Intel® 3210 and 3200 Chipset Thermal/Mechanical Design Guide 3

Contents

1Introduction..............................................................................................................7

1.1 Design Flow........................................................................................................8

1.2 Definition of Terms..............................................................................................8

1.3 Reference Documents ..........................................................................................9

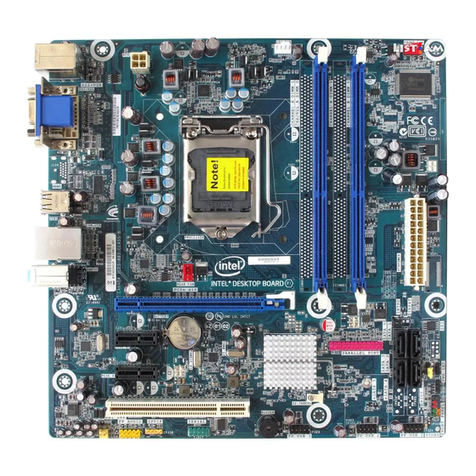

2 Packaging Technology.............................................................................................11

2.1 Non-Critical to Function Solder Joints...................................................................13

2.2 Package Mechanical Requirements.......................................................................13

3 Thermal Specifications ............................................................................................15

3.1 Thermal Design Power (TDP) ..............................................................................15

3.2 Thermal Specification.........................................................................................15

4 Thermal Simulation ................................................................................................. 17

5 Thermal Metrology .................................................................................................. 19

5.1 MCH Case Measurement.....................................................................................19

5.1.1 Supporting Test Equipment...................................................................... 19

5.1.2 Thermal Calibration and Controls..............................................................20

5.1.3 IHS Groove ...........................................................................................20

5.1.4 Thermocouple Attach Procedure ...............................................................22

6 Reference Thermal Solution.....................................................................................35

6.1 Operating Environment ......................................................................................35

6.2 Heatsink Performance........................................................................................35

6.3 Mechanical Design Envelope ...............................................................................36

6.4 Thermal Solution Assembly.................................................................................36

6.4.1 Extruded Heatsink Profiles.......................................................................37

6.4.2 Retention Mechanism Responding in Shock and Vibration.............................38

6.4.3 Thermal Interface Material.......................................................................38

6.4.4 Reference Thermal Solution Assembly Process............................................39

6.5 Reliability Guidelines..........................................................................................40

A Thermal Solution Component Suppliers ...................................................................43

A.1 Heatsink Thermal Solution..................................................................................43

B Mechanical Drawings...............................................................................................45

Figures

1-1 Thermal Design Process .......................................................................................8

2-1 MCH Package Dimensions (Top View)................................................................... 11

2-2 MCH Package Height.......................................................................................... 11

2-3 MCH Package Dimensions (Bottom View)..............................................................12

2-4 Non-Critical to Function Solder Joints...................................................................13

2-5 Package Height................................................................................................. 14

5-1 Omega Thermocouple........................................................................................20

5-2 FCBGA7 Chipset Package Reference Groove Drawing..............................................21

5-3 IHS Groove on the FCBGA7 Chipset Package on the Live Board................................21

5-4 The Live Board on the Fixture Plate...................................................................... 22

5-5 Inspection of Insulation on Thermocouple............................................................. 23

5-6 Bending the Tip of the Thermocouple...................................................................23

5-7 Extending Slightly the Exposed Wire over the End of Groove................................... 24

5-8 Securing Thermocouple Wire with Kapton* Tape Prior to Attach...............................24