Intercom PREMIUM 400 - INOX User manual

EXTERNAL SUCTION

VACUUM PACKAGING MACHINES

PREMIUM

USE AND MAINTENANCE MANUAL

2

WARRANTY RULES FOR OUR

VACUUM-PACKING MACHINES

Dear Customer,

In order to avoid any misunderstanding about our warranty policy, please note the

following:

VACUUM PUMP

is not intended to e replaced y the supplier, even if within warranty

time, without a previous return of the disputed part.

A misuse of vacuum pumps for 2 or 3 months (Packing of hot, wet or

corrosive products, as well as liquids) might prevent any pump from working

properly.

t is therefore necessary to send these pumps back to the manufacturer, in

order to perform accurate checking and/or cleaning.

OUR COMPANY WON’T DELIVER ANY BRAND NEW PUMP

BEFORE RECEIVING THE DISPUTED ONE BACK!

As far as the other internal components are concerned (namely transformers,

micro switches, electronic board… etc.), they do not follow this general rule:

they are all internal components which do not suffer from mechanical wear.

3

CHAPTER 1

Instruction Hand ook

The nstruction Handbook is a document issued by the Manufacturing Company and is a part of the machine. This

document is properly identified for any further reference.

All rights reserved. No information disclosure would be allowed, without having been previously approved by the

manufacturer.

Aim of the document

This handbook contains the information necessary to the customer and qualified staff for a proper installation, use and

maintenance of the machine.

Safety precautions and manufacturer’s lia ility

All operator-machine interaction relating to the intended use of the machine and its overall life cycle has been carefully and

thoroughly analysed during the design phase and the drafting of the nstruction handbook.

t is nevertheless understood that experience, adequate training and common sense of anyone who operates the machine are

vital.

Manufacturer is NOT liable in case of damage to persons or objects if one or more of the following circumstances apply:

_ lack of compliance with safety precautions or specific warnings described in this handbook

_ any improper use of any part of machinery

_ any use of unauthorized spare parts

_ any use of machinery by unauthorized staff

Reference to standards

This document is drawn up in accordance with following indications:

-Attachment “I” of Machinery egulation 89/392/ CEE and following issues: point 1.7.4

-UNI EN 292/2 – 1992, point 5.5

MACHINE MOD. V HZ

SE IAL N.

SHIPMENT DATE

TECH. ENGINEEE

4

CHAPTER 2

WARRANTY

The manufacturing Company delivers a 12 (twelve) month warranty from the delivery date.

All machine components which are subject to constant wear are NOT included in the warranty.

Please note all the following specifications:

A. Electrical resistance-coils – Teflon – Seals – Opening chamber pistons – Sealing diaphragm – Air filters – Oil filters –

Oil change – Pump blades are subject to normal wear.

B. n case a vacuum pump is sent back to the manufacturer, the latter has the right to check whether some foreign bodies

have been vacuumed (liquid or solid substances, sauces, juices and so on). f this case applies, any repair costs (materials

and labour) will be charged to the customer.

C. Any issues due to a malfunctioning electronic board have to be examined by the Manufacturing Company.

D. Any issues with pneumatic, structural, mechanical parts will be solved as per warranty terms without any charge.

E. During the warranty period, there will be no charge for materials, whereas labour may be.

F. Should the machinery need external interventions during the warranty period, any shipping costs will be charged apart

from any other repairing by the manufacturer.

G. Any interventions on the machines are to be carried out at manufacturer’s premises both during the warranty period

and after warranty has expired; we point out that no transport cost will be refunded.

H. Transport for any material sent to the manufacturing company, both during the warranty period and after warranty has

expired, must be arranged as ex works.

. Any material sent to the manufacturer with transport charges will be refused.

J. Any component which is believed to have been manipulated by any customer during the period of warranty coverage

will not be handled. Manufacturer reserves the right to establish if any machinery component has been

modified/changed/manipulated.

5

Do not remove the CE MARKING plate/la el and/or replace it with a different one. Should the CE MARKING

plate/la el e accidentally damaged, detached from the machine or the manufacturer’s seal removed, any

customer must inform immediately The Manufacturer.

nstallation

Remove the package and check machine conditions. Look for possible damages caused by transport. f in doubt, do not use

the machine and contact the manufacturer.

