Integrated Optics MatchBox Series User manual

<$chapnum>-1

Version 2.5 October 2020

Wavelength Combiner

<$chapnum>-2

MatchBox® series | User Manual

<$chapnum>-1

1

INTRODUCTION

As the title hints, MatchBox® products are ultra-compact, single-unit laser

sources with overall dimensions comparable to a regular matchbox

(30x50x18 mm3), connector pins not included.

The MatchBox® series include a range of continuous wave laser sources,

featuring wide range of wavelength, output power, output type and line-

width options.

The series is composed of solid state (DPSS) lasers, passive Q-Switch

short-pulse lasers, multi-wavelength lasers based on classical dichroic

combining, as well as direct laser diode (LD) lasers. Despite the different

technical implementation, physical and electrical properties, usability and

connectivity are almost identical throughout the series, representing our

commitment to perfect user experience and faster time to market for our

customers.

Please take your time to read this instruction manual which provides

essential information about the usage of the continuous wave multi-

wavelength lasers. We have also included various hints and tips that will

help you to get the most out of a certain laser source.

Integrated Optics

<$chapnum>-2

2

MatchBox® series | User Manual

<$chapnum>-3

3

CONTENTS

1 SAFETY INFORMATION ............................................... ... 5

1.1 Labels...................................................................... ... 5

1.2 Electrical safety ....................................................... ... 6

1.3 Optical Safety .......................................................... ... 7

1.4 Laser Safety and Classification ............................... ... 9

2 DESCRIPTION AND SPECIFICATIONS ....................... ... 11

2.1 Part Numbers .......................................................... ... 11

2.2 Description of Series ............................................... ... 12

2.3 Thermal Management ............................................. ... 12

2.4 Power Supply .......................................................... ... 14

2.5 Cables ..................................................................... ... 14

2.6 Power and Signal Connections ............................... ... 15

2.7 Specifications .......................................................... ... 16

2.8 Mechanical Design .................................................. ... 16

2.9 Laser Output Options .............................................. ... 18

2.10 Operating Environment............................................ ... 21

3 INSTALLATION.............................................................. ... 23

3.1 Preliminary Checks.................................................. ... 23

3.2 Heatsink Requirements ........................................... ... 24

3.3 Heatsink Installation ................................................ ... 25

3.4 Starting the laser ..................................................... ... 26

4 OPERATION .................................................................. ... 29

4.1 Operating Fiber Coupled Laser ............................... ... 29

4.2 Operating Free-space Output Laser........................ ... 30

4.3 UART bus ................................................................ ... 31

Integrated Optics

<$chapnum>-4

4

4.4 Laser Control Software ............................................... 31

4.5 Changing Output Power........................................... ... 44

4.6 Communication Command Table ............................ ... 45

4.7 Communication with Multiple Lasers in a Bus ......... ... 46

4.8 TTL modulation ........................................................... 49

4.9 Attaching Control Interfaces........................................ 51

5 ACCESSORIES .............................................................. ... 53

6 TROUBLESHOOTING Q&A .............................................. 55

6.1 Frequently Asked Questions.................................... ... 55

7 GLOSSARY .................................................................... ... 61

8 WARRANTY ................................................................... ... 65

8.1 Limitations of Warranty ............................................ ... 66

MatchBox® series | User Manual

<$chapnum>-5

5

1. SAFETY INFORMATION

1.1: Labels

Along the text you will find icons designed to draw your attention to

different bits of safety or otherwise important information:

This icon is used to draw your attention to important information, related

to the usage of a laser.

This symbol is a warning sign. It marks safety precautions related to

optical laser radiation and alerts the operator to the danger of exposure

to hazardous visible or invisible laser radiation.

This symbol is a warning sign. It marks safety precautions related to

electrical safety and alerts the operator about the presence of dangerous

voltage, which might appear on certain conditions. Electric shocks

caused by such voltage may constitute risks to the operator and the

equipment used.

Figure 1-1. Labels on a side of the laser indicates product safety information.

MatchBox lasers belong to the class 3B or class 4.

