INSTALLATION

1. Remove the four #10 hex head screws from the back

of the enclosure and attach mounting brackets to

enclosure.

2. Select the proper location for the Control Panel and

hang enclosure on a flat vertical surface or other

support, using hardware suitable for the purpose.

3. Prepare the necessary conduit runs, terminate

them at both ends and pull in the conductors as

specified by the installation layout.

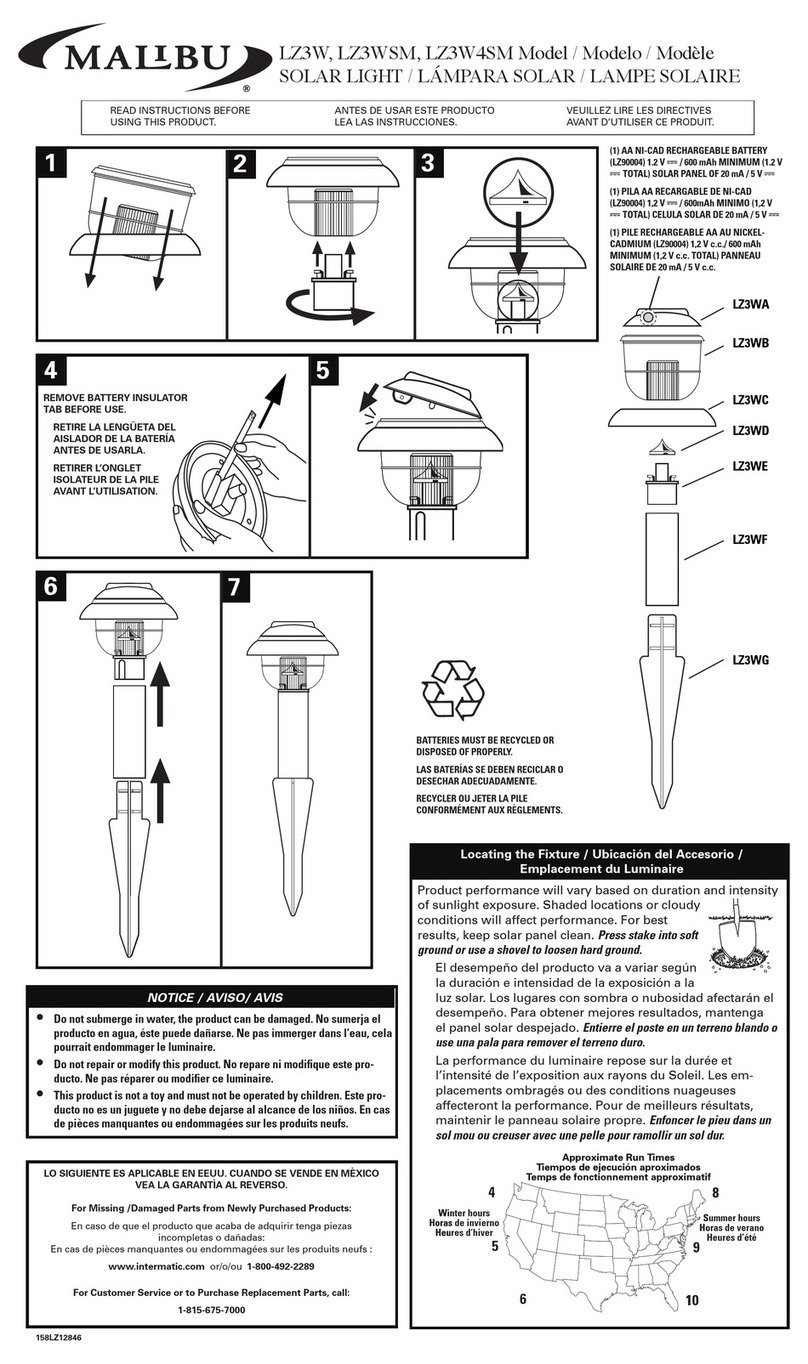

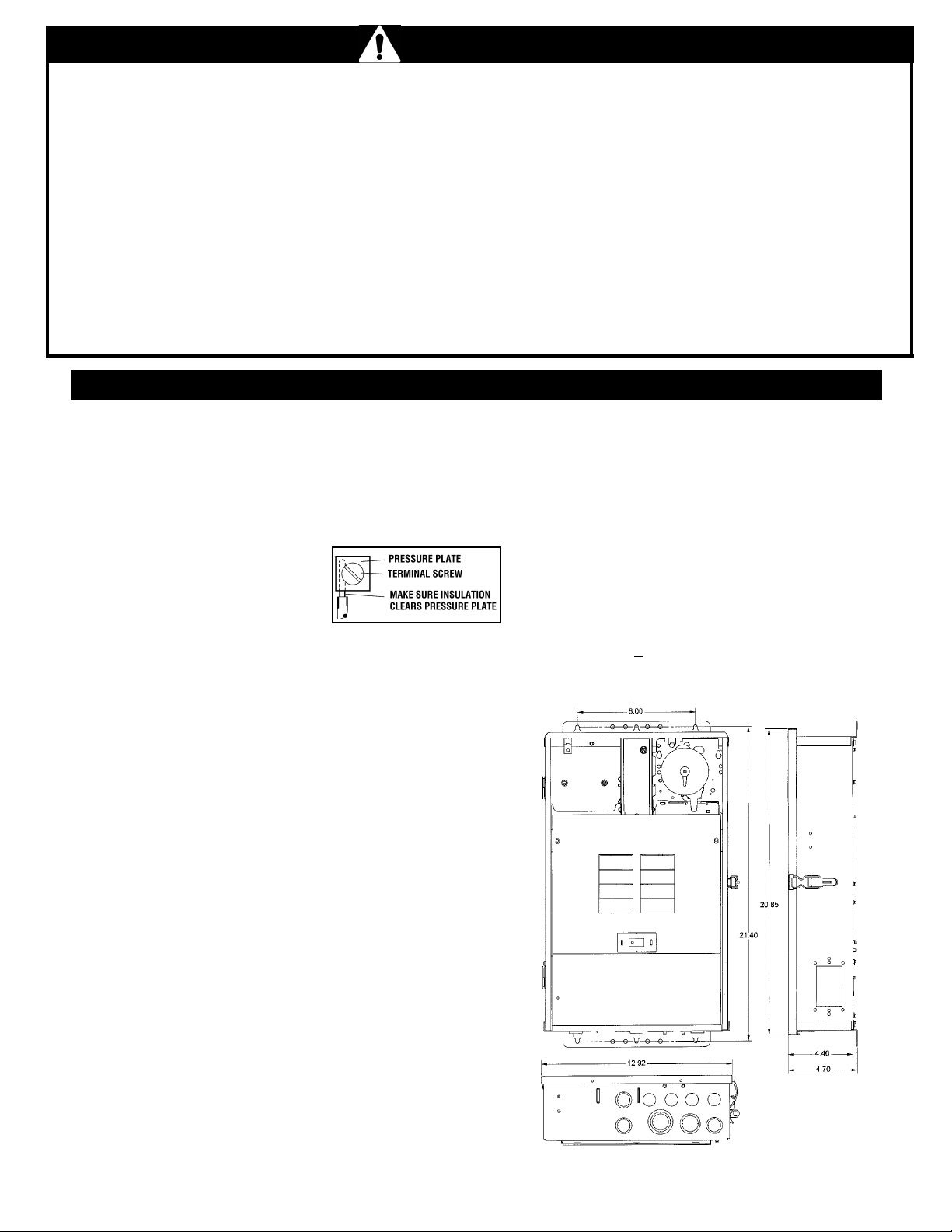

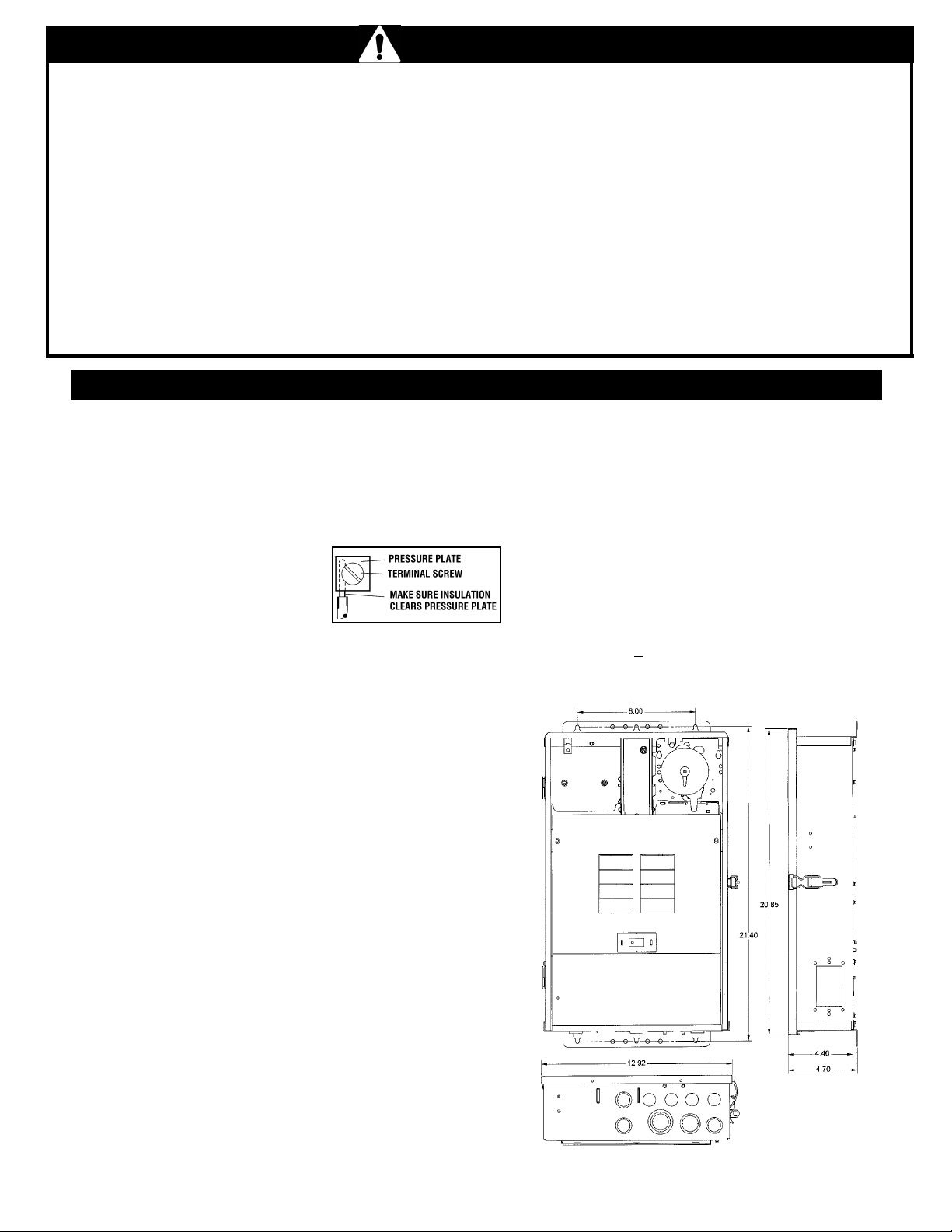

4. Refer to Figure 1 below; note that

this enclosure contains one Time

Switch. To wire the panel, follow

the wiring diagram located inside

the enclosure door. Make sure that

connections to time switch terminals are tight