Place

Store the machine in a place with low humidity percentage and far from heat sources.

DO NOT INSTALL THE MACHINE IN AN EXPLOSIVE ATMOSPHERE

Connections

Before connecting the vacuum packing machine, make sure voltage and sockets match.

The plate is located on either the left or right side of the stainless-steel structure.

After having checked everything, connect the plug to a current outlet of 220V

CONTROL PANEL

DISCONNECT THE PLUG FROM THE MAINS BEFORE STARTING ANY CHECKING OR

TESTING OPERATION.

6

CONTROL PANEL

FOTO A

1) Button for the start of the working cycle: if pressed twice, it stops any working

activity.

When the machine is not running, it enables the selection of programs A T 1 (15 secs-

vacuum cycle) and A T 2 (25 secs- vacuum cycle). At the end of these 2 programs,

machine will automatically seals the vacuum bag.

2) Button for the start of sealing process during manual working cycle. When machine is

not running, this function enables the selection and setting of sealing time.

3) Display: it shows with A the suction/aspiration phase and the time previously set during

sealing phase. Default sealing time 3,5 secs

ATTENTION: swich on / off button is on the side of the machine

WORKING CYCLE

A. Put the product inside the vacuum bag

B. Place the open side of the bag on the lower plate, up to the reference bar

C. Lower the plate/bar, press START button, and press on the 2 marked labels ‘PUSH’, in order to activate

decompression phase and keep the bar closed

D. When air is totally sucked, press button 2 (image A) to start sealing phase. The machine will stop the process

automatically.

E. In 6/7 sec, air re-intake will enable the chamber opening.

WORKING CYCLE SETTING

Through the switch on of the machine, a dash/line in the centre of the display shows the stand-by phase.

1

2

3

7

MANUAL CYCLE: pressing Start/Stop button, a time endless working cycle is on ( A letter for aspiration is shown on

the display).Once wished vacuum level is obtained in the bag, the operator will press SET/SEAL button to let the

sealing phase start, with automatic switch off of the pump.

AUTOMATIC CYCLE: when machine is in stand-by, dash/line in the centre of the display will be positioned on

MAN: pressing START/STOP, the operator will place the dash/line on AUT1 or AUT2.Automatically, the electronic

board will show time sealing (DEFAULT 3,5 sec),which can be modified..

Pressing START/STOP suction phase begins, and after 15 secs (AUT1) or 25 secs (AUT2) machine will automatically

pass to sealing and then download thus end working cycle phases.

