Installing the RDV/RDVQ Terminal Unit

The basic RDV is light enough that it can be supported by the

ductwork in which it is installed. The RDVQ is supplied with

silencers and should be supported directly. Use the support

method prescribed for the round duct in the job specifications.

NOTE: For optimum performance there should be a minimum

of three duct diameters of straight inlet duct, same size as the

inlet, between the inlet and any transition, take off or fitting.

The assembly should be mounted right side up. It should be

level within ±10 degrees of horizontal, both parallel to the

air flow and at right angles to the air flow. The side of the

assembly is labelled with an arrow indicating UP. Do not mount

the control side of the assembly tight to a wall, pipe or other

obstruction. Allow sufficient room for access to the controls

If the RDV/RDVQ is mechanically fastened to the duct work an

approved duct sealer should be used to seal all connections.

Damper rotation is always clockwise to the open position.

An identification mark on the end of the shaft indicates the

damper position.

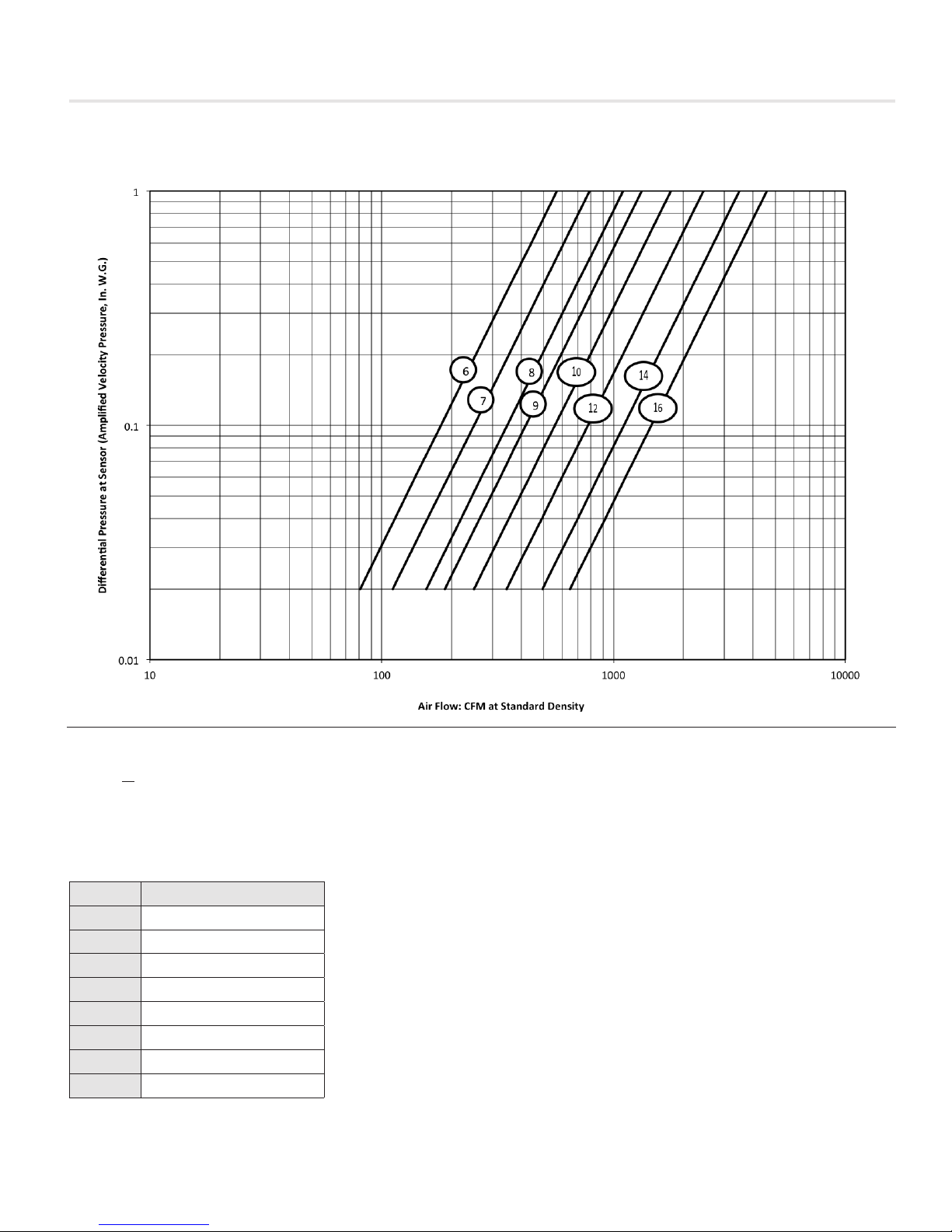

The air volume ranges listed are recommended for optimum

performance. A minimum value of zero is also acceptable if no

heating coils are attached.

Selection of air flow limits below the listed values is not

recommended. Stability and accuracy may not be acceptable

at lower than recommended air flow limits. The actual

performance will vary depending on the terminal unit controls

supply.

