2

Current Adjust Resistor Values ..................................................................40

Recommended IMS Power Supplies .........................................................41

Recommended IMS Motors ........................................................................41

Options and Accessories ...........................................................................42

Section2.2: IB463................................................................................. 43

Section Overview .........................................................................................43

Mechanical Specifications ..........................................................................43

Electrical Specifications ..............................................................................44

Thermal Specifications ...............................................................................44

Current Adjust Resistor Values ..................................................................45

Recommended IMS Power Supplies .........................................................46

Recommended IMS Motors ........................................................................46

Options and Accessories ...........................................................................47

Section2.3: IB104................................................................................. 48

Section Overview .........................................................................................48

Mechanical Specifications ..........................................................................48

Electrical Specifications ..............................................................................49

Thermal Specifications ...............................................................................49

Current Adjust Resistor Values ..................................................................50

Recommended IMS Power Supplies .........................................................51

Recommended IMS Motors ........................................................................52

Options and Accessories ...........................................................................52

Section2.4: IB106................................................................................. 53

Section Overview .........................................................................................53

Mechanical Specifications ..........................................................................53

Electrical Specifications ..............................................................................54

Thermal Specifications ...............................................................................54

Current Adjust Resistor Values ..................................................................55

Recommended IMS Power Supplies .........................................................56

Recommended IMS Motors ........................................................................57

Options and Accessories ...........................................................................57

Section 2.5: IB1010 ............................................................................... 58

Section Overview .........................................................................................58

Mechanical Specifications ..........................................................................58

Electrical Specifications ..............................................................................59

Thermal Specifications ...............................................................................59

Current Adjust Resistor Values ..................................................................60

Recommended IMS Power Supplies .........................................................61

Recommended IMS Motors ........................................................................61

Options and Accessories ...........................................................................62

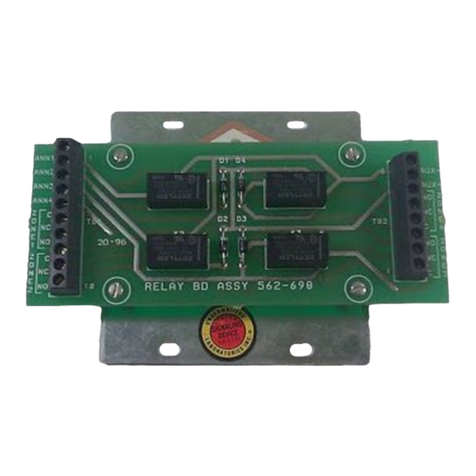

Appendix A: OPT140............................................................................ 63

Optional Interface Board .............................................................................63

Appendix B: Cooling Solutions .......................................................... 67

H-4X Heat Sink ............................................................................................67

H-100 Heat Sink ..........................................................................................67

Thermal Pads .............................................................................................68

AppendixC: MiscellaneousAccessories ............................................ 70