APPROXIMATE VACUUMING TIME IN PLASTIC CONTAINERS

SMALL CONTAINE 30 sec. approximately

MEDIUM CONTAINE 40 sec. approximately

BIG CONTAINE 50 sec. approximately

8

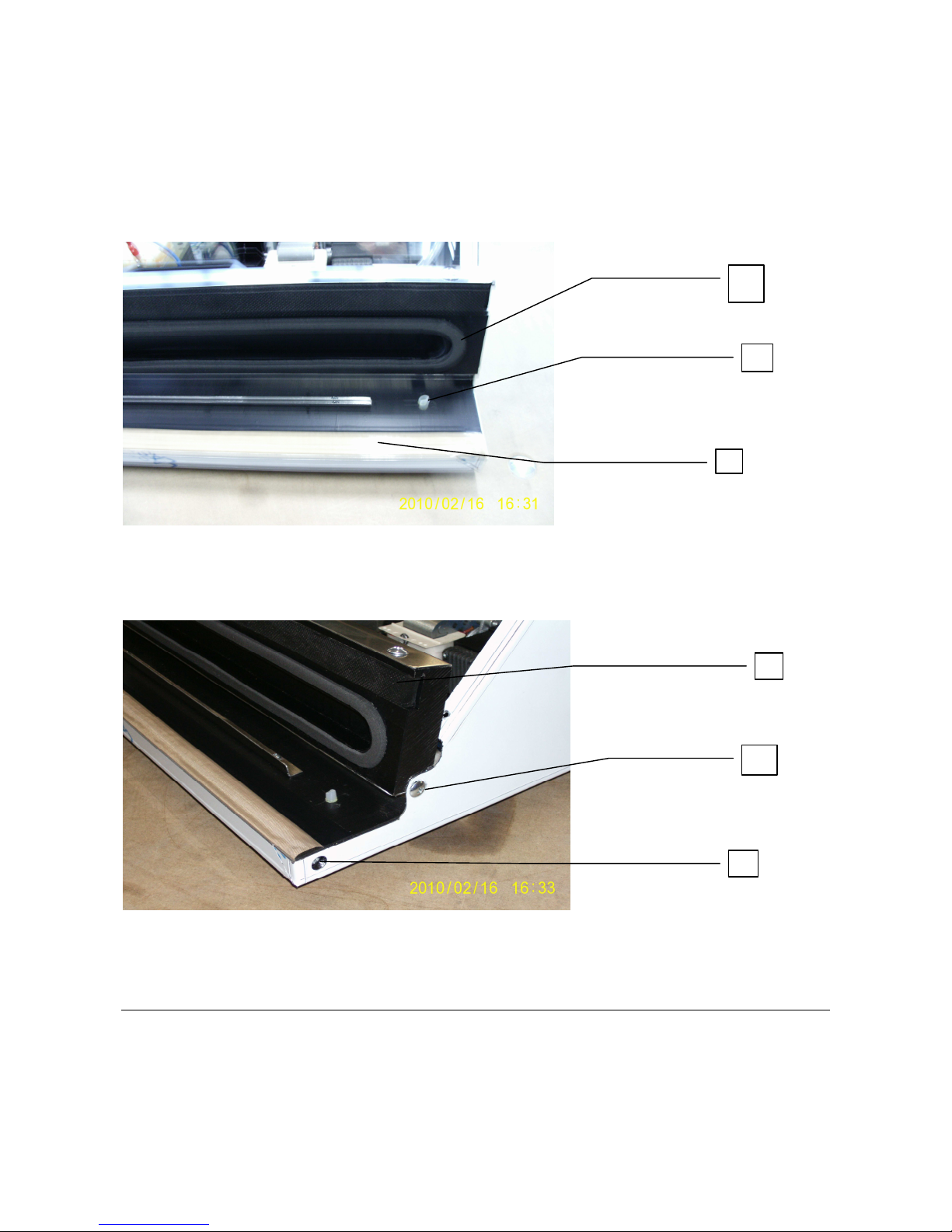

INTERNAL COMPONENTS

FOTO B

FOTO C

LEGEND

1. Sealing bar with Teflon cloth (thickness 0,127µ)

2. Suction join to attach the emptying tube container with valve

3. Plate gasket

4. Milled silicon

5. Clasp to open the blade

6. Internal screw to fix the resistor

3

1

2

5

6

4

9

INTERNAL TECHNICAL COMPONENTS

LEGEND

1. Electronic board (enables control-panel functions)

2. Stainless-steel structure

3. Electronic transformer

4. Vacuum pump

5 Stainless-steel board

2

1

4

3

5

10

RECOMMENDED BAGS

We recommend using textured (gofer) bags (thickness 100 µ) available in our warehouse in any size.

t is possible to use regular smooth ny-rol bags (thickness 140 µ) making sure that lateral bag borders are folded in order to

obtain the suction channels.

MAINTENANCE

We recommend cleaning the external structure and sealing bar with alcohol.

The machine does not require lubrication.

PRESERVATION PERIOD FOR VACUUM

-

PACKAGED PRODUCTS AT A TEMPERATURE

OF +0°/+3° C.

FRESH MEAT

BEEF

20 days

VEAL

20 days

PORK

15

days

WH TE MEAT (Chicken, turkey)

15

da

ys

RABB T AND FOWL (with the bone)

20

days

LAMB AND K D

20

days

SAUSAGES

20

days

G BLETS

10/12

days

Above mentioned periods are valid for fresh products without bones; for meat with bones consider a week less for

preservation

FISH

Average duration, 7/8 days with a really fresh product

MATURED SALAMI

Preserving duration: more than 3 months

MATURED CHEESE

Parmesan cheese, sheep’s milk cheese, etc. 120 days

FRESH CHEESE

“Mozzarella”, “Brie”, ecc 30/60 days

VEGETABLES

Generally, 15/20 days

Table of contents