II available from InstroTek

is specifically designed for verification and calibration of 4640B gauges and 3450

in the Thinlayer mode. Please contact InstroTek for information on how these

gauges can be verified and calibrated.

3430 and 3440 Plus Gauges: Please contact Instrotek for more information on

these gauge models, or reference Verification Procedures on page 18.

Seaman Nuclear

These gauges are not supported.

User Guide Information

ValiDator: Device used to verify and calibrate nuclear gauges.

Validation: Utilizing the ValiDator device to evaluate gauge calibration

accuracy at multiple depths, at an assigned density.

Verification: The process of using the Validation System to verify the calibration

accuracy of a nuclear density gauging device.

Calibration: The process of re-establishing the calibration parameters for a

nuclear density gauging device.

Calibration Parameters established by the calibration program and used by a

Constants: density gauge to calculate density and moisture.

ValiDator Factory established densities assigned to a specific Validator device

Density: for each measurement depth 0-12.

The ValiDator calibration reports are not exchangeable between different

ValiDator units.

InstroTek

5

Important: Follow the requirements of your nuclear materials license when

operating, maintaining and using nuclear gauges.

Safety

Always operate in accordance with the nuclear

gauge manufacturer recommendations.

Stand opposite the source rod when operating the

ValiDator Device.

Move three feet (one meter) back when the

source rod is extended into the measurement

position.

Use proper lifting techniques when loading and

unloading the ValiDator.

Be aware of heavy machinery operating in the

area of testing.

InstroTek

6

Quick Start Instructions

The quick start instructions will benefit the new and the experienced operators

using the ValiDation System. The System Operation portion of this manual

contains detailed information about all aspects of the ValiDator system. The

Validation system is designed for use with various nuclear gauges manufactured

by CPN, Humboldt, InstroTek, and Troxler.

Important: Observe manufacturers recommendations regarding safety

precautions when operating density gauges. Stand opposite the source rod at

a distance of three feet or 1 meter when measurements are being taken. Follow

the requirements of your nuclear materials license.

Standard Counts for Daily or Rapid Verification: If you are evaluating your

gauges frequently for Quality Assurance, or will not be calibrating on-site, a daily

4 minute standard count may be used for the Standard counts on the

Evaluation Form for Verification. Take one 4-minute count at all other depths.

Standard count should be taken on a solid surface such as soil, asphalt or

concrete base. Do not take standard counts with the standard block on the

ValiDator, second floor, or the tailgate of a truck.

Standard Counts for Combination Verification and Calibration: If you will be

performing a scheduled Verification or Calibration and would like to optimize

the data collection process, perform an Extended Standard Count. (CPN: 20

minute count recording the Wet Count and H2O Count. Humboldt and Troxler:

Perform a Stat Test and record the average Density and Moisture count.) Record

the Standard Counts on the Evaluation form. Two 4-minute counts should be

averaged for Backscatter (BS) and Depth 12 measurements, due to the

relatively lower precision at these positions.

I. Verification Process

A. Align gauge on the ValiDator. For lowering the Source rod, slide the

gauge back until the rod is over the access hole. (See Gauge

Placement page 8)

B. Set count time for four (4) minutes. Note: All moisture verification is

done at the Backscatter position.

C. Backscatter measurements should be taken with the gauge aligned

with the surface stops; two four-min. counts should be averaged for

better precision.

D. Direct Transmission measurements require that the gauge

placement be adjusted to minimize the void between the source

rod and the inside of the ValiDator. After lowering the source rod

move it towards the control panel end of the gauge and to the left

InstroTek

7

side alignment stops. Two 4 min. readings at depth 12 should be

averaged for better precision.

E. Complete a four (4) minute reading and record the gauge results

WD, M, DC and MC on the ValiDator Evaluation Form (page 10).

Make additional blank copies of this form for future use.

F. The Wet Density (WD) and Moisture (M) readings from the gauge

should fall between the range indicated on the gauge specific

ValiDator Calibration Data Table.

G. If the resulting densities indicate the gauge passes, consider the

verification process complete. The gauge is now verified for field

use.

H. If the gauge fails Validation, review precautions and repeat

Validation steps A-G.

