Interphase PC/View User manual

INTERPHASEINTERPHASE

PC/VIEW™

for Windows

OPERATION

MANUAL

2

To Our Customer:

Thank you for choosing the Interphase PC/View Forward Scanning Sonar. Throughout

the development of this fine product, we have been primarily concerned with creating a

unit that offers the best possible value for your money. Selection of features, ease of use,

superior performance and outstanding reliability were the benchmarks upon which all

important design decisions were made. We are proud of the PC/View Forward Scanning

Sonar and your satisfaction is very important to us. We welcome any comments or

suggestions that you might have about this equipment.

It is very important that you complete and return the WARRANTY REGISTRATION

CARD within 15 days of purchase so that your unit may be protected under the warranty.

Thank You Again,

INTERPHASE TECHNOLOGIES, INC.

©1999 Interphase Technologies, Inc.

Interphase PC/View™ is a trademark of Interphase Technologies, Inc.

Other brands or products are the trademarks or registered trademarks of their respective holders and

should be treated as such.

Publication # = PC/View 2.0 990531 (P/N 25-1049-000)

3

1Introduction 6

General Information 6

Warranty Information 6

Unpacking and Inspection 7

2Installing PC/View 8

Transducer Installation 8

General Considerations 9

Transom Transducer Installation 10

Selecting a Location 10

Attaching the Bracket 10

Mounting the Transducer 11

Thru-Hull Transducer Installation 13

Selecting a Location 13

Using a Fairing Block 14

Thru-Hull Mounting 15

Acoustic Interface Module Installation 17

Software Installation 18

3Quick Start 20

Running PC/View 20

Defaults 20

Demo Mode 21

Beam Width 21

4Basic Operation 22

Getting Started 22

The Toolbar 22

The Status Bar 23

Operating Modes 23

Demo Mode 23

Real-Time Mode 23

Contents

4

Setting System Parameters 24

Parallel Port Address 24

Transducer Mount Corrections 24

Level Adjustment 24

Align Adjustment 25

Keel Offset 25

Displays 26

Setting Color and Units 26

VERT: Vertical Scan Display 28

HORZ: Horizontal Scan Display 28

DOWN: Downlooker Display 28

VSPLIT: Vertical Split-Screen Display 29

HSPLIT: Horizontal Split-Screen Display 29

Depth Window 30

Adjusting the Gain and Range 30

Gain Adjustment 30

Range Adjustment 31

Using the Alarm 31

Adjusting the Viewing Area 32

Sector Width and Steer 32

Scan Mode and Method 33

Zoom 33

Adjusting the Depth Tracker 34

Surface Masking 34

Threshold 34

Saving Data with Screen Capture 35

5Advanced Operation 36

Working with NMEA Navigation 36

Logging Depth 37

Using PC/View Diagnostics 39

6Interpreting Displays 40

Principles 40

Interpreting the Vertical Display 40

Forward Imaging Capabilities 40

Transducer Sidelobe Effects 41

Interpreting the Horizontal Display 42

Imaging the Bottom 42

Special Situations 43

Forward Imaging Capabilities 43

5

7Reference 44

Theory of Operation 44

Sonar Basics 44

Phased Array Technology 45

Maintenance 47

Troubleshooting Guide 48

Interference Problems 49

Specifications 50

How To Obtain Service 51

Index 52

Warranty 55

6

General Information

Thank you for choosing the Interphase PC/View

Dual-Axis Forward Scanning Sonar. The PC/View

has been designed to work with your on-board PC

and will display water depth, bottom conditions, fish

and other submerged objects and debris, all on your

computer’s high resolution color display. If you al-

ready have an Interphase scanning transducer in-

stalled on your vessel, you can order a PC/View

without a transducer (see page 50).

To insure that you receive the maximum benefits

available from the outstanding features of the Inter-

phase PC/View, this manual includes a detailed

guide to the use and interpretation of the system’s

modes and displays. An instructive demonstration

mode has been designed into the PC/View to famil-

iarize you with the unit’s features. In addition, the

Quick Start chapter gives you the necessary informa-

tion to get your system up and running as quickly as

possible. Please read the Installation chapter care-

fully before attempting to install PC/View on your

vessel.

Warranty Information

Interphase provides a Limited Warranty on the PC/

View Forward Scanning Sonar. Please read this

warranty (reprinted at the back of this manual) and

closely follow its terms and conditions should your

PC/View require repair. It is highly recommended

that you save all packing materials so that, in the

unlikely event that you must return your PC/View for

repair, it can be fully protected.

Should you experience a problem with your PC/

View, first refer to the Troubleshooting section (Page

48) of this manual. Most common problems and

their solutions are described here. If problems per-

NAVIGATION WARNING

Nautical navigation is a critical element in

the safety and success of each open-water

boating experience and should only be

performed by experienced navigators.

