Interphase Color Twinscope User manual

1

2

To Our Customer:

Thank you for choosing the Interphase Color Twinscope Dual-Axis Forward Scanning

Sonar. Throughout the development of this product, we have tried to make sure that we

included all of the suggestions made by owners of our earlier sonar models. Selection of

features, ease of use, superior performance and outstanding reliability were the benchmarks

upon which all important design decisions were made. We feel proud of the Color Twinscope

and your satisfaction is very important to us. To this end, we welcome any comments or

suggestions that you might have in regard to this equipment.

It is very important that you complete and return the WARRANTY REGISTRATION

CARD within 15 days of purchase so that we have a record of your purchase, both to protect

your warranty and to allow us a method to contact you about future enhancements, etc.

Sincerely,

INTERPHASE TECHNOLOGIES, INC.

2880 Research Park Drive, #140

Soquel, CA 95073

Phone: (831) 477-4944

Fax: (831) 462-7444

Email: comments@interphase-tech.com

Website: www.interphase-tech.com

©2005 Interphase Technologies, Inc.

Interphase Color Twinscope™ is a trademark of Interphase Technologies, Inc.

Publication # = Color Twinscope 1.6

3

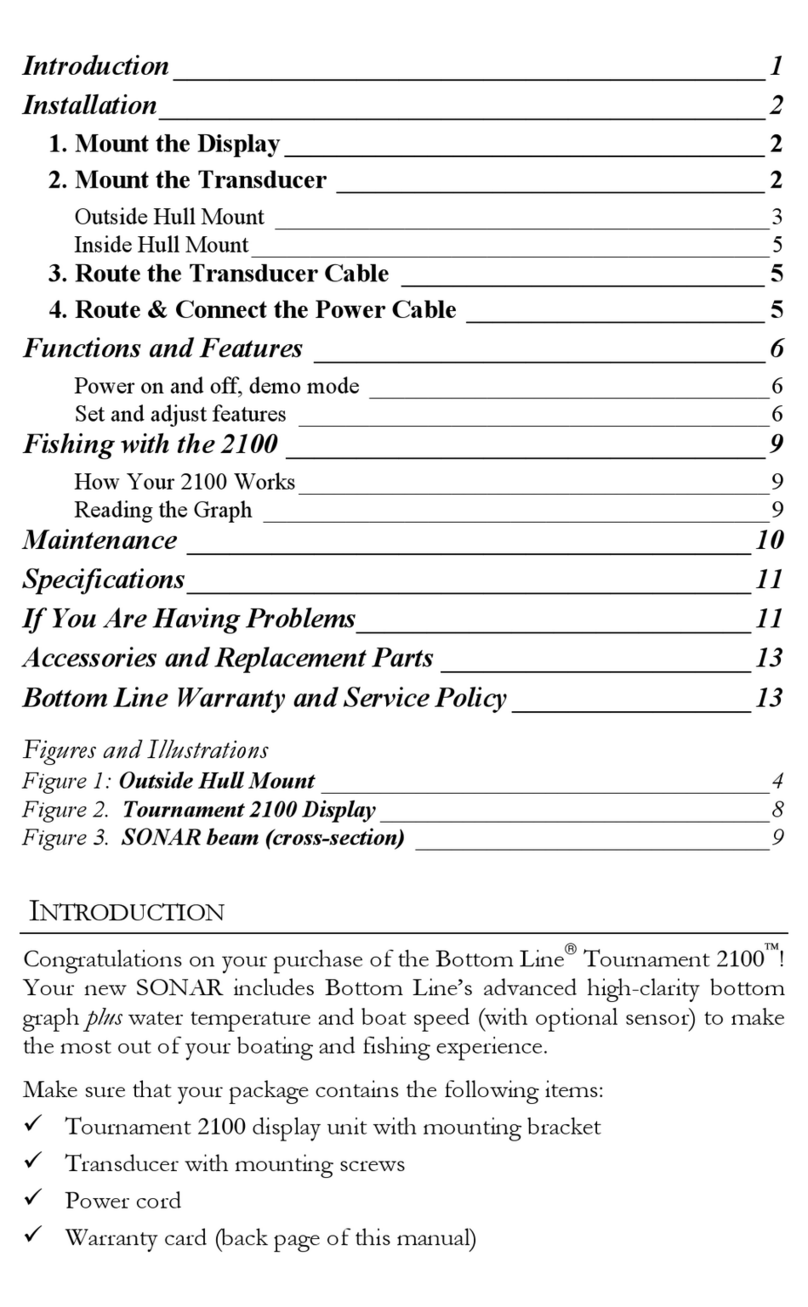

Table Of Contents

Important Notice 4

Principle of Operation 5

Display Unit Installation 6

Transducer Selection and Installation 8

Getting Started 18

Display Colors 19

Set-Up 20

Languages/Units 20

More (Max Gain, Remote/ Master) 20

STC Adjustment__________________________________________________________ 21

Transducer Adjustments 22

Demo 22

System Reset_____________________________________________________________22

Displays 23

Vertical 23

Horizontal 23

Down 24

Down Zoom 24

Data 25

Operating Adjustments 26

Range 26

Gain 26

Screen Cursor 27

Scanning Speed 28

Alarm Adjustment 28

Beam Adjustment 28

Video Input 29

Interpreting the Vertical Display 30

Interpreting the Horizontal Display 32

Inputs and Outputs 34

Video Inputs 34

External Alarm 34

NMEA inputs (GPS, Temp) / NMEA Depth Output 35

Remote Displays (2nd Stations) 36

Software Upgrades 37

Maintenance 38

Trouble Shooting Tips 38

Interference Problems 39

Specifications 40

How to Obtain Service 41

Warranty 43

4

General Information

Thank you for your selection of the Interphase Color

Twinscope Forward Scanning Sonar. The Color Twinscope’s

ruggedly built, compact design makes it ideal for installation

on nearly any boat. It will display water depth, bottom

conditions and submerged objects such as fish, or objects in

your path, on its high resolution display. The Color

Twinscope is available with either a thru-hull or two transom-

mount scanning sonar depth transducers.

