7

ENG

“EVD evolution”+0300005EN - rel. 3.1 - 25.07.2011

1. INTRODUCTION

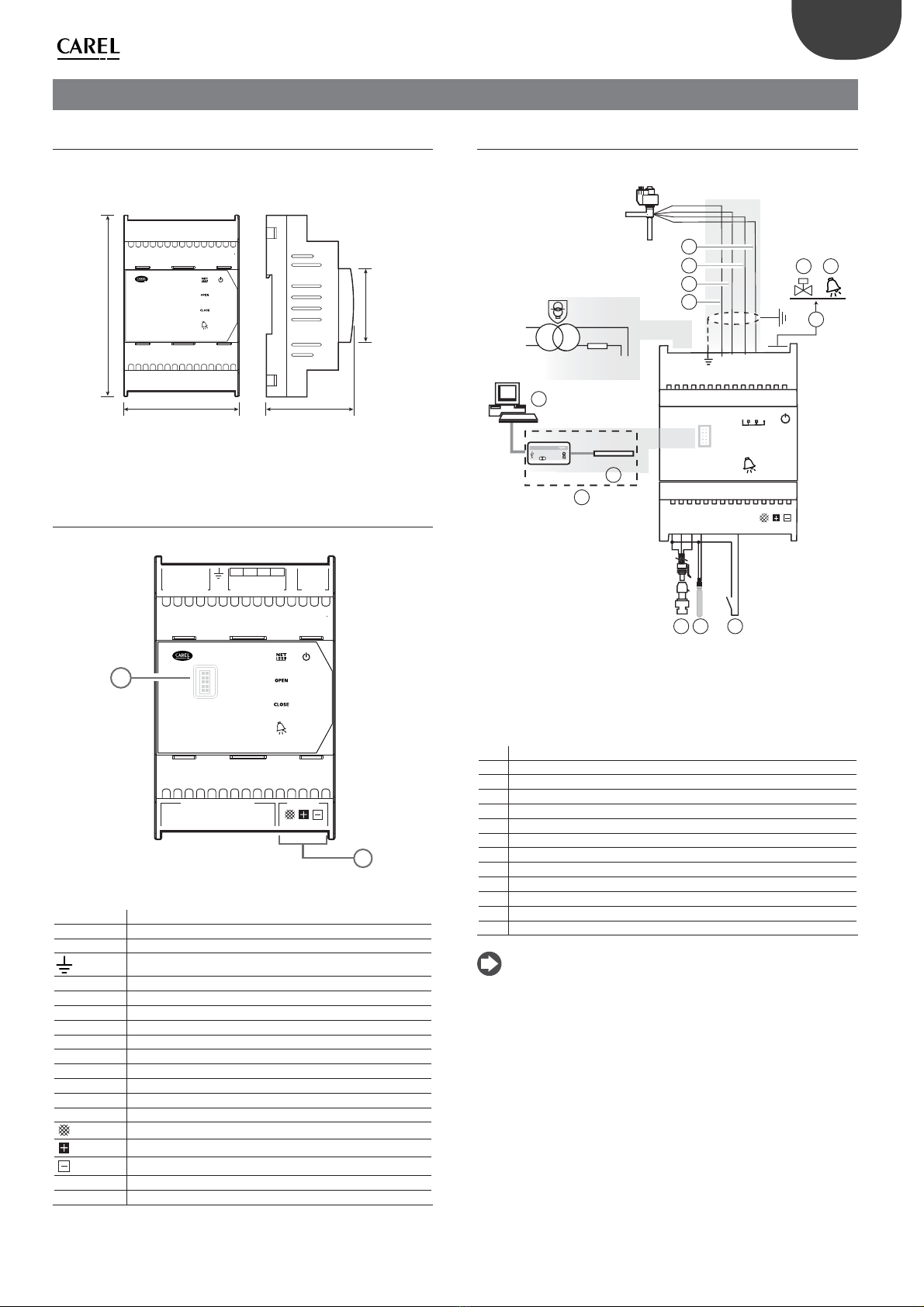

EVD evolution is a driver for double pole stepper motors designed

to control the electronic expansion valve in refrigerant circuits. It is

designed for DIN rail assembly and is tted with plug-in screw terminals.

It controls refrigerant superheat and optimises the eciency of the

refrigerant circuit, guaranteeing maximum exibility, being compatible

with various types of refrigerants and valves, in applications with chillers,

air-conditioners and refrigerators, the latter including subcritical and

transcritical CO2systems. It features low superheat, high evaporation

pressure (MOP), low evaporation pressure (LOP) and high condensing

temperature protection, and can manage, as an alternative to superheat

control, special functions such as the hot gas bypass, the evaporator

pressure control (EPR) and control of the valve downstream of the gas

cooler in transcritical CO2circuits.

In the versions for CAREL valves, if integrated with a specic CAREL pCO

controller via LAN, the driver can control one of the following:

• an electronic expansion valve in a refrigerant circuit with Emerson

Climate Technologies Digital Scroll™ compressor;

• an electronic expansion valve in a refrigerant circuit with SIAM ANB

scroll compressor. In this case the compressor must be controlled

by the CAREL Power+ speed drive (with inverter), this in turn

connected to the pCO controller.