While the PC/View product is a useful

navigation aid, it should never be relied

upon as the only means of navigation. It is

prudent to use more than one proven

instrument and more than one accepted

method in support of navigation decisions.

1 Introduction

Award Winning

Technology

For its pioneering work in developing

Phased Array Scanning Sonar,

Interphase Technologies won the

prestigious IMTEC INNOVATION

AWARD.

The PC/View Forward Looking

Scanning Sonar is based on this same

award-winning technology.

7

sist, call Interphase Technical Service at (831) 477-

4944. We will be happy to assist you, and if required,

we will give you instructions on how to quickly get

your unit repaired.

The enclosed warranty registration card must be com-

pleted and returned to Interphase within 15 days of

purchase so that your unit may be protected under the

warranty. Failure to return the warranty card may

cause unnecessary delays in processing your unit for

warranty repair.

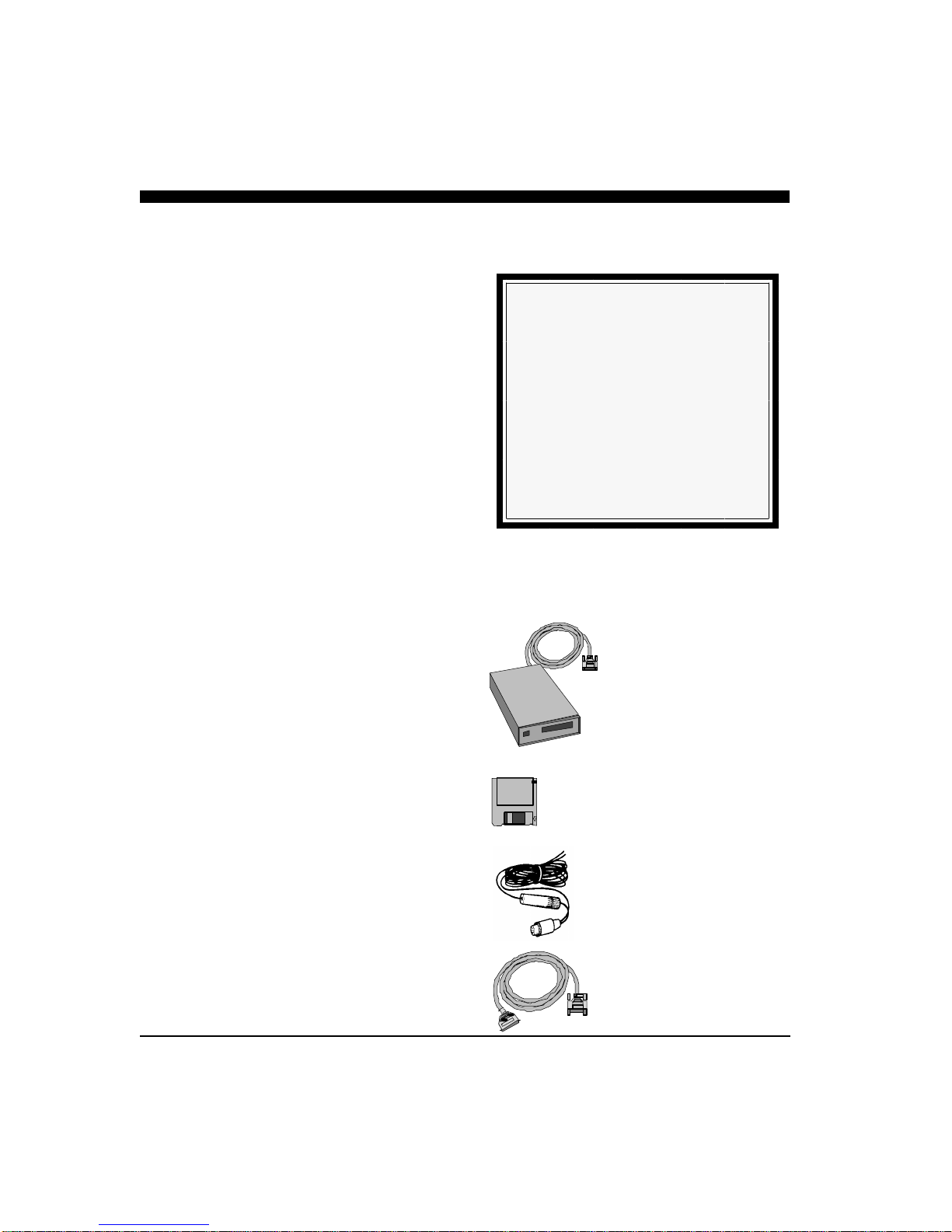

Unpacking and Inspection

When unpacking your PC/View, the following items

should be found in the package. Please notify your

Interphase dealer immediately if any items are missing.

