Interphase Advantage User manual

1

O

PERATION

M

ANUAL

ADVANTAGE

2

To Our Customer:

Thank you for choosing the Interphase Advantage Dual Frequency Sonar. Throughout the

development of this fine product, we have been primarily concerned with creating a unit that

offers the best possible value for your money. Selection of features, ease of use, superior

performance and outstanding reliability were the benchmarks upon which all important design

decisions were made. We feel proud of the Advantage and your satisfaction is very important to

us. To this end, we welcome any comments or suggestions that you might have in regard to this

equipment.

It is very important that you complete and return the WARRANTY REGISTRATION CARD

within 15 days of purchase so that your unit may be protected under the warranty.

Sincerely,

INTERPHASE TECHNOLOGIES, INC.

©2005 Interphase Technologies, Inc.

Interphase Advantage™ is a trademark of Interphase Technologies, Inc.

Publication # = Advantage 4.3

3

Table Of Contents

Important Notice 5

Principle of Operation 6

Display Unit Installation 8

Transducer Installation 10

Basic Operation 18

Getting Started 22

Set-Up View 24

Demo Program 24

Units of Measure 24

Language Selection 25

Display Contrast 25

Plot (Track Plot) View 26

Range 26

Mark 26

Center 27

Reset 27

Transmit Power Adjustment 28

Frequency Selection 29

Chart View 30

Range Adjustment 30

Sensitivity Adjustment 30

Bottom Hardness 32

Alarm Adjustment 32

Zoom & Bottom Track 33

Fish Symbol ID & Scrolling Speed 34

Data View 35

Range Adjustment 35

Log Reset 35

Speed Calibration 35

Sensitivity Adjustment 35

Alarm Adjustment 36

Chart/Plot View 37

Range 37

Mark 37

Center 38

Reset 38

NMEA 0183 Interface 39

Interpreting the Advantage’s Display 40

Maintenance 42

Troubleshooting Guide 43

Interference Problems 44

Specifications 45

How To Obtain Service 46

Warranty 47

4

General Information

T

hank you for your selection of the Interphase Advantage

High Power Dual Frequency Sonar. The Advantage’s

ruggedly built, compact design makes it ideal for installation

on nearly any boat. It will display water depth, bottom

conditions and submerged objects such as fish, on its high

resolution display. The Advantage is available with either a

combination transom or a bronze thru-hull depth/speed/

temperature transducer.

The Advantage has an unprecedented number of advanced

features, to make your boating safer and your fishing more

productive. Its high resolution SuperTwist Liquid Crystal

Display (LCD) provides split screen views of 4X

magnification zoom and bottom lock, large digital display,

speed and temperature history graphs (with the speed/

temperature transducer). You will appreciate the very useful

features of fish and depth alarms, manual or automatic gain

control, bottom hardness indicator and fish symbol

identification.

The Advantage allows operation in your choice of nine

languages: English, French, Italian, Spanish, German, Danish,

Finnish, Swedish, or Greek. Power-off memory saves

language, depth range, gain and contrast settings, screen

advance speed and location in screen menu. Due to its unique

multi-tasking operation, the Advantage provides instant full

screen updates when switching between modes (no data loss).

If you have your Advantage interfaced with a Loran-C or GPS

unit, you can take advantage of the included track plot

displays. The Loran-C, DECCA, and GPS track plot displays

on the Advantage give a whole new dimension, by enabling

you to not only see the depths beneath your boat, but also to

see a graphic display of your boat’s position and progress over

time. The track plot display makes it easy to find and return to

the same fishing spot, or to troll back over the same productive

areas.

To ensure that you receive the maximum benefits available

from the outstanding features of the Interphase Advantage,

please carefully follow the steps outlined in this manual. An

instructive demonstration simulator has been designed into the

Advantage and we highly recommend that you spend some

time using the demo mode prior to actual use of the unit. We

also recommend that you read this entire manual before

attempting to either install or operate your Advantage.

5

Warranty Information

Interphase provides a limited warranty on the Advantage

Dual Frequency Sonar. We strongly urge you to read this

warranty (reprinted at the back of this manual) and closely

follow its terms and conditions should your Advantage require

repair. It is highly recommended that you save all packing

materials so that if you should need to send in the unit for

repair, it can be fully protected. If you wrap your display unit

in the original plastic bag and ship it in the box with cardboard

inserts, this will protect your unit from scratches and shock

during shipment. You do not need to include the mounting

knobs or mounting bracket, however, try to include the

transducer whenever possible. Do not send the power cable

with the unit unless you need it tested for continuity or correct

polarity (Pin #1 to Red Wire).

Should you experience a problem with your Advantage, first

refer to the Troubleshooting section (Page 43) of this manual.

Most common problems and their solutions are described here.

If problems persist, call Interphase Technical Service at

(831) 477-4944. We will be happy to try to assist you, and if

required, we will give you instructions on how to quickly get

your set repaired.

