International Biomedical AeroNOx User manual

AeroNOx

Portable Nitric Oxide

Titration & Monitoring System

Where “NO Man

” has gone before.....

Operating Manual

0086

Document No. 715-7000 Revision E Page 1 of 63

AeroNOx

Portable Nitric Oxide

Titration & Monitoring System

Operating Manual

Phone: (512) 873-0033

Toll Free: 1-800-433-5615

Fax: (512) 873-9090

Website: http://www.int-bio.com

Mailing address:

International Biomedical

8508 Cross Park Dr.

Austin, TX 78754

USA

Authorized representative in Europe for Regulatory Affairs:

Emergo Europe

Molenstraat 15

2513 BH

The Hague, The Netherlands

0086

Document No. 715-7000 Revision E Page 2 of 63

Document No. 715-7000 Revision E Page 3 of 63

AeroNOx

Table of Contents

SECTION I - IMPORTANT INFORMATION ABOUT NITRIC OXIDE DELIVERY........................ 5

SECTION II - UNPACKING AND SET-UP INSTRUCTIONS ....................................................... 6

AeroNOxTransport P/N 731-9148..............................................................................................7

AeroNOxBedside .....................................................................................................................15

AeroNOxPortable Cylinder Cart and Platform.......................................................................... 21

SECTION III - DEVICE DESCRIPTION...................................................................................... 23

General .......................................................................................................................................23

Recommended Use ....................................................................................................................23

Back-Up System .........................................................................................................................25

Titration Delivery System ............................................................................................................28

NO / NO2and O2Sampling.........................................................................................................29

Electrochemical Sensors ............................................................................................................30

Analysis ......................................................................................................................................30

Alarms.........................................................................................................................................31

“Safety” Shut Off .........................................................................................................................31

Front Panel .................................................................................................................................32

Gas Connections ........................................................................................................................33

Quick Connect Gas Fittings ........................................................................................................33

Luer Lock Connections ...............................................................................................................34

Battery ........................................................................................................................................35

Universal Power Supply..............................................................................................................37

SECTION IV - SPECIFICATIONS .............................................................................................. 38

Functional Performance..............................................................................................................38

Physical Specifications ...............................................................................................................41

Safety..........................................................................................................................................41

SECTION V - CALIBRATION..................................................................................................... 42

AeroNOxCalibration Procedure ...............................................................................................43

SECTION VI - NITRIC OXIDE DELIVERY ................................................................................. 45

Inspiratory Limb NO Titration in Constant Flow Ventilators.........................................................45

Precautions for Inspiratory Limb NO Titration .............................................................................45

Ventilators Safe for Use with the AeroNOx...............................................................................45

Nitric Oxide Concentration Profiles .............................................................................................46

SECTION VII - CALCULATIONS & TROUBLESHOOTING ...................................................... 47

Calculations for Nitric Oxide Delivery..........................................................................................47

What is the diluted FiO2? ............................................................................................................ 49

Oxygen Index Calculation ...........................................................................................................49

Calculation of Cylinder Duration .................................................................................................51

How much calibration gas do I need?.........................................................................................52

AeroNOxTroubleshooting Guide..............................................................................................53

Document No. 715-7000 Revision E Page 4 of 63

AeroNOx

Table of Contents

SECTION VIII - CLEANING & MAINTENANCE......................................................................... 57

Cleaning......................................................................................................................................57

Repairs and Replacement ..........................................................................................................57

Customer Service .......................................................................................................................57

Instructions for Disposal..............................................................................................................58

SECTION IX - WARRANTY ....................................................................................................... 59

SECTION X - COMPETENCY BASED PERFORMANCE CHECK-OFF TOOL.........................61

Routine (Weekly) AeroNOxCalibration ....................................................................................62

AeroNOxPortable & Bedside Set-Up .......................................................................................63

Document No. 715-7000 Revision E Page 5 of 63

SECTION I - IMPORTANT INFORMATION ABOUT

NITRIC OXIDE DELIVERY

ATTENTION!

AeroNOxNitric Oxide Titration & Monitoring System delivers nitric oxide gas and

measures nitric oxide and nitrogen dioxide gas concentrations in parts per million (ppm).

“Caution: U. S. Federal and Canadian law restricts this device to sale by or on the order

of a physician or other licensed medical practitioner. Outside Canada and the U. S.,

check with local laws for applicable restrictions.”

“Persons using this device should be trained and experienced in the use of this device to

assure effective administration of nitric oxide, and to avoid injury to the patient or to

others resulting from inhalation of excess nitric oxide, nitrogen dioxide, or other reaction

products.”

“Persons using this device who may be particularly sensitive to nitric oxide or nitrogen

dioxide, or who may be exposed to these gases for prolonged periods as a result of the

use of this device, should be aware that the AeroNOxdoes not scavenge the exhaust

gas, and that this gas is vented from the underside of the AeroNOx, or through the side

vent in the event that the bottom port is occluded. Ambient concentrations of nitric oxide

or nitrogen dioxide expected to result from the use of this device are less than 50 ppb.”

WARNING

The use of oxygen increases the danger of fire. Auxiliary equipment producing sparks should

not be placed near the AeroNOx. Small quantities such as ether or alcohol left near the

AeroNOx can cause fire.

Classification

According to the standard EN60601-1 of the International Electrotechnical Commission,

Medical electrical equipment, Part 1: General requirements for safety, the AeroNOxis

classified as follows:

Class I / Internally Powered, according to the type of protection against electric

shock.

