InstroTek Auto_SCB User manual

www.InstroTek.com

OPERATING MANUAL

innovators in instrumentation technology

Asphalt Load and Tension Testing

Auto_SCB

™

‘This page may be removed from the

manual to prevent the unauthorized

access to the restricted menu functions of

the InstroTek Auto_SCB.’

Restricted Menu Function Access

Codes:

System Configuration

Device Configuration (2222)

Channel Configuration (3333)

Profile Configuration (Golden Tags)

(1111)

Control Panel Software (5555)

This page may be removed from the

manual to prevent the unauthorized

access to the restricted menu functions of

the InstroTek Auto_SCB.

© 2018 InstroTek, Inc.

Auto_SCB Automated Load Frame for Measuring

Cracking in Asphalt Mixtures For

Illinois I-Fit (AASHTO TP124),

LSU Method (ASTM D8044),

And

IDEAL-CT (ASTM Draft)

Testing Protocols

Operation Manual Revision 6

IMPORTANT

WARNINGS WHEN USING THE

Auto_SCB™

DO NOT attempt any repairs while the unit is

powered on.

CAUTION DISCONNECT the unit from wall

power before attempting any repairs.

DO NOT operate this device without prior

training.

DANGER DO NOT insert any part of your body

between the ram and crosshead to prevent

crushing injuries.

Follow all your other related facility safety

instructions while operating this device.

Maintenance on this device must be done

by trained technicians.

Call InstroTek, Inc. (919-875-8371) if you have

any questions or before attempting any

repairs.

DO NOT USE the 10kN Load Cell for TSR testing. Please

contact InstroTek for information on different load cells and

accessories for the Auto_SCB.

IMPORTANT

InstroTek

1

1. Table of Contents

****************************************

1. INTRODUCTION 2

2. SYSTEM LOCATION 5

3. SYSTEM SPECIFICATIONS 5

4. SYSTEM SETUP 6

5. JIG SETUP 9

6. MAIN MENU 10

7. STATUS BAR & SYMBOLS 12

8. OPERATION 13

9. RUNNING THE TEST 16

10. RESULTS 21

11. DEVICE CONFIGURATION 22

12. CHANNEL ALLOCATION 24

13. DATA STORAGE & PRINTING 27

14. ALARMS 29

15. MANUALLY POSITIONING THE RAM 30

16. TEST ARCHIVE 31

17. SYSTEM CONFIGURATION & CALIBRATION 31

18. CHANNEL CONFIGURATION & CALIBRATION 34

19. CONTROL PANEL 37

20. MAINTENANCE 38

21. INDEX 39

22. WARRANTY 41

InstroTek

2

1. Introduction

InstroTek Auto_SCBTM is a load frame designed for conducting

semi-circular bend (SCB) tests described in AASHTO TP 124

(recommended by University of Illinois, I-Fit) and ASTM D8044

(recommended by Louisiana State University). Auto_SCBTM can

also perform a variety of mechanical property tests on asphalt

mixtures such as IDT strength, Marshall Stability, and IDEAL-CT.

The load and displacement parameters measured by the

Auto_SCBTM can be used to predict cracking performance of

asphalt mixtures. The Auto_SCBTM measures the load, the

specimen vertical displacement with a high accuracy linear

variable displacement transducer (LVDT) system, and an

encoder for the displacement of the ram of the load frame.

The loading sequence is fully automated with microprocessor

control of the loading ram such that the seating loads, rests,

unload rates, and loading rates are all performed consistently.

The load and displacement are measured with a built-in data

acquisition system. Also, an SCB jig has been developed to

improve repeatability of the test. All the functions of the

Auto_SCBTM system are automatically controlled and the results

are displayed on a touch screen.