Standard Equipment

Description Part Number

Acoustic Interface Module 06-2000-000

Parallel Cable, 10’ length 04-1035-000

12VDC Power Supply Cable 04-0001-008

PC/View Software Diskettes(2) 52-1001-002

Operation Manual 25-1049-000

Transducer Options

Description Part Number

Two Transom Transducers

200 kHz Vertical Scan T1-0200-025

200 kHz Horizontal Scan T1-0200-028

(2) Transom-Mount Flip-up

Brackets with splash guards 17-0055-008

Two Thru-Hull Transducers

200 kHz Vertical Scan T1-0200-026

200 kHz Horizontal Scan T1-0200-029

Single Thru-Hull Transducer

200 kHz Horizontal/Vertical Scan T1-0200-032

IMPORTANT NOTICE

Please fill out and return the Warranty

Registration Card immediately. This is our

only method of contacting you should new

features and enhancements become

available for your PC/View.

During the first year of your warranty, any

software upgrades will be free of charge,

and after the warranty period has expired,

software upgrades will be available for a

nominal charge.

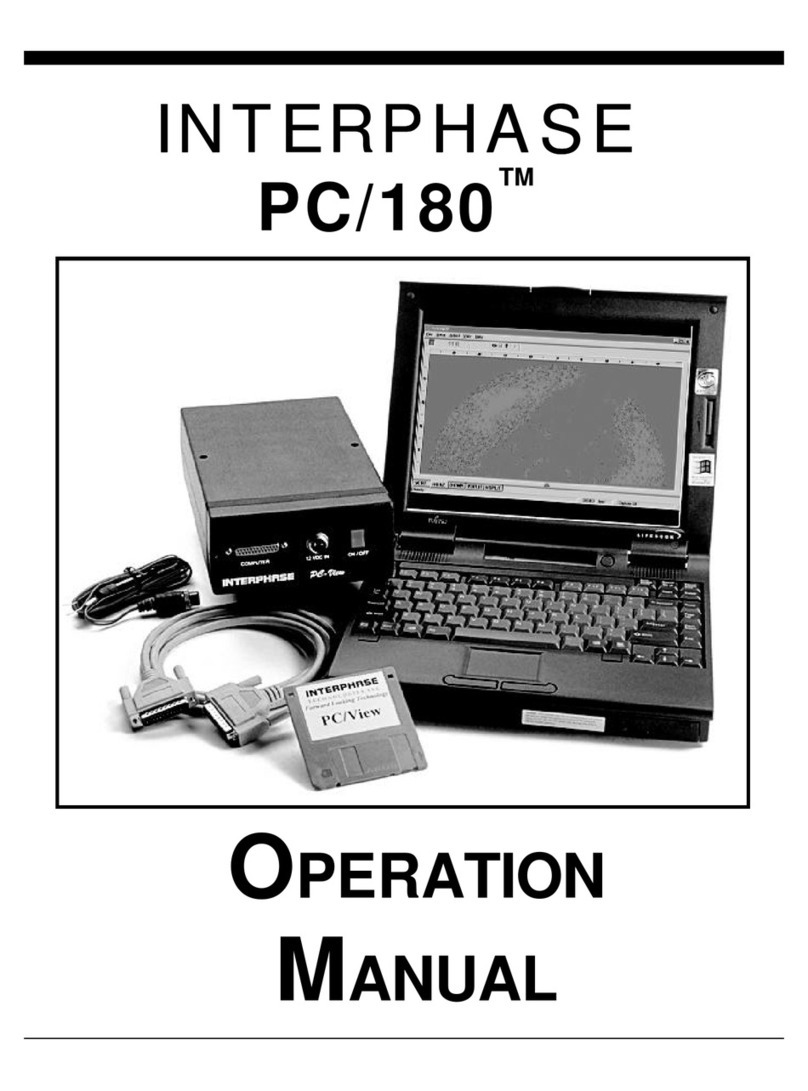

Acoustic Interface

Module

PC/View Software

12 VDC Power Cable

10’ Long Parallel Cable

8

The diagram at left shows a typical installation of the

PC/View using an on-board desktop or laptop PC.

In this manual the PC/View installation procedures

have been divided into three major sections;

1) Location and Installation of the Transducer(s)

2) Installation of the Acoustic Interface Module

3) Installation of the PC/View Software.

Transducer Installation

The PC/View can be ordered with one of several

transducer configurations; two transom mount trans-

ducers, two bronze thru-hull transducers, a special

single bronze thru-hull transducer, or with no trans-

ducer (if you already have an Interphase scanning

transducer installed).

