page 6

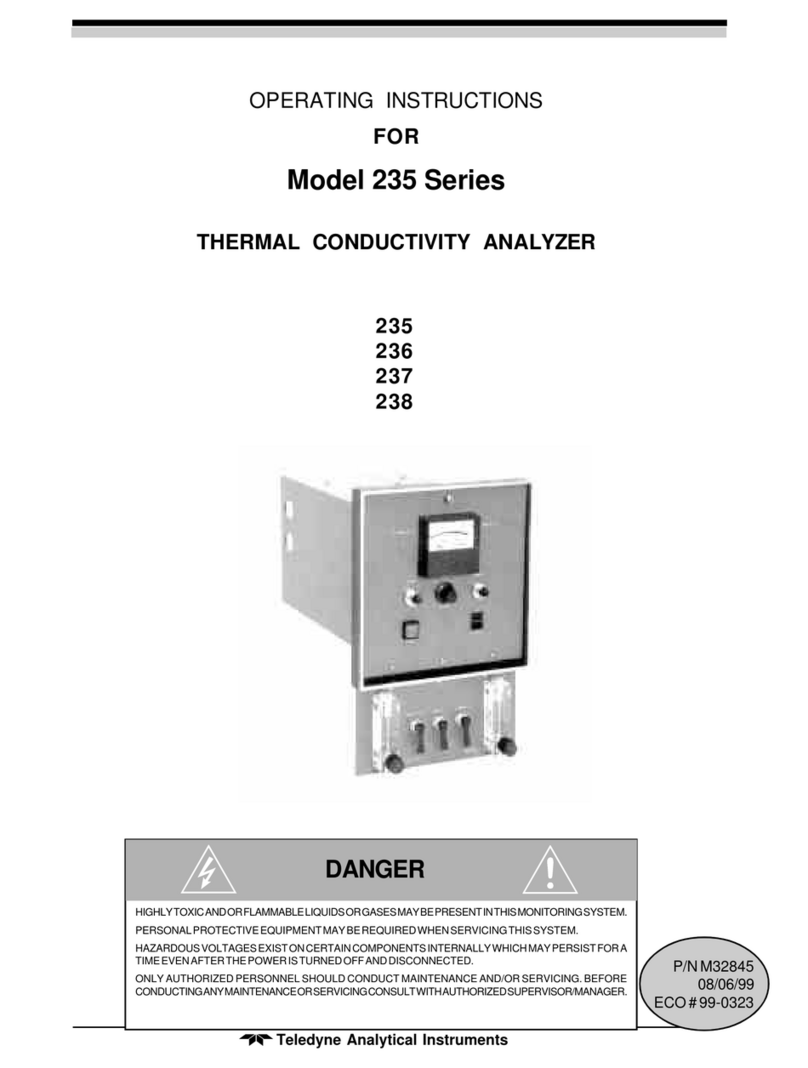

1.3 Model 2002 Control Unit

The Model 2002 control unit consists of the power supply, Pirani resistance bridge control, signal pro-

cessing and display circuitry. The user interface consists of a flat panel display with smooth operating

tactile switches and large green LED digits (0.56"/14.2mm). The pressure is displayed in scientific format

using a 3 digit mantissa and a 1 digit (plus sign) exponent. The pressure can be displayed in Torr,mbar, or

Pascal (optional). The instrument comes standard with 2 alarm setpoints that have TTL level digital

outputs. An optional dual relay board can be internally mounted to trip on the alarm setpoints to turn on/

off various equipment such as pumps, valves, heaters, bakeout ovens, and safety equipment. The Model

2002 instrument accepts an external TTL level "Remote Zero" to zero the instrument when another

instrument (e.g. an ion gauge) indicates that the pressure is less than 1x10-5 Torr. The analog output is

linear per decade directly corresponding to the control units display. The Model 2002 comes calibrated

for nitrogen. Conversion factors for other gases are selectable by the user (see section 3.6). This direct

readout display allows for flexibility in user system configurations which operate with various gases.

An optional serial interface board can be installed to provide RS232 or RS485 support. The Model 2002

control unit fits a standard DIN 43700 insert (1/4 DIN) and mounts into a 3.62 in. (92 mm) square hole.

The case is constructed of NORYL rated UL-94-V1 (self-extinguishing plastic) and is equipped with

mounting brackets that are adjustable up to 3/16 (4.8mm). The control unit case can be configured to be

NEMA 12 compliant.

1.4 Specifications

Measuring range ....................................................................................... 1x10-4 Torr to 10+3 To r r

1.3x10-4 mbar to 1.3x10+3 mbar

Accuracy (1x10-4 to 1x10+3 Torr) .................................................. + 15% of reading (N2,T=230C)

Ambient temperature operating range ..........................................................................00C to 500C

Bakeout temperature (with transducer electronics removed) ................................................. 2500C

Analog output .............................................................. 1.22-4.5 Volts (0.5VDC linear per decade)

Process control................................................................. 2TTL outputs (1TTL auto zero input)

Digital readout ............................................................... Four green LED - resolution is three digit

mantissa (plus exponent)

Power.................................................... 90-130 & 180-260VAC, 50 to 60 Hz IEC-320 receptacle.

A 6 ft., 3-wire power cord is provided with each unit.

Fuse ............................................................................................................................. 250V, 1/4 A.

Transducer mounting .................................................................. Any position without recalibration.

Transducer internal volume ...................................................................................................<1.5cc

Wetted material ....................................................................................... Au, Si3N4, Si, Pt, PyrexTM,

KovarTM and 316 stainless steel

Stability with voltage ..................................................................... Variation in reading undetectable

as power fluctuates within power specification.

Weight (display, cable, and sensor) ................................................ Net: 2.5 lbs., Shipping: 3.4 lbs.

Transducer response time .................................................... Typically less than 400 msec for a step

change from 10-3 Torr to 10+3 To r r .

Positive pressure................................................................................................................. 150 psig

NEMA rating ................................................................. 12 (with use of supplied mounting gasket)