I. A second failure would indicate that a calibration is needed.

II. Calibration Process

Note: Gauge Calibration is a sophisticated process and should only be

attempted by advanced and trained users. Please refer to the Calibration

Section of the Manual for calibrating gauges.

Precautions before You Begin

Nuclear gauge: Note: Do not take a Standard Count on the ValiDator.

Clean Base

Record the Current passing standard count in the field location where

Validation is to be performed.

Count time set to four (4) minute counts

Stable Gauge Electronics (Run the manufacturer recommended diagnostics

if field results are questionable.)

No other gauges should be within 30ft (10 meters) of the testing area.

When taking measurements stand opposite the source side of the unit a

distance of three feet (1 meter) away.

Gauge positioned correctly on the ValiDator. (Refer to Gauge Placement

page 8)

Gauges meet the requirements for supported gauges. (Refer to User Guide

page 4)

InstroTek

8

ValiDator Device:

Top surface free of debris

Placed on solid level surface, three feet from any vertical structure.

Tailgates, Carpeted floors, upper floors of buildings, trailers, and uneven

surfaces are not acceptable.

Equipment

Items required for Verification and Calibration include: ValiDator Device,

ValiDator Density Data (In shipping case), ValiDator Evaluation Form (page 10 of

user guide), stable nuclear gauge, and current gauge calibration data (for

calibration option).

Gauge Placement

Nuclear gauges differ between manufacturers. It is important to align each

gauge using the positioning stops on the top and left of the ValiDator.

Backscatter & Moisture Readings

All Backscatter (Depth 0) and Moisture readings should be taken with the gauge

flush with the stop at the top and on the left as shown below.

InstroTek

9

Direct Transmission (Depths 2-12) Readings

Direct Transmission (Depths 2-12) readings require the gauge to be positioned

such that the void between the source rod and the inside of the ValiDator block

is minimized. Slide the gauge back until you can drop the source rod in the hole

on top of the ValiDator. Once the source rod drops in the hole, make sure to

keep the gauge flush with the left stop and slide the gauge back away from the

top stop until it can’t be moved any further.

InstroTek

10

ValiDator Evaluation Form

ValiDator S/N

___________________________

Verification/Calibration

Date:

____________

Gauge S/N

___________________________

Operator:

____________

Gauge Model

___________________________

Daily Standard

Counts

DS________________________

MS________________________

Calibration

Standard Counts

DS________________________ MS________________________

Establish these counts using the average counts from the results of a Stat Test, 20-

minute count or (5) 4 min. Counts. This data is used for the Calibration process.

Count Time

15 sec 1min 4 (Recommended) 16 20 Circle one

Gauge at Backscatter

Stop

Depth

Pass WD Fail

DC

Pass MFail

MC

BS

P ____________ F

____________

P ____________ F

____________

BS

P ____________ F

____________

P ____________ F

____________

BS Avg.

P ____________ F

____________

P ____________ F

____________

2

P ____________ F

____________

3

P ____________ F

____________

4

P ____________ F

____________

5

P ____________ F

____________

6

P ____________ F

____________

7

P ____________ F

____________

8

P ____________ F

____________

9

P ____________ F

____________

10

P ____________ F

____________

11

P ____________ F

____________

12

P ____________ F

____________

12

P ____________ F

____________

12 Avg.

P ____________ F

____________

Notes/Re-counts:

InstroTek

11

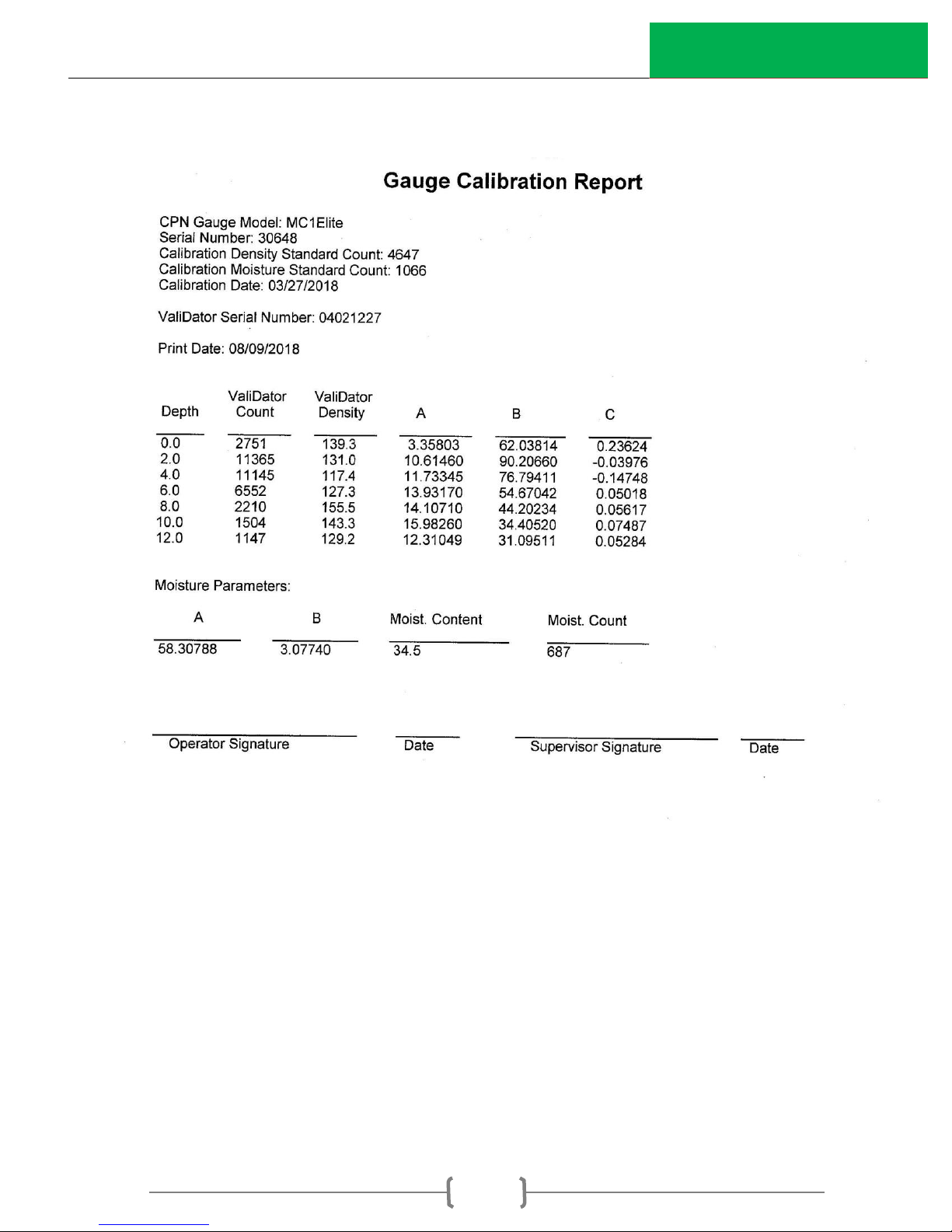

Example of Gauge Calibration Report

InstroTek

12

Example Gauge Calibration Report Key

1) Make (CPN, Humboldt, InstroTek or Troxler)

2) Model

3) Serial Number

4) Calibration Standard Counts

5) Calibration Date

6) Factory Density Constants (A, B, C Parameters)

7) Calibration Block Densities lb. /ft3 or kg/m3

8) Calibration Block Counts

9) Factory Moisture Constants

(E & F or A & B for CPN gauges)

