Intelligent Charging MB/TS25 PC211 User manual

MB/TS25 PC211 UPGRADE Battery Charger

Operators Manual

Doc: DWG1006-34-R3 TS25 PC211 Upgrade Operators ma ual.odtPage 1 of 44 Copyright Material of Intelligent Charging Limited © 2015

Printed On : 02/09/15

MUTE

EXTD

ENTR

DISP DATA

A SET PROC

V SETTEST BATT

CHRG T SET

START

STOP

EXTD

ENTR

DISP DATA

A SET PROC

V SETTEST BATT

CHRG ONE T SET

START

STOP

VOLTS TIME

AMPS

TEST

END ONE

VOLTSTIME

AMPS

TEST

END

%

%

ALARM

MEM

Bxx

ON

OFF

I

O

MEM

Bxx

ON

OFF

I

O

MEM

Bxx

ON

OFF

I

O

MEM

Bxx

ON

OFF

I

O

I N T E L L I G E N T C H A R G I N G

CHARGE

TRIP

ANALYSER

TRIP

MAINS

POWER

BATTERY 'B'BATTERY 'A'

BATTERY 'B'BATTERY 'A'

MB/TS25 PC211 UPGRADE

BATTERY

CHARGER/ANALYSER

OPERATORS MANUAL

MB/TS25 PC211 UPGRADE Battery Charger

Operators Manual

T BLE OF CONTENTS

1 MANUAL REVISION HISTORY 3

2 TS25 PC211 UPGRADE DESCRIPTION 4

2.1 GENERAL NOTES 4

2.2 DIFFERENCES 4

3 CONTROLS AND INDICATORS 5

3.1 DISPLAY 6

3.2 POWER SWITCH 7

3.3 AUDIBLE ALARM 7

3.4 CHARGE CAPACITY TEST CIRCUIT BREAKERS 7

3.5 BATTERY CONNECTORS 7

3.6 KEYBOARD 8

4 USING THE TS25 UPGRADE 9

4.1 CONNECTING BATTERIES 9

4.2 CAPACITY TESTING BATTERIES 12

4.3 CHARGING BATTERIES 15

4.4 ENTERING BATTERY DATA 18

4.5 USING THE ONE MODE OF OPERATION 20

4.6 RESETTING THE TS25 UPGRADE 20

4.7 DISPLAY MNEMONICS 22

4.8 ERROR CODES 23

5 CALIBRATION 25

Doc: DWG1006-34-R3 TS25 PC211 Upgrade Operators ma ual.odtPage 2 of 44 Copyright Material of Intelligent Charging Limited © 2015

Printed On : 02/09/15

MB/TS25 PC211 UPGRADE Battery Charger

Operators Manual

5.1 EQUIPMENT REQUIRED 25

5.2 PERFORMANCE CHECKING 25

5.3 RE-CALIBRATION 26

5.4 CALIBRATION PROBLEMS 28

5.5 CALIBRATION EQUIPMENT CONNECTIONS 29

6 ROUTINE MAINTENANCE 30

6.1 INTERNAL BATTERY REPLACEMENT 30

7 BATTERY LIBRARY 31

7.1 RETRIEVING A LIBRARY ITEM 31

7.2 ENTERING OR MODIFYING A LIBRARY ENTRY 31

8 DEFAULT BATTERY LIBRARY 32

9 SPECIFICATIONS 42

10 PRODUCT DISPOSAL INSTRUCTIONS 43

1 Manual Revision History

Rev Date Description

0 12-02-2008 First Written

1 10-03-2009 Removed Warranty Section. dded New Battery Details To Library.

2 24-11-2014 Changed drawings so that an actual TS25 model is shown.

Doc: DWG1006-34-R3 TS25 PC211 Upgrade Operators ma ual.odtPage 3 of 44 Copyright Material of Intelligent Charging Limited © 2015

Printed On : 02/09/15

MB/TS25 PC211 UPGRADE Battery Charger

Operators Manual

2 TS25 PC211 UPGRADE DESCRIPTION

2.1 GENERAL NOTES

You have chosen to have your TS25 Model battery charger analyser upgraded to a

TS25 (UPGR DE) Model.

The upgrade involves the removal of the antiquated processor board (PC200) and the

separate display board (PC204) to the new PC211 combined display and processor

board.

This upgrade extends the life cycle of your equipment by employing a fully supported

processor unit with higher accuracy speed and functionality.

Some TS25 units will be also be able to benefit from the upgrades ability to increase

the charging current from 10 to 12 (24 in one mode).

Operation of the unit is predominantly the same but there are differences because of

the extended functionality. It is important that this manual is read carefully before

undertaking control of the unit to establish the minor differences and how to employ

them.

2.2 DIFFERENCES

When accessing data entry functions the STOP key can be pressed to BORT the data

entry mode.

The library has been modified to list the standard set of batteries used by the UK MOD.

Check the data with manufacturers data sheets before using any data library entries.

ccessing constant voltage and constant current charging modes are no longer done via

the library number. Use the PROC key to set the charge mode. This is also preserved

with the library data.

utomatic calibration checks to ensure that wrongly entered values are not used, which

could potentially damage the battery or unit.

ll process terminations are highlighted with an “E” number to indicate to the operator

why a capacity test or charge has stopped.

Start and run-time checks are employed to ensure that wrongly entered data does not

make the unit perform outside of its capabilities, the run—time checks also test for

battery disconnection while being processed, wrongly connected battery and checks for

possible internal faults. Extra runtime checks are done to ensure that both cables are

connected when used in ONE mode.

The unit now employs 12 bit nalogue to Digital conversion devices which have

dramatically improved its stability and accuracy.

bility to view the firmware revision and internal resets can be accessed by the keypad.

