Intelitek SCORBOT-ER 9 User manual

SCORBOT-ER 9

User Manual

Catalog #100066 Rev. B

Copyright 2003 Intelitek Inc.

SCORBOT-ER 9

Catalog # 100066 Rev. B

March 1996

Every effort has been made to make this book as complete and accurate as possible. However, no

warranty of suitability, purpose, or fitness is made or implied. Intelitek is not liable or responsible

to any person or entity for loss or damage in connection with or stemming from the use of the

software, hardware and/or the information contained in this publication.

Intelitek bears no responsibility for errors that may appear in this publication and retains the right

to make changes to the software, hardware and manual without prior notice.

Safety Warning!

Use the SCORBOT ER-9 with extreme caution.

The SCORBOT ER-9 can be dangerous and can cause severe injury.

Setup up a protective screen or guard rail around the robot to keep people away from its

working range.

INTELITEK INC.

444 East Industrial Park Drive

Manchester NH 03109-537

Tel: (603) 625-8600

Fax: (603) 625-2137

Web site www.intelitek.com

Table of Contents

CHAPTER 1 Unpacking and Handling

Unpacking the Robot . . . . . . . . . . . . . . . . . . . . . 1-1

Handling Instructions . . . . . . . . . . . . . . . . . . . . . 1-2

Acceptance Inspection . . . . . . . . . . . . . . . . . . . . 1-2

Repacking for Shipment . . . . . . . . . . . . . . . . . . . 1-3

CHAPTER 2 Specifications

Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Work Envelope . . . . . . . . . . . . . . . . . . . . . . . . 2-3

CHAPTER 3 Safety

Precautions . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

CHAPTER 4 Installation

Preparations . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Controller and Computer/Terminal Setup . . . . . . . . 4-1

Robot Setup . . . . . . . . . . . . . . . . . . . . . . . 4-1

SCORBOT-ER IX Installation . . . . . . . . . . . . . . . . 4-3

Controller Installation . . . . . . . . . . . . . . . . . . 4-3

Robot Installation . . . . . . . . . . . . . . . . . . . . 4-3

Homing the Robot . . . . . . . . . . . . . . . . . . . . 4-4

Gripper Installation . . . . . . . . . . . . . . . . . . . . . . 4-5

Pneumatic Gripper . . . . . . . . . . . . . . . . . . . . 4-5

DC Servo Gripper . . . . . . . . . . . . . . . . . . . . 4-7

Activating the Gripper . . . . . . . . . . . . . . . . . . 4-8

CHAPTER 5 Operating Methods

Software . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

ACL . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

ATS . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

ACLoff-line . . . . . . . . . . . . . . . . . . . . . . . . 5-2

SCORBASE Software . . . . . . . . . . . . . . . . . . 5-2

Teach Pendant . . . . . . . . . . . . . . . . . . . . . . . . 5-2

CHAPTER 6 Drive System

Motors . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

DC Motor Structure . . . . . . . . . . . . . . . . . . . 6-3

SCORBOT-ER IX Motors . . . . . . . . . . . . . . . . 6-4

Harmonic Drive Gears . . . . . . . . . . . . . . . . . . . . 6-5

Harmonic Drive Gear Ratios . . . . . . . . . . . . . . . 6-6

Axis Gear Ratios . . . . . . . . . . . . . . . . . . . . . . . 6-7

User’s Manual-v -SCORBOT-ER IX

9603

CHAPTER 7 Position and Limit Devices

Encoders . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Encoder Resolution . . . . . . . . . . . . . . . . . . . 7-3

End of Travel (Limit) Switches . . . . . . . . . . . . . . . . 7-4

Hard Stops . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

Home Switches . . . . . . . . . . . . . . . . . . . . . . . 7-6

CHAPTER 8 Wiring

Robot (Power) Cable and Connector . . . . . . . . . . . . 8-2

Encoder Cable and Connector . . . . . . . . . . . . . . . . 8-3

CHAPTER 9 Maintenance

Daily Operation . . . . . . . . . . . . . . . . . . . . . . . . 9-1

Periodic Inspection . . . . . . . . . . . . . . . . . . . . . . 9-2

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . 9-2

Messages . . . . . . . . . . . . . . . . . . . . . . . . . . 9-6

User’s Manual-vi -SCORBOT-ER IX

9603

CHAPTER 1

Unpacking and Handling

This chapter contains important instructions for unpacking and inspecting the

SCORBOT-ER IX robot arm.