InstroTek

3

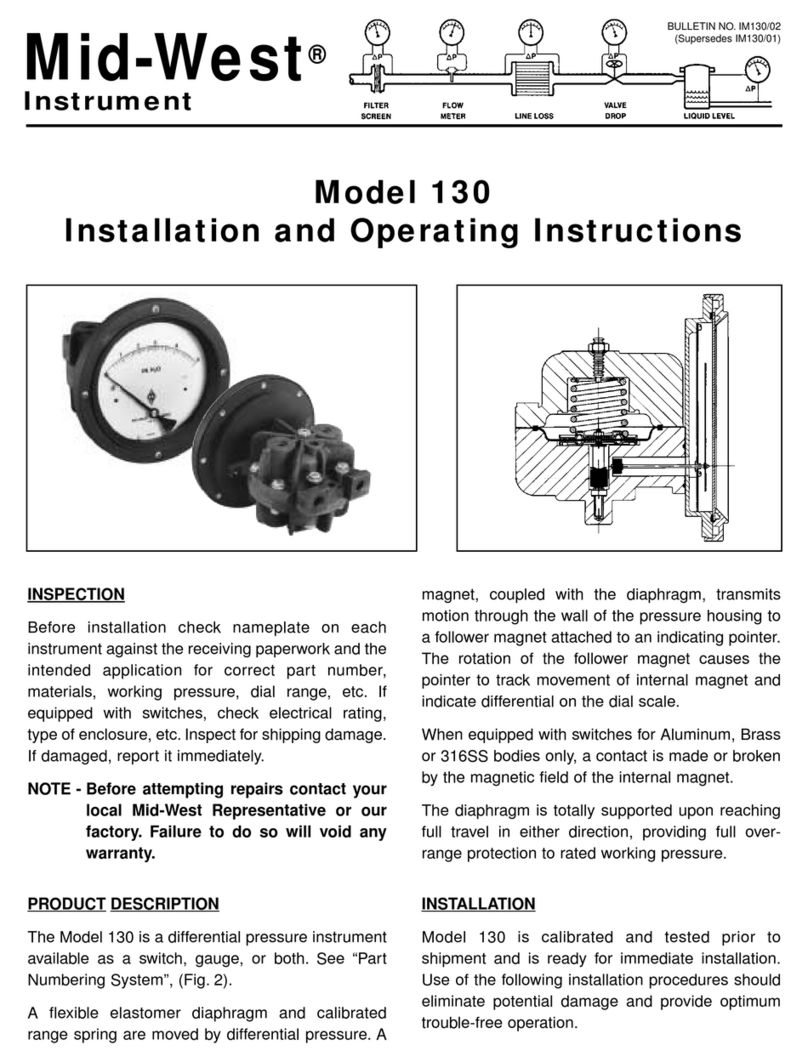

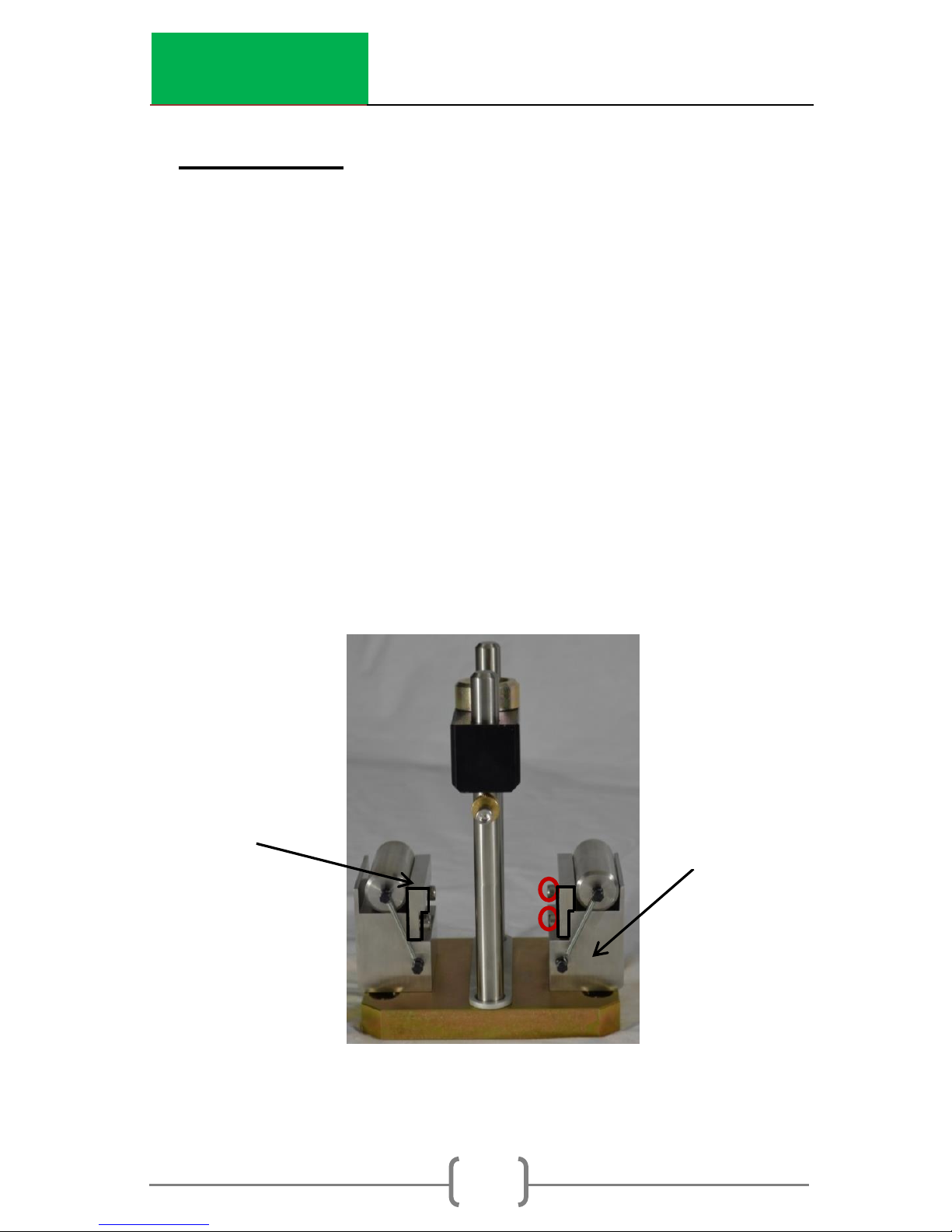

Machine Components

Loading Rod

SCB Jig

Reaction Bar

Reaction Bar

Load Cell

LVDT

Ram

Control Screen

(Touch Screen)

