Intelitek JobMaster 00-1800 Series User manual

JobMaster® Mechanical Training Bench

QUICK START GUIDE

For the New 00-1800 Series Benches

Catalog #34-8000-0016 Rev. F

Copyright © 2022 Intelitek Inc.

JobMaster Mechanical Bench Quick Start Guide

Cat. # 34-8000-0016 Rev. F

November 2022

website: http://www.intelitek.com

email: [email protected]

Intelitek software and documentation are available at http://intelitekdownloads.com.

Tel: (603) 625-8600

Fax: (603) 437-2137

All rights reserved. No part of this publication may be stored in a retrieval system, or reproduced in any way,

including but not limited to photocopy, photography, magnetic, or other recording, without the prior agreement and

written permission of the publisher. Program listings may be entered, stored, and executed in a computer system,

but not reproduced for publication.

Every effort has been made to make this book as complete and accurate as possible. However, no warranty of

suitability, purpose, or fitness is made or implied. Intelitek is not liable or responsible to any person or entity for loss

or damage in connection with or stemming from the use of the software, hardware and/or the information

contained in this publication.

Intelitek bears no responsibility for errors that may appear in this publication and retains the right to make changes

to the software, hardware and manual without prior notice.

Table of Contents

1. In This Guide .........................................................................................................................................................4

1.1. Overview ....................................................................................................................................................................... 4

1.2. Version Update: Main Differences ................................................................................................................................ 4

2. List of Accessories .................................................................................................................................................5

3. Mounting and Assembly .......................................................................................................................................6

3.1. Mounting onto a Table.................................................................................................................................................. 6

3.2. Mounting onto the Mobile Bench ................................................................................................................................. 9

3.2.1. Assembling the Mobile Bench........................................................................................................................................................9

3.2.2. Assembling the Shelves..................................................................................................................................................................9

3.2.3. Assembling the Working Surface..................................................................................................................................................10

3.3. Motor Controller and Safety Guard Assembly............................................................................................................. 12

4. Operating the Motor...........................................................................................................................................15

5. Mounting Training Bench Accessories ................................................................................................................19

5.1. Overview ..................................................................................................................................................................... 19

5.2. Map for Assembly Mounting....................................................................................................................................... 20

5.3. Mounting Bearing Kit Accessories ............................................................................................................................... 20

5.4. Mounting Laser Alignment Accessories....................................................................................................................... 22

4

JobMaster® Mechanical Training Bench|In This Guide

© 2022 Intelitek Inc. All rights reserved | 34-8000-0016-F-JM-Mechanical-Bench-QS_v1.1

1. In This Guide

1.1. OVERVIEW

Thank you for purchasing the JobMaster Mechanical Training Bench for use in your classroom or

laboratory. This guide is meant to help you assemble the bench and prepare it for use with the online

learning curriculum.

1.2. VERSION UPDATE: MAIN DIFFERENCES

The main differences between this version of the Mechanical Bench and the previous version (00-ME10

series) are related to:

•Modularity: This version of the Mechanical Bench includes plastic containers with equipment

that can be placed on the shelves of the bench. Different levels of equipment may be purchased,

and containers can be moved, interchanged, or stored elsewhere. For more information about

the different levels of modularity, see Section 2 List of Accessories.

•Safety: With the introduction of a new magnetic key/lock system, the motor can only run when

the plexiglass enclosure is securely in place. See Section 3.3 Motor Controller and Safety Guard

Assembly for more information.

•Motor Controller: The motor controller has been updated. For instructions on its use, see

Section 4 Operating the Motor.

•Materials: The previous version of the Mechanical Bench contained rigid metal racks and an

inflexible working surface. The 00-1800 series is made up of more flexible and user-friendly

materials.

5

JobMaster® Mechanical Training Bench|List of Accessories

© 2022 Intelitek Inc. All rights reserved | 34-8000-0016-F-JM-Mechanical-Bench-QS_v1.1

2. List of Accessories

You may have purchased additional, optional Mechanical Training Bench accessories. You can find a list

of these accessories in this table.

Part

Cat. No.