The ONE mode of operation where both channels can be connected in parallel to double

charge or discharge rates has been simplified.

Doc: DWG1006-34-R3 TS25 PC211 Upgrade Operators ma ual.odtPage 4 of 44 Copyright Material of Intelligent Charging Limited © 2015

Printed On : 02/09/15

MB/TS25 PC211 UPGRADE Battery Charger

Operators Manual

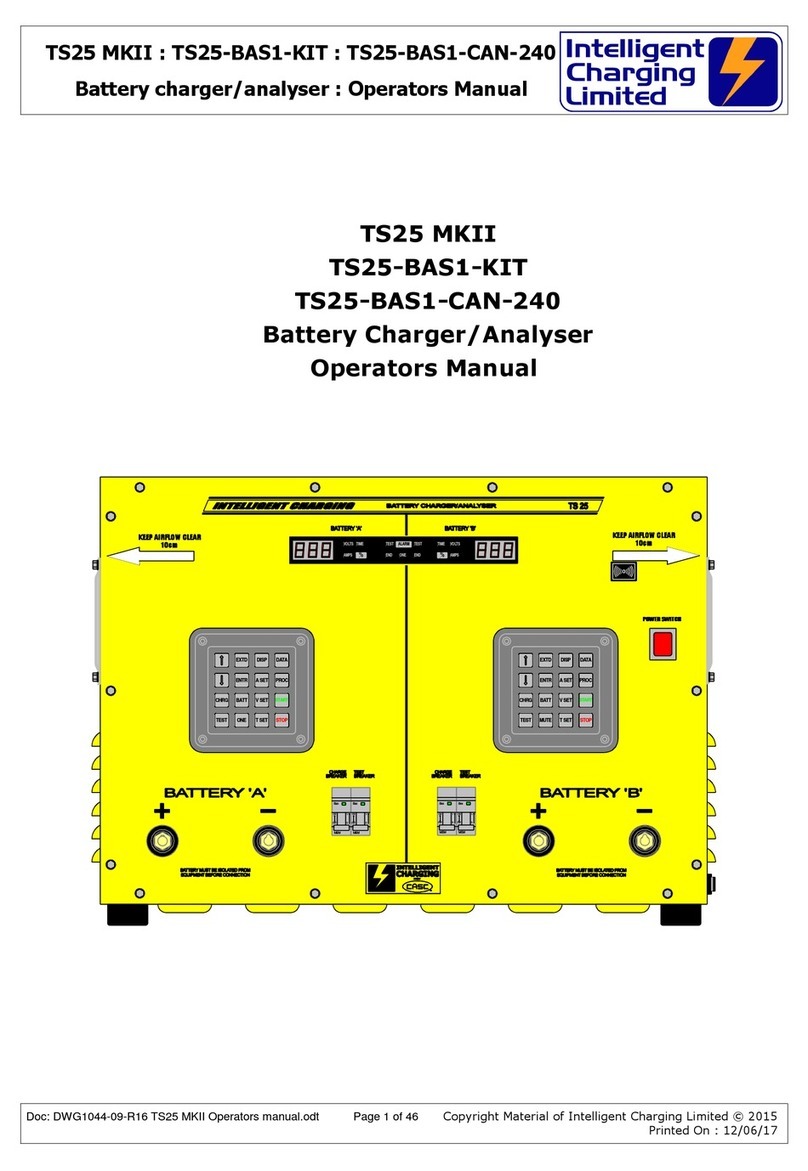

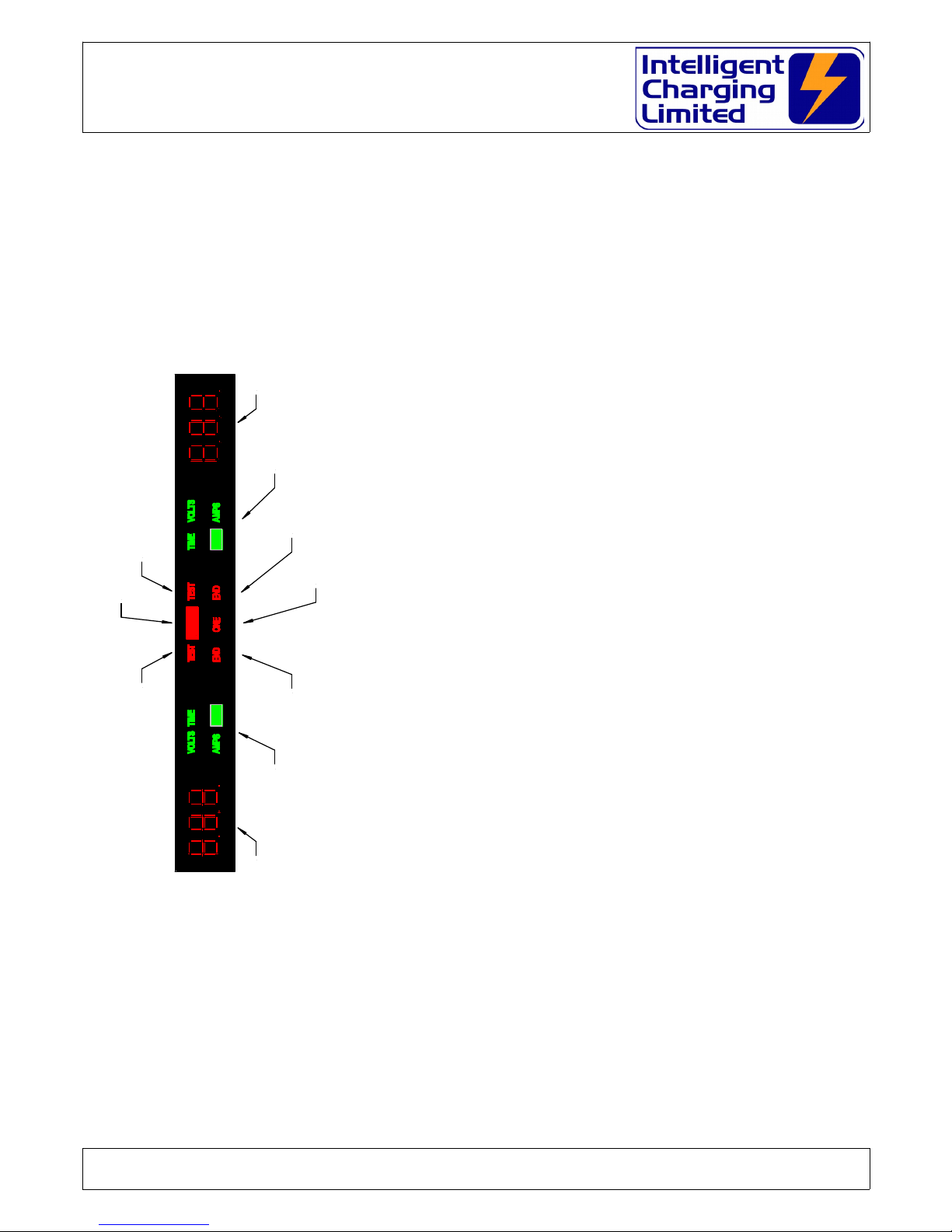

3 CONTROLS AND INDICATORS

Doc: DWG1006-34-R3 TS25 PC211 Upgrade Operators ma ual.odtPage 5 of 44 Copyright Material of Intelligent Charging Limited © 2015

Printed On : 02/09/15

AUDIBLE ALARM

MUTE

EXTD

ENTR

DISP DATA

A SET PROC

V SETTEST BATT

CHRG T SET

START

STOP

EXTD

ENTR

DISP DATA

A SET PROC

V SETTEST BATT

CHRG ONE T SET

START

STOP

VOLTS TIME

AMPS

TEST

END ONE

VOLTSTIME

AMPS

TEST

END

%

%

ALARM

MEM

Bxx

ON

OFF

I

O

MEM

Bxx

ON

OFF

I

O

MEM

Bxx

ON

OFF

I

O

MEM

Bxx

ON

OFF

I

O

I N T E L L I G E N T C H A R G I N G

CHARGE

TRIP

ANALYSER

TRIP

MAINS

POWER

BATTERY 'B'BATTERY 'A'

BATTERY 'B'BATTERY 'A'

A CHANNEL DISPLAY B CHANNEL DISPLAY

POWER SWITCH

AC POWER FUSE & INLET

B CHANNEL DATA

ENTRY KEYPAD

A CHANNEL DATA

ENTRY KEYPAD

CHANNEL A POSITIVE

BATTERY LEAD CONNECTOR

CHANNEL A NEGATIVE

BATTERY LEAD CONNECTOR

CHANNEL B NEGATIVE

BATTERY LEAD CONNECTOR

CHANNEL B POSITIVE

BATTERY LEAD CONNECTOR

CHANNEL A SAFETY CIRCUIT BREAKERS

CHANNEL B SAFETY CIRCUIT BREAKERS

MB/TS25 PC211 UPGRADE Battery Charger

Operators Manual

3.1DISPLAY

NUMERIC DISPL Y

oVoltage is displayed in volts to a resolution of 0.1V

oCurrent is displayed in mperes to a resolution of

0.1

oCapacity test time is displayed in minutes to a

resolution of 1 minute.