)Read this chapter carefully before you unpack the SCORBOT-ER IX robot and

controller.

Unpacking the Robot

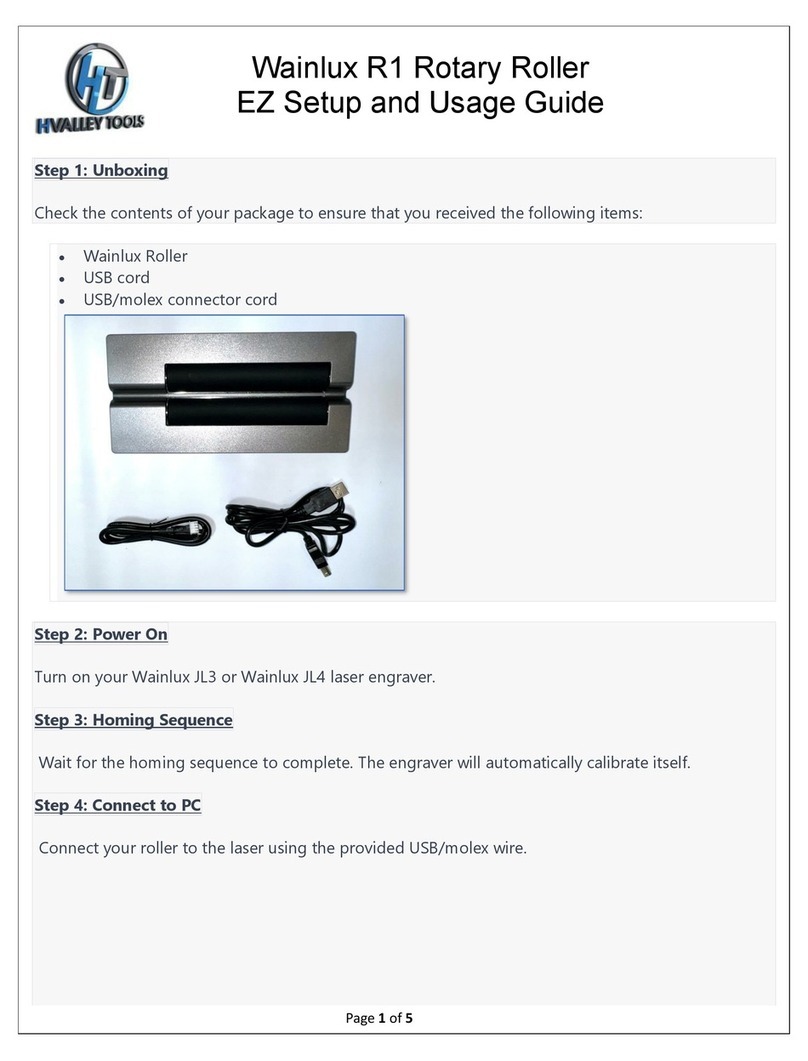

The robot is packed in expanded foam, as shown in Figure 1-1.

To protect the robot during shipment, a metal plate holds the gripper- mounting

flange to the robot base. The plate is fixed to the flange with three bolts and to the

base with two bolts. Use a 3mm hex socket wrench to detach these bolts.

Save these bolts and the plate. You will need them should you repack the robot

for shipment.

Save the original

packing materials and

shipping carton. You

may need them later for

shipment or for storage

of the robot.

Figure 1-1: SCORBOT-ER IX in Packing

User’s Manual 1 - 1 SCORBOT-ER IX

9603

Handling Instructions

The robot arm weighs 38 kilos (83 pounds). Two people are needed to lift or

move it.

Lift and carry the robot arm by grasping its body and/or base. Do not lift or

carry the robot arm by its upper arm or forearm.