InstroTek

13

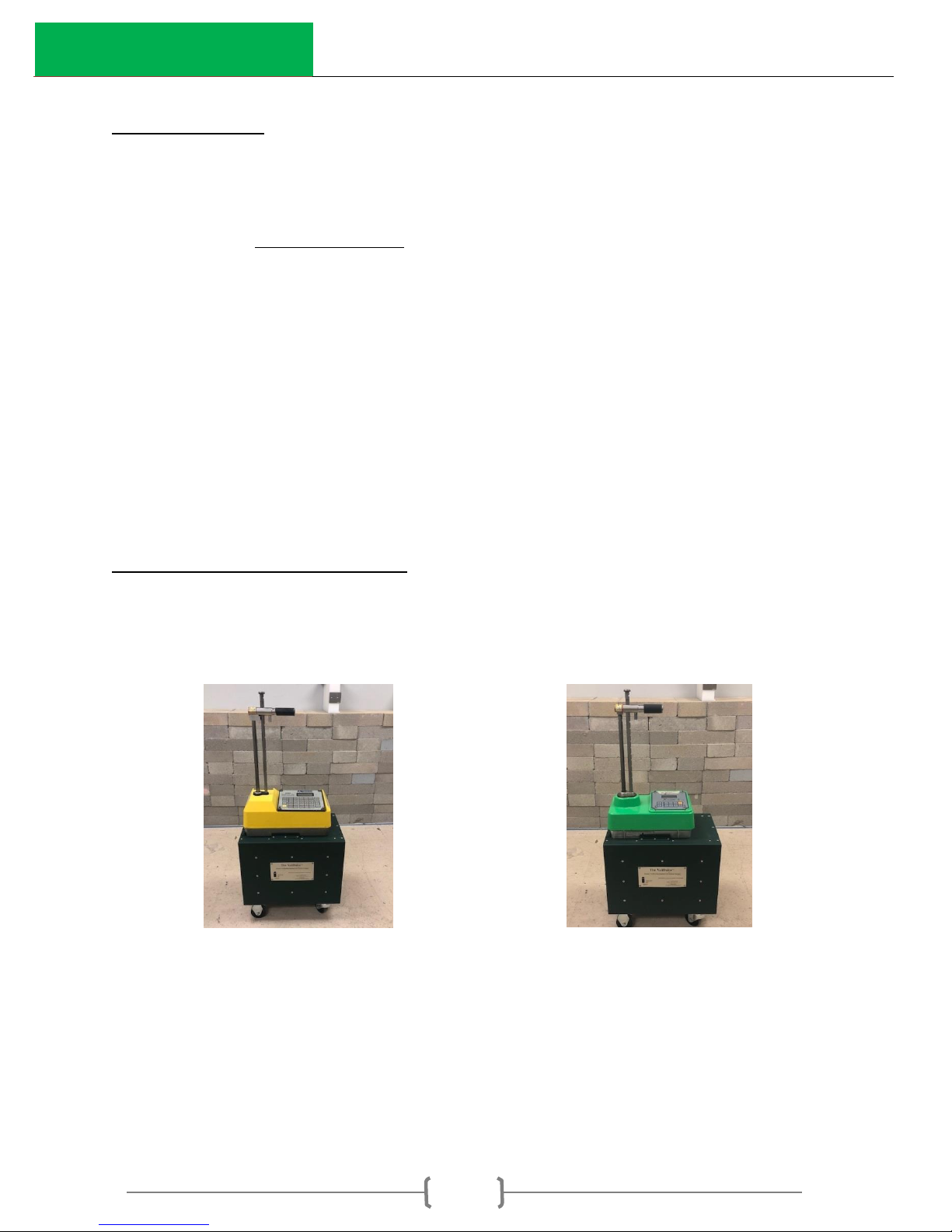

2. ValiDator Accessories and Application

Before using the ValiDator, it is recommended that the user read this manual

and understand the operation of this system.

List of Equipment & Accessories

User Guide

ValiDator (Calibration Box)

ValiDator Density Data (Laminated Sheets)

Quick Start Instructions

NIST Certificate

List of Optional Accessories

Optional VeriFier Software (USB Flash Drive)

3430 and 3440 Constant Download Cable

InstroTek 3500 Gauge Constant Download Cable

Note: Small scratches should be expected on the ValiDator working surface due

to extensive quality control process utilizing measurements with multiple gauges.

Application Overview

Verification & Calibration Process

There are several steps necessary to accomplish a gauge verification and

calibration. Gauge calibration verification is the most fundamental use of the

ValiDator device. Position a density gauge on top of the ValiDator device, take

a four (4) minute density reading and evaluate the resulting density using the

laminated gauge specific ValiDator Density Data Table provided.

The steps below describe a procedure within the Verification and Calibration

process. Density and Moisture gauge data is required by the VeriFier Software

and should reflect the most recent calibration. If not available, this data may

be obtained from the organization that completed this calibration.