Ordinary, according to the degree of protection against harmful ingress of water.

Continuous operation for the mode of operation.

Document No. 715-7000 Revision E Page 6 of 63

SECTION II - UNPACKING AND SET-UP INSTRUCTIONS

Verify that the shipping carton (s) contain one of the following groups of equipment. Complete

descriptions of these groupings can be found in this section.

1. AeroNOxTransport, P/N 731-9148

Nitric Oxide Titration & Monitoring System

2. AeroNOxBedside Option

Nitric Oxide Titration & Monitoring System

Document No. 715-7000 Revision E Page 7 of 63

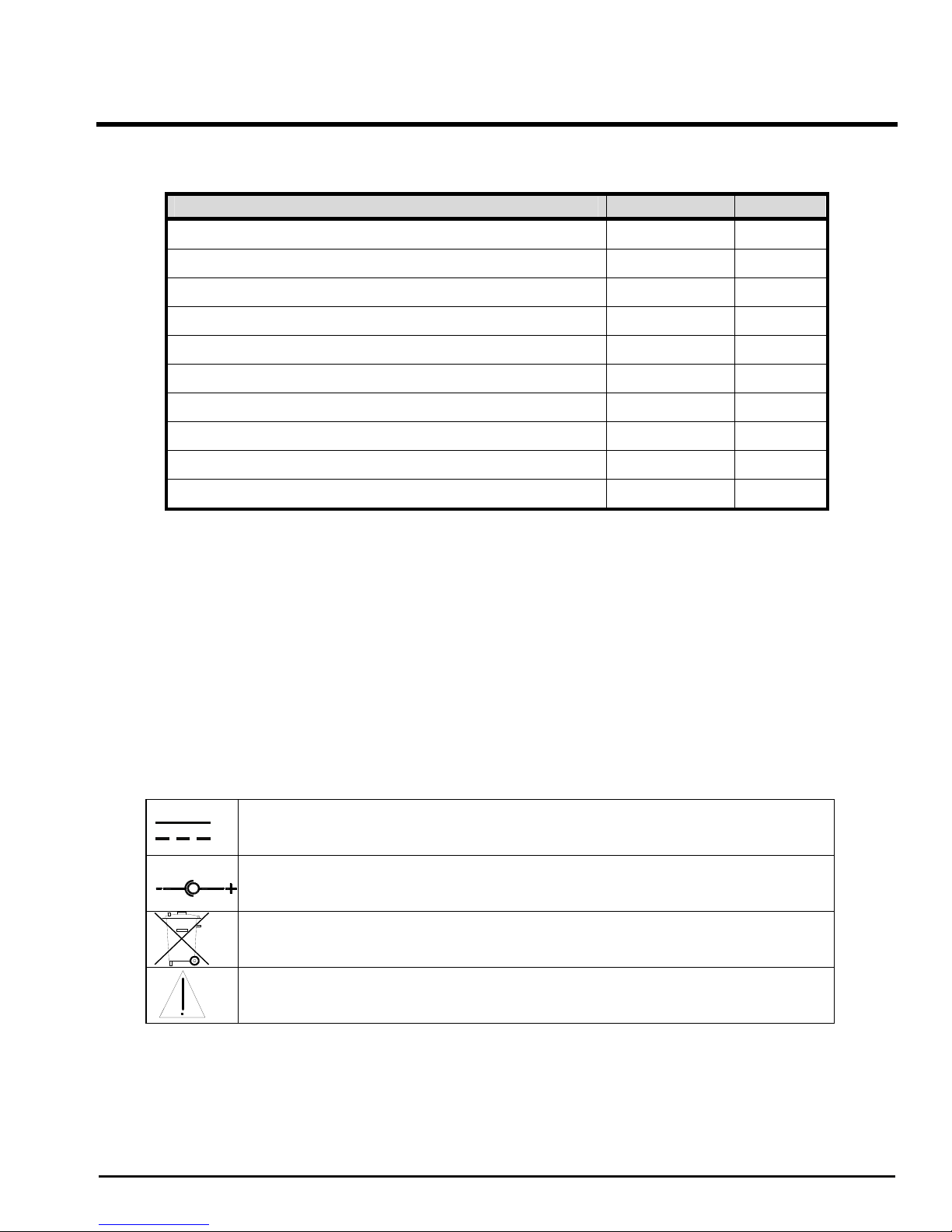

The AeroNOx

Transport P/N 731-9148

Nitric Oxide Titration & Monitoring System

Component Part Number Quantity

AeroNOx731-9138 1

SS Hose with Quick Connect (3 ft.) 731-9371 1

AeroNOxOperating Manual 715-7000 1

AeroNOxTechnical Manual 715-7001 1

12 V Universal Power Supply 293-0040 1

Medical Grade Power Cord 711-0179 1

SS NO Transport Delivery Regulators, CGA 626 731-9142 2

AeroNOx“NO WORRIES” Connector Sample Pak 731-9373 1

AeroNOxCalibration Circuit 415-0000 1

Single Calibration Screwdriver 416-0010 1

The AeroNOxmust be used with calibration gas and

accessories specified by the manufacturer.

Symbols

The following symbols appear in the AeroNOx documentation and labels. These

internationally recognized symbols are defined by the International Electrotechnical

Commission, IEC 417A and IEC 878 or by the Institute of Electrical and Electronics

Engineers, 315(a).