The enclosed warranty registration card must be completed

and returned to Interphase within 15 days of purchase so that

your unit may be protected under the warranty. Failure to

return the warranty card may cause unnecessary delays in

processing your unit for warranty repair.

WARNING

Navigation based solely on one method or

one instrument should never be practiced.

While the Advantage can be quite useful in

showing underwater structure and changing

bottom conditions below your vessel, there

are many situations and conditions which

can cause erroneous or distorted readings.

In addition, there are many situations that

can cause “blind spots” in the Advantage’s

field of view including the presence of

temperature inversion layers (thermoclines),

water turbulence, and high concentrations

of suspended particles in the water.

While the Advantage may be considered as

a useful aid to navigation, it should never be

the only means of navigation.

IMPORTANT NOTICE

As sonar technology advances, there is a

strong possibility that we will develop

many new and exciting features in the

future. We would like to make sure we can

send you information about these new

features and enhancements.

Please fill out and return the Warranty

Registration Card immediately. This is our

only method to keep in contact with you

and we may want to advise you of future

enhancements to your Advantage.

If future changes or improvements are

made, software upgrades will be available

for a nominal charge.

6

Principle of Operation

The Advantage Dual Frequency Sonar uses a proprietary

acoustic technology to develop short high energy underwater

acoustic signals that can detect submerged objects and

changing bottom conditions far below your boat. Because of

it’s extremely high pulse power and outstanding receiver

sensitivity, the Advantage can probe the water beneath your

boat to depths of 2,000 feet.

The Advantage Sonar system consists of an LCD display

module and a multi-featured dual frequency transducer. The

transducer contains a single specially designed piezoelectric

ceramic element that can operate at both 200 and 50 kilohertz.

When operating, the Advantage Display module converts a

small amount of electrical current from your battery into short

bursts of high energy electrical pulses. These high energy

pulses are fed to the transducer where they excite the dual

frequency ceramic element. When excited by these electrical

bursts, the ceramic element converts them into a strong

underwater acoustic signal. These acoustic signals travel out

from the transducer in a cone shaped pattern, called the cone

angle.

When the ceramic element in the transducer is excited with a

200 kHz electrical signal, the resulting acoustic cone angle is

approximately 15 degrees and increases to about 45 degrees

with a 50 kHz signal. When the acoustic pulse strikes an

underwater object, it is reflected back (echo return), received

by the same ceramic element in the transducer, and converted

back into small electrical impulses. These impulses are

amplified, then displayed as an image on the LCD screen after

processing by the display module’s microprocessor.

The strength of the echo, the depth of the object, and the angle

of the transducer’s beam all affect how the image appears on

the display. Other factors which affect the image include boat

speed relative to the movement and position of the underwater

target and the number of objects reflecting pulses back to the

Advantage.

The Advantage’s transducer also includes a sensor for

measuring the boat’s speed through the water and the water’s

temperature at the transducer.

Because the Advantage can operate at either 200 or 50 kHz, it

offers several advantages over single frequency depth

sounders. This is because acoustic signals at different

frequencies behave quite differently and each has it’s own

7

benefit, and drawbacks. For example:

1) 50 kHz signals can penetrate to much deeper depths

than 200 kHz signals. Even with high power, 200

kHz signals usually can not reliably penetrate

beyond 1,200 feet while 50 kHz signals can easily

reach depths beyond 2,000 feet.

2) 200 kHz signals typically give much better

resolution and definition to bottom structure in the

shallower depths. If you see a return echo from the

200 kHz signal, you can be pretty sure the object

which caused the echo is almost directly beneath

your boat.

3) 50 kHz signals cover a much wider area (cone or

beam angle) than 200 kHz signals. This can be very

useful when searching for bait, bottom structure or

even when monitoring the depths or tracking

downrigger weights.

4) 200 kHz and 50 kHz signals react differently when

they strike underwater schools of bait and encounter

temperature inversion layers. With experience, you

can use the two different frequencies to better

understand and interpret underwater signals.

The Advantage allows you to view the water beneath your

boat with either a full screen 200 kHz view, a full screen 50

kHz view or a split screen dual frequency view. In the split

screen dual frequency view the Advantage alternately pulses

the transducer with each frequency and then displays the

returning echoes.

The Advantage’s unique variable output power system allows

you to manually adjust for optimum power transmission in

either shallow or deep conditions. In shallower water you can

reduce the output power to help reduce screen clutter from

unwanted objects, while in deeper water the power can be

adjusted upwards to achieve outstanding depth penetration and

fish detection.

8

Installation

Display Unit

The compact size of the Advantage display unit allows

for easy installation in almost any vessel. To get

maximum performance and life from your unit, the

following guidelines should be considered when selecting

a mounting location:

1) Select a location where the unit is protected from

excessive temperatures. Heat is one of the worst enemies

of electronic components, and will accelerate component

aging, thereby reducing the trouble-free life of your

Advantage.

