INTECNO BLD15 Operating and maintenance instructions

D.C. BRUSHLESS

MOTORS DRIVE

BLD15

Quick installation Manual

Standard Version

INTECNO s.r.l.

Via Caduti di Sabbiuno n. 9/E

40011 Anzola Emilia (BO) - Italy

tel. 051.19985350 fax 051.19985360

www.intecno-srl.com

Quick installation manual for Brushless DC motor drive. Model BLD15___Versione 01/19

2

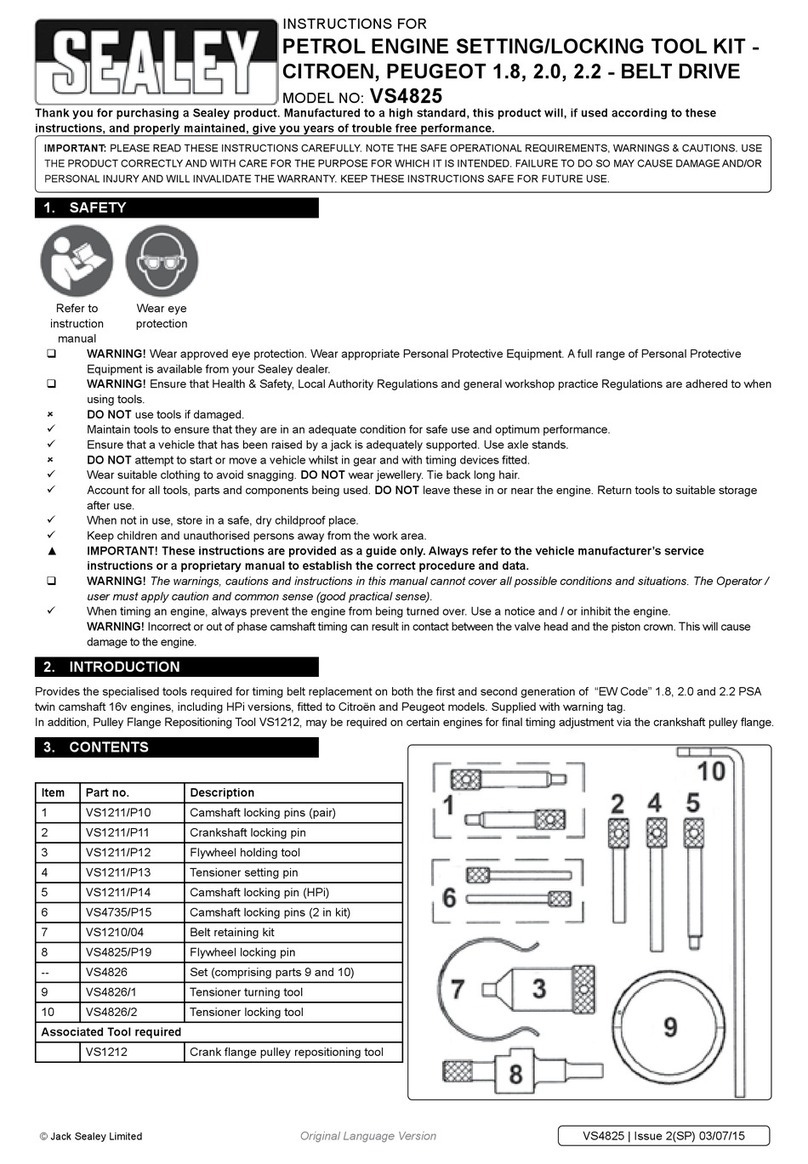

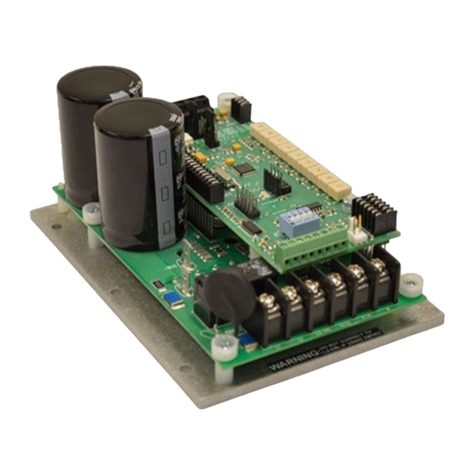

LAYOUT AND TERMINAL OF THE DRIVE

From right

Power connection:

+V = power supply, positive

GND = power supply, negative

U, V, W = power motor phases

HALL connector:

+12V= supply power of sensors

GND = negative for power of the sensors

H1 Hall U, H2 Hall V, H3 Hall W = the three phases of the hall sensors

Connector of potentiometer (or external analogue signal 0-10V):

GND, SIG, +10V pins of the potentiometer. The cursor (variable pin) goes to the

terminal SIG.

Connector I/O:

FREQ= square wave output proportional to speed, NPN open collector signal.

FAULT = alarm output, NPN open collector signal.

F/R = selector of the direction of the rotation.

R/S = start/stop operation command

GND= common for the commands of R/S and F/R

IN1, IN2 = not used

Quick installation manual for Brushless DC motor drive. Model BLD15___Versione 01/19

3

DIAGRAM CONNECTIONS OF POWER S. AND MOTOR

Connections for motors: BL012.240 –BL018.240 –BL025.24E –

BLS022.240 –BL032.240 –BLS043.240 –BL043.240

SUPPLY POWER:

lead the positive on +V, and the negative to GND.

Be careful, not to reverse the polarity, risk of damage to the board.

MOTOR POWER:

The phases, U = yellow, V = red, W = black.

HALL MOTOR:

The phases, +12V = red, HU= blue, HV = green, HW = white, GND = black

This color sequence must be followed.

Quick installation manual for Brushless DC motor drive. Model BLD15___Versione 01/19

4

DIAGRAM CONNECTIONS OF POWER SUPPLY AND

MOTOR

Connections for motor: BL070.240 –BL070.480 –BL070.48E –BL140.480

SUPPLY POWER:

lead the positive on +V, and the negative to GND.

Be careful, not to reverse the polarity, risk of damage to the board.

MOTOR POWER:

The phases, U = Blu, V = Brown, W = Black.

HALL MOTOR:

The phases, +12V = red, HU= blue, HV = green, HW = white, GND = black.

This color sequence must be followed.

Quick installation manual for Brushless DC motor drive. Model BLD15___Versione 01/19

5

SIGNAL CONNECTION

Connect the potentiometer as shown in diagram. Be careful: the cursor (variable pin) must be connected to

SIG. in case of analog power supply 0/+10 V, the reference goes to GND and the signal to SIG.

Closing the R/S terminal to GND for managing the run and stop operations.

Closing the F/R terminal to GND to determine the direction selection.

DANGER:

This command forces the run in reverse direction immediately without the needing to open

and close again the R/S.

Quick installation manual for Brushless DC motor drive. Model BLD15___Versione 01/19

6

OUTPUT

There are two NPN outputs open collector. Can be used as open collector outputs (if equipped with PLC which

accepts the NPN output), or with a resistance R = 10 KOHM (one for each output) to get a voltage signal. 50

V & 100 mA NPN outputs, MAX.

Note: The FAULT output is normally closed. It opens when an alarm happens. In the case of the pull up

resistor, the alarm output is a voltage (+12 Vdc signal).

The signal is output at the point of the arrow (see diagram below).

Quick installation manual for Brushless DC motor drive. Model BLD15___Versione 01/19

7

DIP SWITCH, TRIMMER and LEDs

Motor

Poles

Dip Switch 4

Nom. Current [A]

Motor Voltage [V]

BL 012.240

8

On

3,5

24

BL 018.240

8

On

5

24

BL 025.24E

8

On

6,6

24

BL 032.240

4

Off

5

24/36

BL 043.240

4

Off

6,8

24/36

BLS 022.240

4

Off

3,7

24/36

BLS 043.240

4

Off

6,0

24/36

BL 070.240

8

On

13

24

BL 070.480

8

On

6,5

48

BL140.480

8

On

13

48

Dip switch

Descrizione

1 Selecting input for speed reference

OFF = speed controlled by on board trimmer (TR1).