Level

Working Surface

00-1800-0002

1

Coupling Kit

10-1800-0002

1

Shaft & Bearing Kit

10-1800-0003

1

Accessories Kit 1

10-1800-0004

1

Sheave, Pulley, & Sprocket Kit

10-1800-0005

2

Motor Kit

10-1800-0006

2

Accessories Kit 2

10-1800-0007

2

Gear Kit

10-1800-0008

3

C-Brake/Speed Reducer Kit

10-1800-0009

3

Gearbox Kit

10-1800-0010

3

Tool Set

10-1800-0020

1

Mobile Bench

00-1800-0001

Optional

Shelf Set

10-1800-0001

Optional

Bearing Kit

00-1800-6000

Optional

6

JobMaster® Mechanical Training Bench|Mounting and Assembly

© 2022 Intelitek Inc. All rights reserved | 34-8000-0016-F-JM-Mechanical-Bench-QS_v1.1

3. Mounting and Assembly

The JobMaster Mechanical Training Bench’s working surface (catalog #00-1800-0002) can be mounted

onto a standard table/bench or onto the JobMaster Mechanical Training Bench’s mobile bench (00-

1800-0001). The two sections below (3.1 Mounting onto a Table immediately below and 3.2 Mounting

onto the Mobile Bench on page 9) describe how to mount the working surfaces onto the respective

fixtures.

3.1. MOUNTING ONTO A TABLE

This section provides instruction for attaching the working surface onto an existing table in your work

area. A fully equipped table-mounted working surface is shown in the image below.

For instructions on how to mount the working surface onto the mobile bench, see section 3.2 Mounting

onto the Mobile Bench on page 9.

Warning: The working surface should only be lifted and moved by two

people, one at each side.

Warning: Never drag the working surface, as dragging may damage it

and/or the surface beneath it. Always lift the working surface when moving

it from place to place.

7

JobMaster® Mechanical Training Bench|Mounting and Assembly

© 2022 Intelitek Inc. All rights reserved | 34-8000-0016-F-JM-Mechanical-Bench-QS_v1.1

Warning: Ensure that the table or bench that you intend to use for the

mounting of the working surface is large and sturdy enough to support the

working surface when it is fully loaded with equipment. When fully

equipped, the working surface can collapse the table if it is not wide enough

or sturdy enough to support the weight. Recommended surfaces should be

rated to support at least 100 kg (220 lbs.) and have minimum dimensions of

1500 mm x 500 mm. Surface thickness must be between 20 mm and 40 mm.

Read the mounting instructions in this section before selecting a table.

Additional length and/or width may be required depending on the structure

of the table itself. You may also want to consider the properties of the table

with regard to storage space, ease of access, and mobility. You will be

drilling holes into the table and then securing the working surface with

screws and washers, which are included.

To mount the working surface onto a table or bench:

Note: For detailed diagrams of the assembly and part numbers of the fasteners, see document

101970 (sub-document D00-1800-0002).

1. Choose an appropriately sized (minimum dimensions 1500 mm x 500 mm) and sturdy table.

2. Using a pencil, mark four targets for drilling, as shown in this diagram.

3. Using a power drill with the appropriately sized drill bits, drill four holes, each 12 mm in

diameter, into the targets on the table.

4. Carefully lift the working surface and place it onto the table. Center each of the four legs

(vertical profiles) on top of the four holes.

8

JobMaster® Mechanical Training Bench|Mounting and Assembly

© 2022 Intelitek Inc. All rights reserved | 34-8000-0016-F-JM-Mechanical-Bench-QS_v1.1

5. Use the four M8x50 socket button head cap screws and the flat washers included in the package,

and a hex wrench to secure each of the working surface’s legs to the table. The order of the

assembly, from bottom to top, is screw head, square washer, tabletop, working surface leg

(profile).

9

JobMaster® Mechanical Training Bench|Mounting and Assembly

© 2022 Intelitek Inc. All rights reserved | 34-8000-0016-F-JM-Mechanical-Bench-QS_v1.1

3.2. MOUNTING ONTO THE MOBILE BENCH

The JobMaster Mechanical Training Bench includes two main sections: the main mobile bench (00-1800-

0001) with shelves (10-1800-0001), and the working surface (00-1800-002).

This section provides instruction for assembling the mobile bench (with shelves) and for mounting the

working surface onto the mobile bench. For instructions on how to mount the mobile bench onto a pre-

existing table, see above section 3.1 Mounting onto a Table on page 6.

3.2.1. Assembling the Mobile Bench

Unpack and assemble the mobile bench (00-1800-0001) according to the instructions in document

101969.

3.2.2. Assembling the Shelves

Assemble the shelve set (10-1800-0001) onto the mobile bench according to the instructions in

document 101970.