Fig 1. Auto_SCBTM Load Frame with SCB Jig

InstroTek

4

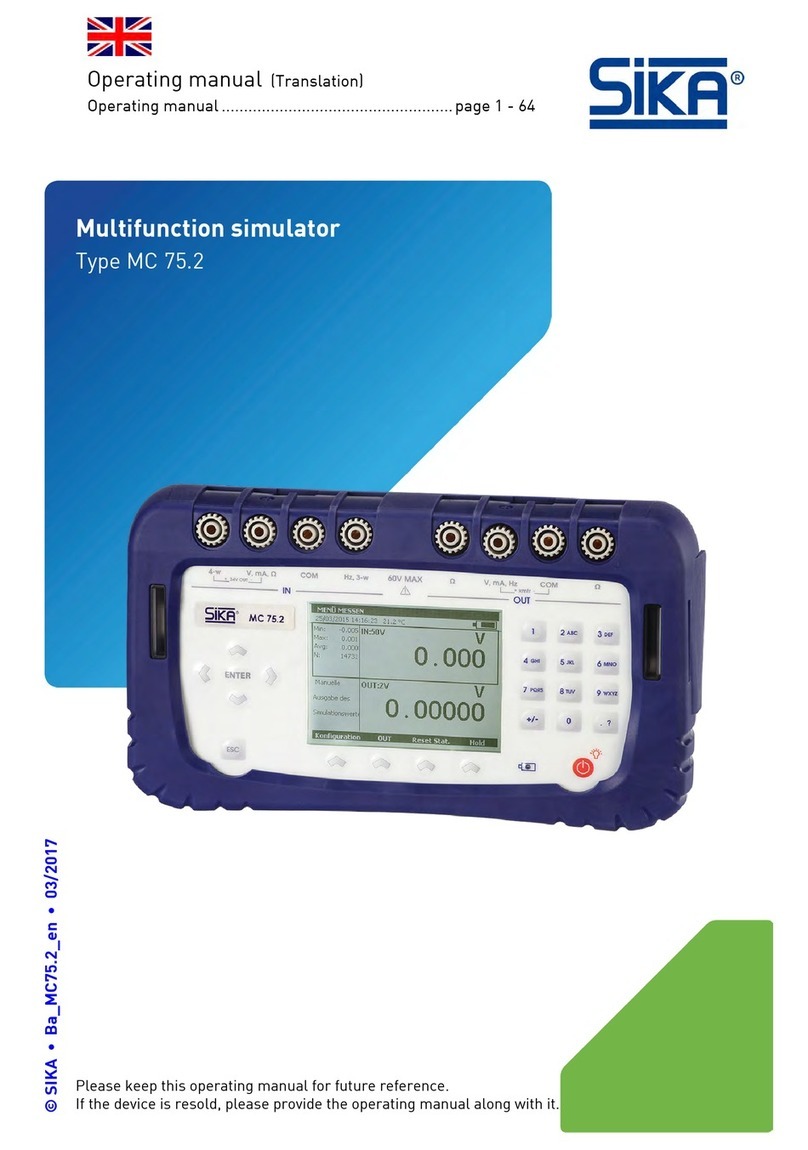

Loading Rod

Lottman

Breaking Jig

Reaction Bar

Load Cell

LVDT

Ram

Fig 2. Auto_SCBTM Load Frame with Lottman Breaking Jig

InstroTek

5

2. System Location

When setting up this unit, please select a location that can

meet the minimum requirements below.

1. The unit is designed to be a bench-top unit. Provide

adequate space for the user to utilize the control

screen and insert the SCB jig from the front of the load

frame.

2. Set the unit on a level and stable surface. It is

recommended that the unit be leveled before testing

using the attached feet.

3. System Specifications

Dimensions: 20” W x 18” L x 57” H

Weight: 300 lbs.

Displacement Speed: 0.01 –51 mm (0.0004 –2.0 inch)

per minute

Electrical Requirement: 120VAC, 150W, 1.5A

Maximum Ram Travel: 100 mm

LVDT Maximum Displacement: 25 mm

Load Capacity: 10 kN (2,200 lbs.) and optional 50 kN

(11,000 lbs.)

InstroTek

6

4. System Setup

The following steps will guide you through the required

connection for powering up the unit:

1. Plug the power cord in the appropriately rated outlet

(120VAC/15A).

2. Mount the load cell onto the threaded rod with the I-

bolt (as shown in Figure 1).

3. Attach the loading rod to the load cell.

4. Mount the LVDT holder onto one of the reaction frame

posts (as shown in Figure 1).

5. Plug either the 10 kN or (optional) 50 kN Load Cell into

Channel 1, LVDT into Channel 2.

6. Ensure that the nuts on either side of the reaction bar

are tightened by hand.

7. Power ON the Auto_SCBTM using the switch located on

the right side of the device next to the power cord.

8. The unit will perform a self-test and will show when

ready.

9. If an alarm ( ) is shown, please refer to the Alarms

section.

InstroTek

7

Reaction Bar and LVDT Height Adjustment

The following steps will guide you through positioning the

reaction bar and LVDT to work properly with the SCB or Lottman

Breaking jig:

1. Loosen the top bolts of the reaction bar to allow

the bar to move freely upward.

2. Enter the test menu .

3. Place the test jig on the ram by aligning the

centering pin in the ram and the slot in the jig.

NOTE: The centering pin can be removed if the jig does

not have a slot.

4. Place an asphalt specimen in the test jig (see

Figure 3).

5. Press the TEST Position button.

6. Raise or lower the reaction bar so that the

loading rod is within 2 mm (thickness of a penny)

but not touching the loading bar on the test jig

and centered over the jig loading bar.

7. Tighten the top bolts of the reaction bar by

hand.

8. Clamp the LVDT in the LVDT holder. Adjust the

LVDT until it reads 2-5 mm while in the TEST

position. This will allow sufficient clearance for

InstroTek

8

the jig to slide in and out when in the HOME

position with the LVDT in place.

NOTE: Tighten the LVDT holder thumb screws finger tight

to prevent damaging the LVDT.