(25 lb.-in. minimum)and insulation clears the

pressure plate - see illustration.

5. If required by the heater manufacturer, install

fireman switch kit 156T4042A (not furnished)

on Time Switch Plate and make the fireman switch

connections. Use at least #18 AWG wiring with

insulation rated 300 Volt or higher. Place heater

ON/OFF switch on heater to ON (see Figure 2

on page 3). Some heaters may require a special con-

necting harness, contact heater manufacturer for details.

6. To install an additional wiring device inside the

enclosure, first remove rectangular knock-out(s) in

dead front. Next, remove hex head screws in back of

enclosure and install stand-offs* in place of screws.

Attach wiring device to stand-offs.

*Stand-offs are not furnished. Order 21T156A for a set of four

(4) stand-offs and mounting hardware.

7. If external bonding is required, install a bonding lug

at bottom of enclosure and bond installation

according to code requirements.

8. Testing of the installation is optional and

recommended only if pump is securely in place

and will not be damaged by this test:

a. Turn the manual lever of the Time Switch to OFF.

b. Turn ON power at breaker panel.

c. Move the manual lever of Time Switch to the

right (ON). Pump should start and run on full

speed. In case of unsatisfactory results, turn OFF

power, check your wiring, refer to Troubleshoot-

ing on Page 3.

2

Figure 1

9. The enclosure must be grounded as required by

NEC, Article 680 and any applicable local codes.