oCharge time is displayed in hours to a resolution of

0.1H (One tenth)

oBattery efficiency is displayed in percent to a

resolution of 1%.

NUMERIC DISPL Y INDIC TORS

oVOLTS illuminated means voltage is being displayed

or entered.

oMPS illuminated means current is being displayed

or entered.

oTIME illuminated means time is being displayed or

entered.

o% Illuminated means that battery efficiency is

being displayed.

oTEST illuminated means that the unit is set to

capacity test mode otherwise it is set to charge

mode.

oEND illuminated means that the unit is stopped.

oL RM illuminated means that the unit has just

stopped and the alarm has sounded.

oONE illuminated means that ONE mode has been

selected and the paralleling leads must be used.

Doc: DWG1006-34-R3 TS25 PC211 Upgrade Operators ma ual.odtPage 6 of 44 Copyright Material of Intelligent Charging Limited © 2015

Printed On : 02/09/15

%

%

ALARM

CHANNEL A NUMERIC DISPLAY CHANNLE B NUMERIC DISPLAY

CHANNEL A NUMERIC DISPLAY MODE INDICATOR CHANNEL B NUMERIC DISPLAY MODE INDICATOR

ILLUMINATED IF CAPTEST SELECTED ILLUMINATED IF CHANNEL B CAPTEST MODE IS SELECTED

ILLUMINATED IF THE CHARGER ALARM HAS SOUNDED

ILLUMINATED IF CHANNEL A IS STOPPED ILLUMINATED IF CHANNEL B IS STOPPED

ILLUMINATED IF THE "ONE" MODE OF OPERATION IS SELECTED

MB/TS25 PC211 UPGRADE Battery Charger

Operators Manual

3.2 POWER SWITCH

Operation of this switch will either apply or remove the ac inlet power from the TS25

UPGR DE

WARNING

AVOID REMOVING THE POWER FROM THE UNIT WHILE THE UNIT IS

PERFORMING A CAPACITY TEST OR CHARGE.

3.3 AUDIBLE ALARM

When a charge or capacity test has completed or stopped in error the audible alarm

will sound until the MUTE or STOP key is pressed.