The PC/View uses two 8-element phased transducer

arrays (a total of 16 elements). The arrays are

“potted” in a smooth-surfaced plastic material that is

acoustically transparent. DO NOT allow any sol-

vents (i.e. gasoline, acetone) to come in contact

with the transducer(s) as this may dissolve the

plastic housing.

In the single thru-hull configuration all 16 elements

are enclosed in a single transducer. For transom-

mount applications two transducers are required,

each containing an 8-element array. One of the 8-

element arrays is positioned to scan vertically from

straight ahead to directly below the boat, while the

other array is positioned to scan forward horizontally

from side to side. When the two thru-hull configura-

tion is chosen, each transducer contains an 8-element

array. One is positioned for vertical scanning and

the other for horizontal scanning.

2 Installing PC/View

PARALLELPORT

VERTICAL

SCAN

HORIZONTAL

SCAN

12 VDC

1AMP

SEASCOUT

TRANSDUCER

PROBE

TRANSDUCER

P/NX1-VIEW-PC1NmadeinSantaCruz,CA,USA

To Computer’s

Parallel Port

12 VDC

Vertical Scanning

Transducer Cable

Horizontal

Scanning Trans-

ducer Cable

+/-

12

VDC

Acoustic Interface Module

9

General Considerations

The orientation of the mounted transducer(s) is criti-

cal to the performance of the PC/View. The lower

diagram at right shows the proper orientation for

both the transom-mount and thru-hull transducer(s).

For all three types of transducers, the broader,

rounded or blunt side must point forward.

It is also important to think carefully about the loca-

tion of the transducer(s) before proceeding. Consider

the following:

1) The transducer(s) should be located where there

is the least amount of acoustic noise, air bubbles

or turbulence caused by the boat’s movement.

The transducer(s) should not be located near or

especially directly behind the propeller.

2) The transducer(s) must be mounted so that it

will be level with the water’s surface and will

not be tilted to either side.

3) The transducer(s) must always remain sub-

merged, regardless of the speed of the boat.

4) The transducer(s) should not be mounted where

it could be damaged by underwater obstacles or

when loading the vessel on a trailer.

5) DO NOT locate the transducer(s) in the ex-

treme bow of the boat where it will be subject to

intense turbulence as the boat pounds through

the water.

6) DO NOT locate the transducer(s) directly be-

hind any hull protrusion which will cause the

water to be turbulent when it reaches the trans-

ducer(s) or which will obstruct the transducer’s

forward looking view. For displacement-hull

power and sail boats, the thru-hull installation is

usually required.

7) Transducer cable(s) will need to be routed to the

Acoustic Interface Module. If you need trans-

ducer cable lengths greater than the standard

30’ length, order two 30’ extension cables

(Interphase Part # 04-0014-008).

Scanning Directions.

Vertical Scan mode

shown above and

Horizontal Scan

mode below

Forward

Forward

Thru-Hull Transducer(s)

Transom Mounted Transducer

Side View

Top View

10

Transom Transducer Installation

The transom transducers are attached to the boat with

heavy-duty stainless steel kick-up brackets to provide

protection against impact at speeds up to 35 knots (40

MPH). When the water force exceeds this setting, the

transducer automatically kicks up and becomes non-

operational.

Selecting a Location

To achieve optimal performance, the transducers

should be mounted in a location which:

*Minimizes acoustic noise reception.

*Minimizes the chance that aerated water will

flow across the front of the transducer(s).

*Optimizes the transducers view of the area ahead

and directly below the boat.

The transducers can be installed on either side of an

outboard or inboard/outboard engine, or between twin

outboards. Choose a location where water flow is the

smoothest. Refer to the diagram at right.

Because the transducers rotate back and upwards when

the brackets kick up, they must be mounted in a loca-

tion where there is sufficient clearance and headroom

to allow the full kick-up.

For single-engine installations, choose a location 18”

to 24” outboard of the propeller center line and, prefer-

ably, on the down-stroke side of the propeller.

For dual engine installation, choose a location just off

the center line of the vessel.

Attaching the Bracket

Position the spray shield inside the transducer’s

mounting ears. Make sure the spray shield is orien-

tated as shown in the diagram at far right.

Attach the kick-up bracket to the transducer using the

4 screws, washers and lock nuts provided. The bracket

arms must be mounted outside the mounting ears of the

transducer. Do not fully tighten the lock nuts at this

time.

Tools Required for Transducer

Installation:

♦ Variable speed electric drill with a chuck

capacity of 10 mm (3/8”) or larger.

♦ Hole saw or spade bit 19 mm (7/8”) for

transom hole to route cable and connector

♦ Chamfer bit or 6 mm (1/4”) drill bit

♦ Drill bit No. 28 or 4 mm (9/64”)

♦ Drill bit 3 mm (7/64”)

♦ Marine bedding/sealing compound

Note: Make sure your tooling is sharp and of

the correct diameter before proceeding.