Acceptance Inspection

After removing the robot arm from the shipping carton, examine it for signs of

shipping damage. If any damage is evident, do not install or operate the robot.

Notify your freight carrier and begin appropriate claims procedures.

The following items are standard components in the SCORBOT-ER IX package.

Make sure you have received all the items listed on the shipment’s packing list. If

anything is missing, contact your supplier.

Item Description

SCORBOT-ER IX

Robot Arm Includes: Cabling with air hoses; Hardware for mounting robot: 3

M8x60 bolts; 3 M8 washers; 3 M8 nuts.

Gripper: 2 options

Pneumatic Gripper includes: pneumatic solenoid valve;

Hardware for mounting gripper: 6 4Mx8 screws.

Electric DC Servo Gripper with encoder includes: Hardware for

mounting gripper: 4 M4x10 screws.

ACL Controller-B

Includes: Power Cable 100/110/220/240VAC; RS232 Cable;

3 driver cards for 6 axes.

Optional:

Emergency By-Pass Plug (required when TP not connected)

Additional driver cards for control of up to 12 axes;

Auxiliary multiport RS232 board, cable and connectors.

Teach Pendant: optional Includes: mounting fixture; connector adapter plug;

Teach Pendant for Controller-B User’s Manual

Software ATS (Advanced Terminal Software) diskette;

includes ACLoff-line software

SCORBASE Level 5 Software diskette

Documentation

SCORBOT-ER IX User’s Manual

ACL Controller-B User’s Manual

ACL for Controller-B Reference Guide

ATS for Controller-B Reference Guide

ACLoff-line User’s Manual

SCORBASE Level 5 for Controller-B Reference Guide

SCORBOT-ER IX 1 - 2 User’s Manual

9603

Repacking for Shipment

Be sure all parts are back in place before packing the robot.

When repacking the robot for shipping, bolt the flange and base to the metal

plate. Failure to do so may result in irreversible damage to the arm, particularly

to the Harmonic Drive transmissions. Also be sure to secure the cables around the

foam spool.

The robot should be repacked in its original packaging for transport.

If the original carton is not available, wrap the robot in plastic or heavy paper. Put

the wrapped robot in a strong cardboard box at least 15 cm (about 6 inches)

longer in all three dimensions than the robot. Fill the box equally around the unit

with resilient packing material (shredded paper, bubble pack, expanded foam

chunks).

Seal the carton with sealing or strapping tape. Do not use cellophane or

masking tape.

User’s Manual 1 - 3 SCORBOT-ER IX

9603

This page intentionally left blank.

SCORBOT-ER IX 1 - 4 User’s Manual

9603

CHAPTER 2

Specifications

The following table gives the specifications of the SCORBOT-ER IX robot arm.

Robot Arm Specifications

Mechanical Structure Vertical articulated, enclosed casting

Number of Axes 5 plus gripper

Axis Movement

Axis 1: Base rotation

Axis 2: Shoulder rotation

Axis 3: Elbow rotation

Axis 4: Wrist pitch

Axis 5: Wrist roll

Axis Range Effective Speed

270° 79°/sec 112°/sec

145° 68°/sec 99°/sec

210° 76°/sec 112°/sec

196° 87°/sec 133°/sec

737° 166°/sec

Maximum Operating Radius 691mm (27.2") without gripper

End Effector: options: Pneumatic Gripper

Electric DC Servo Gripper

Hard Home Fixed position on all axes

Feedback Incremental optical encoders with index pulse

Actuators DC servo motors

Transmission Harmonic Drive gears and timing belts

Maximum Payload 2 kg (4.4 lb.), including gripper

Position Repeatability ±0.09mm (0.0035")

Weight 38 kg (83 lb.)

Ambient Operating Temperature 2°–40°C (36°–104°F)

User’s Manual 2 - 1 SCORBOT-ER IX

9603

Structure

The SCORBOT-ER IX is a vertical articulated robot, with five revolute joints. With

gripper attached, the robot has six degrees of freedom. This design permits the

end effector to be positioned and oriented arbitrarily within a large work space.

Figures 2-1 and 2-2 identify the joints and links of the mechanical arm.