3.4 CHARGE CAPACITY TEST CIRCUIT BREAKERS

The circuit breakers are fitted to prevent high currents from being driven into the

battery or into the unit should a fault condition occur. lways ensure that the circuit

breaker is in the ON position before starting a charge or capacity test.

WARNING

NEVER SWITCH THE CIRCUIT BREAK TO ON WHEN THE UNIT IS PERFORMING

A CHARGE OR CAPACITY TEST AS SEVERE DAMAGE MAY OCCUR TO THE

BATTERY OR THE TS25 UPGRADE

ALWAYS PRESS STOP FIRST

If the circuit breaker operates during a charge immediately press STOP on BOTH

charger channels and remove power from the unit and disconnect the battery.

Operation of the circuit breaker is an indication of a fault and the unit will need to be

checked before use.

3.5 BATTERY CONNECTORS

The battery terminal are where the supplied leads are connected to the TS25

UPGR DE. It is recommended that replacement leads are always purchased from

Intelligent Charging.

Doc: DWG1006-34-R3 TS25 PC211 Upgrade Operators ma ual.odtPage 7 of 44 Copyright Material of Intelligent Charging Limited © 2015

Printed On : 02/09/15

MB/TS25 PC211 UPGRADE Battery Charger

Operators Manual

3.6 KEYBOARD

Each keypad on the unit controls only information for that channel, except when the

unit is put into ONE mode both keypads control the ONE mode of operation. The only

difference is that if a data entry function is invoked in the channel B keypad the data

entry will always have to be performed on the right hand keypad. There are 16 keys

on each keypad and each key performs a particular function depending if the channel

is running or stopped.

3.6.1 STOPPED KEY MAPPING

Increases D splay Br ghness

Reduces D splay Br ghtness

Selects CHARGE MODE

Selects CAPACITY TEST MODE

2 X To Save Battery Data Into The LIBRARY

Selects A Battery From The LIBRARY

2 X Reset Parameters In The Un t Cycles Through D splayed Data

Br efly D splays Battery Data

Enters The Battery AMPS

Enters The Battery VOLTS

Enters The Battery TIME

Starts CHARGE/CAPACITY TEST

Clears The D splay And Alarm

On CHANNEL A (ONE) Selects ONE Mode

On CHANNEL B (MUTE) Stops The Aud ble Alarm

Enters The Battery MODE

EXTD

ENTR

DISP DATA

A SET PROC

V SETCHRG BATT

TEST ONE T SET

START

STOP

3.6.2 RUNNING KEY MAPPING

Increases D splay Br ghness

Reduces D splay Br ghtness

2 X To In t ate CALIBRATION

Br efly D splays Battery Number

Cycles Through D splayed Data

Br efly D splays Battery Data

Bre fly D splays The Battery AMPS

Bre fly D splays The Battery VOLTS

Br efly D splays The Battery TIME

Manually STOPS The CHARGE/CAPACITY TEST

Bre fly D splays The Battery MODE

EXTD

ENTR

DISP DATA

A SET PROC

V SETCHRG BATT

TEST ONE T SET

START

STOP

Note keys that have no comments against them do nothing while RUNNING

Doc: DWG1006-34-R3 TS25 PC211 Upgrade Operators ma ual.odtPage 8 of 44 Copyright Material of Intelligent Charging Limited © 2015