2) Mount the display in a location where it will be

convenient to route the power cord and transducer cable.

Power connection

Connect the two-pin plug on the end of the power supply

cable to the power supply jack located at the rear of the

main display unit. Connect the red wire to the positive

terminal and the black wire to the negative terminal of

your boat’s 12 DC battery.

To minimize electrical interference, carefully route the

power cable so that it does not run parallel or close to the

transducer cable, engine, refrigeration, bilge pump or any

other critical wiring.

IMPORTANT: The Advantage’s 12 VDC power leads

should go directly to the boat’s battery, distribution board,

or breaker panel. Instability of the display may result if

the unit has to share leads with other electrical systems

aboard your boat.

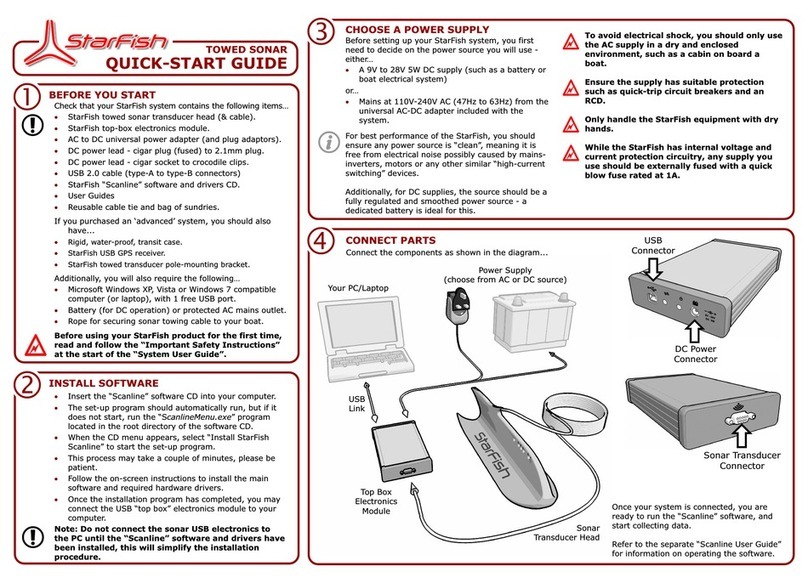

Wiring for Power and Transducer

Connectors

The correct pin-out wiring sequences for the power and

transducer connectors are shown at right. DO NOT

SHORTEN THE TRANSDUCER CABLE. If a

transducer cable longer than the 30’ length supplied with

your unit is needed, please contact your Interphase

dealer. A 30-foot transducer extension cable is available.

(P/N # 04-0009-008)

Shelf/Table

Overhead

Panel Flush Mount Installation

Optional flush mount bracket available

Interphase part # 17-0054-008

9

DANGER: Removal of any connector, disassembly of

transducer, shortening of any cable or use of any cable

other than that supplied by Interphase will void your

warranty (no exceptions).

Cable Connectors

(view from front of female plug)

9 Pin Spare:

(Not Used - reserved for

future use)

8 Pin Transducer:

1 Speed Data

2 +5VDC

3 Depth element

4 Depth shield

5 Depth element

6 +Temp. Sensor

7 -Temp. Sensor

8 Shield/Ground

Power Connector:

1 +12 vdc

2 - (Ground)

NMEA Input:

1 Data

2 Return ( Ground)

3 N/C

N/C = No Connection

12 Volt Battery

Red Wire NMEA 0183

Input (3-pin)

Spare

(9-pin)

12 VDC

Power Cable

(2-pin)

Transducer:

Depth /

Speed /

Temp.

(8-pin)

10

Transducer Installation

The Advantage comes standard with either a transom

mount or thru-hull style transducer. The transducer

includes both a speed and temperature sensor which

allows the Advantage to display current boat speed,

surface water temperature and elapsed distance in

addition to the depth below the boat.

IMPORTANT: If for any reason you prefer another type

of transducer available through Interphase, we will

exchange your unused transducer for one of your choice.

In some cases an additional cost may apply. Contact

Interphase’s Accessory Sales Department (831) 477-

4944, extension 14 for additional information.

The Advantage’s transducer contains a single ceramic

element which will operate on both the 200 kHz and 50

kHz frequency. The Advantage has an amazing amount

of capabilities, but it can not perform magic. It can not

see through objects such as your boat’s hull. Therefore, it

is important to position the transducer so that it has as

clear a view as possible of the water below your boat, as

indicated in the top left illustration.

The sketch at left shows the proper orientation for both

the transom mount or the thru-hull transducer.

General Considerations

DO NOT CUT OR SPLICE YOUR TRANSDUCER

CABLE OR REMOVE THE 8-PIN CONNECTOR .

THIS ACTION WILL VOID YOUR WARRANTY.

If you need a longer length cable than comes with the

transducer (30’), then purchase the optional 30’ extension

cable, Interphase Part # 04-0009-008.