InstroTek

9

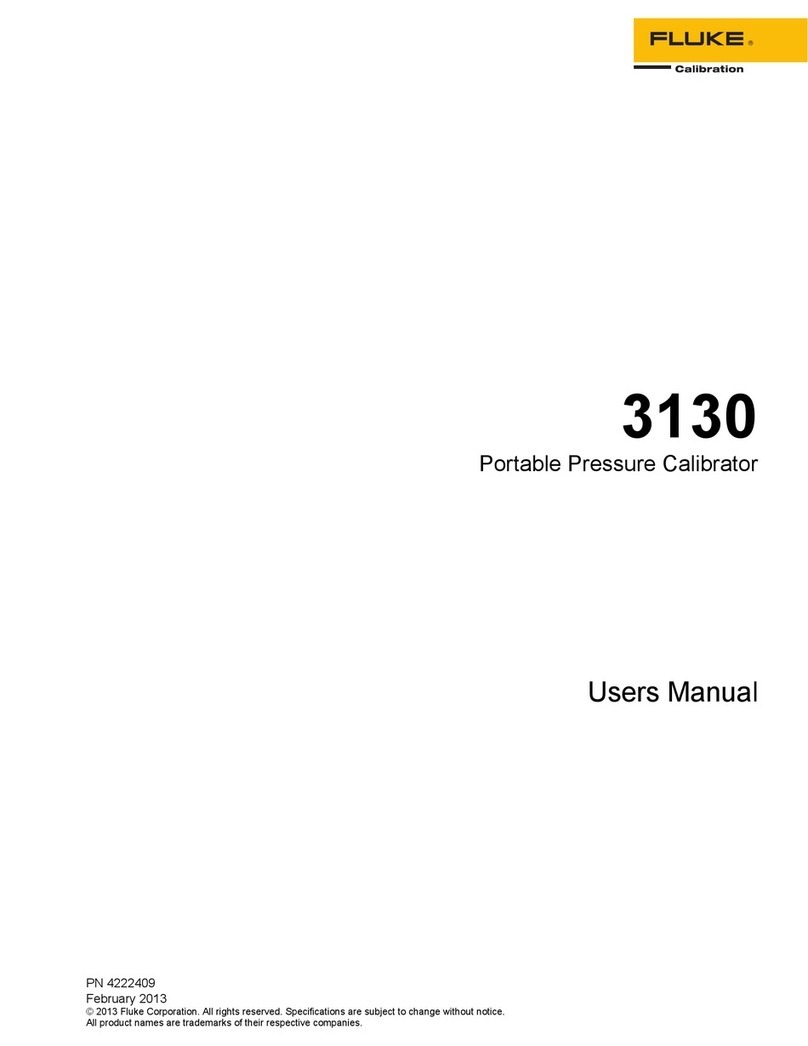

5. Jig Setup

The SCB jig is designed to comply with the requirements of both

the I-FIT and LSU SCB standards. The difference in the jig for the

standards is the spacing between the rollers. The I-FIT (AASHTO

TP 124) test requires an 120 mm spacing while the LSU (ASTM

D8044) test requires an 127 mm spacing.

1. Remove the two screws (5/32” Allen wrench) from the

roller support, as shown in the circles in Figure 3.

2. Flip the mounting block around until it is oriented like

the appropriate method.

a. I-FIT –the mounting block is flush to the roller

support.

b. LSU –the mounting block overhangs the roller

support.

Fig 3. SCB Jig Setup

NOTE: SCB Jig may look different but still functions the same.