Printed On : 02/09/15

MB/TS25 PC211 UPGRADE Battery Charger

Operators Manual

4 USING THE TS25 UPGRADE

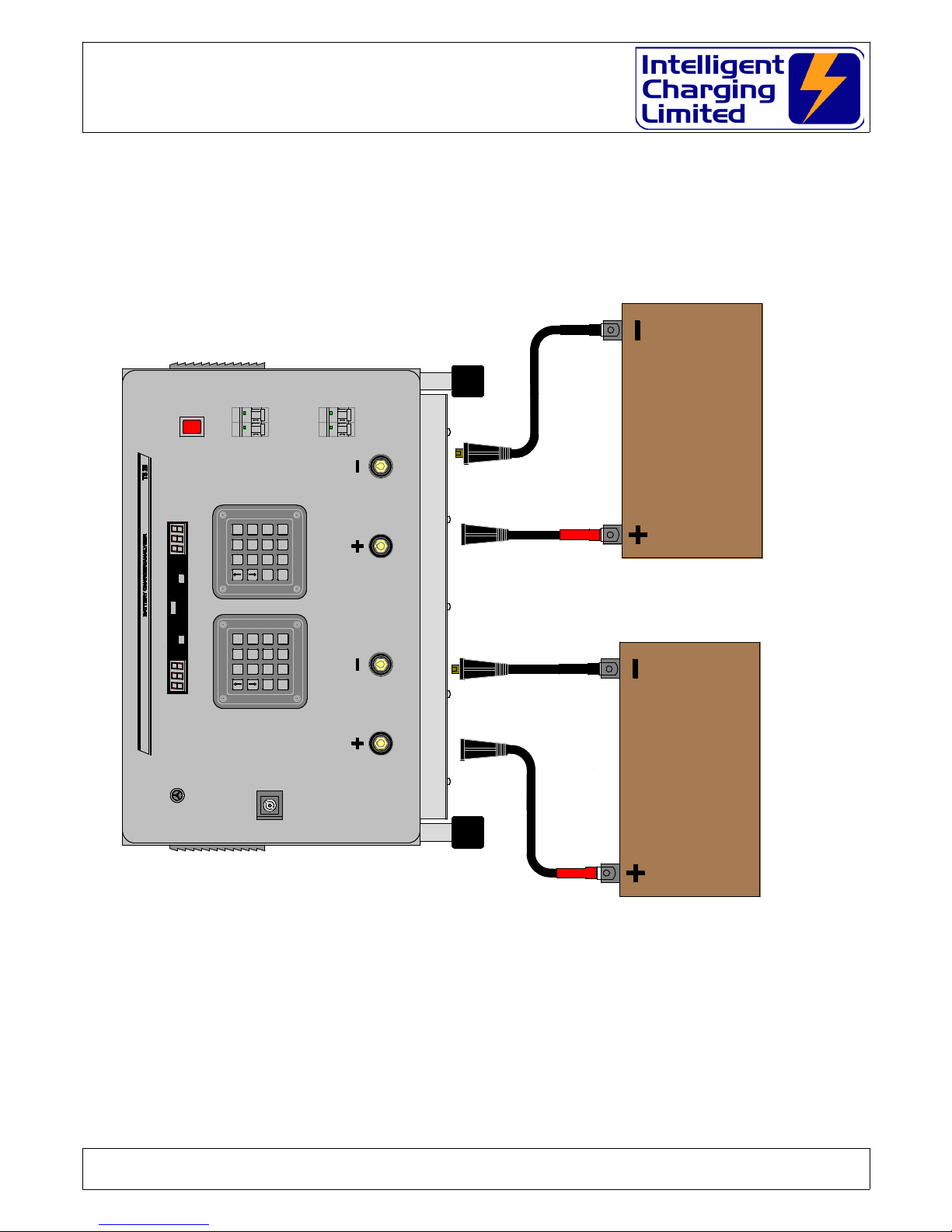

4.1 CONNECTING BATTERIES

For all methods of use of the battery charger the battery to be tested or charged must

only be connected when the charger is either:

SWITCHED OFF

or

SWITCHED ON ND END L MP ILLUMIN TED

Connecting a battery while the charge is operational would damage the equipment,

and possible draw an electrical arc that, may cause an explosion from the venting

gases being emitted from the battery.

Care must also be executed in ensuring that the bared ends of the battery leads do

not come in contact with the metalwork of the charger as this may also cause

electrical arcing and or explosion risk.

WARNING

THE BATTERY SHOULD NEVER BE CONNECTED OR DISCONNECTED FROM THE

UNIT WHEN A CHARGE OR TEST IS IN PROGRESS AS ARCING CAN OCCUR

CAUSING AN EXPLOSION FROM GASSES VENTING FROM BATTERIES BEING

PROCESSED

THE BATTERY SHOULD ALWAYS BE ISOLATED FROM ANY EQUIPMENT

BEFORE BEING CONNECTED

Stray ground loops between the attached equipment and the TS25 UPGR DE could

cause catastrophic damage to the unit and the attached equipment.

The battery or batteries must be connected to the TS25 UPGR DE as shown in the

following diagram: -

Doc: DWG1006-34-R3 TS25 PC211 Upgrade Operators ma ual.odtPage 9 of 44 Copyright Material of Intelligent Charging Limited © 2015

Printed On : 02/09/15

MB/TS25 PC211 UPGRADE Battery Charger

Operators Manual

SINGLE OR TWIN CHANNEL BATTERY CONNECTION

Doc: DWG1006-34-R3 TS25 PC211 Upgrade Operators ma ual.odtPage 10 of 44Copyright Material of Intelligent Charging Limited © 2015

Printed On : 02/09/15

AVIATION BATTERY AVIATION BATTERY

BATTERY #1 BATTERY #2

MUTE

EXTD

ENTR

DISP DATA

A SET PROC

V SETTEST BATT

CHRG T SET

START

STOP

EXTD

ENTR

DISP DATA

A SET PROC

V SETTEST BATT

CHRG ONE T SET

START

STOP

VOLTS TIME

AMPS

TEST

END ONE

VOLTSTIME

AMPS

TEST

END

%

%

ALARM

MEM

Bxx

ON

OFF

I

O

MEM

Bxx

ON

OFF

I

O

MEM

Bxx

ON

OFF

I

O

MEM

Bxx

ON

OFF

I

O

I N T E L L I G E N T C H A R G I N G

CHARGE

TRIP

ANALYSER

TRIP

MAINS

POWER

BATTERY 'B'BATTERY 'A'

BATTERY 'B'BATTERY 'A'

MB/TS25 PC211 UPGRADE Battery Charger

Operators Manual

BATTERY CONNECTION WHEN USING “ONE” MODE OF OPERATION

Doc: DWG1006-34-R3 TS25 PC211 Upgrade Operators ma ual.odtPage 11 of 44Copyright Material of Intelligent Charging Limited © 2015

Printed On : 02/09/15

AVIATION BATTERY

MUTE

EXTD

ENTR

DISP DATA

A SET PROC

V SETTEST BATT

CHRG T SET

START

STOP

EXTD

ENTR

DISP DATA

A SET PROC

V SETTEST BATT

CHRG ONE T SET

START

STOP

VOLTS TIME

AMPS

TEST

END ONE

VOLTSTIME

AMPS

TEST

END

%

%

ALARM

MEM

Bxx

ON

OFF

I

O

MEM

Bxx

ON

OFF

I

O

MEM

Bxx

ON

OFF

I

O

MEM

Bxx

ON

OFF

I

O

I N T E L L I G E N T C H A R G I N G

CHARGE

TRIP

ANALYSER

TRIP

MAINS

POWER

BATTERY 'B'BATTERY 'A'

BATTERY 'B'BATTERY 'A'

MB/TS25 PC211 UPGRADE Battery Charger

Operators Manual

4.2 CAPACITY TESTING BATTERIES

The main purpose of a capacity test is to establish that a battery under test can

maintain current output as specified by its ampere hour rating above a certain

terminal voltage.

s a rule of thumb a battery will maintain an output voltage 5/6ths above its terminal

voltage for one hour if discharged at its ampere hour rating. battery that can

maintain this is considered 100% or more of its rated capacity.