10

JobMaster® Mechanical Training Bench|Mounting and Assembly

© 2022 Intelitek Inc. All rights reserved | 34-8000-0016-F-JM-Mechanical-Bench-QS_v1.1

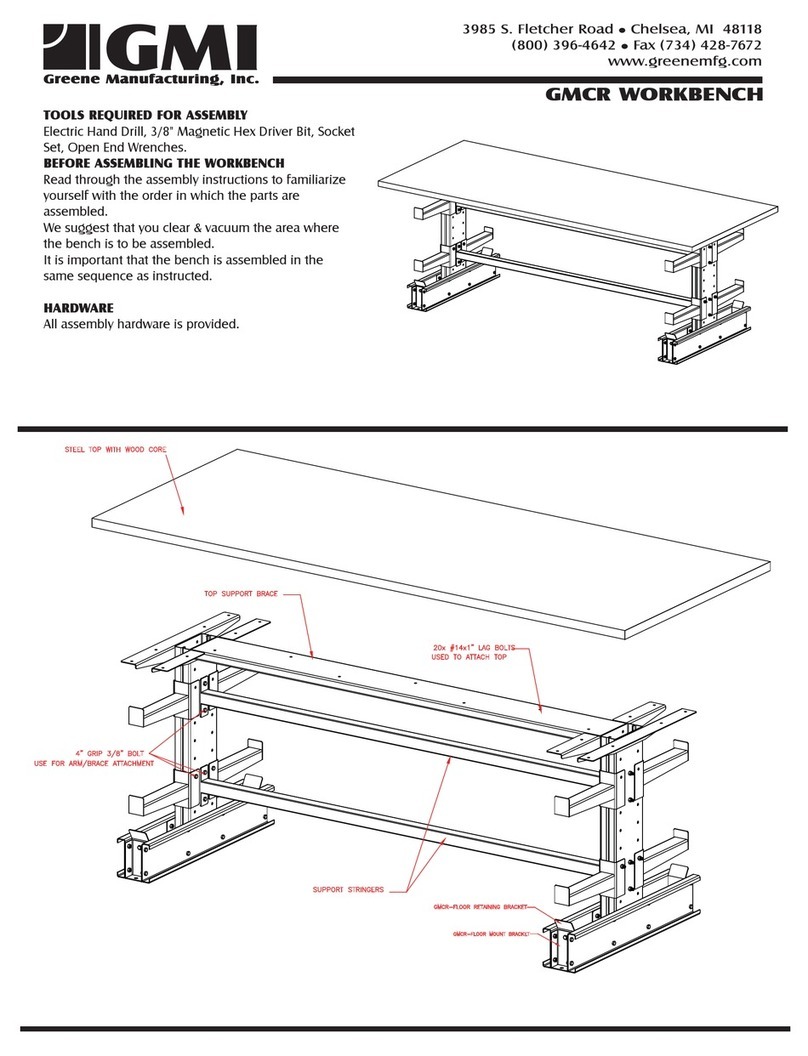

3.2.3. Assembling the Working Surface

The working surface must be secured to the top of the mobile bench at all four legs of the working

surface. This section provides basic instructions for the assembly. For more additional technical

instructions, see document 101970.

To assemble the working surface:

1. With the help of at least one other person, place the working surface on top of the mobile bench

with the four legs of the working surface situated at the points indicated by the X’s.

Note: Placement at the points shown above allows for the placement of a second working

surface on top of the mobile bench.

2. Secure each of the legs of the working surface to the mobile bench in the following manner:

a. Slot an M8 nut into the slot of the mobile bench’s profile near the location of one of the legs

of the working surface (on the side of the leg’s circular pocket).

11

JobMaster® Mechanical Training Bench|Mounting and Assembly

© 2022 Intelitek Inc. All rights reserved | 34-8000-0016-F-JM-Mechanical-Bench-QS_v1.1

b. Slide an M8 screw through a leg fastener and tighten the fastener to the nut with an

appropriate hex key. Do not tighten completely.

c. Push the screw/fastener/nut assembly into the circular pocket of the working surface’s leg.

d. Perform steps a-c for all four working surface legs.

3. Tighten all four M8 screws completely using the rounded end of the hex key.

12

JobMaster® Mechanical Training Bench|Mounting and Assembly

© 2022 Intelitek Inc. All rights reserved | 34-8000-0016-F-JM-Mechanical-Bench-QS_v1.1

3.3. MOTOR CONTROLLER AND SAFETY GUARD ASSEMBLY

The safety guard assembly (021216) and motor power controller (26-0000-0003) include a motor lock.

The motor lock is a magnetic lock/key safety device. The lock has two magnetic read heads, one of

which is wired to the controller, and the other is attached to the safety guard assembly. When the two

read heads are separated, the controller is disabled and the motor (021217) cannot run. When the two

read heads are coupled together, the controller is enabled, and the motor can run.

This section contains an overview of how to mount the controller and the safety guard assembly. For

additional details, see document 101970.