Integrated Optics

<$chapnum>-6

6

Figure 1-2. Serial number is marked on the back of the laser body, right above

the pin connection.

1.2: Electrical safety

Do not disassemble the enclosure. All units are designed to be operated

as assembled. Warranty will be voided if the enclosure is opened.

Electric shocks from an unsuitable or poorly grounded power supply, can

cause extreme pain, severe burns, cardiac arrest and in some cases can

be even lethal, that is why the operator should always obey the safety

measures given below.

The laser body of MatchBox is connected to the ground, this means that

all internal electronics share the same ground of the laser body.

It is recommended to make sure that the power supply used with

MatchBox laser pin connection, is well grounded and that there are no

grounding interruptions with other devices. Otherwise it can be

dangerous for an operator and it can cause malfunction of the laser.

MatchBox® series | User Manual

<$chapnum>-7

7

1.3: Optical Safety

Light, emitted from a laser source, features hazardous properties, as

compared to conventional light sources, such as: luminescent bulbs, light

emitting diodes and etc. It is important for users or other persons

approaching to laser systems, to know the dangers involved. Only users,

who are familiar with laser safety should use laser systems, this way the

risks of laser radiation related accidents would be minimized.

MatchBox lasers are Class 3B laser products with rare exceptions of

Class 4. Different models are arranged to emit up to 500 mW of visible or

invisible (infrared) radiation.

The radiation is hazardous if the eye is exposed directly to the beam or to

it’s specular reflection. The risk of permanent eye damage or even

blindness increases due to longer exposure time.

Diffuse reflections as those from paper or other matte surfaces are

typically not harmful if observed at a distance of 1 m (3 ft) or larger.

The use of eye protection when operating a MatchBox laser is necessary

if at any circumstances the laser beam could be exposed to an eye

directly or through a specular reflection.

Eye protection in the form of spectacles or goggles is preferred to be with

appropriate wavelength filtering. For example, spectacles absorbing

waves of spectral region from 180 to 532 nm are suitable to work with e.g.

405 nm, 457 nm, 473 nm, 488 nm, 491 nm, 515 nm and 532 nm

MatchBox lasers. However, these spectacles shouldn’t be used to filter

561 nm, 593 nm waves or radiation in the red and infrared regions.

Protective eyewear provides another significant advantage - when

working in dark rooms, laser radiation could haze user’s eyes even if it is

observed from diffuse reflections. Properly chosen eyewear definitely

reduce or even eliminate such haze and extend productive hours.

Integrated Optics

<$chapnum>-8

8

The beam emitted from Class 3B and Class 4 lasers can easily damage

photosensitive surfaces like those found in photodiodes, CCD cameras or

photomultipliers. It is important to make sure that an unattenuated beam

does not strike any of aforementioned devices directly. Calculation of

allowed fluency is necessary before using such devices with our lasers.

In addition to laser safety from the laser source alone, given safety

precautions must be followed:

• Experimental setup must ALWAYS be horizontal and below eye lev-

el;

• To avoid accidental exposure, never bend over or look down. If

something falls off of experimental setup, user must first turn off the laser

or close the mechanical shutter and only then pick up the fallen parts;

• Use protective shields or filters to get rid of unnecessary reflections

and scattering;

• User must never wear any kind of jewellery or watches while using

the laser system to avoid any laser beam reflections from those surfaces;

• The laser system must be used in a closed room, because high pow-

er and collimated laser beam can damage biological tissues even at long

distances;

• Extreme precautions must be taken while using volatile substances

in laser operational area;

• High level of ambient light in laser operating room should be main-

tained whenever it is possible, in order to keep the pupil of the eye as

small as possible and to prevent the risk of eye damage;

• Warning signs must be posted near the entrance to the laser opera-

tion area and inside of it;

MatchBox® series | User Manual

<$chapnum>-9

9

• Use of laser must be limited to users, who are completely familiar

with the rules above.

1.4: Laser Safety and Classification

The European requirements for Electromagnetic Compatibility (EMC) are

specified in the EMC Directive (published in 2004/108/EC).