To ensure that you receive the maximum benefits available

from the outstanding features of the Interphase Color

Twinscope, please carefully follow the steps outlined in this

manual. An instructive demonstration simulator has been

designed into the Color Twinscope and we highly recommend

that you spend some time using the demo mode prior to actual

use of the unit. We also recommend that you read this entire

manual before attempting to either install or operate your

Color Twinscope.

Warranty Information

Interphase provides a limited warranty on the Color

Twinscope Forward Scanning Sonar which is printed on the

inside rear cover of this manual. We recommend that you save

all packing materials so that if you should need to send the unit

in for repair, it can be fully protected. Should you experience

a problem with your Color Twinscope, first refer to the

Troubleshooting section (Page 38) of this manual. Most

common problems and their solutions are described here. If

problems persist, call Interphase Product Support at (831)

477-4944. We will be happy to try to assist you, and if

required, we will give you instructions on how to quickly get

your set repaired.

The enclosed warranty registration card must be completed

and returned to Interphase within 15 days of purchase so that

your unit may be protected under the warranty. Failure to

return the warranty card may cause unnecessary delays in

processing your unit for warranty repair. (See warranty, page

43).

WARNING

Navigation based solely on one method or

one instrument should never be practiced.

While the Color Twinscope can be quite

useful in showing underwater structure and

changing bottom conditions both below and

in front of your vessel, there are many

situations and conditions which can cause

erroneous or distorted readings.

In addition, there are many situations that

can cause “blind spots” in the Color

Twinscope’s field of view including the

presence of temperature inversion layers

(thermoclines), water turbulence, and high

concentrations of suspended particles in the

water.

While the Color Twinscope can be

considered as a useful aid to navigation, it

should never be the only means of

navigation.

5

Principle of Operation

The Color Twinscope Forward Scanning Sonar uses a

proprietary and patented phased array acoustic technology first

developed for marine use by Interphase Technologies.

Known as “phased array ultrasound technology”, its

capabilities have been proven in the military and medical

industries for many years. The amazing video images

provided by medical ultrasound equipment are familiar to most

people and clearly demonstrate the technology’s ability to

show highly defined images in a "real time" or "live action"

mode.

Interphase’s phased array is a group of piezoelectric ceramic

elements that are precisely sized and spaced. Each element

can send and receive acoustic pulses. When all elements in the

array are sending or receiving acoustic energy at the same

time, the entire array behaves like a single larger element with

one important difference: the ability of the array to concentrate

its acoustic energy in different directions, depending on the

different “phasing” of the signals applied or received by each

element. Depending on the signal phasing of the array,

acoustic beams can be directed in an almost unlimited number

of directions. For example, using an 8 element phased array

transducer, the COLOR TWINSCOPE is capable of steering

the acoustic beam in any of 60 different directions.

Since the acoustic beam in the phased array is steered

electronically, requiring no moving parts, it can be quickly and

reliably scanned and re-scanned over a large area. When

displayed, the changing information between subsequent scans

takes on an almost animated quality - for example, showing

movement of underwater targets such as fish or rapidly

changing bottom conditions.

During operation, the Color Twinscope converts a small

amount of electrical current from your battery into ultrasonic

sound pulses, which are then fed to the phased array

transducer. These acoustic pulses travel out from the

transducer in a cone shaped pattern, called the cone angle.

When the sound pulse strikes an underwater object, it is

reflected back (echo return), received by the transducer and

converted back into small electrical impulses. These impulses

are amplified, then displayed as an image on the LCD screen.

Award Winning

Technology

For its pioneering work in

developing Phased Array

Scanning Sonar,

Interphase Technologies

won the prestigious

IMTEC INNOVATION

AWARD.

The Color Twinscope is

based on this same award-

winning technology.

6

Installation

Display Unit

The compact size of the Color Twinscope display unit allows

for easy installation in almost any vessel. To get maximum

performance and life from your unit, the following guidelines

should be considered when selecting a mounting location:

1) Select a location where the unit is protected from excessive

temperatures. Heat is one of the worst enemies of electronic

components, and will accelerate component aging, thereby

reducing the trouble-free life of your Color Twinscope.

2) Mount the display in a location where it will be convenient

to route the power cord and transducer cable.

Power connection

The Color Twinscope’s power leads are the red and black

wires inside the cable that connects to the rear mount. These

wires must be connected to a source of 12VDC voltage. The

red wire should connect to the plus (+) 12 VDC and the black

wire should be connected to the minus (-) side of the 12 VDC.

To minimize electrical interference, carefully route the power

cable so that it does not run parallel or close to the transducer

cable, engine, refrigeration, bilge pump or any other critical

wiring. An in-line fuse holder is included with your unit and

should be placed in the positive lead as shown at left. A 2

Amp fuse is included.

IMPORTANT: The Color Twinscope’s 12 VDC power leads

should go directly to the boat’s battery, distribution board, or

breaker panel. Instability of the display may result if the unit

has to share leads with other electrical systems aboard your

boat.