Direct current

Positive to center pin, Negative to outer ring of connection

Recycle or dispose of properly, contains sealed lead batteries

Attention, consult accompanying documents

Document No. 715-7000 Revision E Page 8 of 63

The AeroNOx

Transport P/N 731-9148

Nitric Oxide Titration & Monitoring System

Prepare the AeroNOx

Transport Nitric Oxide

Titration & Monitoring System

for initial operation as follows:

1. Unpack the AeroNOxand inspect for damage.

2. Install battery as per SECTION III, “Battery”.

3. Unpack 12 V universal power supply (P/N 293-0040) and Medical Grade Power Cord

(P/N 711-0179). Plug in AeroNOxand charge for ~ 24 hrs.

4. Calibrate AeroNOx. (See SECTION V.)

5. Attach CGA 626 regulators to the transport tanks as per “Purge procedures to follow

when changing tanks and/or regulators” in this section.

6. Connect selected regulator outlet to the AeroNOxgas inlet using the stainless steel hose

with quick connect adapters.

7. Turn on nitric oxide gas supply.

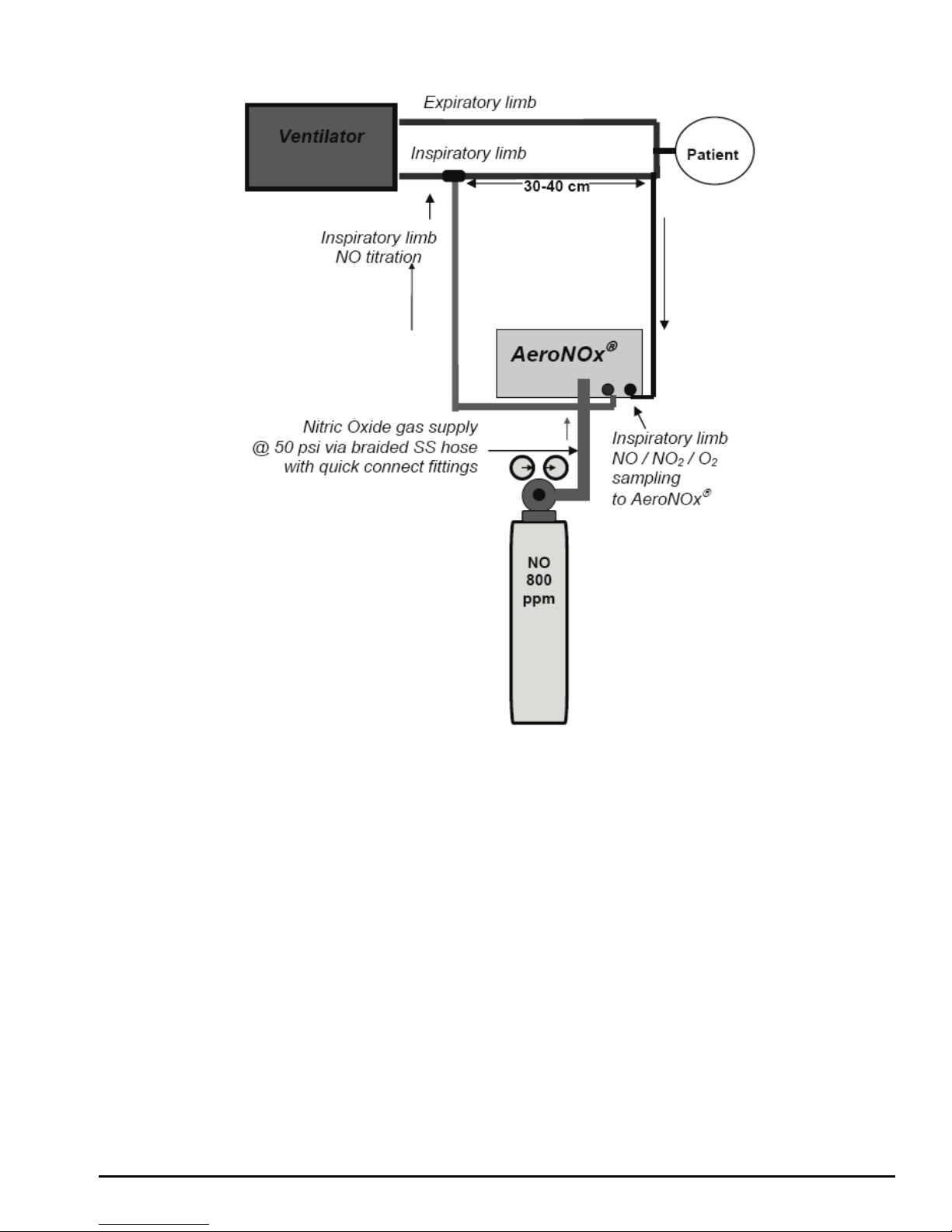

8. Attach the delivery line from the AeroNOxBagger (See Diagram # 2) or the AeroNOx

delivery line (P/N 415-0001) found in the AeroNOx“NO WORRIES” connector sample

pak to the female luer connector marked “NITRIC OXIDE DELIVERY OUTLET” on the

AeroNOx. Tee the other end of the delivery line into the patient breathing circuit at least

30 - 40 cm upstream of the sampling site (see Diagram # 1).

9. Attach the “NO WORRIES” sample line (P/N 415-0004) to the male luer connector

marked “ANALYSIS SAMPLE INLET” on the AeroNOx.