Transom Mount Bracket in Released

Position

Note: Will not

work at speeds

above 40 MPH

**WARNING**

Do not cut or splice your phased-array

transducer cables or remove the 9-pin

connectors. Doing so will seriously

degrade the performance of your PC/View

and VOID YOUR WARRANTY.

11

Mounting the Transducer

After you have selected a mounting location and at-

tached the mounting brackets to the transducers, po-

sition each transducer-bracket assembly so it is level

in both the fore-aft and port-starboard directions.

Check the orientation of your boat’s waterline and

position the flat top surface of the transducer so that

it is parallel to the waterline as shown on the follow-

ing page.

Mount the bracket on the hull as shown in the dia-

grams at right and on the following page. Once the

transducer is properly positioned, tighten the lock

nuts.

18 - 24"

Cables

Twin Outboards

Transducer

Cable

Transom Mount Locations

Attach Transducer and Spray Shield to

Bracket

Fasten with

4 screws &

nylock

washers as

shown

Side

View

Rear View

Spray

Shield

Boat’s Hull

12

It is important to note that if the vertical scanning

transducer is not mounted so that the fore and aft

direction is parallel to the surface, then the

forward-looking display may be distorted where

flat bottoms appear to be slanted upwards or down-

wards. After mounting the transducer and actually

using the PC/View on the water, you may need to

readjust the transducers' mounting for optimum

performance.

Refer to the discussion of Transducer Mount Cor-

rections on page 24.

Waterline

Transducer

must be

mounted

vertically

Rear

View

Side

view Waterline

Flat area on top of

transducer must be

level with waterline

Mount Transducer So it Will Scan Properly

NOTE

The flat top of the transducer must be

parallel to the water line. This will not

necessarily be parallel to the boat’s hull.

13

Thru-Hull Transducer Installation

The thru-hull transducer is the recommended choice

for larger boats with in-board engines. Thru-hull

mounting is usually required on larger power and

sail craft in order to find a mounting location free of

forward-looking hull obstructions. The PC/View

must have a clear view of the water ahead as it can

not see through obstructions such as the vessel’s

hull. Please read the following carefully before

starting the thru-hull installation.

Normally, thru-hull installations are performed by a

professional in a boat haul-out facility and we rec-

ommend that you seek professional assistance before

attempting to mount this transducer.