Wiring for Power & Transducer Connectors

The correct pin-out wiring sequences for the transducer

connectors are shown at right. DO NOT SHORTEN THE

TRANSDUCER CABLES. If a transducer cable longer than

the 30’ length supplied with your unit is needed, please contact

your Interphase dealer. 30-foot scanning sonar transducer

extension cables are available. (P/N 04-0014-008)

DANGER: Removal of any connector, disassembly of

transducer, shortening of any cable or use of any cable other

than that supplied by Interphase will void your warranty.

(-) (+)

12 VDC

Color Twinscope Rear Panel Connections

Horizontal

Scanning Input

(Blue Nut)

Vertical

Scanning Input

(Green Nut)

Power

and I/O

Cable

Video

Input

2 Amp

In-Line Fuse

Blac Red

7

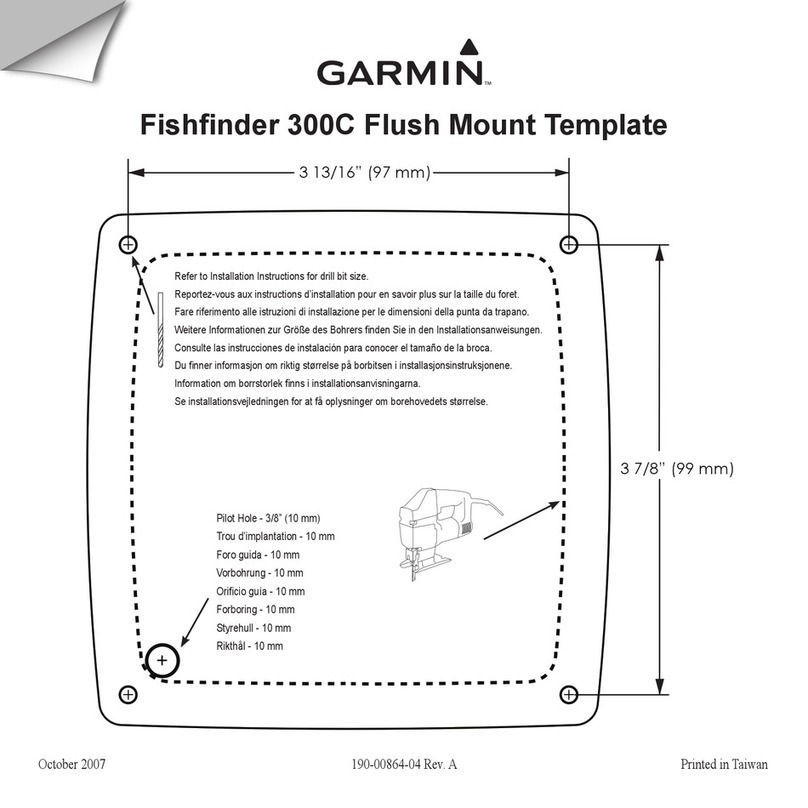

In - Dash Mounting

The Color Twinscope comes with mounting hardware to

mount the display in-dash. Four mounting screws and a

cutout diagram are included.

For in-dash mounting, the mounting base portion of the

Quick Disconnect Mount is removed. To remove the

mounting base loosen the thumb screw until it seperates

from the upper portion of the Quick Disconnect Mount.

While the cutout is included, dimensions of the cutout and

pilot holes has been included in the drawing below.

Loosen to remove

8.3” [211mm]

8.7” [220mm]

3.9” [100mm]

5” [126mm

8

SINGLE THRU-HULL

(T1-I200-032)

TWO TRANSOM MOUNTS

TWO THRU-HULL'S

(T1-I200-026 - vertical)

(T1-I200-029 - horizontal)

(T1-I200-025 - vertical)

(T1-I200-028 - horizontal)

Wiring and Cable Connectors

9 Pin Transducer Connectors:

(view from front of female plug)

1 White 1st element

2 Brown 2nd element

3 Orange 3rd element

4 Yellow 4th element

5 Green 5th element

6 Blue 6th element

7 Violet 7th element

8 Gray 8th element

9 Shield Ground/Return

3 Pin Video Input

1 Ground Return

2 +12 VDC

3 Video Signal

Transducer Connectors

Color Coded. Blue = Horizontal and

Green = Vertical Scanning inputs

Main Power-I/O Wiring .

(Cable from Quick Disconnect Bracket)

WIRE

COLOR DESCRIPTION FUNCTION

BLACK GND/COMMON POWER SUPPLY GND (-)

RED POWER +11-16 VDC POWER SUPPLY (+)

WHITE RXA (+) GPS INPUT PORT

GREEN RX-TX - GND - SERIAL PORT(s) RETURN

YELLOW TXA (+) NMEA OUT/ MASTER-REMOTE/

SOFTWARE DOWNLOADS

BROWN RXC (+) NMEA TEMP INPUT PORT

GRAY +12 Vdc - OUTPUT 12VDC - FOR ALARM

ORANGE RXB (+) MASTER-REMOTE/SOFTWARE

DOWNLOADS

PINK TXB (+) N/C

BLUE TXC - OUTPUT 3+ EXTERNAL ALARM SIGNAL

QUICK DISCONNECT BRACKET CABLE

Thru-Hull or

Transom Mount

Transducers

Transducer Connections

1

2

3

9

Selecting the Transducer

Configuration for your Boat

Keep in mind the primary rule for transducer operation.

This is: the transducer can function as long as it has an

unobstructed forward view and has smooth flowing

non-aerated water surrounding it.

The first line of inquiry should be about the boat.