Conformance (EMC) is achieved through compliance with the

harmonized standards EN55011:2009 for emission and EN61000-6-

1:2007 for immunity.

The laser meets the emission requirements for Class 3B or Class 4 as

specified in EN55011:2009.

Compliance of lasers within the MatchBox series with the (EMC)

requirements is certified by the CE mark.

MatchBox lasers are OEM dedicated lasers and usually come without

necessary safety means. OEM type products are designed for installation

into Class 1 enclosures. However, by adding accessories like beam

shutter and key-switch, CDRH compliance is reached.

The CDRH Accession Number for the MatchBox series lasers and

wavelength combiners is: 1810832-000.

The MatchBox wavelength combiner alone has a simplified physical

interface of 10 pins. These pins are dedicated for power supply,

communication bus (UART), programmable pin and TTL modulation. This

interface is sufficient and convenient for OEM laser integration.

However, for quick laser installation into scientific setups a Break-out-Box

comes handy to provide interlock, USB control, modulation and fan power

supply connector, complying the CDRH requirements.

Integrated Optics

<$chapnum>-10

10

MatchBox® series | User Manual

<$chapnum>-11

11

2. DESCRIPTION AND SPECIFICATIONS

2.1: Part Numbers

The part number is composed as follows for the MatchBox series

wavelength combiners:

Figure 2-1. Understanding part numbers of the MatchBox wavelength

combiners.

The part number of MatchBox wavelength combiners is composed of

seven sections:

• The first four sections describe wavelengths and detector/emitter

types;

• The fifth section describes platform and output type;

• The sixth section describes modulation type;

• The last, seventh section is for fiber termination.

Integrated Optics

<$chapnum>-12

12

2.2: Description of Series

The MatchBox wavelength combiner is configurable turnkey emitter/

detector system for life sciences, sorting and particle analysis

applications. It has a MatchBox footprint and is compatible with most

MatchBox accessories.

The MatchBox laser combiner includes up to 4 laser diode drivers and

digital control electronics, which allows smart control and a TEC controller

diagnostics of the complete module. To operate this module an external

PD (Power Delivery - in the latest generation of Break-out-Boxes) power

supply and interface cables are needed as well. The system can be

mounted on a heatsink and a 'Break-out-Box' can be used for converting

UART communication to USB.

The MatchBox laser system provides power, consistency and great

performance in one of the smallest packages at one of the most attractive

price levels available in the market.

2.3: Thermal Management

Multi-wavelength diode lasers tend to generate more excessive heat than

the single-wave diode lasers, especially if diodes are operated

simultaneously.

The MatchBox series wavelength combiners have a single thermo -

electric cooler (TEC) equipped inside enclosure for thermal management

of up to 4 laser diodes and associated optics. Thermal stabilization of all

critical components is very important for low-noise and efficient operation

of the complete laser.

Depending on laser configuration, heat dissipation of 5 W to 15 W may be

required in a form of conduction-cooled (AM-H8/AM-H3) or water-cooled

heatsink (AM-H4), attachable to the bottom side of the laser.

MatchBox® series | User Manual

<$chapnum>-13

13

Also, depending on a laser model, a suitable heatsink must have low

thermal resistance. For multiwavelength lasers <0.8 °C/W is sufficient.

This requirement is usually met by a larger passive copper heatsink or an

actively cooled aluminium heat sink. The most popular and suitable

cooling option for wavelength combiners is forced air heatsink (AM-H8/

AM-H3).

In case of specific applications, where better power and central

wavelength stability is required, the internal TEC of these lasers might not

provide sufficient thermal stability. For these applications Integrated

Optics, UAB released a number of TEC based coolers and adapter (AM-

H10/AM-H11), which provide the extra stability needed. Furthermore,

these heatsinks provide higher thermal handling capacity and/or extend

operational temperature range.

Additionally, Integrated Optics, UAB offers adapter plates, which help to

accommodate the MatchBox laser in place of previously installed laser of

other brands. However, adapter plates need to be attached to heatsinks,

having sufficiently low thermal resistance.