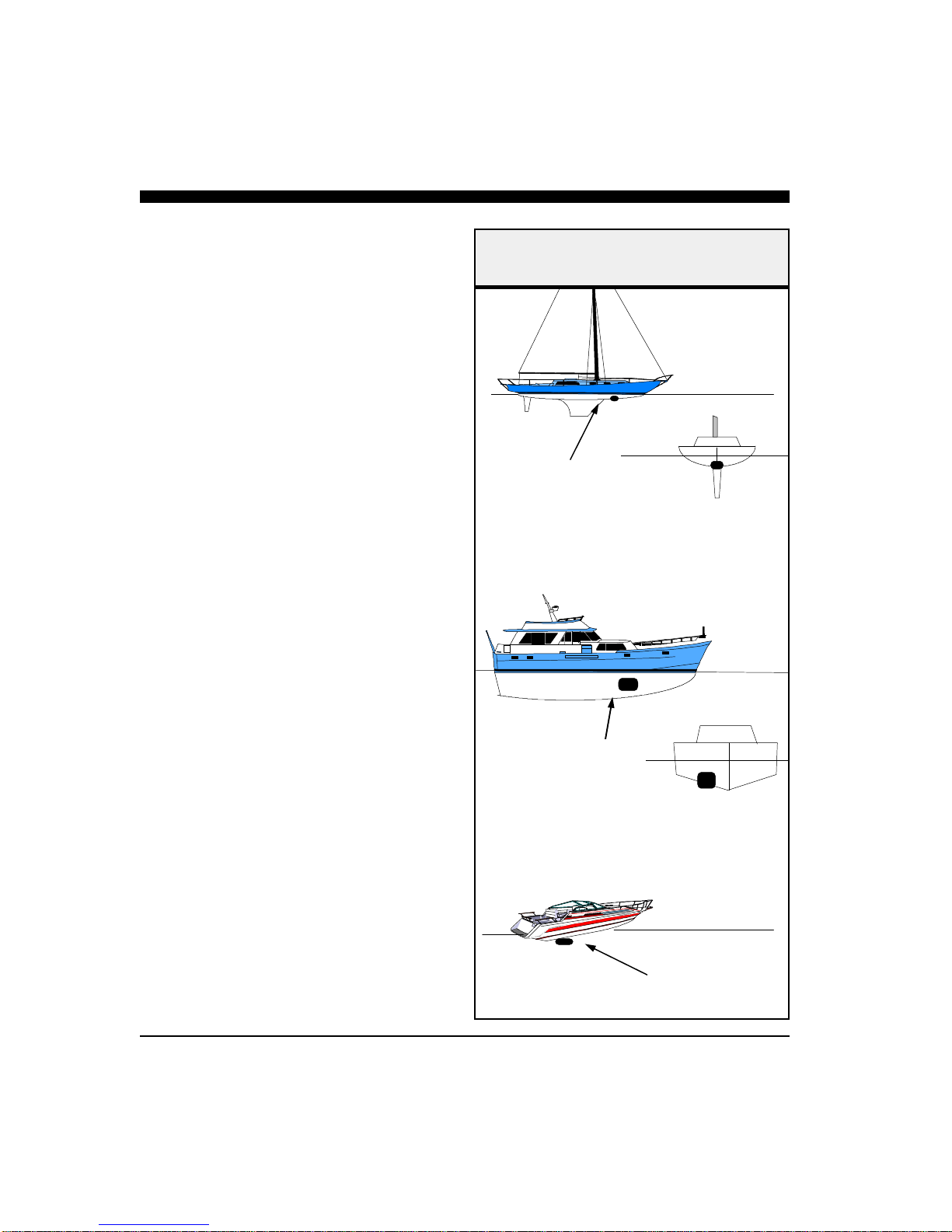

Selecting a Location

The best location to mount the thru-hull transducer

will vary with the type of boat. Try to find a loca-

tion with the smallest dead rise angle to make instal-

lation easiest.

a. On displacement hulls (sailboats, trawlers, etc.)

locate the transducer about 1/3 aft along the wa-

terline. Generally this provides the best compro-

mise between obtaining aeration-free water and

minimizing propeller noise. Water near the bow

and near the keel can be quite aerated. Since the

PC/View’s transducer can not see through aer-

ated water, it is best to mount the transducer

midway between these two areas.

b. On sailboats, the transducer should be mounted

where the acoustic beam will not be shaded by

the keel. A spot forward of a fin keel is usually

best. Try to find an accessible spot with a mini-

mum dead rise angle.

c. On planing powerboat hulls, the transducer

should be mounted well aft and close to the keel

to insure that the transducer is in contact with

the water at higher boat speeds.

On inboard/outboard boats, transducer mounting

close to the engine usually yields good results.

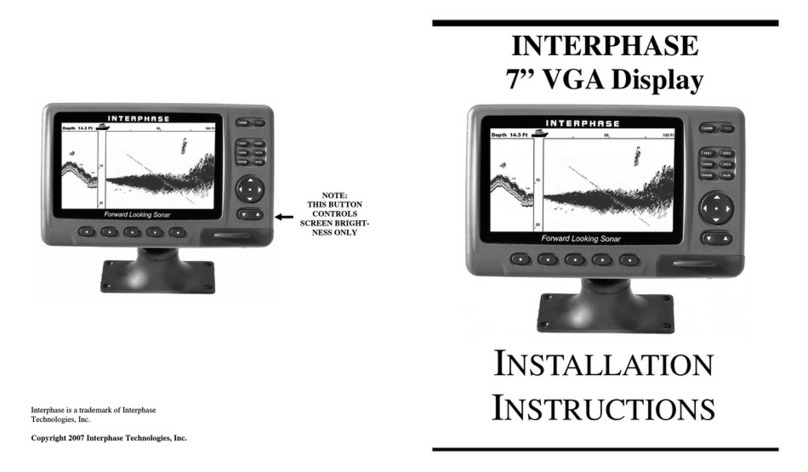

Suggested Thru-Hull

Transducer Locations

Fin Keel

Planing Hull

Displacement Hull

14

On inboards always mount the transducer well

ahead of the propeller(s). Turbulence from props

can seriously degrade performance.

d. Mount the transducer on the side of the hull

where the propeller is moving downwards. The

upward motion of the propeller generates pres-

sure waves and pushes bubbles up against the

hull.

IMPORTANT:

1) Make sure the water flow across the thru-hull

transducer is free of bubbles and turbulence at

all speeds if good performance is to be achieved.

2) Make sure the transducer has an unobstructed

view of the water ahead and below the boat.

3) On displacement-hull power boats, the trans-

ducer should be mounted relatively close to the

center line of the hull.

4) Mount the transducer in a place which has rea-

sonable access from inside the vessel since the

transducer’s bronze nut will require tightening

from inside the hull.

The transducer must be mounted so that it’s bronze

stem is as perpendicular to the water line as possible.

If necessary, use a fairing block to properly position

the transducer.

Using a Fairing Block

Nearly all vessels have some dead-rise angle at the

transducer mounting location. If the thru-hull trans-

ducer were mounted directly to the hull, the sound

beam would be tilted off the vertical at the same an-

gle as the dead-rise. Most thru-hull installations will

require a fairing block to insure the transducer is

mounted properly.