In addition to the above, the following considerations

should be observed:

1) Choose a location where there is the least

amount of acoustic noise, air bubbles or turbulence

caused by the boat’s movement. The transducer should

not be located nearby or especially directly behind the

propeller.

Dual Frequency (Two Cone Angles)

200 kHz

50 kHz

Transom Mounted Transducer

Thru-Hull Transducer

Front

Front

11

2) Choose a location where the transducer can be

mounted so that it will be level to the water’s surface and

will not be tilted to either side.

3) The transducer must always remain submerged,

regardless of the speed of the boat and should not be

mounted where it could be damaged by underwater

obstacles or when loading on a trailer.

4) DO NOT locate the transducer in the extreme

bow of the boat where it will be subject to intense

turbulence as the boat pounds through the water.

5) DO NOT locate the transducer directly behind

any hull protrusion which will cause the water to be

turbulent when it reaches the transducer. For

displacement-hull power and sail boats, the thru-hull

installation is usually required.

DANGER: DO NOT allow any solvents, i.e. gasoline,

acetone, to come in contact with the transducer or head

unit as this may dissolve the plastic material.

Transom Transducer Installation

The transom transducer is attached to the boat with two

stainless steel brackets. The brackets should be mounted

to the ears on the top of the transducer using the hardware

supplied. All metallic parts are stainless steel to resist

corrosion. Good operation up to 40 - 50 MPH is usually

possible. Obtaining operation at higher speeds is possible

but may require considerable experimentation with

transducer positioning.

Transom Mounting Location

On single drive installations, it is strongly recommended

that the transducer brackets be mounted on the side of the

boat where the propeller blade is rotating downwards

which usually is the right (starboard) side. To reduce the

possibility of disturbing the water flow to the propeller,

the transducer should be located about 2” outside the

swing of the prop. If possible, the transducer and bracket

should not be mounted directly behind any strakes, ribs,

intakes and outlets for live wells and/or engine cooling

water, or any protrusion which may cause turbulence or

cavitation. For dual engine installation, just off the center

line is usually acceptable.

30’ Extension Cable

8-pin

Male 8-pin

Female

Interphase Part #

04-0009-008

Transom Mount Locations

18 - 24"

Cables

Twin Outboards

Transducer

Cable

12

Attaching the Transducer to the Bracket

Assemble the mounting bracket to the transducer using the 4

screws, washers and lock nuts provided. The bracket arms

must be mounted outside the plastic mounting ears of the

transducer. Do not fully tighten the lock nuts at this time.

Mounting the Transducer to the Boat

1) Place transducer and bracket at the selected location

on the boat’s transom. Align the bracket so that the bottom

surface of the transducer is about 1/4” below the underside of

the boat’s hull. (See figure at bottom left). Good results can be

achieved on most boats when the bow of the transducer is

about 1/4” below the hull. It is not recommended to place the

transducer further down than necessary because it increases

drag and spray, reduces boat top speed and increases water

noise generated by the transducer.

2) Mark an outline of the slot locations on the hull.

Mark the screw locations in each slot outline as shown in the

sketch at the top left of the following page. Drill four holes,

each 1/2” to 5/8” deep using a 9/64” drill. (Masking tape

wrapped around the drill 5/8” back from the point is one

method to prevent drilling too deep.) Also, in fiberglass hulls,

chamfer the gelcoat to prevent surface cracks. Drilling first

with a 1/4” drill about 1/8” deep is an easy way to prevent

surface cracks.

3) Using the four panhead sheet metal screws provided,

attach and tighten the bracket to the hull so that the transducer

projects 1/4” below the underside of the hull. Align the fore/

aft angle of the transducer so that the rear is approx. 1/8” lower

than the forward point. (See figure at right on following page).

Tighten the four transducer bolts and the four sheet metal

screws.

4) Route the cable to the Advantage display being

careful not to tear the cable jacket when passing through

bulkheads, etc. To reduce electrical interference, keep the

transducer cable separated from ignition, tachometer,

alternator or other electrical wiring. Secure the transducer

cable in place with “tie-wraps” or lacing twine.

5) Do not remove the connector or cut or splice the

cable to ease cable routing. Either cut holes large enough to

pass the connector or choose a different route to the display.

Connector removal or cable splicing voids the transducer

warranty. Flake out any excess cable and secure in place.

Rear View

Side View

Attach Brackets to Transducer

Boat’s Hull

1/4”

Bottom of Transducer 1/4” Below Bottom of

Hull

13

Testing

After connecting the transducer to the Advantage display, a

test of installation should be conducted. After becoming

familiar with the Advantage’s performance at speeds of 5 to 6

knots, gradually increase your boat’s speed. As the boat speed

increases, there will be a gradual degradation of the

transducer’s performance because flow of water over the

transducer generates acoustic noise. If you’re in the manual

gain mode (not Auto Gain), you may have to increase the gain

setting to get a clear bottom reading. When aeration of the

transducer occurs, the degradation is usually not gradual, but

sudden. If this occurs, note the boat’s speed and gain setting at

the onset of the degradation. Remove the boat from the water

and recheck the alignment of the transducer. If necessary,

readjust the bracket to make sure the rear of the transducer is

approx. 3 to 5 degrees (1/8”) below the front as shown in the

sketch at bottom right. If the transducer alignment is correct,

then lower the transducer 1/4” further below the hull and

repeat the test. If still unsatisfactory, try a new location closer

to the center keel where aeration is usually less pronounced.