10. Select the appropriate sample gas connector from your “NO WORRIES” connector

sample pak and attach it to the free end of the sample line. *NB if attaching the sample

line to the bagger, skip this step.

11. Connect the sample gas connector to the patient breathing circuit. The connector should

be placed in the inspiratory limb, just prior to the patient wye connection (refer to Diagram

# 1).

OR

Connect the sample line to the sampling port on the bagger (see Diagram # 2).

12. “Flush” your system according to “Suggested flush procedure for the delivery portion of

the AeroNOxsystem”, or according to the instructions for the AeroNOxBagger.

13. You are now ready to deliver NO gas and sample mixed inspired gases.

CAUTION!

Never turn on the NO delivery gas without first turning on the

ventilator or bagger flow. Failure to do this will result in undiluted

delivery gas entering the sampling chamber and exposing the

sensors to levels of NO and/or NO2which may damage the

sensors.

CAUTION!

NO2gas may have collected in the AeroNOxdelivery circuitry. Prior

to delivering gas to the patient, “flush” your delivery system with

fresh NO delivery gas. This should be repeated every time you begin

NO gas administration. Analyze the gas for high NO2levels prior to

patient connection.

Document No. 715-7000 Revision E Page 9 of 63

Suggested “flush” procedure for the delivery portion of the AeroNOxsystem:

1. Set up the AeroNOxfor delivery as outlined in “AeroNOxTransport Nitric Oxide

Titration & Monitoring System for initial operation”.

2. Hook up the ventilator to a test lung (patient should be manually ventilated during this

procedure and the ventilator parameters should be set to the patient’s pre-NO gas

settings).

3. Inactivate the “Safety Shut Off” system by simultaneously depressing the NO and NO2

alarm silence buttons for 5 seconds or until the display reads “SAFETY OFF”. For more

information on the “Safety Shut Off” system, see “Safety Shut Off” in SECTION III.

4. Turn on the NO gas flow to 2 lpm by turning the knob on the precision metering valve in a

counter-clockwise direction. This knob is located in the bottom right hand quadrant of the

front panel of the AeroNOxbelow the LCD flow display. Allow the gas to flow into the

ventilator circuit.

5. As soon as the NO2value has dropped to a stable level, allow the gas to run for an

additional 3 seconds and then adjust the NO flow to the desired level (see SECTION VII -

Calculations for NO Delivery to determine flow required for desired NO concentration).

6. Re-activate the “Safety Shut Off” system by simultaneously depressing the NO and NO2

alarm silence buttons for at least 5 seconds or until the display reads “SAFETY ON”.

7. Once the desired NO concentration has been reached, ensure that NO2level is

acceptable for patient administration. Below you will find a table which will give you the

approximate NO2values you can expect for a given NO concentration and ventilator flow

at an FiO2of 1.0.