Each joint is driven by a permanent magnet DC motor via a Harmonic Drive gear

transmission and timing belt.

The movements of the joints are described in the following table:

Axis No. Joint Name Motion Motor No.

1 Base Rotates the body. 1

2 Shoulder Raises and lowers the upper arm. 2

3 Elbow Raises and lowers the forearm. 3

4 Wrist Pitch Raises and lowers the end effector. 4

5 Wrist Roll Rotates the end effector. 5

Figure 2-1: SCORBOT-ER IX Joints Figure 2-2: SCORBOT-ER IX Links

SCORBOT-ER IX 2 - 2 User’s Manual

9603

Work Envelope

The length of the links and the degree of rotation of the joints determine the

robot’s work envelope. Figure 2-3 shows the dimensions and reach of the

SCORBOT-ER IX, while Figure 2-4 gives a top view of the robot’s work envelope.

The base of the robot is normally fixed to a stationary work surface. It may,

however, be attached to a slidebase, resulting in an extended working range.

Figure 2-3: Operating Range (Side View)

User’s Manual 2 - 3 SCORBOT-ER IX

9603

Figure 2-4: Operating Range (Top View)

SCORBOT-ER IX 2 - 4 User’s Manual

9603

CHAPTER 3

Safety

The SCORBOT-ER IX is a potentially dangerous machine. Safety during operation

is of the utmost importance. Use extreme caution when working with the robot.

Precautions

The following chapters of this manual provide complete details for proper

installation and operation of the SCORBOT-ER IX. The list below summarizes the

most important safety measures.

1. Make sure the robot base is properly and securely bolted in place.

2. Make sure the cable from the body to the base can move freely during all

movements of the robot’s base axis.

3. Make sure both the encoder cable and the robot power cable are properly

connected to the controller before it is turned on.

4. Make sure the robot arm has ample space in which to operate freely.

5. Make sure a guardrail or rope has been set up around the SCORBOT-ER IX

operating area to protect both the operator and bystanders.

6. Do not enter the robot’s safety range or touch the robot when the system is in

operation.

7. Press the controller’s EMERGENCY switch before you enter the robot’s

operating area.

8. Turn off the controller’s POWER switch before you connect any inputs or

outputs to the controller.

)To immediately abort all running programs and stop all axes of motion, do any of

the following:

press the teach pendant’s EMERGENCY button;

use the ACL command A <Enter>;

press the controller’s red EMERGENCY button.

User’s Manual 3 - 1 SCORBOT-ER IX

9603

Warnings

1. Do not operate the SCORBOT-ER IX until you have thoroughly studied both this

User’s Manual and the ACL Controller-B User’s Manual. Be sure you follow the

safety guidelines outlined for both the robot and the controller.

2. Do not install or operate the SCORBOT-ER IX under any of the following conditions:

•Where the ambient temperature drops below or exceeds the specified limits.

•Where exposed to large amounts of dust, dirt, salt, iron powder, or similar

substances.

•Where subject to vibrations or shocks.

•Where exposed to direct sunlight.

•Where subject to chemical, oil or water splashes.

•Where corrosive or flammable gas is present.

•Where the power line contains voltage spikes, or near any equipment which

generates large electrical noises.

3. Do not abuse the robot arm:

•Do not operate the robot arm if the encoder cable is not connected to the

controller.

•Do not overload the robot arm. The combined weight of the workload and

gripper may not exceed 2kg (4.4 lb.). It is recommended that the workload be

grasped at its center of gravity.

•Do not use physical force to move or stop any part of the robot arm.

•Do not drive the robot arm into any object or physical obstacle.

•Do not leave a loaded arm extended for more than a few minutes.

•Do not leave any of the axes under mechanical strain for any length of time.

Especially, do not leave the gripper grasping an object indefinitely.

SCORBOT-ER IX 3 - 2 User’s Manual

9603

CHAPTER 4

Installation

Preparations

Before you make any cable connections, set up the system components according

to the following “Preparation” instructions.

Controller and Computer/Terminal Setup

Place the controller and computer at a safe distance from the robot—well outside

the robot’s safety range.