Remember to fill unused screw holes with sealant.

To overcome the effect of surface roughness on aluminum

boats, it may be necessary to move the transducer down so that

it projects 1/2” to 3/4” below the transom. On a few hull types

specifically designed to direct air under the hull, moving the

transducer away from the keel can improve performance.

3 degrees

Line of Hull

Attach Brackets To Stern Of Boat

Bottom of Boat’s

Hull

Angle Rear of Transducer Slightly (3 to 5

degrees) Below Front.

Mark Hull

Before Drilling

14

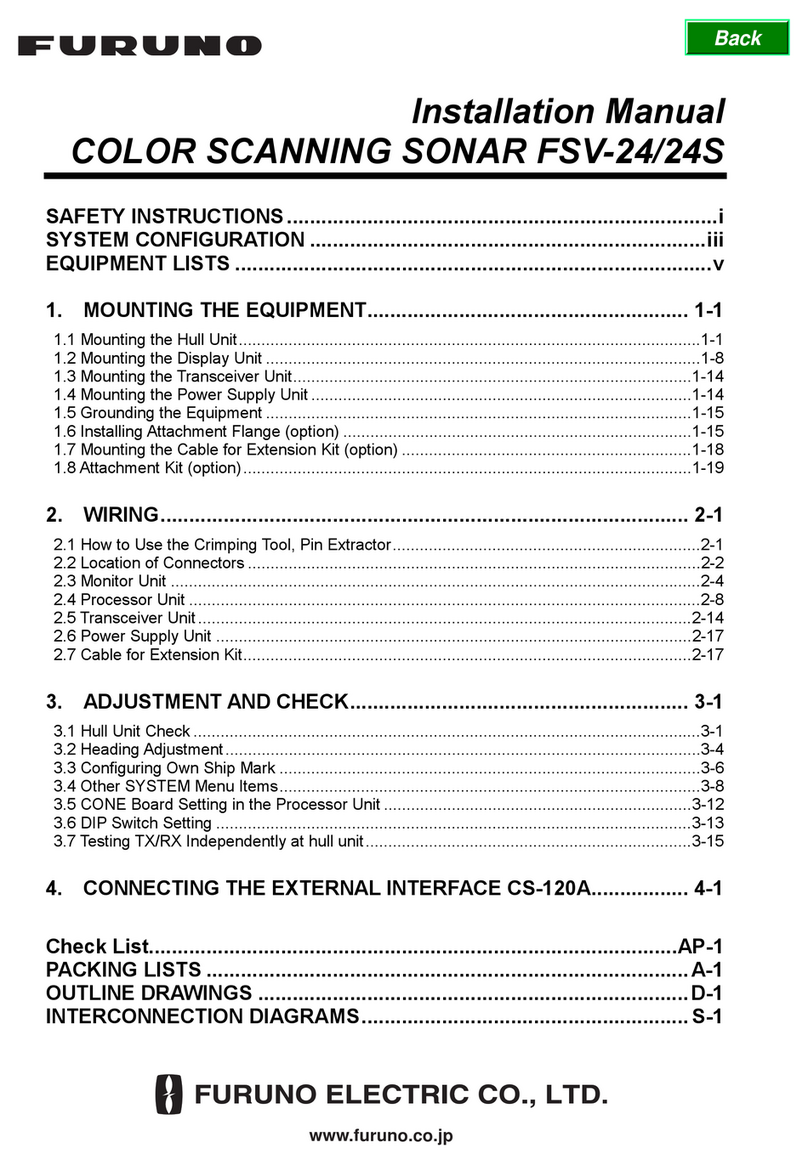

Thru-Hull Transducer Installation

The thru-hull transducer is the recommended choice for

larger boats with in-board engines. Thru-hull mounting is

usually required on larger power and sail craft. The

Advantage must have a clear view of the water below as

it can not magically see through obstructions such as the

vessel’s hull. Please read the following carefully before

starting the thru-hull installation.

Normally, thru-hull installations are performed by a

professional in a boat haul-out facility and you may want

to seek professional assistance before attempting to mount

this transducer.

Selecting the Best Location

The best location to mount the thru-hull transducer will

vary with the type of boat. Try to find a location with the

smallest dead rise angle to make installation easiest.