Attaching a multiwavelength laser to a stainless steel breadboard through

M6 optical breadboard adapter will not provide sufficient heat dissipation

and the laser will most likely overheat. Steel is a very poor heat conductor.

For efficient cooling, make sure that there are no other heat radiating

devices, such as heat exchangers, heaters or computers in the proximity

of the laser. Also, make sure that the laser is not covered with or

obstructed by any obstacles, which could prevent air circulation around

the laser.

All MatchBox lasers are equipped with internal thermal protection feature.

If the internal temperature reaches 45 °C, the laser shuts down or starts

to blink, turn off the laser and ensure better heat dissipation by decreasing

the heatsink temperature and increasing the heat dissipation capabilities

thereof.

Integrated Optics

<$chapnum>-14

14

2.4: Power Supply

The MatchBox series include a variety of lasers featuring different power

ratings, thus requiring different power supply parameters. Power supply

requirements are provided below.

The wavelength combiner can be operated with power supplies of 9-12 V

at 1.5-3 A. At lower voltages, the 405 nm, 450 nm, 488 nm, 520 nm

wavelength combiner might not turn on or operate properly.

For wavelength combiners the optimal power supply that Integrated

Optics, UAB offers is the 18 W USB type C PD (Power Delivery) power

supply (AM-P7), suitable with wavelength combiner dedicated Break-out-

Box (AM-C9).

Free space lasers are pre-set to start instantaneously when power is

applied.Once the power is applied, all laser combiner wavelengths start

emmiting the laser beam. Fiber coupled lasers must be turned on via

MatchBox laser control software.

2.5: Cables

The MatchBox wavelength combiner features an OEM design, where

integrators implement their own physical interface to connect directly to

the pins of the laser. This is the reason why it is sold without any cables

in its standard configuration. However, standard cables are handy for

end-user setups, and therefore MatchBox accessories come with

compatible cables - power supplies are shipped with USB-C to USB-C

type cables for power delivery and Break-out-Boxes are shipped with

USB-A to USB-micro cable for data communication.

Please contact Integrated Optics, UAB for a customized physical

interface for data and power.