A fairing block is typically made of teak or ma-

hogany wood or plastic and should be glued between

the transducer and the hull (both inside and outside)

to insure that the transducer’s mounting shaft is per-

pendicular to the water’s surface. Make the fairing

block as smooth as possible, and not bigger than the

Fairing Block Before Cutting

KEY -

matches hole

in

transducer’s

body (keeps

transducer

properly

positioned)

WARNING

DO NOT install a bronze transducer

housing directly into an aluminum or steel

hull because electrolytic corrosion will

occur.

15

transducer’s face, to minimize possible turbulence

(see below).

After cutting the fairing block, trial-fit the block to

the hull. It is very important that the flat top surface

of the transducer be parallel to the water.

Thru-hull Mounting

Take the following steps to mount the thru-hull

transducer:

1) Drill a 1/8” pilot hole from inside the hull to

assure access to tighten the housing nut and

clearance for the transducer cables. If there is

any hull irregularity near the selected mounting

location, it may be desirable to drill from the

outside.

2) Use a 1” hole saw and drill the hole from the

outside of the hull. Sand or clean the area

around the hole, inside and outside to insure

that the sealing compound will adhere properly

to the hull. Select a marine grade bedding/

caulking compound and use according to the

instructions.

3) Remove the bronze hex nut from the housing

and cables.

4) Uncoil the two transducer cables and thread

them through the hole to the inside of the hull.

Apply a 1/8” thick layer of sealant on the upper

flat surface of the bronze housing and fairing

block (if used).

5) From the outside of the hull, push the cables

and housing into the 1” hole. Twist the housing

Hull

Hull

Waterline

Waterline

Keep parallel

to waterline !

Keep parallel

to waterline !

Forward

Transducer

Mount the Transducer so it is Vertical

Make Sure “Blunt Side” of Transducer is

Pointed Forward

Side View

Top View

Forward

Direction

WARNING

DO NOT apply tension to the transducer

cables as this may sever internal connections.

16

slightly to squeeze out excess sealant. Care-

fully confirm that the transducer is aligned

so that the blunt rounded end (the front) is

pointed directly toward the front of the boat.

6) Install and tighten bronze hex nut (allow for

swelling in wooden hulls). Do not over-tighten

nut - especially if a wooden fairing block is

used as it will expand in water.

7) Remove excess sealant from the outside to as-

sure smooth water flow over the transducer.

Transducer

Wood or

Plastic

Fairing

Block (Add

sealing

compound

between

faring block

& hull).

Boat’s

Hull

Bronze Nut

WARNING

Wood hulls and fairing blocks will expand

after the boat is put back into the water, so it is

important that the transducer be only hand-

tightened until the wood fully expands.

Otherwise the wood fairing block may crack.

WARNING

Be sure to check for leaks when the boat is

placed in the water. Allow at least 24 hours

after installation for any leak to appear.

IMPORTANT NOTE

If the boat is kept in saltwater it is

recommended that the transducer be coated

with an anti-fouling paint. USE ONLY

WATER BASED ANTI-FOULING PAINT.

DO NOT USE KETONE-BASED PAINTS.

Ketone-based anti-fouling paint will attack the

plastic materials used in the transducer.

17

Acoustic Interface

Module Installation

The black box that came with your PC/View is called

the Acoustic Interface Module. It houses the trans-

mitters and receivers that communicate with the

transducers. The Acoustic Interface Module must be

connected to the parallel port of the on-board com-

puter, to the transducers and to a source of 12 VDC

power.

1) Select a location to mount the Acoustic Interface

Module. Keep in mind that the unit must be

protected from from moisture and extreme tem-

peratures. Also, you will need to route the 10’

computer parallel cable, the power cord and

transducer cables to the location that you

choose.

2) Connect the two-pin plug on the end of the

power supply cable to the power supply jack on

the back panel of the Acoustic Interface Module.

Connect the red wire to the positive terminal

and the black wire to the negative terminal of

your boat’s 12 VDC battery.

3) Connect one end of the parallel cable to the con-

nector labeled PARALLEL PORT on the back

panel of the Acoustic Interface Unit. Connect

the other end of the parallel cable to the parallel

port on your computer.

4) Connect the two transducer cables to the match-

ing ports on the back panel of the Acoustic In-

terface Module:

Cable label Panel label

HORZ HORZIZONTAL TRANSDUCER

VERT VERTICAL TRANSDUCER

WARNING

Signals transmitted through adjacent cables

can interfere with one another. Thus, it is

advisable, where possible, to route sensitive

cables and antennas so that they do not run

adjacent to or parallel to one another.