The EVD evolution driver can control an electronic expansion valve in

a refrigerant circuit with Digital Scroll compressor, if integrated with a

specic CAREL controller via LAN. In addition, it features adaptive control

that can evaluate the eectiveness of superheat control and if necessary

activate one or more tuning procedures. Together with superheat

control, it can manage an auxiliary control function selected between

condensing temperature protection and “modulating thermostat”. As

regards network connectivity, the driver can be connected to either of

the following:

• a pCO programmable controller to manage the controller via pLAN,

tLAN and RS485/Modbus®;

• a PlantVisorPRO supervisor via RS485/Modbus®. In this case, On/O

control is performed via digital input 1 or 2, if suitably congured. As

well as regulation start/stop, digital inputs 1 and 2 can be congured

for the following:

- valve regulation optimization after defrost;

- discharged battery alarm management;

- valve forced open (at 100%);

- regulation backup;

- regulation security.

The second digital input is available for optimised defrost management.

Another possibility involves operation as a simple positioner with 4 to 20

mA or 0 to 10 Vdc analogue input signal. EVD evolution comes with a LED

board to indicate the operating status, or a graphic display (accessory) that

can be used to perform installation, following a guided commissioning

procedure involving setting just 4 parameters: refrigerant, valve, pressure

probe, type of main control (chiller, showcase, etc.). The procedure can

also be used to check that the probe and valve motor wiring is correct.

Once installation is complete, the display can be removed, as it is not

necessary for the operation of the driver, or alternatively kept in place to

display the signicant system variables, any alarms and when necessary

set the control parameters.The driver can also be setup using a computer

via the service serial port. In this case, the VPM program (Visual Parameter

Manager) needs to be installed, downloadable from http://ksa.carel.com,

and the USB-tLAN converter EVDCNV00E0 connected.

Only on RS485/ Modbus® models can the installation procedure be

managed as described above by computer, using the serial port (see

paragraph 2.8) in place of the service serial port. The “universal” models

can drive all types of valves, while the CAREL models only drive CAREL

valves.

1.1 Models

Code Description

EVD0000E00 EVD evolution universal - tLAN

EVD0000E01 EVD evolution universal - tLAN, multiple pack of 10 pcs (*)

EVD0000E10 EVD evolution universal - pLAN

EVD0000E11 EVD evolution universal - pLAN, multiple pack of 10 pcs (*)

EVD0000E20 EVD evolution universal - RS485/Modbus®

EVD0000E21 EVD evolution universal - RS485/Modbus®, multiple pack of

10 pcs (*)

EVD0000E30 EVD evolution for CAREL valves - tLAN

EVD0000E31 EVD evolution for CAREL valves - tLAN, multiple pack 10

pcs (*)

EVD0000E40 EVD evolution for CAREL valves - pLAN

EVD0000E41 EVD evolution for CAREL valves - pLAN, multiple pack 10

pcs (*)

EVD0000E50 EVD evolution for CAREL valves - RS485/Modbus®

EVD0000E51 EVD evolution for CAREL valves - RS485/Modbus®, multiple

pack 10 pcs

EVD0002E10 EVD evolution universal - pLAN opto-isolated

EVD0002E20 EVD evolution universal - RS485/Modbus®opto-isolated

Tab. 1.a

(*)The codes with multiple packages are sold without connectors,

available separately in code EVDCON0021.

1.2 Functions and main characteristics

In summary:

• electrical connections by plug-in screw terminals;

• serial card incorporated in the driver, based on the model (tLAN, pLAN,

RS485/Modbus®);

• compatibility with various types of valves (“universal”models only) and

refrigerants;

• activation/deactivation of control via digital input 1 or remote control

via pLAN, from pCO programmable controller;

• superheat control with protection functions for low superheat, MOP,

LOP, high condensing temperature;

• adaptive superheat control;

• function to optimise superheat control for air-conditioning units

tted with Emerson Climate Digital Scroll™ compressor. In this case,

EVD Evolution must be connected to a CAREL pCO series controller

running an application program that can manage units with Digital

Scroll compressors. This function is only available on the controllers for

CAREL valves;

• conguration and programming by display (accessory), by computer

using the VPM program or by PlantVisor/PlantVisorPro supervisor and

pCO programmable controller;

• commissioning simplied by display with guided procedure for setting

the parameters and checking the electrical connections;

• multi-language graphic display, with “help” function on various

parameters;

• management of dierent units of measure (metric/imperial);

• parameters protected by password, accessible at a service (installer)

and manufacturer level;

• copy the conguration parameters from one driver to another using

the removable display;

• ratiometric or electronic 4 to 20 mA pressure transducer, the latter can

be shared between up to 5 drivers, useful for multiplexed applications;

• possibility to use S3 and S4 as backup probes in the event of faults on

the main probes S1 and S2;

• 4 to 20 mA or 0 to 10 Vdc input to use the driver as a positioner

controlled by an external signal;

• management of power failures with valve closing (only for drivers with

24 Vac power supply and connected to the EVBAT00400 /EVBAT00500

accessory);

• advanced alarm management.