For example a 24V 20 /H battery would be capacity tested at 20 for one hour and

have the voltage end point set to 20V. If after a one hour discharge at 20 the battery

terminal voltage was greater than 20V the battery would be considered at least 100%

efficient.

Intelligent Charging do not make any recommendations on what point a battery is

considered not efficient enough to be used, although a rule of thumb is that a battery

less than 80% should be discarded where it it's use is considered critical.

The TS25 UPGR DE has two capacity test modes: -

Perform a capacity test only to the time period specified.

This mode will auto terminate the process if either the battery voltage reaches

the voltage end point, or if the total capacity test time is achieved. t the end of

the test the TS25 UPGR DE will report a percentage of 100% or less depending

on why the capacity test was terminated.

Perform a capacity test until the final voltage is reached.

This mode will perform a capacity test until the voltage end point is reached. t

the end of test the TS25 UPGR DE will report a percentage, which is the true

capacity of the battery, which may be more than 100%. This method is

sometimes employed so that records of battery deterioration over time or use

can be monitored.

4.2.1 MANUAL CAPACITY TEST

To perform a manual capacity test four parameters have to be programmed.

These are: -

Capacity test current ( mperes).

Capacity test time (Minutes)

Capacity test voltage end point (Volts)

Capacity test mode (Time or Volts)

To program these values the TS25 UPGR DE needs to powered and not

performing either a capacity test or charge on the channel to be used.

Doc: DWG1006-34-R3 TS25 PC211 Upgrade Operators ma ual.odtPage 12 of 44Copyright Material of Intelligent Charging Limited © 2015

Printed On : 02/09/15

MB/TS25 PC211 UPGRADE Battery Charger

Operators Manual

Press ASET to change the capacity test amperes.

Press VSET to change the capacity test voltage end point.

Press TSET to change the capacity test duration.

Press PROC to change the capacity test mode.

See section 4.4 ENTERING B TTERY D T for details on how to enter the

required parameters.

4.2.2 LIBRARY CAPACITY TEST

To perform a capacity test from the library the library number has to be selected

first. To select the library number the following procedure has to be performed.

Press the BATT key. The display will show the current library item selected and

the rightmost digit will be flashing. Enter the library number by using the and

keys and the EXTD key to move to the next digit. Only library numbers 01 to

99 can be selected.

The TS25 UPGR DE needs to be placed in capacity test mode by pressing TEST

and ensuring that the visual indicator TEST is illuminated.

4.2.3 REVIEWING CAPACITY TEST PARAMETERS

Once these values have been programmed into the unit they can be reviewed by

selecting the DISP key to cycle the display between VOLTS, AMPS,TIME and

% and then pressing the DATA key. This display will show the values

programmed in and the corresponding indicator will flash. Note when the %

indicator is lit there is no data to display. To check the capacity test mode simple

press the TEST key and the current capacity test mode will be displayed TIM or

VOL.

4.2.4 STARTING A CAPACITY TEST

Before a capacity test is performed for the first time it is important that the

parameters are reviewed using the reviewing feature above as incorrect

parameters could damage the battery under test.

Once satisfied that he data is correct the battery to undergo the capacity test

must be connected to the unit. Care must be taken when connecting batteries

which are not fitted with non reversible connectors, i.e. where the use of

crocodile clamps are implemented, as damage to the battery and or unit may

occur if a capacity test is started with reverse connection.

To begin the capacity test press START. The display will momentarily display

RUN, the END light will extinguish and it will then display battery voltage. During

the normal capacity test process the DISP key may be pressed to cycle the

display between VOLTS, AMPS,TIME and %. The DATA key can also be

pressed to review the parameters programmed in for the current test under

progress. If the TEST key is pressed this will briefly display the current test

mode.

Doc: DWG1006-34-R3 TS25 PC211 Upgrade Operators ma ual.odtPage 13 of 44Copyright Material of Intelligent Charging Limited © 2015

Printed On : 02/09/15

MB/TS25 PC211 UPGRADE Battery Charger

Operators Manual

4.2.5 STOPPING A CAPACITY TEST

t any time during the capacity test the process can be terminated by simply

pressing the STOP key. When the STOP key is pressed the process will be

terminated immediately and the display will show END and the END led will

remain illuminated.

The display will remain in this state until either MUTE of STOP is pressed.

4.2.6 CAPACITY TEST AUTO TERMINATE

If the capacity test has been programmed to auto terminate on time then the

process will automatically stop when either the battery voltage falls below the

voltage end point or when the capacity test time has elapsed.

If the capacity test has been programmed to auto terminate only when the

voltage falls below the voltage end point, then the process will stop when the

battery voltage falls below the voltage end point.

In both cases the capacity test process will terminate immediately, the audible

alarm will sound and the ALARM and END lights will illuminate and the display will

show the reason for terminating the process.

To clear the alarm the MUTE or STOP key must be pressed. Upon these being

pressed the display will show the actual efficiency percent value.

Process termination codes:

E 1 The process time is complete.

E 2 Battery voltage has reached the voltage end point.

Doc: DWG1006-34-R3 TS25 PC211 Upgrade Operators ma ual.odtPage 14 of 44Copyright Material of Intelligent Charging Limited © 2015

Printed On : 02/09/15

MB/TS25 PC211 UPGRADE Battery Charger

Operators Manual

4.3 CHARGING BATTERIES

To keep batteries in good condition it is important that correct charging procedures

are observed.

The TS25 UPGR DE is an important tool in ensuring the its flexibility allows the user to

choose charge processes that are best suited to the battery. The TS25 UPGR DE has

two inbuilt charging processes that suite a wide range of batteries.

The use of constant voltage charging is best suited to lead acid types of batteries and

the TS25 UPGR DE controls constant voltage charging to ensure that no excess of

current can be driven into the batteries causing it damage.