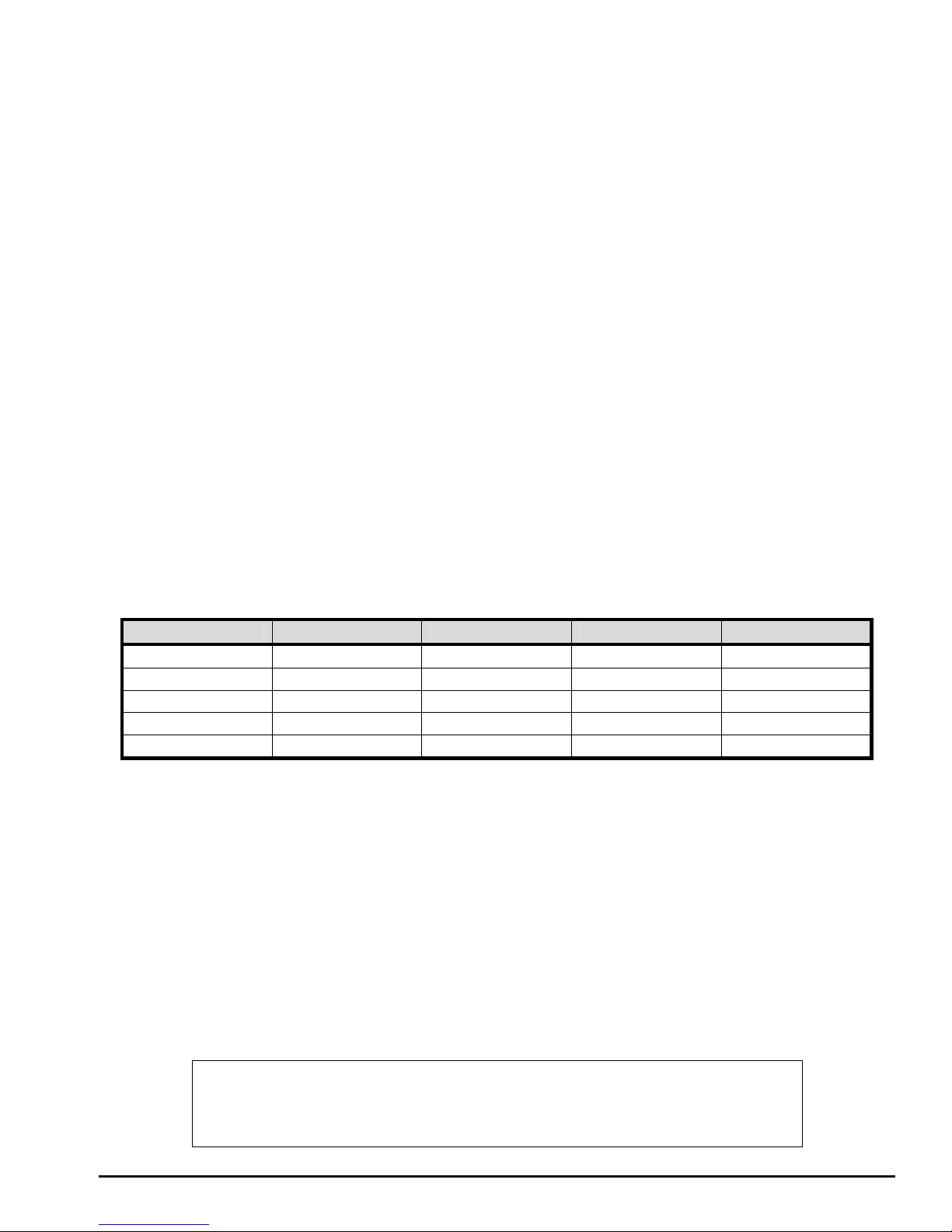

Minute Volume / Ventilator Flow

[NO] 5 10 15 20

5 ppm 0.5 0.1 0.1 0.1

10 ppm 0.5 0.2 0.2 0.1

20 ppm 0.5 0.3 0.2 0.2

40 ppm 0.8 0.6 0.4 0.4

80 ppm 2.0 1.5 1.2 1.1

NO2in PPM

The table above is for reference only.

Factors such as the accuracy of the ventilator flow, percent error in delivery apparatus,

and human error, may all affect the actual delivered patient dose. The calculated NO flow

should be compared with the analyzed NO dose to confirm accurate NO dosing. Should

the actual NO flow differ from the calculated NO flow by more than 10% beyond

published specifications, the cause must be determined and corrected immediately. If the

cause can not be immediately determined, ensure patient safety and contact International

Biomedical at 1-800-433-5615 for further assistance.

8. Connect the patient to the ventilator and monitor according to study and/or institution

protocol.

CAUTION!

The flush procedure must be performed each time NO therapy is

started. This includes initial therapy starts, tank changes, and re-

starting therapy after trials off NO.

Document No. 715-7000 Revision E Page 10 of 63

Purge Procedures to follow when changing tanks and/or regulators.

Important!

Purge Procedure Required before Use

Please follow purge instructions below to ensure gas purity. Failure to follow these

instructions may introduce potentially harmful contaminants into the patient’s

breathing gas or may affect the monitoring analyzer’s accuracy by introduction of

contaminants into the calibration gas.

Warning:Perform cylinder connection and purge procedures in well-ventilated areas

to prevent inadvertent exposure to nitric oxide or nitrogen dioxide gas. Follow your

facility’s safety procedures for handling medical gas cylinders.

Purge Procedures for use with Medical Gas Regulators:

1. Connect cylinder to a matching CGA nitric oxide or nitrogen dioxide

regulator only.

2. Open, then immediately close the cylinder valve.

3. Release (bleed) all of the gas from the regulator.

4. Repeat steps 2 and 3 four more times for a total of five purge cycles.

5. Leave the regulator installed until it is time to change to a new cylinder.

6. Repeat the purge procedure any time a regulator is reattached.

Any time a regulator is installed on a tank or cylinder of compressed gas, certain precautions

must be followed. This is to prevent contamination of the gas in the tank and in the system by

air that is trapped in the dead space of the regulator and fittings. To eliminate the possibility of

the oxygen in this air reacting with the nitric oxide to form nitrogen dioxide in the system, the

regulator and fittings must be purged before use. The valve on the tank must not be opened

and left open until the regulator is purged. The stainless steel line must also be purged prior to

connection to the AeroNOx.

CAUTION!

Should there be a sudden need to change therapy tanks, a second tank

should always be purged and ready for immediate use. Perform the

purge procedure immediately upon installation of a new regulator.

Although the dead space volume in the regulator and hose assembly is physically small, if it had

been exposed to room air for a period of time it will contain sufficient oxygen to convert a

significant amount of nitric oxide to nitrogen dioxide.

Document No. 715-7000 Revision E Page 11 of 63

The following purge procedure must be followed any time a regulator is installed on a tank of

gas. It should be done immediately after connecting a regulator to a tank to avoid contaminating

a tank of gas with the air trapped in the dead space of the regulator in the event someone turns

on and leaves on the valve on the tank.

1. Install and tighten the regulator onto the tank.

2. Insert the quick-connect on one end of the stainless steel hose into the quick-connect

fitting on the regulator. Leave the other end of the stainless steel hose free.

3. Crack open and immediately close the tank valve.

4. Gently press the center tip of the quick-connect on the free end of the stainless steel hose

against a clean hard surface and allow the pressure to bleed to zero. A small amount of

high concentration delivery gas will be released at 50 psig. Keep the hose away from

patients and clinicians in order to avoid exposure to the gas.

5. Repeat Step 3 and Step 4 above five times (five complete purge cycles).

6. Connect equipment and open the tank valve as needed.

Any time a regulator is installed onto a cylinder and before each patient use, the

AeroNOxsystem should be purged. - NO EXCEPTIONS!!