Transom mounted transducers are intended for low

speed boats with external props. Boats with inboard

motors and boats that regularly exceed 40MPH cannot

use transom mounted transducers. Inboard motors

create aeration and excess turbulence that prevent the

transducers from operating properly. I/O motors where

the prop is aft of the transom do not create this

situation. Be careful that the driveshaft of the I/O does

not block the forward horizontal scan. Boats that exceed

40MPH run a risk of having the transom mounted

transduers torn free of the transom. The transom

mounted transducers are not designed to be used at

these speeds.

In addition, the transom mounted transducers are

mounted on kick-up brackets. This allows the brackets

to kick up at about 35-40MPH. This is intended to

allow the transducers to kick-up if they strike an

object, or to be pulled up when trailering a boat. Once

kicked up, the transducers must be manully reset in

order to function.

Thru-hull transducers are for boats that exceed 40MPH

and /or have inboard motors. Transducer placement

depends on boat size, speed, hull configuration and

sonar application. On displacement hulls, the

transducer is generally located 1/3 aft of where the bow

meets the water line. This is the farthest forward the

transducer should ever be mounted. It is important that

the transducer be below turbulent aerated water created

by the bow.

Special Thru-Hull Mounting Considerations

On sailboats with a fin keel, the transducer is most often

placed at the leading edge of the keel and sometimes

faired into the keel. As this location may be where the

sling rests when hauling the boat, the

transducer may be placed on either side of the hull with

the foremost face of the transducer even with the

leading edge of the keel. Alternatley, the transducer may

be placed forward of the keel ahead of the lifting strap

location. This should not be ahead of 1/3 aft of where the

bow meets the waterline.

On planing hulls the transducer is typically placed near

the transom. This is to provide smooth flowing water at

the greastest speed. However, most planing hull boats

create transducer aeration when on plane regardless of

transducer location.

It should be noted that thru-hull transducers can effect

boat performance in two important ways. The first

concern is cavitation created by the transducer that causes

reduced engine performance by disrupting water flow

around the propeller. This is smoothed out by the hull in

some boats, but on planing hulls with the

transducer near the transom, the hull is not able to clear

the cavitation. The second concern is uneven drag on

high-speed boats. This may occur when the thru-hull

transducer is mounted far off of the centerline of the boat.

At low speeds and on large boats the effect is

negligible. On smaller boats at high speeds the drag can

effect the steering. The effect increases as the boat’s

speed rises. Boats with trim tabs can usually trim this out,

but boats without trim tabs may feel a pulling

sensation toward the transducer side of the boat.

A less intuative mounting location for the single thru-hull

transducer on a planing hull is on the centerline just

forward of midship. The goal in this mounting is to place

the transducer so that it is out of the water at planing

speed. As most transducers are aerated at planing speeds,

this removes the transducer from the water flow

preventing cavitation and steering problems. Most

applications for forward scanning sonar occur when the

boat is at low non-planing speeds including fishing and

navigating hazardous waters. Under these speed

conditions the transducer is in the water.

On trailered boats, be certain that the mounting is such

that the boat does not rest on the transducers. This could

result in damage to the transducer and/or boat hull.

Explore possible mounting locations while the boat is on

the trailer.

10

Special Note on the

Color Twinscope Transducers

Q: There are 2 types of thru-hull transducers for the

Color Twinscope, 1 with a single transducer and 1 with

dual transducers. What are the dual transducers for? Do

they provide an extra function for the display or is it to

offset a larger keel? Does a large keel affect the

horizontal sweep of the sonar (single or dual)?

A: Interphase offers the twin thru-hull transducers for

small high speed boats. The single thru-hull transducer

is nearly twice as wide as each of the dual thru-hulls. If

the boat does no allow an installation on or close to the

center line, then the transducer is sometimes placed

2-3 feet away from the center line. On a high speed boat

(40+MPH) the drag can be felt in the steering. If the

boat does not have trim tabs to trim this out, then the

boat can 'pull'to one side at high speeds. The dual

transducer configuration allows for a transducer on each

side of the hull which evens out the water flow across

the hull.

This does not account for the forward horizontal sweep

being blocked by a keel, or deep V hull. In order for the

forward horizontal scan to pass beneath the hull, the

angle between the transducer and lowest point on the

hull must be less than 10 degrees. If the keel or hull of

the boat will block the forward horizontal scan, then the

Interphase iScan 180 should be considered.

The Transom Mounted Transducer is designed

for boats with a top speed below 40MPH.

The Thru-hull Transducer is for boats that

EXCEED 40MPH and /or have inboard motors.

11

Transducer Installation

The Color Twinscope comes standard with either a single or

twin thru-hull or with two transom mount forward scanning

transducers.

The Color Twinscope uses two phased arrays. In the single

thru-hull model both arrays are enclosed in a single

transducer. For transom mount applications two transducers

are required, each containing a phased array. One of the

phased arrays is positioned to scan vertically from straight

ahead to directly below the boat, while the other array is

positioned to scan forward horizontally from side to side. It is

important to position the transducer so that it has as clear a

view as possible of the water directly below and ahead of your

boat, as indicated at left.

The scanning transducer(s) must be positioned properly so

that it scans in the proper direction (i.e. from in front of the

boat to the bottom below). The sketch at left shows the proper

orientation for both the transom mount or the thru-hull

transducer(s). NOTE THAT ON THE TRANSOM

MOUNT TRANSDUCERS, THE ROUNDED SIDE

MUST POINT FORWARD, AND ON THE THRU-HULL

TRANSDUCER, THE MORE BLUNT AREA MUST

POINT FORWARD.