InstroTek

14

Calibration constants are used by the gauges to perform the calculations

necessary to process raw count data into a density. Density and moisture tables

may be used for any gauge, but are more common with units that do not have

internal memory or an internal processor. Gauge manufacturers use NVRAM

(Non-Volatile Random Access Memory) or EPROM’s (Erasable Programmable

Read-only Memory) in their gauges.

Calibration constants may be entered into a gauge (CPN MC3, MC3 Elite, MC1

Elite, Humboldt EZ and SD, InstroTek 3500 and Troxler 3430, 3440, 3430 Plus and

3440 Plus) using the operating keypad. Units that employ EPROM’s (Troxler 3411

and Humboldt 5001 series) may operate using density tables while an EPROM is

programmed and mailed for installation. InstroTek can program EPROM’s for

your gauges. Simply fax or mail the Calibration Constants Report and InstroTek

will program and ship your EPROM by Priority Mail for a nominal charge. You

can also purchase a Prom Programmer Package to burn proms at your facility.

VeriFier allows creation of hexfiles for Troxler 3411B and Humboldt 5001C gauges.

There is an option available on 3401 and 3411 gauges that you can use to allow

direct entry of constants through the keypad. SmartPanel from InstroTek is a

“drop in” replacement for the existing 3401 and 3411 scalars. SmartPanel

upgrades the 3401 and 3411 gauges with many features, including direct entry

of calibration constants through the keypad. For more information on the

InstroTek SmartPanel, please visit our website at www.InstroTek.com.

InstroTek

15

3. Software Installation

Computer Requirements: Windows operating system

Installing VeriFier Software on a PC

Object: Allow the operator to access the software and re-calibrate a nuclear

gauge.

Support: Before loading any software, consult with your organization PC

Manager or operating system manuals.

Locate your flash drive included with your ValiDator system. Please

read license agreement before opening software package. This

software should only be loaded on one computer. Access codes will

be needed to complete installation.

NOTE: ValiDator and its’ associated software is licensed to a single user. Use

of the ValiDator and its’ associated software is not allowed for

calibration of gauges from other organizations.

Windows

1. Download VeriFier software from USB flash drive provided by InstroTek.

2. Follow prompts, click finish when complete.

3. Call InstroTek for registration codes:

Enter Main Registration Code

Click on Calibrate and enter Calibration Registration Code

Enter Password “calibratenow” or “calnow”

Provide Product Key to InstroTek service Representative

Enter Product Code

Upgrading Software Version

You may load the new software version directly over the existing version and not

lose your existing data.

Close all Windows programs.

InstroTek

16

Follow the Install instructions.

Follow prompts.

Moving Software

VeriFier software may only be installed on one computer.

Moving to another computer is possible. Please contact InstroTek for procedures

and access codes.

InstroTek

17

4. System Operation

Calibration Accuracy Verification & Calibration Process

Verification Process

Verification of the gauge is necessary to determine the status of the gauge

calibration. Gauges are calibrated when they are shipped from the manufacturer.

Without performing periodic verification, it is not possible to assess the accuracy of

your gauge calibration. ASTM and AASHTO standards require gauges to be verified

for calibration accuracy at least once every 12 months and also the calibration is

checked on newly acquired or repaired nuclear gauges. With the ValiDator,

gauges may be verified to meet this requirement.

Verification

Definition: Use the reference densities assigned to a ValiDator device for

evaluating the calibration accuracy of a density gauge.

Resources: ValiDator Device, Gauge Field Evaluation Form, ValiDator Calibration

Tables, *Density Gauge, **Stable surface.

Important: Follow the requirements of your nuclear materials license when

operating, maintaining and using your gauge.

Calibration

Calibration is a process of calculating new parameters for the nuclear gauge.

Only advanced users with a high degree of experience and understanding of

gauge measurement and operations should perform this process. It is

recommended that one individual in an organization be responsible for the

calibration process. The Verifier Software with counts taken on the ValiDator can be

used to generate new moisture and density calibration constants for the gauge.

Resources: InstroTek VeriFier Software, PC, Completed Evaluation Form, *Density

Gauge, Gauge Calibration Constants, **Stable surface

Note: The VeriFier Software used for calibrating your gauge assumes that the

current gauge calibration information is obtained and entered

accurately.

Table of contents

Other InstroTek Test Equipment manuals