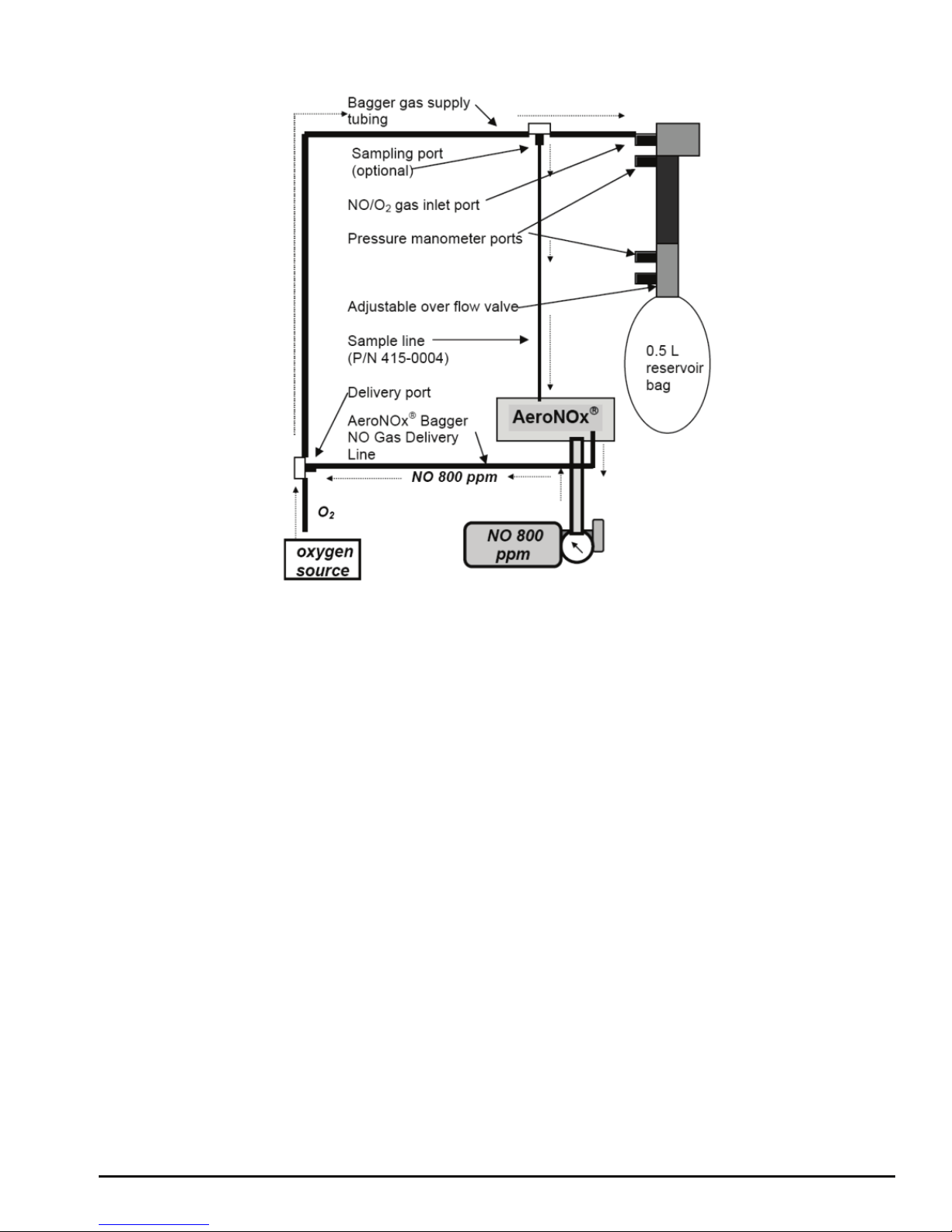

AeroNOxBagger: Instructions for use with the AeroNOx

(See Diagram # 2.)

CAUTION!

Oxygen and Nitric Oxide mix in the reservoir bag and stagnant flow will cause NO2to be

formed. Turn off NO flow when not actively bagging patient. Flush the bagger with

oxygen for a least 20 seconds to completely remove NO and NO2before and after patient

use.

Concentrations of nitrogen dioxide in the reservoir bag may exceed 1 ppm. Large tidal

volumes may expose patients to the nitrogen dioxide in the reservoir bag.

Flush the bagger with oxygen for at least 20 seconds to completely remove NO and NO2

after any interruption in active patient bagging.

The AeroNOxmay not be able to detect rapid, short acting fluctuations in the

concentration of the delivered gas, including nitrogen dioxide. For this reason, the

AeroNOxBagger is designed for short-term use only.

If a patient requires nitric oxide concentrations other than 20 ppm, a separate system

capable of providing the required concentration must be available. DO NOT USE THE

AERONOXBAGGER TO DELIVER CONCENTRATIONS IN EXCESS OF 20 PPM!

The generation of nitrogen dioxide increases rapidly above this concentration.

Do not alter the length of the Bagger Gas Supply Tubing as this may cause generation of

excessive levels of nitrogen dioxide.

Document No. 715-7000 Revision E Page 12 of 63

Do not substitute AeroNOxBagger components! The AeroNOxBagger has been

designed and tested for patient safety with the components included in the current

configuration.

The AeroNOxBagger is designed for use only with the AeroNOxDelivery System. Do

not attempt to use the AeroNOxwith any other manual resuscitator. Do not attempt to

use the AeroNOxBagger with any other delivery system.

A backup system must always be available in the event that the primary system should

fail. For instructions for use of a Back-Up System in the event of a failure of the

AeroNOxsystem, please see SECTION III, Back-Up system.

The AeroNOxBagger is intended to be connected directly to the patient’s endotracheal

tube. Do not insert any additional tubing between the AeroNOxBagger and the

endotracheal tube.