General Considerations

DO NOT CUT OR SPLICE YOUR PHASED ARRAY

TRANSDUCER CABLE OR REMOVE THE 9-PIN

CONNECTOR BECAUSE THE SYSTEM

PERFORMANCE MAY BE SERIOUSLY DEGRADED.

THIS ACTION WILL VOID YOUR WARRANTY.

If you need a longer length cable than comes with the

transducer (30’), then purchase the optional 30’ extension

cables, Interphase Part # 04-0014-008. It is recommended

that only one extension cable length (total of 60’) be used as

additional extensions will decrease the effective power and

depth range. The Color Twinscope requires two extension

cables - one for the vertical scan and one for the horizontal

1) Choose a location where there is the least amount of

acoustic noise, air bubbles or turbulence caused by the boat’s

movement. The transducer should not be located nearby or

especially directly behind the propeller.

2) Choose a location where the transducer can be mounted so

that it will be level to the water’s surface and will not be tilted

to either side. Otherwise the transducer will not scan from the

surface ahead to directly beneath the boat.

Forward Direction

Transom Mounted Transducers

Forward

Thru-Hull Transducer(s)

Scanning Directions.

Vertical scan mode

shown above and

Horizontal mode

below

side view

top view

12

3) The transducer must always remain submerged,

regardless of the speed of the boat and should not be

mounted where it could be damaged by underwater

obstacles .

4) DO NOT locate the transducer in the extreme bow of the

boat where it will be subject to intense turbulence as the boat

pounds through the water.

5) DO NOT locate the transducer directly behind any hull

protrusion which will cause turbulence at the transducer or

which will obstruct the transducer’s forward looking view.

For displacement-hull power and sail boats, the thru-hull

installation is usually required.

DANGER: DO NOT allow any solvents, i.e. gasoline,

acetone, to come in contact with the transducer or head unit

as this may dissolve the plastic material. In addition, DO

NOT force the cable by pulling on it. This may cause

damage to the internal transducer wiring.

Transom Transducer Kick-Up Bracket

The transom transducer is attached to the boat with a heavy-

duty stainless steel kick-up bracket to provide protection

against impact.When the transducer strikes an object, or the

water force exceeds the resistance of the bracket, the

transducer automatically kicks up and becomes non-

operational. The bracket does not automatically reset at

lower speeds. The transducer must be manually returned to

its operational position.

The transducer is designed to kick up at speeds between 35

and 40MPH (30-35 knots). We do not recommend transom

mount transducers on boats that regularly exceed 35MPH

(30 knots). Boats that exceed 40MPH (35knots) cannot use

transom mounted transducers, but instead must use thru-hull

transducers.

Special Note: The kick-up feature is designed as a safety

consideration to prevent the transducer from being removed

from the boat due to impact or excessive speed. The kick-up

bracket is not designed for repeated kick-up or to be pulled

up manually during loading and unloading from boat trailers.

Tests have shown that the bracket can kick-up as many as 30

times before there is a negative effect on the bracket.

Repeated kick-up will cause the transducer to kick-up at

progressively lower speeds. Excessive kick-ups can cause

the transducer bracket to fail. Brackets that fail due to

repeated kick-up are not covered under the transducer

warranty.

30’ Extension Cable

9-pin

Male 9-pin

Female

Interphase Part #

04-0014-008

(2 required)

Suggested materials required for installation:

♦Variable speed electric drill with a chuck

capacity of 10mm (3/8”) or larger.

♦Hole saw or spade bit 19 mm (7/8”) for

transom hole to route cable and

connector

♦Chamfer bit or 6 mm (1/4”) drill bit

♦Drill bit No. 28 or 4 mm (9/64”)

♦ Drill bit 3 mm (7/64”)

♦ Marine bedding/sealing compound

Note: Will

not work at

speeds above

35 MPH

Transom Mount Bracket in Released Position

13

If the transducer must be kicked up for installation, boat service

or loading, the nylok nut on the end of the bracket axle can be

loosened. Tighten the nut to 50 inch pounds of torque before

operating the boat.

Kick-up Bracket Replacement Parts

If during installation parts are somehow lost are damaged, they

can be replaced as follows:

Part# 17-0088-008 - Spray Shield Kit - Includes: Spray Shield,

four Mounting Bolts and Nuts, Rubber Grommet and four Large

Mounting Screws.

Part# 17-0089-008 - Transom Transducer Hardware Kit -

Includes: Complete Bracket Axle Assembly and four Large

Mounting Screws.

Part# 17-0056-008 - Kick-Up Bracket Assembly - Includes:

Complete Bracket Axle Assembly, four Large Mounting Screws

and the Stainless Steel Mounting Bracket.

Bracket Axle Assembly

On some boats it will be neccessary to remove the Bracket Axle

during installation. See the diagram to the left and instructions

below for details on assembling the axle.

1. Place one stainless steel washer onto the axle against the hex

end.

2. Place one small stainless steel spacer against washer.

3. Slide two urethane spacers over the small steel spacer.

4. With the transducer bracket in place, align the long stainless

steel spacer with the mounting holes of the mounting bracket

and slide the axle in place through the spacer.

5. Place one small stainless steel spacer against the transducer

bracket.

6. Slide two urethane spacers over the small steel spacer.

7. Place one stainless steel washer onto the axle against the

urethane spacer.

8. Place the nylok nut onto the threaded end of the axle and

tighten to 50 inch pounds. If you do not have a torque wrench,

tighten until the nut will not turn easily. The stainless steel

spacers should prevent over-tightening.