13

JobMaster® Mechanical Training Bench|Mounting and Assembly

© 2022 Intelitek Inc. All rights reserved | 34-8000-0016-F-JM-Mechanical-Bench-QS_v1.1

Warning

Ensure that the motor controller is NOT connected to a power source before

starting this procedure.

To assemble the motor power controller and safety guard assembly:

1. Place the controller on the left side of the top shelf.

2. Slide the magnetic read head that is connected to the controller around the top of the mobile

bench and through the corner hole of the working surface.

14

JobMaster® Mechanical Training Bench|Mounting and Assembly

© 2022 Intelitek Inc. All rights reserved | 34-8000-0016-F-JM-Mechanical-Bench-QS_v1.1

3. Secure the read head to the top of the working surface using the included bracket and screws.

Do not completely tighten the read head itself to the bracket at this point, as its height may have

to be adjusted.

4. Place the safety guard assembly on top of the working surface. Ensure that the two read heads

are touching and aligned. If they are not, remove the safety guard and adjust the height of the

read head connected to the controller. Replace the safety guard to confirm alignment.

5. Remove the safety guard and completely fasten the lower magnetic read head to the bracket.

6. Secure the controller with the included M4x12 screws and M4 washers. (See document 101970

for diagrams and details.)

15

JobMaster® Mechanical Training Bench|Operating the Motor

© 2022 Intelitek Inc. All rights reserved | 34-8000-0016-F-JM-Mechanical-Bench-QS_v1.1

4. Operating the Motor

Motor operation is performed via the motor power controller. This section documents the basic

operation of the controller.

Warning: The controller has two voltage options. Ensure that you are using

the correct voltage. To change the controller’s voltage, see document

101976.

16

JobMaster® Mechanical Training Bench|Operating the Motor

© 2022 Intelitek Inc. All rights reserved | 34-8000-0016-F-JM-Mechanical-Bench-QS_v1.1

For basic motor operation, the components labelled below are used:

Label

Component

Function

A

Controller input power switch (INPUT)

Sends single-phase power to the controller unit.

B

Controller power indicator lamp

The controller is powered with single-phase power

when the lamp is illuminated.

C

Output power switch (OUTPUT ON/OFF)

Sends single-phase power brake output (middle) and

motor control (left) sections of the controller.

D

Motor power on/off switch (MOTOR ON/OFF)

Sends single-phase power to the motor driver.

E

Motor power indicator lamp

The motor's driver is powered with single-phase when

the lamp is on.

F

Motor start button (START)

Starts the motor. (Sends 3-phase power to the motor.)

G

Motor speed adjustment knob (MOTOR SPEED)

Adjusts the motor speed. (Adjusts the 3-phase power

amplitude.)

H

Output to brake socket

Connects to the brake plug and powers the brake. The

brake is locked by default. When the brake is powered

(when the output power switch [C] is on), the brake is

released, allowing the motor shaft to run.

17

JobMaster® Mechanical Training Bench|Operating the Motor

© 2022 Intelitek Inc. All rights reserved | 34-8000-0016-F-JM-Mechanical-Bench-QS_v1.1

Warning

Before beginning this procedure, ensure that the controller is properly

secured to the mobile bench or the worktable (depending on your setup),

and that the motor is properly secured to the working surface. For

instructions on how to secure the motor, see course ME05: Belt Drives, Skill

Drill 2 in the online curriculum.

Ensure that the safety guard assembly is in place.

To start the motor:

1. Turn the controller input power switch (A) on. The controller input indicator lamp (B) is

illuminated.

2. Turn the controller output switch (C) on (upwards).

3. Turn the motor on/off switch (D) on (upwards). Power is sent to the motor and the motor power

indicator lamp is illuminated (E).

Ensure that motor speed knob is turned to a low speed.

4. Press START (F) to start the motor.

5. Adjust the motor speed dial (G) as desired.

18

JobMaster® Mechanical Training Bench|Operating the Motor

© 2022 Intelitek Inc. All rights reserved | 34-8000-0016-F-JM-Mechanical-Bench-QS_v1.1

To stop the motor without applying the brake:

•Turn the MOTOR ON/OFF switch (D) off (downwards).

To stop the motor while applying the brake:

•Turn the OUTPUT ON/OFF switch (C) off (downwards).

Note: After stoppage of the motor for any reason (including removal of the safety guard), the

START button (F) must be pressed to restart the motor.

19

JobMaster® Mechanical Training Bench|Mounting Training Bench Accessories

© 2022 Intelitek Inc. All rights reserved | 34-8000-0016-F-JM-Mechanical-Bench-QS_v1.1

5. Mounting Training Bench Accessories

5.1. OVERVIEW

In the ME series skill drills (course lab activities), parts are secured to the working surface by screwing

them onto the top of the surface via the surface’s holes.