PARALLEL PORT

12 VDC

1 AMP

P/N X1-VIEW-WIN made in Santa Cruz, CA, USA

Power Supply Jack

Transducer Connectors

Parallel Ports

(use either one)

Acoustic Interface Module

Back Panel

HORIZONTAL

TRANSDUCER VERTICAL

TRANSDUCER

18

Software Installation

The PC/View software includes a group of program

files and a demonstration data set. These files will

all be automatically copied to your computer’s hard

disk during installation.

The total size of the PC/View installation is about 3

megabytes. We recommend that you make sure that

there is at least 10 megabytes of free space on your

hard drive before you begin the installation. If you

plan to save screen-captured images, you will need

additional space. We recommend beginning with a

minimum of 20 megabytes of free space.

PC/View will run only on a computer with Microsoft

Windows 95, 98 or NT. This is because PC/View is

a 32-bit program which uses true multi-tasking and,

thus, requires a 32-bit operating system.

Take the following steps to install PC/View on your

Windows 95, 98 or NT computer:

1) Exit all programs that are currently running.

2) Insert the PC/View Disk 1 into your computer’s

A drive (or B drive).

3) From the Start Bar, select Run. Browse to find

Setup.exe on the A: (or B:) drive or type

A:\setup (or B:\setup). Click on the OK button

to begin the installation.

4) Follow the Setup instructions in each dialog box

that is displayed. Click the Next button to ac-

cept the defaults.

The second dialog box (shown at right) will

prompt you to accept the default destination

folder for the PC/View files or select a different

folder. The default destination folder is:

C:/Program Files/Interphase/PCView

The third dialog box will prompt you to select a

destination for the PC/View icon in your Win-

dows Start Bar.

PC/View’s Operating Software is lo-

cated on the two 3.5” diskettes that are

included with your system.

NOTE

If you are not running Windows 95, 98 or

NT on your computer but instead are using

Windows 3.1 or a version of DOS (6.0 or

greater), you need PC/View for DOS.

INTERPHASE

PC/VIEW™

Operating Software

Disk 1

19

5) When you are prompted by the Setup program, as

shown below, remove Disk 1 from your floppy

drive and insert Disk 2.

6) The Setup program will prompt you to restart your

computer after it has completed the installation.

You do not have to restart your computer immedi-

ately but you must restart it before you can run

PC/View.

20

Running PC/View

To start the PC/View system, turn the Acoustic Inter-

face Module power switch ON. Then run PC/View

by clicking on the Windows Start Bar. Select Pro-

grams and PCView, then click on the PCView icon.

Alternatively you can click on the Windows Start

Bar, select Run... and type in the path and name of

the PC/View program (C:\Program

Files\Interphase\PCView\PCView.exe).

Each time you run PC/View, you will be prompted to

agree with the Warranty Terms and acknowledge

that you have read the Navigation Warning. After

you have read this agreement once, the appearance of

the box will serve as a reminder of the limitations of

navigation aids. Use the scroll bar to move through

the text then click on the I Agree button to run PC/

View.

If all components have been installed and all cables

are connected, and the Acoustic Interface Module is

on, PC/View will immediately begin to collect and

display data. Take the following steps to adjust PC/

View for basic operation:

1) Set defaults as described below. Be sure that

Auto Gain and Auto Range are off.

2) Select a display (see p.26).

3) Select a range setting that is slightly greater

than your current water depth (see p.30).

4) Adjust the gain by first turning it down until no

imagery is visible on the display. Increase the

gain until you begin to see noise, then decrease

the setting by one (see p.30).

Defaults

The default settings for many of the PC/View fea-

tures are shown in the table at left. Hard defaults are

always reset when you exit the program. Soft de-

3 Quick Start

Parameter Menu Default Type

Auto-Screen Capture File Off Hard

Color Setup Normal Soft

Units Setup Feet Soft

Surface Masking Setup Off Hard

Depth Threshold Setup Normal Hard

Auto Gain Adjust Off Hard

Gain Adjust 32 Soft

Auto Range Adjust Off Hard

Range Adjust 25 Feet Soft

Alarm Adjust Off Hard

Sector Width Adjust 90 Degrees Soft

Sector Steer Adjust 45 Degrees Soft

Scan Mode Adjust Normal Soft

Scan Method Adjust Swept Soft

Zoom Adjust Off Soft

Table of contents

Other Interphase Sonar manuals

Interphase

Interphase Matrix User manual

Interphase

Interphase 180 User manual

Interphase

Interphase PC/180 User manual

Interphase

Interphase Advantage User manual

Interphase

Interphase Color Twinscope User manual

Interphase

Interphase Spectra User manual

Interphase

Interphase Color Twinscope User manual

Interphase

Interphase Outlook User manual

Interphase

Interphase Proble User manual

Interphase

Interphase Sea Scout User manual