P/N 466-5418 • REV A • 7MAR18 © 2018 United TechnologiesCorporation. All rightsreserved

TX-E121Command Button –Installation Instructions

PLEASE SEE REVERSE SIDE FORIMPORTANT PRODUCT WARNINGS

AND DISCLAIMER INFORMATION.

Description(See reverseside forproductwarnings and disclaimers)

The TX-E121 Command Button allows for up to 3 different commands, scenes, and/or automations to be

triggered through threedifferent button pressing sequences. To the securitypanel, the button appears as

3door/window sensor zones, each withtheir own uniqueTX-ID (located on the printed card included in

the box). Depending on the securitypanel’s capability and/or the capability of the interactive services

utilizedwiththe panel, triggering any of the Command Button’s 3 zones can be set up as the initiating

actiontothen trigger a pre-configuredautomationor rule.

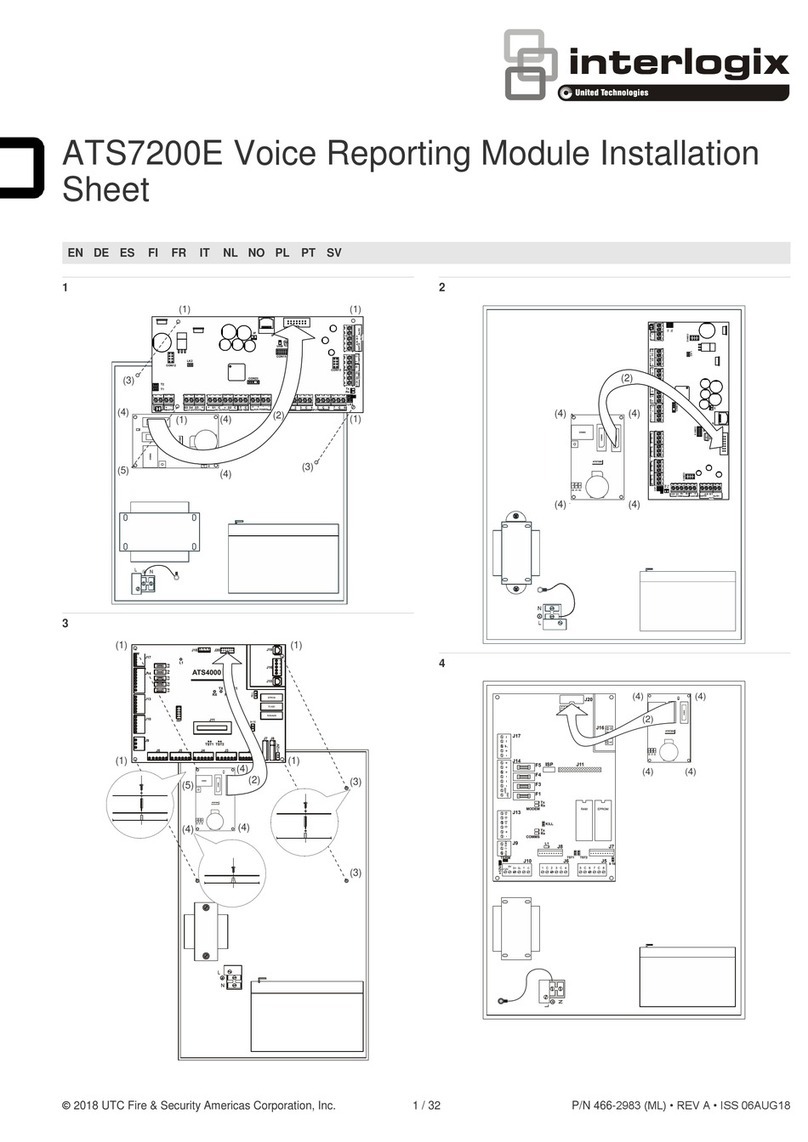

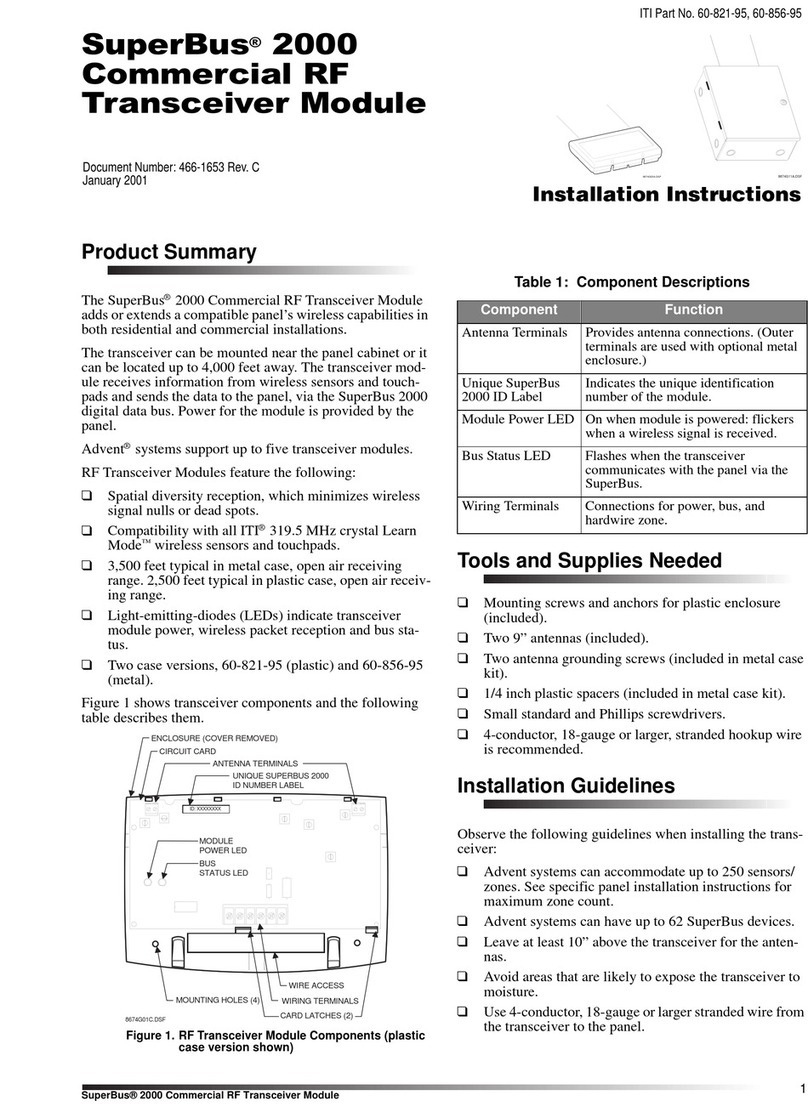

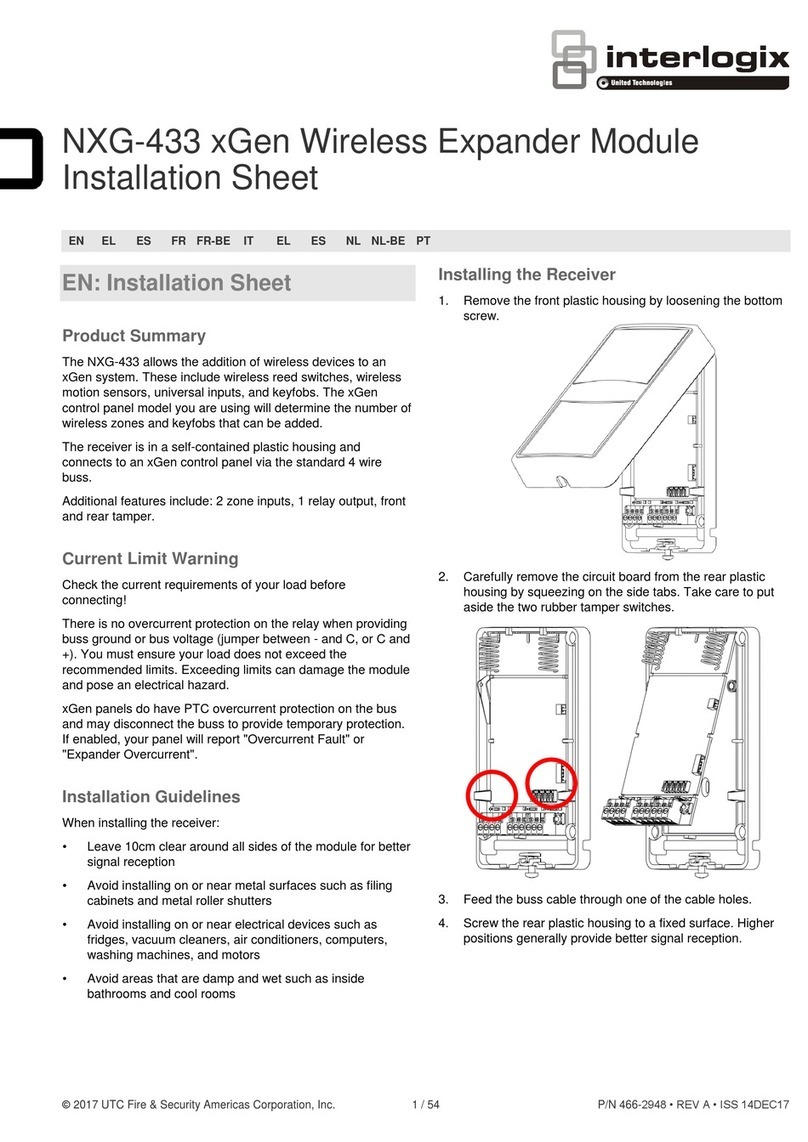

Figure 1: TX-E121CommandButton

Enrolling

Keep in mindthatto thepanel, each command appears as a door/window sensor open, followed byan

automatic restoral. Whenenrolling the device, it is recommended to name each zone accordinglyso they

can easily be assigned to the scene of your choice. For instance, zone #1 = “CB1 ST” (command button