Transom Mounting Location

The main source of vessel acoustic noise is the propeller. It is

very important to position the transducer to minimize noise

pickup and provide as clear a view as possible of the water

ahead of the boat. Study the hull shape of the vessel carefully to

determine the best transducer mounting location. To achieve

optimal operation the transducer should be mounted in a spot

which:

* Minimizes acoustic noise reception.

Bracket

Axle

Nylok

Nut

1

2

3

5

4

6

7

8

14

* Minimizes the chance that aerated water will flow

across the transducer’s frontal nose area.

* Optimizes the transducer’s view of the area

ahead and directly below the boat.

Note: The Forward Horizontal Transducer must be able to

scan beneath the hull. The deadrise angle of the hull must be

less than 10 degrees in order for the forward horizontal scan

to sweep beneath the hull. Alternately, the transducer can be

mounted at or below the lowest point on the hull.

The transducer can be installed on either side of an outboard

or inboard/outboard engine, or between twin outboards. For

single engine installations, normally 18” to 24” outboard of

the propeller center line is acceptable and the down stroke

side of the propeller is preferred. Choose a location where

water flow is smoothest. For dual engine installation, just off

the center line is usually acceptable.

Because the transducer rotates back and upwards when the

bracket releases, it must be mounted in a location where there

is sufficient clearance and headroom to allow the full release.

Attach the Transducer & Spray Shield to the Bracket

Locate the Stainless Spray Shield inside the transducer’s

stainless mounting ears. Make sure the spray shield is

orientated as shown in sketch below. Then, assemble the

stainless kick-up bracket to the transducers using the 4

screws, washers and lock nuts provided. Place the rubber

grommet around the transducer cable and slide it into the slot

in the spray shield. The bracket arms must be mounted

outside the stainless steel mounting ears of the transducer. Do

not fully tighten the lock nuts at this time. Tighten them after

the transducer is mounted and the spray shield is positioned.

Position the transducer so that it is perpendicular from side to

side and make sure the wider curved end is pointed towards

the front of the boat.

Mounting the Transducer to the Boat

After you have selected the optimum mounting location and

have assembled the mounting bracket to the transducer,

mount the bracket onto the hull as shown on the right.

Make sure to position the transducer so that it is level in the

fore and aft direction and so it will look straight down. Check

the location of your boat’s waterline and position the flat top

surface of the transducer so that it is parallel to the waterline

as shown below.

Note: If the transducer is not mounted so that its fore and aft

direction is parallel to the surface, then the forward looking

display will be distorted and flat bottoms will appear to be

Waterline

Rear

View

Spray Shield

Transducer must be

mounted vertically

Fasten Spray Shield

with 4 screws & nylok

washers as shown

Bracket

Axle

Rubber

Grommet

Side

View

Boat Hull

Mounting

Bracket

Waterline

Fasten Spray Shield

with 4 screws & nylok

washers as shown

Spray

Shield

18 - 24"

Cables

Twin Outboards

Transducers

Cables

Transom Mount Locations

15

slanted upwards or downwards. After mounting the transducer

and actually using the Color Twinscope on the water, you may

need to readjust the transducer’s mounting for optimum

performance.

Thru-Hull Transducer Installation

The thru-hull transducer is the recommended choice for larger

boats with in-board engines. Thru-hull mounting is usually

required on larger power and sail craft in order to find a

mounting location free of forward looking hull obstructions.

The Color Twinscope must have a clear view of the water

ahead as it can not see through obstructions such as the vessel’s

hull. Please read the following carefully before starting the

thru-hull installation.

Normally, thru-hull installations are performed by a

professional in a boat haul-out facility. We suggest you seek

professional assistance before attempting to mount this

transducer.

Selecting the Best Location

The best location to mount the thru-hull transducer will vary

with the type of boat. Try to find a location with the smallest

dead rise angle to make installation easiest.

a. On displacement hulls (sailboats, trawlers, etc.) locate the

transducer about 1/3 aft along the waterline. Generally this

provides the best compromise between obtaining aeration-free

water and minimizing propeller noise. The Color Twinscope’s

transducer can not see through aerated water and water near the

bow and near the keel can be quite aerated. Aeration of the

transducer can be minimized by keeping the transducer

mounted away from the keel and by not mounting too far

forward. Because the Color Twinscope scans horizontally

from side to side, it is also important to find a location where

the beam will not be shaded by the keel. This can often be

accomplished by use of a fairing block to place the transducer

below the keel, or by mounting the transducer forward or

beside but at some distance from the keel.

b. On sailboats, the transducer should be mounted where the

acoustic beam will not be shaded by the keel. A spot forward

of a fin keel is usually best. Try to find an accessible spot with

a minimum dead rise angle.

c. On planing powerboat hulls, the transducer should be

mounted well aft and close to the keel to insure that the

transducer is in contact with the water at higher boat speeds.

On I/O’s, transducer mounting close to the

engine usually yields good results.

If you’re installation requires a fairing block, you

may either have one made locally, or purchase a

molded plactic unit from Interphase or your

Interphase distributor.

For the T1-I200-032 Thru-Hull transducer, the

molded Fairing Block Part Number is:

42-2005-000

MOLDED FAIRING BLOCK

Suggested Thru-Hull

Transducer Locations

Fin Keel

Planing Hull

Displacement Hull

L = waterline length

~ 1/3 L

16

On inboards always mount the transducer

well ahead of the propeller(s). Turbulence

from props can seriously degrade performance.

(Thru-hull installation is recommended.)

d. Mount the transducer on the side of the hull where the

propeller is moving downwards. The upward motion of the

propeller generates pressure waves and pushes bubbles up

against the hull.