Consider that from time to time you will need to

remove the speed/temperature plug (from within the

vessel) in order to clean the speed paddle wheel. Make

sure you choose a location that is easily accessible

from inside the vessel!

a. On displacement hulls (sailboats, trawlers, etc.) locate

the transducer about 1/3 aft along the waterline.

Generally this provides the best compromise between

obtaining aeration-free water and minimizing propeller

noise. The Advantage’s transducer can not see through

aerated water and water near the bow and near the keel

can be quite aerated. Aeration of the transducer can be

minimized by keeping the transducer mounted away from

the keel and by not mounting too far forward.

b. On sailboats, the transducer should be mounted where

the acoustic beam will not be shaded by the keel. Try to

find an accessible spot with a minimum dead rise angle.

c. On planing powerboat hulls, the transducer should be

mounted well aft and close to the keel to insure that the

transducer is in contact with the water at higher speeds.

On I/O’s, transducer mounting close to the

engine usually yields good results.

(Transducer in front of propeller.)

On inboards always mount the transducer

well ahead of the propeller(s). Turbulence

from props can seriously degrade perform-

ance.

(Thru-hull installation is recommended.)

15

d. Mount the transducer on the side of the hull where the

propeller is moving downwards. The upward motion of

the propeller generates pressure waves and

pushes bubbles up against the hull which can then flow

across the transducer’s face causing a loss of signal.

DO NOT install a bronze transducer housing directly into

an aluminum or steel hull because electrolytic corrosion

will occur.

IMPORTANT:

1) Make sure the water flow across the thru-hull

transducer is bubble and turbulence free at all speeds if

good performance is to be achieved.

2) Make sure the transducer has an unobstructed view of

the water below the boat.

3) On displacement-hull power boats, the transducer

should be mounted relatively close to the center line of

the hull.

4) Mount the transducer in a place which has reasonable

access from inside the vessel since the transducer’s speed/

temperature plug will need to be removed from time to

time. Also, during installation, the bronze nut will require

tightening from inside the hull.

The transducer must be mounted so that it’s bronze stem

is as perpendicular to the water line as possible. If

necessary, use a fairing block to properly position the

transducer.

Use of a Thru-hull Fairing Bl

ock

Nearly all vessels have some dead rise angle at the

transducer mounting location. If the thru-hull transducer

were mounted directly to the hull, the sound beam would

be tilted off the vertical at the same angle as the dead-rise.

Most thru-hull installations will require a fairing block to

insure the transducer is mounted properly.

A fairing block is typically made of teak or mahogany

wood or plastic and should be glued between the

transducer and hull (both inside and outside) to insure that

the transducer’s mounting shaft is perpendicular to the

water’s surface. Make the fairing block as smooth as

possible, and not bigger than the transducer’s face, to

minimize possible turbulence (see next page).

Suggested Thru-Hull

Transducer Locations

Fin Keel

Planing Hull

Displacement Hull

16

After cutting the fairing block, trial fit the block to the hull. It

is very important that the flat top surface of the transducer be

parallel to the water.

Installing the Thru-hull Transducer

1) Drill a 1/8” pilot hole from inside the hull to assure access

to tighten the housing nut and clearance for the transducer

cables. If there is any hull irregularity near the selected

mounting location, it may be desirable to drill from the

outside.

2) Use a 2” hole saw and drill the hole from the outside of the

hull. Sand or clean the area around the hole, inside and outside

to insure that the sealing compound will adhere properly to the

hull. Select a marine grade bedding/caulking compound and

use according to the instructions.

3) Remove the bronze hex nut from the housing and cable.

4) Uncoil the transducer cable and thread it through the hole

into the inside of the hull.

DANGER: DO NOT apply tension to the transducer cables

as this may sever internal connections. Apply a 1/8” thick

layer of sealant on the upper flat surface of the bronze housing

and fairing block (if used).

5) From the outside of the hull, push the cable and housing

into the 2” hole. Twist the housing slightly to squeeze out

excess sealant. Carefully confirm that the transducer is aligned

so that the rounded end (the front) is pointed directly toward

the front of the boat.

6) Install and tighten bronze hex nut (allow for swelling in

wooden hulls). Do not overtighten nut - especially if a

wooden fairing block is used as it will expand in water.

7) Remove excess sealant from the outside to assure smooth

water flow over the transducer.

DANGER: Wood hulls and fairing blocks will expand after

the boat is put back into the water, so it is important that the

transducer be only hand-tightened until the wood fully

expands. Otherwise the wood fairing block may crack.

DANGER: Be sure to check for leaks when the boat is placed

in the water. Allow at least 24 hours after installation for any

leak to appear.

Hull

Hull

Waterline

Transducer

Mount Transducer so it is Vertical

Hex Nut

Fairing

Block

Fairing

Block

17

DANGER: If the boat is kept in saltwater or in an area with

excessive marine growth it is recommended that the transducer

be coated with an anti-fouling paint. USE ONLY WATER

BASED ANTI-FOULING PAINT. DO NOT USE

KETONE BASED PAINTS. Ketone based anti-fouling paint

will attack the plastic materials used in the transducer. See

page 42 for a list of tested paints. This is not an exhaustive

list. If you are using other paints, verify with the paint

manufacturer that the paint does not react with urethane

plastic.