For Canadian installations, the transformer supply

circuit must be protected by a ground fault circuit

interrupter.

10. If this enclosure is used for direct connection of

underwater lights, refer to 1999 NEC 680-21(b),

2002 NEC 680-24(b) or CEC 68-060, 062 and 066

for further details.

11. Make sure that all unused transformer taps (leads)

are separately insulated.

12. Use the tables at the top of page 3 as a guide to

determine the correct wire size.

13. Check voltage at lamp terminals after installation.

It should be 12+0.3 volts.

14.Install front panel over wiring compartment. The

control is now ready for programming, see

OPERATION section on Page 3.

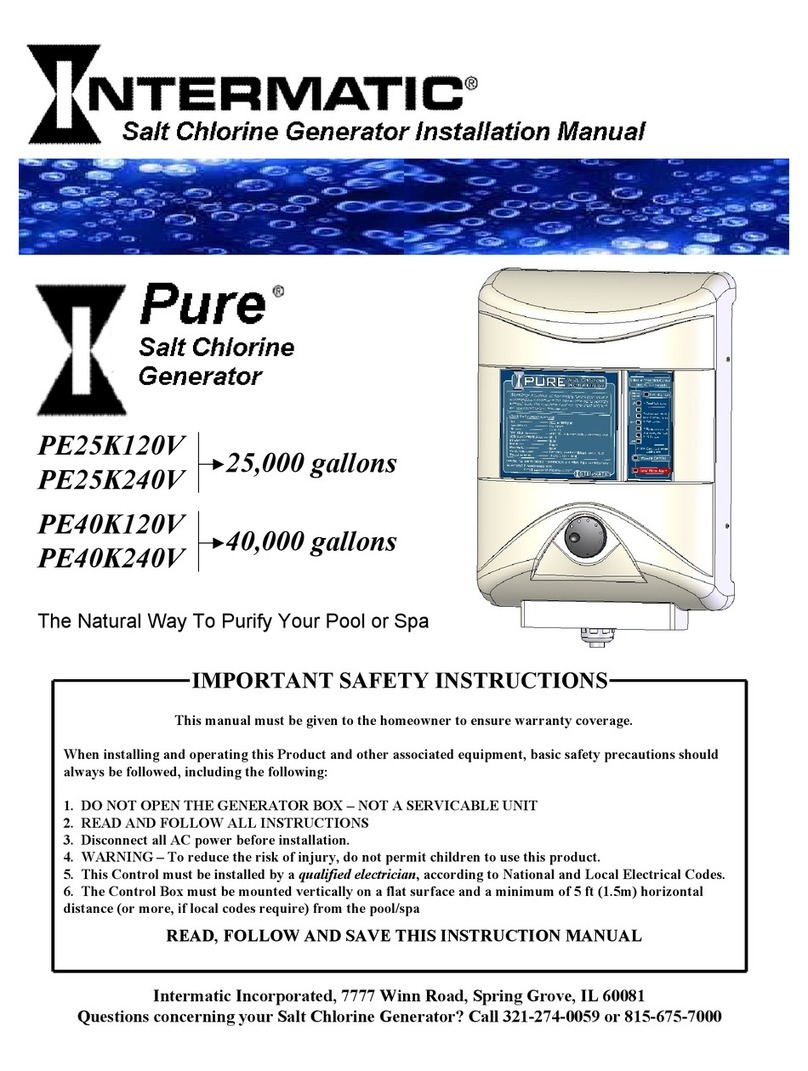

Risk of injury or property damage!

Do not install or operate this equipment and other associated equipment without basic safety

precautions.

Read and follow the safety instructions listed below and other basic safety precautions before

installation or operation of this control and other associated equipment.

1. This control must be installed by a qualified person, according to the national and local electrical

codes.

2. Install this control not less than 5 feet (3 meters in Canada) from inside edge of pool and 1 foot

(30cm) above ground.

3.USECOPPERCONDUCTORSONLYrated75˚Cminimum.

4. Do not exceed maximum ratings of individual components, wiring devices and current carrying

capacity of conductors.

5. For control grounding, bonding, installing and the wiring of underwater lights, refer to Article 680

of the National Electrical Code or Article 68 of the Canadian Electrical Code.

6. The control should not operate any equipment which would cause bodily injury or property

damage should it be activated unexpectedly.

CAUTION