I-FIT

Mounting

Block

Roller Support

Roller

Support

LSU

InstroTek

10

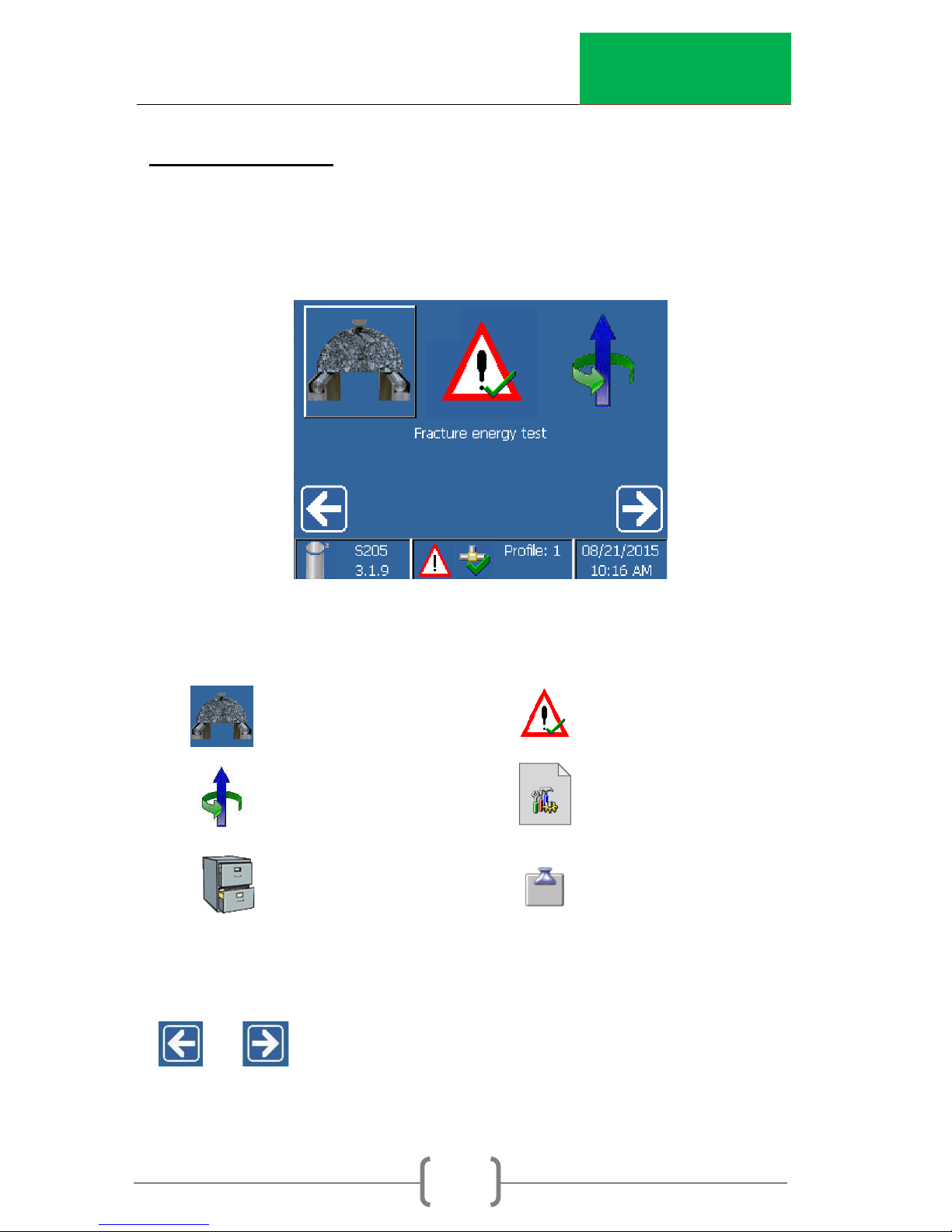

6. Main Menu

The Main Menu allows the user to select the main functions of

the machine.

The main functions are:

Cracking Test Active alarms

Ram Position

Test archive Control panel

Select an item with the touch-screen: Scroll through the menu

or until the desired menu item is highlighted and

select the item by touching the screen.

System config.

Cracking Test

Position

InstroTek

11

Select an item with the keypad: Scroll through the menu using

the arrow keys or until the desired menu is

highlighted. Push the Enter key to select an item.