DO NOT install a bronze transducer housing directly into an

aluminum or steel hull because electrolytic corrosion will

occur. Consult your boat-yard for more information on how to

properly install transducers into these types of hulls.

IMPORTANT:

1) Make sure the water flow across the thru-hull transducer is

bubble and turbulence free at all speeds if good performance is

to be achieved.

2) Make sure the transducer has an unobstructed view of the

water ahead and below the boat.

3) On displacement-hull power boats, the transducer should be

mounted relatively close to the center line of the hull.

4) Mount the transducer in a place which has reasonable

access from inside the vessel since the transducer’s bronze nut

will require tightening from inside the hull.

Because the Color Twinscope scans a 12 degree beam from

the surface ahead to directly below the boat, it is important to

make sure that the transducer is installed so that it will scan in

a vertical direction and not off to either side. The transducer

must be mounted so that it’s bronze stem is as perpendicular to

the water line as possible. If necessary, use a fairing block to

properly position the transducer.

Use of a Thru-hull Fairing Block

Nearly all vessels have some dead rise angle at the transducer

mounting location. If the thru-hull transducer were mounted

directly to the hull, the sound beam would be tilted off the

vertical at the same angle as the dead-rise. Most thru-hull

installations will require a fairing block to insure the

transducer is mounted properly.

A fairing block is typically made of teak, mahogany, or plastic

and should be glued between the transducer and hull (both

inside and outside) to insure that the transducer’s mounting

shaft is perpendicular to the water’s surface. Make the fairing

block as smooth as possible, and not bigger than the

transducer’s face, to minimize possible turbulence.

Hull

Hull

Waterline

Waterline

Keep parallel

to waterline !

Keep parallel

to waterline !

Forward

Transducer

Mount Transducer so bronze stem is Vertical

Bronze

Hex Nut

Fairing

Block

Transducer

Wood or

Plastic

Fairing Block

(Add sealing

compound

between

faring block

& hull).

Boat’s

Hull

17

After cutting the fairing block, trial fit the block to the

hull. It is very important that the flat top surface of the

transducer be parallel to the water. Because of the skill

required, we suggest that your professional boatyard

provide the fairing block.

Installing the Thru-hull Transducer

1) Drill a 1/8” pilot hole from inside the hull to assure

access to tighten the housing nut and clearance for the

transducer cables. If there is any hull irregularity near

the selected mounting location, it may be desirable to

drill from the outside.

2) Use a 1-1/16” hole saw and drill the hole from the

outside of the hull. Sand or clean the area around the

hole, inside and outside to insure that the sealing

compound will adhere properly to the hull. Select a

marine grade adhesive sealant, such as 3M 5200, and

use according to the instructions.

3) Remove the bronze hex nut from the housing and

cable.

4) Uncoil the transducer cable and thread it through the

hole into the inside of the hull.

DANGER: DO NOT apply tension to the transducer

cables as this may sever internal connections.

5) Apply a 1/8” thick layer of sealant on the upper flat

surface of the transducer, bronze alignment pin and

fairing block (if used).

6) From the outside of the hull, push the housing into

the 1” hole. Twist the housing slightly to squeeze out

excess sealant. Carefully confirm that the transducer is

aligned so that the round front end is pointed directly

toward the front of the boat.

7) Install and tighten the bronze hex nut (allow for

swelling in wooden hulls).

8) Remove excess sealant from the outside to assure

smooth water flow over the transducer.

DANGER: Wood hulls and fairing blocks will expand

after the boat is put back into the water, so it is

important that the transducer be only hand-tightened

until the wood fully expands. Otherwise the wood

fairing block may crack.

DANGER: Be sure to check for leaks when the boat is

placed in the water. Allow at least 24 hours after

installation for any leak to appear.

DANGER: If the boat is kept in saltwater it is

recommended that the transducer be coated with an

anti-fouling paint. USE ONLY WATER BASED

ANTI-FOULING PAINT. DO NOT USE KETONE

BASED PAINTS. Ketone based anti-fouling paint will

attack the plastic materials used in the transducer. See

the maintenance section on page 38 for

recommendations.

18

CURSR

VERT HORIZ

DOWN DATA

RANGE GAIN

PWR

FORWARD LOOKING SONAR

CURSR

VERT HORIZ

DOWN DATA

RANGE GAIN

PWR

FORWARD LOOKING SONAR

Screen Menu

Softkeys

NAV Button

UP/DOWN Button

Getting Started

ON/OFF - PWR Button.

Press the red "PWR" button located at the upper right of the unit

to turn the Color Twinscope on. The unit will respond with a

beep when it turns on. Briefly pressing the PWR button again

brings up the menu for adjusting the screen brightness and color.

To turn the COLOR TWINSCOPE off, press and hold down

the PWR button for longer than 3 seconds.

Soft Keys and Screen Menus

The five unmarked buttons below the display are called softkeys

(because their use is determined by the menu choices and the

Color Twinscope’s software). Whenever one of the softkey

buttons are pressed, or when making adjustments (like changing

the color mode, brightness, gain or range) a screen menu will

appear at the bottom of the display. For example, the screen

menu shown at left is used for selecting the display color mode

and adjusting the brightness.

The screen menu provides visual feedback on the adjustment and

often allows further choices by pressing one of the 5 softkeys

below the menu.

If no button is pressed for several seconds the screen menu will

disappear. On some screen menus, the menu will disappear as

soon as you make a choice or press the button below the EXIT

choice. Note: on some menus, the exit symbol is used

instead of the EXIT word.