Transducer

Wood or

Plastic

Fairing

Block (Add

sealing

compound

between

fairing block

& hull).

Boat’s

Hull

Bronze Hex Nut

Outer part of

fairing block

18

Basic Operation

The Advantage has been designed to be as easy to learn and

operate as possible. The raised push-button keys provide a

tactile feel to each operation and the Advantage responds with

an audible beep each time a key is pressed. All keys necessary

for operation of the unit are on the front panel. The Advantage

uses a unique approach called “soft keys” along the bottom of

the display. These five keys are labeled by the LCD display and

are controlled by the unit’s software, thus the name “soft keys”.

In addition, a large front panel rotating knob eliminates the need

for multiple button pushes while making gain, depth range,

display contrast and many other adjustments. The knob

provides easy and quick adjustments while giving the user a

familiar style of operation.

The “soft key” buttons allow very easy operation as they almost

guide you along, even though the Advantage possesses an

amazing number of advanced sonar features. It would take a

considerable number of additional buttons and greatly add to the

unit’s operational complexity if each function had a dedicated

button instead of using the “soft key” approach. In addition, the

use of “soft keys”, coupled with the front panel adjustment

knob, allow for easy future software upgrades which may

include new important features. The use of fixed, permanently

labeled buttons would severely limit any future upgrade ability.

User Interface

The Advantage is a very advanced product with many features

never before found on marine instrumentation. In order to

provide these sophisticated new features while continuing to

keep user operation simple and easy to learn, several new design

approaches were adopted. Some of the more significant

approaches are described in the following.

Multi-Tasking Operation

The Advantage’s Multi-Tasking operation was developed to

make sure your time would not be wasted whenever you change

screen displays. When changing displays with other

conventional systems, the microprocessor has to completely re-

assemble a new display picture which can take a considerable

amount of time. These time delays can be very frustrating and

are unnecessary if a Multi-Tasking operating system is used.

Interphase Advantage

Short-cut

In this manual you will find

instruction on how to change all

adjustable settings by using the

“soft keys”. However, any setting

adjustment can be done (when the

appropriate menu selection is made)

by turning the control knob.

Settings which can be adjusted by

using the control knob include:

Range

Alarm

Contrast

Sensitivity

Zoom

Output Power

Frequency Select

LCD screen contrast can be changed

any time while in the Control

Center simply by turning the

control knob.

soft key Power On/

Off

19

Pre-Programmed Screen Displays

Rather than ask you to “build” different screen displays while

operating the unit, the Advantage has seven of the most

valuable LCD screen displays pre-programmed into its

operating system memory. Thanks to the Multi-Tasking

operating system, each of these pre-programmed displays

(known as Views) are always being updated, regardless of

which screen display is presently being used. This means, for

example, that the two Track Plotter’s will continue to plot and

update your vessel’s position - even while you’re looking at a

Zoomed picture of the bottom! Similarly, even while viewing

your vessel’s position on one of the Track Plot displays, the

digital and graphic depth screens are simultaneously being

updated in the background - ready for immediate access. And,

thanks to the lithium battery memory backup, as described in

the next section; ranges, gain, zoom and other settings are

remembered as you go from View to View and are even

remembered when you turn the unit off.

Internal System Memory

There is nothing so frustrating as having your depth sounder

re-start when you start your boat’s engine and having to

completely re-set the range, gain, contrast and all your other

settings. Because the Advantage contains an internal lithium

memory battery, it remembers all system settings with the

power removed. When you turn your Advantage on, it will

immediately start in the last View that you used, complete with

the proper range, zoom, gain and other important settings.

Instead of using a non-volatile RAM, a lithium battery was

used to ensure a long error-free memory life. Most non-

volatile RAM’s exhibit increasing errors with time and can

become a serious problem after only 100,000 operations.

Cold Cathode back light

The Advantage has the best LCD back light system available.

It uses a Cold Cathode Fluorescent lamp (CFL) with

exceptionally long life characteristics which greatly exceed the

more common electro-luminescent and incandescent bulb back

light. In addition to its exceptional reliability, the cold cathode

lamp provides a much more visible display than other back

light systems. Screen clarity and contrast are greatly

enhanced. The typical half-life (when output brightness

diminishes to 1/2 its original value) of the cold cathode back

light is in excess of 20,000 hours. A typical electro-

luminescent panel, for comparison, has a half life of only 2,000

hours!

Interphase Advantage

Control

Knob

Pre-Programmed Screen Displays

20

Common Soft Key Functions

The Advantage’s innovative Multi-Tasking operating system

is controlled through the Control Center, where several

different screen displays (views) can easily be selected by the

push of a button. Each of these screens (views) reside in the

Advantage’s internal memory and all are being updated in the

background, regardless of which screen is currently being

displayed. This allows the Advantage to provide instant full

screen displays of different features with no data loss on other

screens.