InstroTek

12

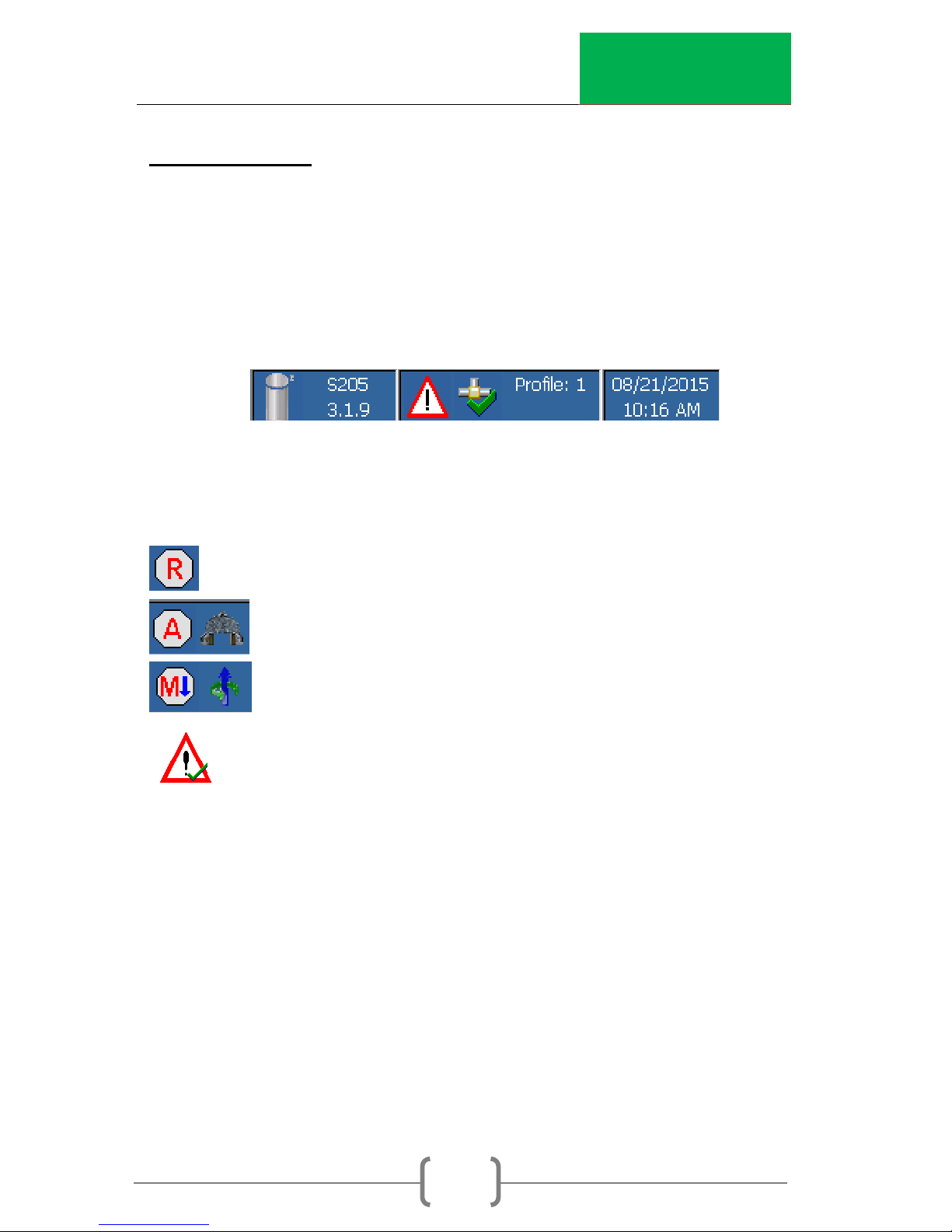

7. Status Bar

The bottom of the main screen contains the status bar. The left

side of the status bar provides the current software version

installed on the machine. The center of the bar provides the

current status of the machine. The right side provides the

current date and time.

Status Symbols

Machine is ready to test

Running the test (automatic)

Moving the ram (manually)

Warning

InstroTek

13

8. Operation

This section will provide a general guide to set up, run, and

record the data for a test in the Auto_SCBTM.

Sample Preparation for SCB

1. Prepare specimens according to the instructions in the

relevant standard.

a) I-FIT –AASHTO TP 124

b) LSU –ASTM D8044

NOTE: Specimens may be prepared using the gyratory

compactor, kneading compactor, cores cut from the field, or

slabs from a laboratory compactor. Consistent air voids are

necessary for consistent results.

2. Saw cut the specimens to the desired thickness. Measure the

air voids of the circular disks.

a) I-FIT –Gyratory-prepared specimen thickness shall

be 50 ± 1 mm.

b) LSU –Gyratory-prepared specimen thickness shall be

57 ± 1 mm.

3. Cut the specimens in half. Then, create a notch in the

sample to the depth(s) specified in the standard.

a) I-FIT –Notch width shall be 1.5 ± 0.1 mm and the

depth shall be 15 ± 1 mm for all samples.

b) LSU –Notch width shall be < 3.5 mm and the notch

depth shall be 25, 32, or 38 mm ± 1 mm.

InstroTek

14

NOTE: A wet saw, tile saw, or table saw with a

masonry bit may be used to consistently cut the

notch.

4. Insert a specimen into the SCB Jig (Figure 4). Adjust the

horizontal alignment bolt such that the specimen is

centered on the roller supports. Raise the perpendicular

alignment bar into the notch cut into the specimen to align

it perpendicularly to the horizontal alignment bolt.

Table of contents

Other InstroTek Test Equipment manuals