RDV Basic

Size CFM L/S

MIN MAX MIN MAX

445 225 21 106

560 350 28 165

665 450 31 212

795 650 45 307

8125 800 59 378

9160 1050 76 496

10 210 1350 99 637

12 300 2100 142 991

14 430 3000 203 1416

16 575 4000 271 1888

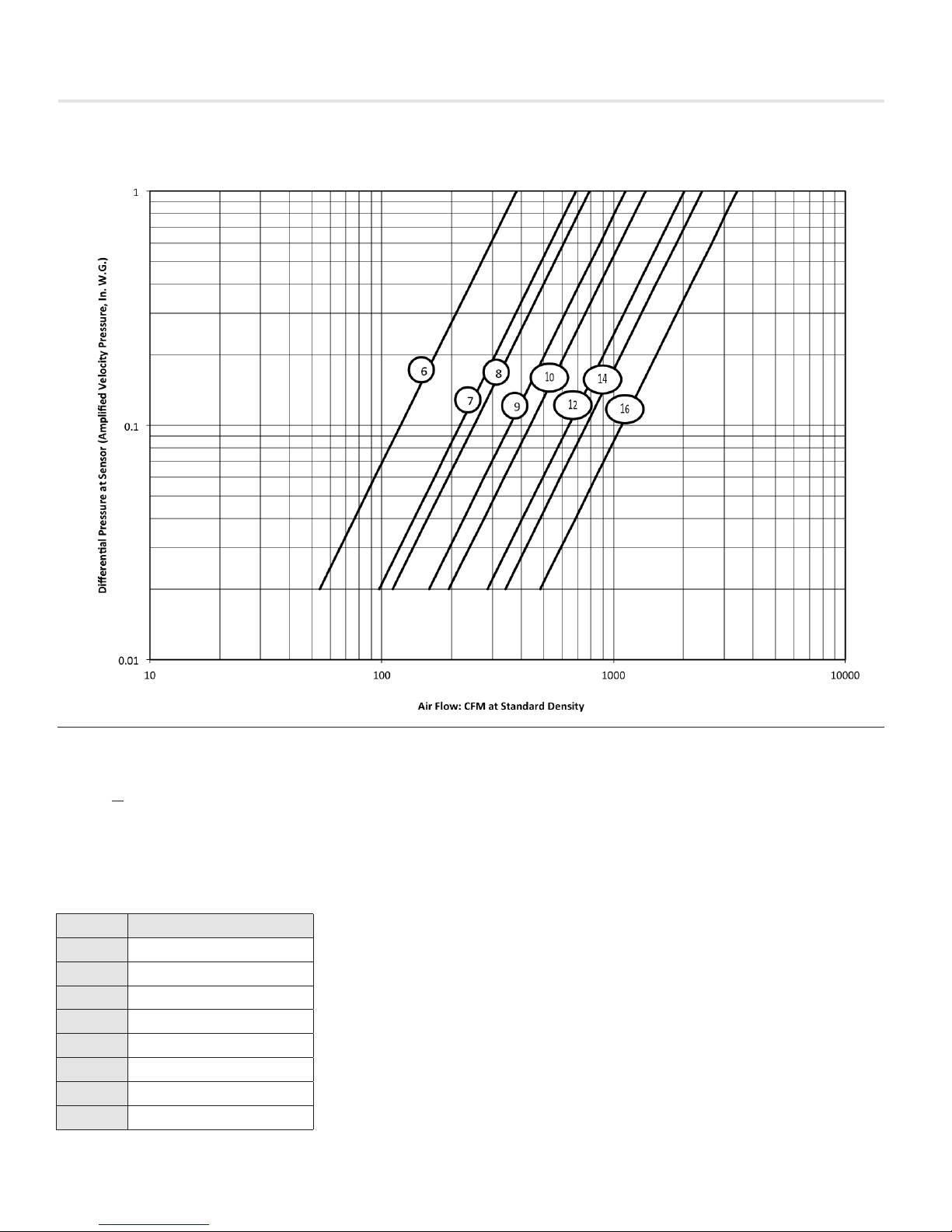

RDVQ - Absorptive

Size CFM L/S

MIN MAX MIN MAX

4-- -- -- --

5-- -- -- --

680 450 38 212

7110 650 52 307

8160 800 76 378

9200 1050 94 496

10 270 1350 127 637

12 350 2100 165 991

14 500 3000 236 1416

16 650 4000 307 1888

RDVQ - Absorptive

Size CFM L/S

MIN MAX MIN MAX

4-- -- -- --

5-- -- -- --

665 380 31 179

795 650 45 307

8125 790 59 373

9160 1050 76 496

10 210 1350 99 637

12 300 2025 142 956

14 430 2400 203 1133

16 575 3425 271 1616

Air Volume Ranges

2AIR VOLUME CONTROL VALVE - Manual |priceindustries.com

AIR VOLUME CONTROL VALVE

INSTALLATION INSTRUCTIONS

NOTE: Factory calibrated controls must be selected

within the above flow range limits. A minimum value

of zero is also available. When an auxiliary flow

setting is specified, the value must be greater than

the minimum setting and within the range limits.

On controls mounted by Price but supplied by others, the air

volume ranges are guidelines only.

Selection of air flow limits below the listed values is not

recommended. Stability and accuracy may not be acceptable

at lower than recommended air flow limits. The actual

performance will vary depending on the terminal unit controls

supplied.