UP/DOWN (

) and “NAV” Buttons

These buttons are often used to make adjustments to increase or

decrease something - like the GAIN, RANGE and screen

BRIGHTNESS, etc. In several menus you can also use the

softkeys below the

symbol that appears in the menu to

make the adjustment. The

button and the

symbols on

the NAV button have the same function.

The

symbols on the NAV button are used to select an

item in the menu. For example, when the GAIN menu is

displayed, the

symbol on the NAV key will select the DOWN

gain to adjust, while pressing the

symbol will select the SCAN

gain to adjust. See RANGE/GAIN on page 26 for details.

19

Adjust Display Color/Brightness

Briefly press the red PWR button when the unit is on, and a

menu will appear at the bottom of the display which can be

used to select the color mode and the screen brightness.

Three display color modes are available: NORMAL (normal

viewing), SUNLIGHT (white background for sunlight

viewing) and NIGHT (black background for night viewing).

A 3-color palette designates the strength or intensity of the

returning signal. RED indicates the strongest signal.

YELLOW indicates a mid-level return, while BLUE returns

are the weakest.

You can also adjust the display brightness from this menu. If

no buttons are touched for 6 seconds the screen menu will

disappear.

SET-UP Menu

Press any of the 5 buttons beneath the display to bring up the

“softkey” menu at the bottom of the display as shown at right.

Press the button below the SETUP symbol to bring up the

SETUP MENU where you can select languages, change the

display units, select a boat icon, customize the system gain

settings, adjust the NMEA baud rate, set a transducer keel

offset, add a compensation for the transducer level adjustment

and start/stop the demo mode. For more information about

using the SET-UP Menu, please refer to the SET-UP section

on page 20-21.

DEMO

Your Color Twinscope includes a built-in DEMO simulator

program which makes it easy to practice with the unit and to

get a feeling for its many features before actually using it in

real situations on the water.

To start the DEMO mode, Press any of the 5 buttons beneath

the display will bring up the “softkey” menu. Then press the

softkey beneath DEMO.

CURSR

VERT HORIZ

DOWN DATA

RANGE GAIN

PWR

FORWARD LOOKING SONAR

Normal Sunlight Night Down-Brightness-Up

2

CURSR

VERT HORIZ

DOWN DATA

RANGE GAIN

PWR

FORWARD LOOKING SONAR

Interphase Color Twinscope

Version 2.03

3

EXIT LANGUAGE MORE DEMO TRANSDUCER

UNITS

1

CURSR

VERT HORIZ

DOWN DATA

RANGE GAIN

PWR

FORWARD LOOKING SONAR

Depth 13.2 Ft 25 50

25

12.5

Scan Speed Beam Adj Video Alarm Set-up

20

Set-Up

The Color Twinscope’s SET-UP menu allows you to

make several important initial settings. Typically, most of

these settings are only made once and don’t have to be

changed. The keel offset adjustment is a good example.

The SET-UP menu is shown at left and the following

paragraphs describe each choice in detail.

Language/Units

The Color Twinscope allows the choice of several

operating languages and conversions for distance, speed

and temperature. To select the operating language or

choose the unit conversion to use, press the button labeled

LANGUAGE/UNITS. A display window as shown at

left will pop up on the screen showing the available

languages and unit conversions and the ones which are

currently selected.

Use the softkeys to highlight your desired choice for

language, units for range, temp and speed. When finished

press the EXIT softkey to save your selection and exit this

menu.

More - Max Vert Gain, Remote/Master

Press the softkey below the MORE choice to bring up a

menu to set the MAXIMUM VERTICAL GAIN/range,

choose the boat icon, configure the display as either a

MASTER or REMOTE or press MORE to adjust the

STC to minimize the effect of surface clutter.

To choose the boat icon and the MASTER(#1)/

REMOTE(#2) setting, use the softkeys to highlight

your choice. To adjust the MAX VERT GAIN*, use the

softkey to highlight the desired range - then use the

NAV or

UP/DOWN button to adjust the Max Gain.

When finished with all settings, press the EXIT symbol to

save your selections and exit the menu.

* Note: the Max Vert Gain adjustment applies to the

Forward Vertical Scan only.

CURSR

VERT HORIZ

DOWN DATA

RANGE GAIN

PWR

FORWARD LOOKING SONAR

EXIT LANGUAGE MORE DEMO TRANSDUCER

UNITS

Interphase Color Twinscope

Version 2.03

English

French

Spanish

German

Chinese

Korean

Greek

Danish

Ft.

Fa.

M

oF

oC

MPH

Km/Hr

Knots

RANGE DEFAU

LT MAX G

100 FT 11 11

200 12 12

400 14 14

MORE

RANGE SUGGESTED

MAX GAIN

SETTING

0 - 50 Ft 10

0 - 100 Ft 10

0 - 200 Ft 10

0 - 400 Ft 16

0 - 800 Ft 31

0 - 1,200 Ft 31

The Color Twinscope allows you to customize the maximum

possible gain for each range. The table below shows a

suggested range of Max Gain settings that you can set. Too

much gain on the shallow ranges will cause excess noise and

false forward targets .

Other manuals for Color Twinscope

1

Table of contents

Other Interphase Sonar manuals

Interphase

Interphase Spectra User manual

Interphase

Interphase PC/View User manual

Interphase

Interphase PC/180 User manual

Interphase

Interphase Sonar Engine SE-200 User manual

Interphase

Interphase Advantage User manual

Interphase

Interphase Color Twinscope User manual

Interphase

Interphase PC/180 User manual

Interphase

Interphase Outlook User manual

Interphase

Interphase Vista User manual

Interphase

Interphase 180 User manual