ON = speed controlled by external potentiometer or 0-10V

analog signal

2 Speed fine tuning function

OFF = enabled (closed loop)

ON = disabled (open loop)

3Acceleration/deceleration selection

OFF = fast ramps (about 0.1 seconds)

ON = slow ramps (about 1.0 seconds)

4 Motor polarity selection

OFF = 4 poles motors

ON = 8 poles motors

Quick installation manual for Brushless DC motor drive. Model BLD15___Versione 01/19

8

Use of TRIMMER for current

limitation (TR2):

The trimmer limits the supply of the current, in order

to match the current to the motor’s rated one. To set

correctly: adopt a current amperometer (to be placed

on the positive supply), rotate fully counterclockwise

this trimmer load the motor, up to read the rated value

on the amperometer. Afterwards, turn the trimmer

clockwise until you see a light flashing but persistent.

Indicative positions of the trimmer:

30 A

20 A

10 A

3 A

Trimmers

TR1 = speed selection trimmer (it rises in clockwise rotation)

TR2 = trimmer for current limitation (it rises in counter-clockwise rotation)

LEDs

LED1 = green, POWER ON (voltage is present) blinking

LED2 = red, active alarm

LED3 = yellow, it has two functions: during normal operation it indicates the current limit. In case of alarm

blinks according to precise coding to show the type of alarm active. (see pag. 15)

There are on board other two LEDs that light up at the closing of the contacts of R/S and F/R.

Quick installation manual for Brushless DC motor drive. Model BLD15___Versione 01/19

9

DIAGNOSTIC AND TROUBLE SHOOTING

Alarms mean certain dangerous conditions (for the drive or the mechanism) that the drive is able to verify

and, in the case, to interrupt operation.

LED 2 (red) indicates alarm in progress, while the LED 3 (yellow), is used to identify the type of alarm;

depending on the number of flashes it indicates a different problem.

N° Flashes

Description

Possible solutions (in order)

1

The sequence of the Hall

signals is not correct and

the drive is not able to

determine the correct

sequence of the phases.

• Check wire (colors) sequence of the Hall, they must be

exactly as per the manual.

• Check that the cables are properly inserted into the

connector.

• Contact technical department Intecno srl.

2

Short circuit. The drive is

delivering the current in

an excessive way.

• Recheck that the power and signal cables are properly

connected (according to the colors shown in this manual).

• Check that the motor is free to rotate.

• Check that the load on the motor does not exceed the

motor nameplate data (including radial loads of potential

pulleys and belts).

• Disconnect the motor and try to run without the motor,

if the alarm persists.

• Contact technical department Intecno srl.

3

too low voltage level (<18

V)

• Check the quality of power source.

• Check the voltage level of the source.

• Make sure the power supply is adequate.

• Ensure proper cable section and length.

4

too high level voltage

(>80V)

• Check the voltage level of the power source.

• Check that the load is not inertial one, in which case make

longer the deceleration ramp.

5

Sudden motor block

• Check the mechanics of the application

6

Power failure Hall

• Check the connection of the signals and power Hall and

the connection of the connector.

Problematic Vibrations:

Vibrations

Possible solutions

the motor vibrates visibly and it also absorbs a

lot of current even together with an empty

motor.

carefully check the sequence of the signal cables and

power, as it is in the manual.

Table of contents

Popular DC Drive manuals by other brands

Lenze

Lenze 9300 vector Series Mounting instructions

ABB

ABB UNITROL 1010 Quick installation guide

WEG

WEG CFW700 Programming and troubleshooting manual

American Control Electronics

American Control Electronics Minarik MDBL03 Series quick start guide

Cytron Technologies

Cytron Technologies MDS160A user manual

ABB

ABB ACS 800 Series Installation Notice

Bosch

Bosch REXROTH IndraDrive Applications manual

Danfoss

Danfoss MCA 122 Modbus TCP operating instructions

Invertek Drives

Invertek Drives Optidrive ODE-2-12005-1H01 01 Series user guide

Vicruns

Vicruns 2S-0.4G-B user manual

Unitek

Unitek Classic P3 Series manual

Grundfos

Grundfos CUE Safety instructions and other important information