The AeroNOxBagger is for single patient use only. Do not reprocess.

Persons using this device should be trained and experienced in the use of this device to

assure affective administration of nitric oxide, and to avoid injury to the patient or to

others resulting from inhalation of excess nitric oxide, nitrogen dioxide, or other reaction

products.

Persons using this device who may be particularly sensitive to nitric oxide, or who may be

exposed to these gases for prolonged periods as a result of the use of this device, should

be aware that the gases exiting the AeroNOxBagger are not scavenged.

1. Connect the large end of the bagger gas supply tubing to an oxygen source. Ensure that

the small end of this tubing is connected to the NO / O2gas inlet port on the bagger.

2. Connect AeroNOxBagger gas delivery line to the AeroNOxdelivery gas port.

3. Connect male end of the sample line (P/N 415-0004) to the sampling port on the bagger

gas supply tubing and the female end to the AeroNOxsampling port.

4. Set O2flow on the O2flow meter to exactly 10 LPM. Let the oxygen run for at least 20

seconds to flush out any residual NO or NO2left in the AeroNOxBagger.

5. Turn on NO delivery gas source to 0.25 LPM. If you have correctly set your O2flow at

exactly 10 LPM, the delivered NO concentration will be ~20 ppm and delivered NO2

values should not exceed 0.2 ppm. Do not exceed 20 ppm during manual ventilation!

6. Connect test lung and set overflow valve to desired positive end expiratory pressure

(PEEP).

Document No. 715-7000 Revision E Page 13 of 63

7. Continue to run the AeroNOxBagger with the test lung until the analyzed NO and NO2

values stabilize. This will prevent high doses of NO2, which can form in the bagger and

delivery line, from being delivered to your patient. The NO2sensor in the AeroNOx

Bagger may not react quickly enough to detect NO2boluses.If you do not have time

to use a test lung, in an emergency situation for example, you must still flush the

bagger with fresh gas for at least 20 seconds prior to patient connection!

8. Analyze NO and NO2concentration prior to patient administration.

9. Flush bagger with O2after each patient use to flush out residual NO and prevent

NO2formation.

AeroNOxBagger Specifications:

O2Gas Flow 10 LPM

NO Gas Flow 0.25 LPM

Delivered [NO] ~ 20 ppm

NO2Generated Maximum 0.2 ppm @ 20 ppm Delivered [NO]

Reservoir Volume 0.5 L

Bagger Dimensions 12” from Reservoir Bag to Patient Connection, ½” I. D.

Tidal Volume Maximum 0.5 L (500 cc)

Breath Rate

Maximum 100 bpm at Pressures 18/5 (pip/peep)

Maximum 50 bpm at Pressures 40/5

(Pressures Listed in cmH2O)

I:E Ratio Variable

Diagram # 1

NO Titration with a Transport Ventilator

Document No. 715-7000 Revision E Page 14 of 63

Diagram # 2 NO Titration with AeroNOxBagger

Document No. 715-7000 Revision E Page 15 of 63

The AeroNOx

Bedside

Nitric Oxide Titration & Monitoring System

Component Part Number Quantity

AeroNOx731-9138 1

AeroNOxOperating Manual 715-7000 1

AeroNOxTechnical Manual 715-7001 1

AeroNOxCart including Stand, Platform, Basket, & Power Bar 1

AeroNOxMounting Block 1

12 V Universal Power Supply 293-0040 1

SS Hose with Quick Connect Fittings 731-9371 1

Medical Grade Power Cord 711-0179 1

CGA 626 NO Delivery Regulators 731-9142 2

AeroNOx“NO WORRIES” Connector Sample Pak 731-9373 1

AeroNOxCalibration Circuit 415-0000 1

Single Calibration Screwdriver 416-0010 1

Recommended Bedside Gases: (Not Included)

Concentration: 800 ppm NO in balance N2of pharmaceutical

grade gas

Size: 38” (1 meter) height by 7” (18 cm) diameter

2

The AeroNOxmust be used with calibration gas and accessories

specified by the manufacturer.

Document No. 715-7000 Revision E Page 16 of 63

The AeroNOx

Bedside Set-Up

Prepare the AeroNOx

Bedside Nitric Oxide Titration & Monitoring System

for initial operation as follows:

1. Unpack the AeroNOxand inspect for damage.

2. Install battery as per SECTION III, “Battery”.

3. Secure the therapeutic tanks to the AeroNOxcart.

4. Unpack 12 V universal power supply (P/N 293-0040) and Medical Grade Power Cord

(P/N 711-0179). Plug in AeroNOxand charge for ~ 24 hrs.

5. Calibrate AeroNOxusing the Calibration Kit (P/N 731-9145) NO and NO2Calibration

Gas specified by the manufacturer and the instructions found in SECTION V of this manual.

6. Attach CGA 626 regulators (P/N 731-7142) to delivery gas cylinders as per “Purge

procedures to follow when changing tanks and/or regulators” in this section.

7. Connect selected regulator outlet to the AeroNOxgas inlet using the stainless steel hose

with quick connect adapters.

8. Turn on nitric oxide gas supply.

9. Attach the AeroNOxdelivery line (P/N 415-0001) found in the AeroNOx“NO

WORRIES” connector sample pak to the female luer connector marked “NITRIC OXIDE

DELIVERY OUTLET” on the AeroNOx. Tee the other end of the delivery line into the

patient breathing circuit at least 30 - 40 cm upstream of the sampling site. Attach the “NO

WORRIES” sample line (P/N 415-0004) to the male luer connector marked “ANALYSIS

SAMPLE INLET” on the AeroNOx.