On many of the display screens you will note a recurrence of

the left most soft key labeled “MENU”. When the MENU

soft key is pressed, the Advantage will return to the Control

Center display. Use of the MENU soft key is required in

order to return to the Control Center where another mode of

operation (i.e. normal depths, track plotting, etc.) can be

chosen.

Power/back light Key

Press the "Power/back light" key located at the lower right of

the unit to turn the Advantage on. The unit will respond with

an audible beep when it turns on. Pressing this key again turns

the back light on and off, each time accompanied by a beep.

To turn the Advantage off, press this key and hold it down for

several seconds until the unit goes off.

Simulator/Demo Mode

Your Advantage includes a built-in DEMO simulator

program which makes it easy to practice with the unit and to

get a feeling for its many features before actually using it in

real situations on the water. We highly recommend you run

through this section on operation of the Advantage with the

DEMO mode activated to first learn basic feature controls.

The DEMO mode can be started from the SETUP menu as

described in the following section.

Split Screen Displays

The Advantage has several different split screen display

capabilities such as Split Screen Zoom, Split Screen Chart and

Data and Split Screen Chart and Track Plot, among others. It

is important to realize that whatever is displayed on the right

side of the display is the PRIMARY information. This means

that when you are in split screen displays, the soft key menus

will usually only relate to the right side of the display.

Control Center Softkey Menu

Typical Sub-Menu

Table of contents

Other Interphase Sonar manuals

Interphase

Interphase Color Twinscope User manual

Interphase

Interphase Sea Scout User manual

Interphase

Interphase Spectra User manual

Interphase

Interphase iScan V90 User manual

Interphase

Interphase Outlook User manual

Interphase

Interphase Sonar Engine SE-200 User manual

Interphase

Interphase PC/View User manual

Interphase

Interphase Matrix User manual

Interphase

Interphase Sonar Engine SE-200 User manual

Interphase

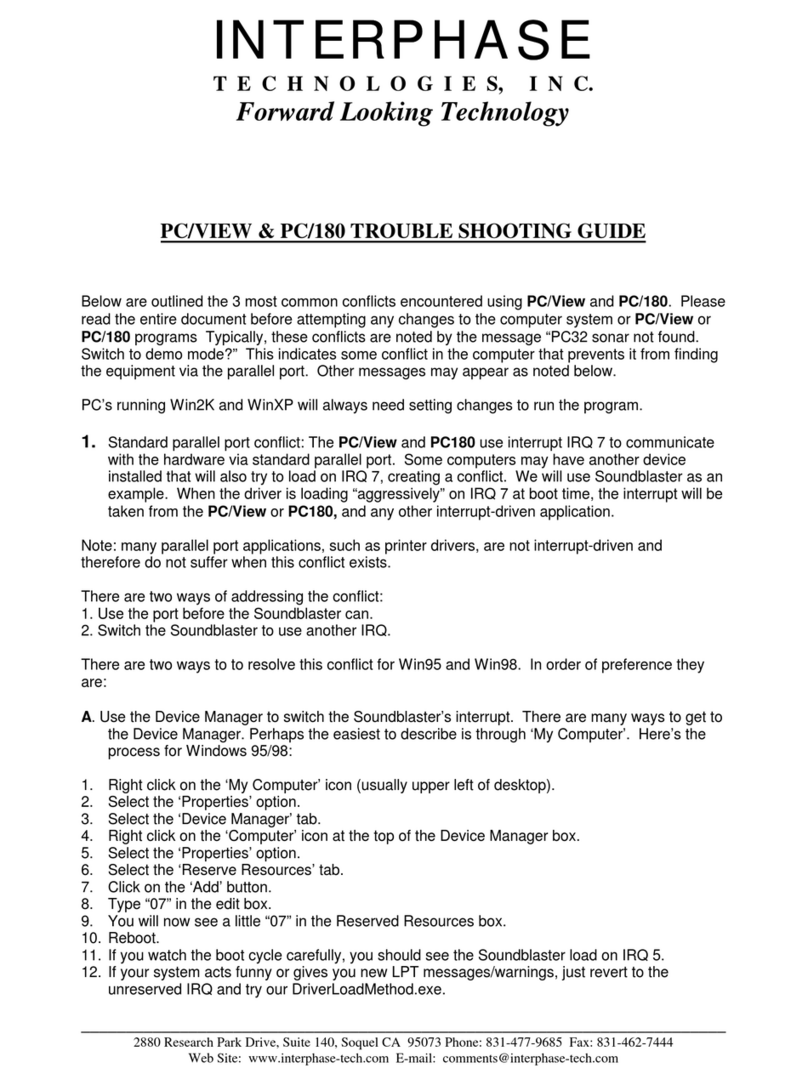

Interphase PC/180 User manual