single tap), zone #2 = “CB1 DT” (for double tap), and zone #3 = “CB1 PH” (for press and hold).

Toenroll thecommand-button into the panel utilizing the panel’s “Learn Mode” procedure, the sensor

needs tobeplaced into enrollment mode. Toenter enrollment mode on the button, followthesesteps:

1) Press and hold the button for approximately 10 seconds. During this 10 second time frame, the

LED will blinkthreetimes,then remainonfor 3moreseconds.Continue holding downthebutton and after

a total of approximately 10seconds, the LED will quicklyflash 5 times indicating that enrollment mode has

been enabled.

2) Withthe panel inlearn mode, brieflytapthe button oncetotrigger a tamper transmissionfor zone

#1. This should successfullylearn it into thepanel. If the panel does not respond, wait for the LED to shut

off and trypressing the button again, until successful enrollment occurs.

3) After the panel has recognized the first zone, besure to assign it to a zone type that is “chime

only”. Because each zonetransmits as a door/window sensor, achime-only zone type is necessaryto

ensure that the panel does not go into alarmif the system is armed and the end user wishes to activate a

particular sceneor automation.

For Simon, Concord, and NetworX control panels, zone type 25 is recommended.

For Ultrasync control panels, set the sensor type to “Event Only”

4) Take notethat the command buttonautomatically ends theenrollment mode after 15 seconds of

not sending anycommands (i.e. after pressing and holding for 10seconds andverifying enrollment is

enabled with the 5 LED flashes, if the button isn’t pressed for 15 seconds immediately after the enrollment

mode activation, it will revert backto its normal operation of sending open+ automatic restorals onbutton

presses vs sending tampers). Depending onhowlong it takes tosetup eachzoneon thepanel after a

zoneis learnedin,you may need tore-enter enrollmentmode again(holding down for 10 seconds) when

ready to enroll zones 2and 3.

OperatingInstructions

Each of the Command Button’s three different command configurations (Single tap, double tap, & press

and hold) canbeused as the initiating action to trigger a pre-configuredscene, automation, or other smart

device(s). To learn how to set up scenes/automations, refer to the instructions provided by the panel’s

interactive services provider.

Brieflytap the buttononce totrigger an “OPEN” transmission for zone #1. The red LED willflash

once, and then re-illuminate,staying illuminated for approximately3seconds. During this continual

illuminationperiod, the sensor is sending an automatic restoral transmission. Wait until the LED light isno

longer illuminated to send another command.