Make sure the setup complies with the guidelines defined in the chapter,

“Safety,” in the ACL Controller-B User’s Manual.

Robot Setup

Refer to Figures 4-1, 4-2 and 4-3.

1. Set up the SCORBOT-ER IX

on a sturdy surface with at

least one meter of free space

all around the robot.

2. Note that the robot cable

clamp is located at the

midpoint of the robot’s

horizontal range. Using this

midpoint as a reference, set

up the robot so that it faces in

the proper direction—

towards the application or

machine it will serve.

3. Fasten the base of the robot to

the work surface with three sets

of M8 bolt, washer and nut. Figure 4-1: Robot Safety Range

User’s Manual 4 - 1 SCORBOT-ER IX

9603

Make sure the robot is securely bolted in place. Otherwise the robot could

become unbalanced and topple over while in motion.

4. Grasp the robot body and turn the robot to each extreme of its base axis.

)Make sure the segment of cable from

the body to the base is not

obstructed, and/or cannot become

caught under a corner of the robot’s

platform or work surface during all

movements of the base axis.

Make sure the robot is mounted on a

surface large enough to provide

support for this segment of the robot

cable during all movements of the

base axis.

5. Set up a guardrail or rope around the

SCORBOT-ER IX operating area to

protect both the operator and

bystanders.

Figure 4-2: Robot Base Layout

Figure 4-3: Robot Setup

SCORBOT-ER IX 4 - 2 User’s Manual

9603

SCORBOT-ER IX Installation

Controller Installation

Perform the installation procedures detailed in the following sections of

Chapter 2, “Installation,” in the Controller-B User’s Manual:

•Computer/Terminal–Controller Installation

•Power On

•Controller Configuration

)When the Peripheral Setup screen appears at the end of the controller

configuration, select Gripper Connection: None. (You will change this setting

after the gripper is installed.) Refer to the section, “Peripheral Devices and

Equipment--Robot Gripper,” in the Controller-B User’s Manual.

Robot Installation

)Before you begin, make sure the controller POWER switch is turned off.

The robot cable has a number of connectors. Connect them to the controller

according to following three steps. Refer to Figure 4-4.

1. Connect the green/yellow wire to the Safety Ground:

Unscrew and remove the ground nut and washer from the Safety Ground stud.

Place the ground wire terminal onto the stud, then replace and tighten the washer

and nut.

2. Plug the the D37 connector into the Robot Encoders port.

Tighten the retaining screws on the connector.

3. Plug the 19-pin round connector into the Robot Power port.

AIR HOSES

(for pneumatic

gripper only)

3

2

1

Figure 4-4: Robot—Controller Cable Connections

User’s Manual 4 - 3 SCORBOT-ER IX

9603

Note: When disconnecting the robot from the controller, do it in the reverse order; that

is:

•Disconnect the 19-pin round Robot Power connector.

•Disconnect the 37-pin Encoders connector.

•Disconnect the ground wires.

Homing the Robot

After you have completed the robot installation, execute the robot’s Home

routine, as described below.

)The robot must be homed before you mount the gripper.

)Before you begin the homing procedure, make sure the robot has ample space in

which to move freely and extend its arm.

1. Turn on the controller. Turn on the computer.

2. From the ATS diskette or directory, activate the ATS software. Type:

ats <Enter>

If the controller is connected to computer port COM2, type:

ats /c2

3. When the ATS screen and > prompt appear, you may proceed.

4. Give the ACL command to home the robot. Type:

home <Enter>

The monitor will display:

WAIT!! HOMING...

During the Home procedure, the robot joints move and search for their home

positions in the following sequence: shoulder, elbow, pitch, roll, base.

If home is found, a message is displayed:

HOMING COMPLETE (ROBOT)

If the HOME process is not completed, an error message identifying the failure is

displayed. For example:

*** HOME FAILURE AXIS 3

If the home switch is found, but not the encoder’s index pulse, the following

message is displayed:

* * * INDEX PULSE NOT FOUND AXIS 2

SCORBOT-ER IX 4 - 4 User’s Manual

9603

Table of contents