10. Select the appropriate sample gas connector from your “NO WORRIES” connector

sample pak and attach it to the free end of the sample line.

11. Connect the sample gas connector to the patient breathing circuit. The connector should

be placed in the inspiratory limb, just prior to the patient wye connection (refer to Diagram

# 3).

12. “Flush” your system according to “Suggested “flush” procedure for the delivery portion of

the AeroNOxsystem”.

13. You are now ready to deliver NO gas and sample mixed inspired gases.

CAUTION!

Never turn on the NO delivery gas without first turning on the

ventilator or bagger flow. Failure to do this will result in undiluted

delivery gas entering the sampling chamber and exposing the sensors

to levels of NO and/or NO2which may damage the sensors.

CAUTION!

NO2gas may have collected in the AeroNOxdelivery circuitry. Prior

to delivering gas to the patient, “flush” your delivery system with

fresh NO delivery gas. This should be repeated every time you begin

NO gas administration. Analyze the gas for high NO2levels prior to

patient connection.

Document No. 715-7000 Revision E Page 17 of 63

Suggested “flush” procedure for the delivery portion of the AeroNOxsystem:

1. Set up the AeroNOxfor delivery as outlined in “AeroNOxBedside Set-Up”.

2. Hook up the ventilator to a test lung (patient should be manually ventilated during this

procedure and the ventilator parameters should be set to the patient’s pre-NO gas

settings).

3. Inactivate the “Safety Shut Off” System by simultaneously depressing the NO and NO2

alarm silence buttons for 5 seconds or until the display reads “SAFETY OFF”. For more

information on the “Safety Shut Off” system, see “Safety Shut Off” in SECTION III.

4. Turn on the NO gas flow to 2 lpm by turning the knob on the precision metering valve in a

counter-clockwise direction. This knob is located in the bottom right hand quadrant of the

front panel of the AeroNOxbelow the LCD flow display. Allow the gas to flow into the

ventilator circuit.

5. As soon as the NO2value has dropped to a stable level, allow the gas to run for an

additional 3 seconds and then adjust the NO flow to the desired level (see SECTION VII -

Calculations for NO Delivery to determine flow required for desired NO concentration).

6. Re-activate the “Safety Shut Off” system by simultaneously depressing the NO and NO2

alarm silence buttons for at least 5 seconds or until the display reads “SAFETY ON”.

7. Once the desired NO concentration has been reached, ensure that NO2level is

acceptable for patient administration. Following, you will find a table which will give you

the approximate NO2values for a given NO concentration and ventilator flow at an FiO2of

1.0.

Minute Volume / Ventilator Flow

[NO] 5 10 15 20

5 ppm 0.5 0.1 0.1 0.1

10 ppm 0.5 0.2 0.2 0.1

20 ppm 0.5 0.3 0.2 0.2

40 ppm 0.8 0.6 0.4 0.4

80 ppm 2.0 1.5 1.2 1.1

NO2in PPM

The table above is for reference only.

Factors such as the accuracy of the ventilator flow, percent error in delivery apparatus,

human error, and accuracy of calibration of the AeroNOxmay all affect the actual

delivered patient dose. The calculated NO flow should be compared with the analyzed

NO dose to confirm accurate NO dosing. Should the actual NO flow differ from the

calculated NO flow by more than 10% beyond published specifications, the cause must

be determined and corrected immediately. If the cause can not be immediately

determined, ensure patient safety and contact International Biomedical at 1-800-433-

5615 for further assistance.

8. Connect the patient to the ventilator and monitor according to study and/or institution

protocol.

CAUTION!

The flush procedure must be performed each time NO therapy is

started. This includes initial therapy starts, tank changes, and re-

starting therapy after trials off NO.

Document No. 715-7000 Revision E Page 18 of 63

Diagram # 3 AeroNOxBedside Set-Up

The Sensormedics 3100A or 3100B

To set up the AeroNOxfor use with the 3100A & 3100B, tee in the AeroNOxDelivery Line

(P/N 415-0001) immediately post humidifier. To connect the “NO WORRIES” sample line, you

will require the 3100A / 3100B sample port adapter (P/N 415-0009). The port can be placed in

one of three positions. All three positions are labeled as “temperature probe ports” in the

3100A / 3100B literature. The “set back” temperature port is pictured in Figure 1 and Figure 2.

The proximal temperature port is pictured in Figure 3. The third port (not shown) is the second

proximal temperature probe port located next to the “dump valve” on the inspired limb of the

flexible circuit.

Document No. 715-7000 Revision E Page 19 of 63

Sampling Ports for the Sensormedics 3100A / 3100B:

Figure 1 The “Set Back” Temperature Probe Port

Figure 2 The “Set Back” Temperature Probe Port

Other manuals for AeroNOx

1

Table of contents

Popular Laboratory Equipment manuals by other brands

Belden

Belden HIRSCHMANN RPI-P1-4PoE installation manual

Koehler

Koehler K1223 Series Operation and instruction manual

Globe Scientific

Globe Scientific GCM-12 quick start guide

Getinge

Getinge 86 SERIES Technical manual

CORNING

CORNING Everon 6000 user manual

Biocomp

Biocomp GRADIENT MASTER 108 operating manual