MatchBox® series | User Manual

<$chapnum>-15

15

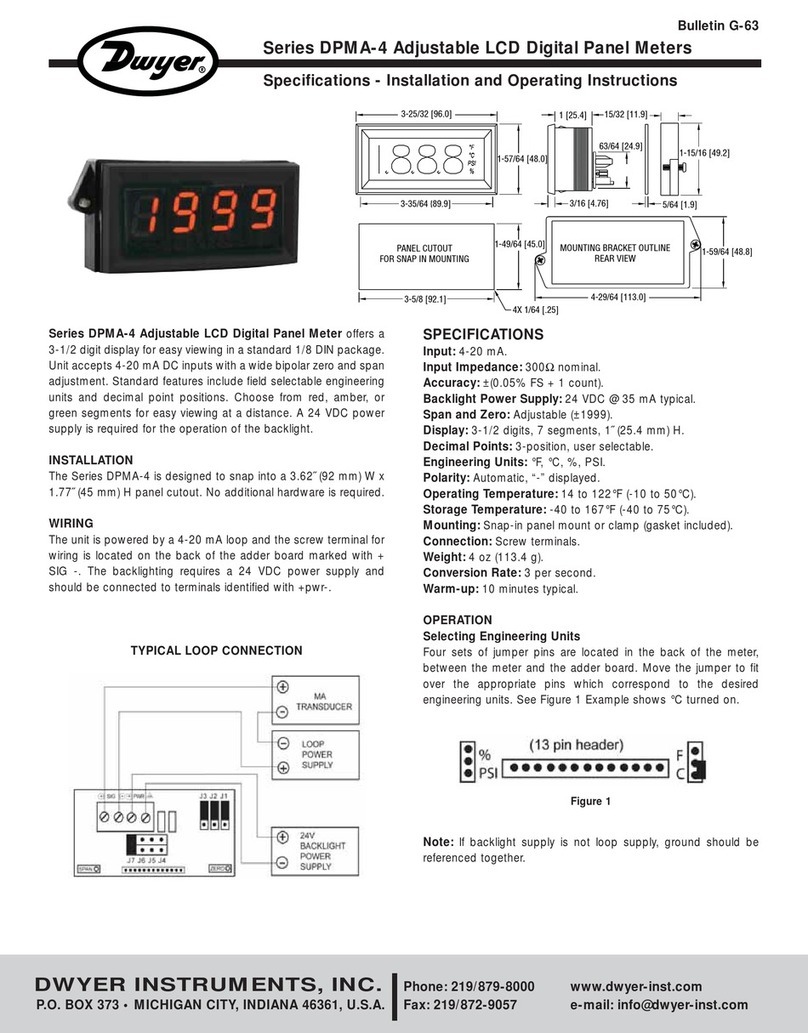

2.6: Power and Signal Connections

Different from the CW (continuous-wave) and pulsed lasers, the

MatchBox wavelength combiner has a physical interface of 10 pins. The

pins are 0.7 mm diameter with 2.54 mm spacing, which provide full

access to complete functionality of the laser.

The pinout of MatchBox Combiner is an expanded version of standard

MatchBox pinout. The lower row of pins is the same as for single-

wavelength lasers, while the second (upper) row is added for individual

TTL modulation of each laser diode installed in the wavelength combiner.

Figure 2-2. Wavelength combiner pinout on the back side of the laser.

Wavelength combiner pin-out explanation:

• L1: on/off diode TTL modulation, up to 10 MHz, 3.3-5 V tolerant;

• L2: on/off diode TTL modulation, up to 10 MHz, 3.3-5 V tolerant;

• GND: ground, connected to the laser body;

• L3: on/off diode TTL modulation, up to 10 MHz, 3.3-5 V tolerant;

• L4: on/off diode TTL modulation, up to 10 MHz, 3.3-5 V tolerant;

Integrated Optics

<$chapnum>-16

16

• GND: ground, connected to the laser body;

• Prog.pin: pre-programmed to supply heatsinks’ fan with up to 5 V

PWM signal, depending on laser body temperature;

• Rx: UART communication, 3.3-5 V tolerant;

• Tx: UART communication, 3.3-5 V tolerant;

• Vcc:+9 or +12 VDC at 1.5-3 A.

Empty slots are used as a key, ensuring that the female pinhead

connector will not be polarizing in a wrong orientation or position.

2.7: Specifications

The MatchBox series includes a variety of lasers featuring different

wavelength and power ratings. The actual specifications of a laser are

provided in a test report accompanying a laser, which is sold to the

customer. General specifications for all laser models can be found at

www.integratedoptics.com , you can scan the QR code below for a quick

access to our website:

2.8: Mechanical Design

Laser sources within the MatchBox series employ a single-box design,

which means that all optics, power electronics and thermal management

components are arranged inside a single enclosure.

The overall dimensions of wavelength combiners are 30 x 50 x 18 mm3

(Width x Depth x Height), not taking into account the pins, which are used

MatchBox® series | User Manual

<$chapnum>-17

17

for connecting the laser to a power source and control interface. Pins

extend approx. 10 mm from the back of the laser. Different output options,

such as free-space output with or without a mechanical shutter,

permanently fixed fibers, have different arrangements on the front facet

of the laser.

Figure 2-3. Top and side view drawing of wavelength combiner free-space

laser.

Integrated Optics

<$chapnum>-18

18

Figure 2-4. Top and side view drawing of the fiber coupled MatchBox

wavelength combiner fiber laser.

2.9: Laser Output Options

MatchBox wavelength combiners are offered in two main configurations

regarding to the type of the output.

Other manuals for MatchBox Series

1

Table of contents

Other Integrated Optics Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Dwyer Instruments

Dwyer Instruments DPMA-4 Series Installation and operating instructions

Anritsu

Anritsu Network Data Analyzer MD6430A Specifications

Teledyne

Teledyne HASTINGS 2002 instruction manual

Siemens

Siemens SITRANS F M MAGFLO operating manual

Stanley

Stanley CL2i user manual

Extech Instruments

Extech Instruments 461891 user guide