Double tapping the button will trigger an “OPEN” transmission for zone #2. The redLED will flash

twice,and then re--illuminate, staying illuminated for approximately3 seconds. During this continual

illuminationperiod, the sensor is sending an automatic restoral transmission. Wait until the LED light isno

longer illuminated to send another command.

Press and hold the button for approximately3 seconds to trigger an “OPEN” transmission for

zone #3. TheredLED will flash threetimes, andthenre-illuminate, staying illuminated for approximately 3

seconds. During this continual illumination period, the sensor is sending an automatic restoral

transmission. Wait until the LED light is nolonger illuminated tosend another command.

Mounting

Includedwith this deviceis onepieceof doublesidedtape for permanently securing theCommandButton

in a desired location. Choosea suitable locationfor the sensor by following the procedure in section

“Testing the Sensor” ensuring desired signal strength is achieved.

Where possible, install sensors within 100 ft. (30 m) of the panel. While atransmitter may have anopen-

air range of 500ft. (150m) or more, theenvironment at the installation site mayhave a significant effect

on operational range. Changing a sensor location mayimprove wireless communication.

For reliable bonding, ensurethesurfaceis cleanand dry. Applythe tape to the backside of the sensor,

and thento thedesired location. Apply firmpressure for several seconds. Whenmounting withdouble

sided tape, ensure temperatures are above 50°F and will remain above 50°F for at least 24 hours to

ensure proper bond. After 24hours, the bond will holdatlower temperatures.

SensorTesting (Test before permanentlymounting, as well as weekly)

The sensor test verifies proper communicationbetween the sensor and the panel/receiver. To test the

sensor, refer tothe specific panel/receiver documentation anddo the following:

1) Put the panel/receiver into sensor test mode

2) Press theCommandButton once –the sensor will then transmit a signal

3) Listen for the siren beeps to determinethe number of packets received (Eachbeepindicates

one packet received, out of 8total). It is recommended that the panel receives at least 5out

of 8 packets fromthe desired sensor location. If the panel is consistentlyreceiving less than

5out of 8packets froma certain location,tryrotating thesensor and/or relocating thesensor

toan areawhere it canachieve better communication.

4) Exit sensor test modewhen proper communicationbetween the sensor and panel/receiver

has been verified.

Replacing the Battery

The Command Buttoncomes pre-installedwitha single Panasonic CR2032Lithiumcoin-cellbatterythat

provides 5 years of battery life under normal usage conditions. When the battery is low, a signal will be

sent to the control panel. To replacethe battery, do the following:

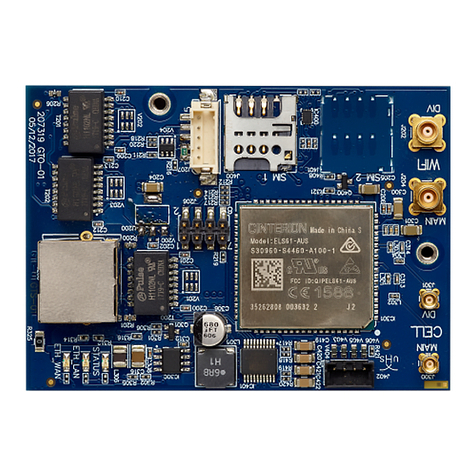

1) Insert a small coin (suchas a dime) into one of the corner notches of the Command Button

and twist toreleasethe top cover fromthe bottom cover.

2) Set the top cover aside, andgently remove the circuit board from thebottom case

3) Flip the circuit board over, revealing the Panasonic CR2032 coin cell battery. Remove the

battery and insert a newPanasonic CR2032 battery, ensuring that the positive side(+) of

the battery is facing towards the (+) signindicatedonthe batteryholder

4) Place the circuit board backinto the bottom case withthe battery sidefacing down. Take

note that the boardwill onlyfit properlyinto thebottom case inone direction. Onone side of

the middle of the circuit board is a small notch. This notchshould align witha small piece of

plastic extending out from the inside edge of the circuit board. Whenproperlyinserted, the

circuit board will fit snuglyandsecurelyinside the bottom case.

5) Replacethe front cover back onto the bottom case.