Constant voltage charging is achieved by inserting a maximum specified current into a

battery until its terminal voltage reached the voltage set point. Once this voltage set

point has been reached the unit will reduce the current injected to maintain the

voltage set point. The charging process will continue until the charge time has

elapsed.

Constant current charging is employed mainly for Nickel Cadmium and Nickel Metal

hydride types if batteries, where a constant current can be driven into a battery for a

specified time and parameters can be set to prevent over charging.

Constant current charging is achieved by the unit driving a specified constant current

into the battery for a specified amount of time. During this time it will monitor the

battery voltage and auto terminate the process if this voltage is reached. This voltage

set point can be either the rise point of the battery or can be used as an over-voltage

parameter.

The TS25 UPGR DE has a new charge mode implemented, which is more suitable to

alkaline batteries. In this mode known as Constant Current Plus mode the unit will

drive the constant current into the battery until the voltage set point is reached. Once

this point is reached the unit will continue charging at the same current for the time

specified.

4.3.1 MANUAL CHARGING

The unit required four parameters to perform a constant voltage charge. These

are: -

Maximum charge current ( mperes).

Charge time or charge additional time (Hours).

Voltage set point (Volts).

Charge mode.

To program these values the unit needs to powered and not performing either a

capacity test or charge on the channel to be used.

Press ASET to change the charge amperes.

Press VSET to change the charge test voltage set point.

Press TSET to change the charge duration or additional time.

Doc: DWG1006-34-R3 TS25 PC211 Upgrade Operators ma ual.odtPage 15 of 44Copyright Material of Intelligent Charging Limited © 2015

Printed On : 02/09/15

MB/TS25 PC211 UPGRADE Battery Charger

Operators Manual

Press PROC to change the charge mode.

See section 4.4 ENTERING B TTERY D T for details on how to enter the

required parameters.

4.3.2 LIBRARY CHARGING

To perform a charge from the library the library number has to be selected first.

To select the library number the following procedure has to be performed.

Press the BATT key. The display will show the current library item selected and

the rightmost digit will be flashing. Enter the library number by using the and

keys and the EXTD key to move to the next digit. Only library numbers 01 to

99 can be selected.

The unit needs to be placed in charge mode by pressing CHRG and ensuring that

the visual indicator TEST is extinguished.

4.3.3 REVIEWING CHARGE PARAMETERS

Once these values have been programmed into the unit they can be reviewed by

selecting the DISP key to cycle the display between VOLTS, AMPS and TIME

and then pressing the DATA key. This display will show the values programmed

in and the corresponding indicator will flash. To check the charge mode simply

press the CHRG key and the current charge mode will be displayed CV, CC or

CCA.

4.3.4 STARTING A CHARGE

Before a charge is performed for the first time it is important that the parameters

are reviewed using the reviewing feature above as incorrect parameters could

damage the battery under charge.

Once satisfied that he data is correct the battery to undergo charging must be

connected to the unit. Care must be taken when connecting batteries which are

not fitted with non reversible connectors, i.e. where the use of crocodile clamps

are implemented, as damage to the battery and or TS25 UPGR DE may occur if

a charge is started in reverse connection.

To begin the charge press START. The display will momentarily display RUN, the

END light will extinguish and it will then display battery voltage. During the

normal charge process the DISP key may be pressed to cycle the display

between VOLTS, AMPS and TIME. The DATA key can also be pressed to review

the parameters programmed in for the current test under progress. Pressing the

CHRG key will also briefly display the current charge mode.

4.3.5 STOPPING A CHARGE

t any time during the charge the process can be terminated by simply pressing

the STOP key. When the STOP key is pressed the process will be terminated

Doc: DWG1006-34-R3 TS25 PC211 Upgrade Operators ma ual.odtPage 16 of 44Copyright Material of Intelligent Charging Limited © 2015

Printed On : 02/09/15

MB/TS25 PC211 UPGRADE Battery Charger

Operators Manual

immediately and the display will show END and the END led will remain

illuminated.

The display will remain in this state until either MUTE of STOP is pressed.

4.3.6 CHARGE PROCESS AUTO TERMINATE

If constant voltage charging the process will automatically stop when the test

time has been completed.

If constant current charging is programmed then the charge will terminate on the

full charge time completed or if the battery terminal voltage reached the voltage

set point.

If constant current with additional time mode is being performed then the unit

will stop when the additional time has been used or if the voltage set point is not

reached within 24 hours of the charge starting.

In all cases the charge process will terminate immediately, the audible alarm will

sound and the ALARM and END lights will illuminate and the display will show the

reason for terminating the process.

To clear the alarm the MUTE or STOP key must be pressed.

Process termination codes:

E 1 The process time or additional time is complete.

E 3 Voltage set point reached (Constant Current Mode Only).

E 4 The voltage set point has not been reached within 24Hours.

Doc: DWG1006-34-R3 TS25 PC211 Upgrade Operators ma ual.odtPage 17 of 44Copyright Material of Intelligent Charging Limited © 2015

Printed On : 02/09/15

MB/TS25 PC211 UPGRADE Battery Charger

Operators Manual

4.4 ENTERING BATTERY DATA

In all cases of entering battery data the channel that data is to be entered on must be

in the stopped state. This is indicated by the END lamps being illuminated.

4.4.1 SETTING CAPACITY TEST MODE

Press PROC the display will flash the current mode on the display. Using the

and arrow keys the flashing display can be changed from TIM to VOL and visa

versa. Once selection has been made the ENTR key will be pressed to program

this parameter into the unit. If no change is required then simply pressing STOP

will clear the display.

TIM Programs the capacity testing mode to auto terminate when the battery

voltage falls below the voltage end point or when the time up has been

reached.