Consider this example where the motor and speed reducer are installed on the working surface:

Here is an additional example with pillow blocks, shaft with coupling, and dial indicator:

20

JobMaster® Mechanical Training Bench|Mounting Training Bench Accessories

© 2022 Intelitek Inc. All rights reserved | 34-8000-0016-F-JM-Mechanical-Bench-QS_v1.1

5.2. MAP FOR ASSEMBLY MOUNTING

This high-angle image of the Mechanical Training Bench’s working surface provides a general map for

where to secure various assemblies when performing the skill drills. In general, all skill drills provide the

exact locations of where to mount the devices and assemblies.

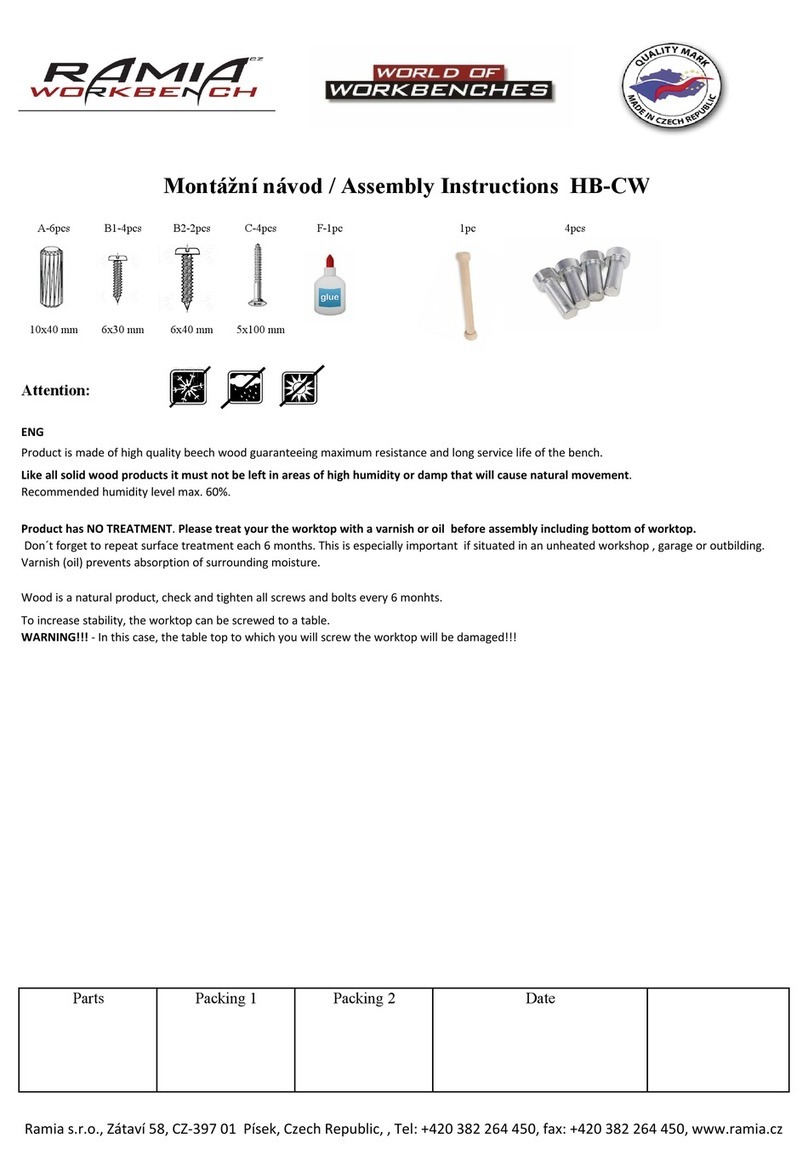

5.3. MOUNTING BEARING KIT ACCESSORIES

ME13 skill drills that do not make use of the arbor press require any flat working service of at least 800

mm x 600 mm. The lamp (36-9000-0038) can be clamped onto any edge of the working surface.

Other manuals for JobMaster 00-1800 Series

1

This manual suits for next models

1

Table of contents

Popular Tools Storage manuals by other brands

Vigor

Vigor 1000 operating instructions

ramia

ramia HB-CW Assembly instructions

IAC INDUSTRIES

IAC INDUSTRIES Quick Value AMERICAN Series Assembly instructions

Seville Classics

Seville Classics UltraHD 20213 Assembly instructions

Sealey

Sealey AP850MB instructions

Craftsman

Craftsman 3000 Series Operator's manual