VOL Programs the capacity testing mode to only auto terminate when the

voltage end point has been reached.

4.4.2 SETTING THE CHARGE MODE

Press PROC the display will flash the current mode on the display. Using the

and arrow keys the flashing display can be changed from CV, CC and CCA and

visa versa. Once selection has been made the ENTR key will be pressed to

program this parameter into the unit. If no change is required then simply

pressing STOP will clear the display.

CV Programs the charge mode to perform a constant voltage charge where the

charge current is not exceeded until the voltage set point is reached at

which point it reduces current to maintain the voltage set point until the

charge time is completed.

CC Programs the charge mode to perform constant current charging for the

time specified terminating abnormally if the voltage set point is reached.

CCA Programs the charge mode to perform constant current charging until the

voltage set point is reached and then continue charging at the same current

until the additional time has elapsed.

4.4.3 ENTERING CURRENT DATA

Press the ASET key. The current setting will be displayed. The rightmost digit will

be flashing and can be modified by pressing the and arrow keys. Pressing

the EXTD key will cause the middle digit to flash and this can then be modified by

using the and arrow keys. Pressing the EXTD key again will cause the

leftmost digit to flash and this can then be modified using the and arrow

keys. If the EXTD key is pressed again the rightmost digit will then flash. This

cycle is repeated each time the EXTD key is pressed. The values cannot be

Doc: DWG1006-34-R3 TS25 PC211 Upgrade Operators ma ual.odtPage 18 of 44Copyright Material of Intelligent Charging Limited © 2015

Printed On : 02/09/15

MB/TS25 PC211 UPGRADE Battery Charger

Operators Manual

modified to greater than 12.0 for charge mode and 25.0 for capacity test

mode.

Note: In ONE mode the maximum values that can be entered are 24.0 for

charge mode and 50.0 for capacity test mode.

4.4.4 ENTERING VOLTAGE DATA

Press the VSET key. The current setting will be displayed. The rightmost digit will

be flashing and can be modified by pressing the and arrow keys. Pressing

the EXTD key will cause the middle digit to flash and this can then be modified by

using the and arrow keys. Pressing the EXTD key again will cause the

leftmost digit to flash and this can then be modified using the and arrow

keys. If the EXTD key is pressed again the rightmost digit will then flash. This

cycle is repeated each time the EXTD key is pressed. The voltage value to be

entered cannot exceed 45.0V and the display will not allow digits to be

incremented above this amount.

4.4.5 ENTERING CAPACITY TEST TIME

Press the TSET key. The current setting will be displayed. The rightmost digit will

be flashing and can be modified by pressing the and arrow keys. Pressing

the EXTD key will cause the middle digit to flash and this can then be modified by

using the and arrow keys. Pressing the EXTD key again will cause the

leftmost digit to flash and this can then be modified using the and arrow

keys. If the EXTD key is pressed again the rightmost digit will then flash. This

cycle is repeated each time the EXTD key is pressed. The value entered is in

minutes and the maximum time that can be entered is 999 minutes.

4.4.6 ENTERING CHARGE TIME

Press the VSET key. The current setting will be displayed. The rightmost digit will

be flashing and can be modified by pressing the and arrow keys. Pressing

the EXTD key will cause the middle digit to flash and this can then be modified by

using the and arrow keys. Pressing the EXTD key again will cause the

leftmost digit to flash and this can then be modified using the and arrow

keys. If the EXTD key is pressed again the rightmost digit will then flash. This

cycle is repeated each time the EXTD key is pressed. The value entered is in

hours and the maximum time than can be entered in 99.9H.

Doc: DWG1006-34-R3 TS25 PC211 Upgrade Operators ma ual.odtPage 19 of 44Copyright Material of Intelligent Charging Limited © 2015

Printed On : 02/09/15

MB/TS25 PC211 UPGRADE Battery Charger

Operators Manual

4.5 USING THE ONE MODE OF OPERATION

The TS25MKII has a special feature in that if higher currents for charging or capacity

testing are required the unit can be "paralleled". Using special paired cables, which

connect, channel and channel B together both channels can be used in unison.

WARNING

PAY CAREFUL ATTENTION TO BATTERY CONNECTION

WHEN USING “ONE” MODE

Control of the unit is all achieved through the use of the channel keypad and the

channel B keypad only mimics some of the channel functions. The channel B display

will change to an alternative display to channel when the DISP key is pressed.

ll operation of the equipment is the same as when using an individual channel, with

the exception that higher currents can be entered for capacity testing and charging.

If a library item has been written in one mode, it will only be recalled in ONE mode if

the current exceeds the single channel limitations of the unit.

Certain actions cannot be performed in ONE mode and these are reported on the

display in the form of an error message and buzzer sound.

4.6 RESETTING THE TS25 UPGRADE

The TS25 UPGR DE keeps users modified data in battery backed R M. It may be

necessary at some time to reset this data to the defaults. Three sets of data can be

reset.

4.6.1 GENERAL PARAMETER DATA

The general parameter data covers the current battery data that is set and

indicators to general unit operation. It is not usually necessary to reset this data

as is checked internally for correctness, but when the unit has been serviced and

the battery backup removed the general parameter data can be come corrupt

and may need resetting through the use of this function.

4.6.2 DEFAULT LIBRARY DATA

The operator may want at some time to reset the internal data library back to

the default battery library, this function copies the internal library into the user

definable battery library. Warning: The use of this function will remove all user

defined library items.

Doc: DWG1006-34-R3 TS25 PC211 Upgrade Operators ma ual.odtPage 20 of 44Copyright Material of Intelligent Charging Limited © 2015

Printed On : 02/09/15

Table of contents

Other Intelligent Charging Batteries Charger manuals