3

1Introduction.........................................................................................................................................5

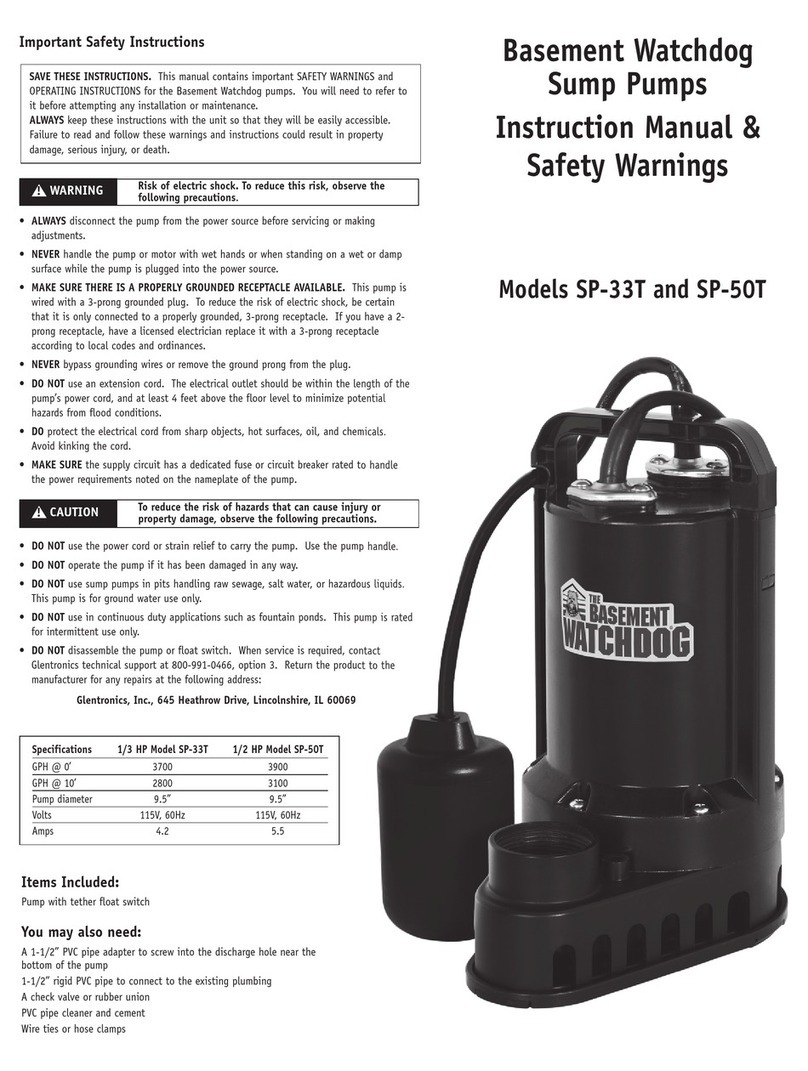

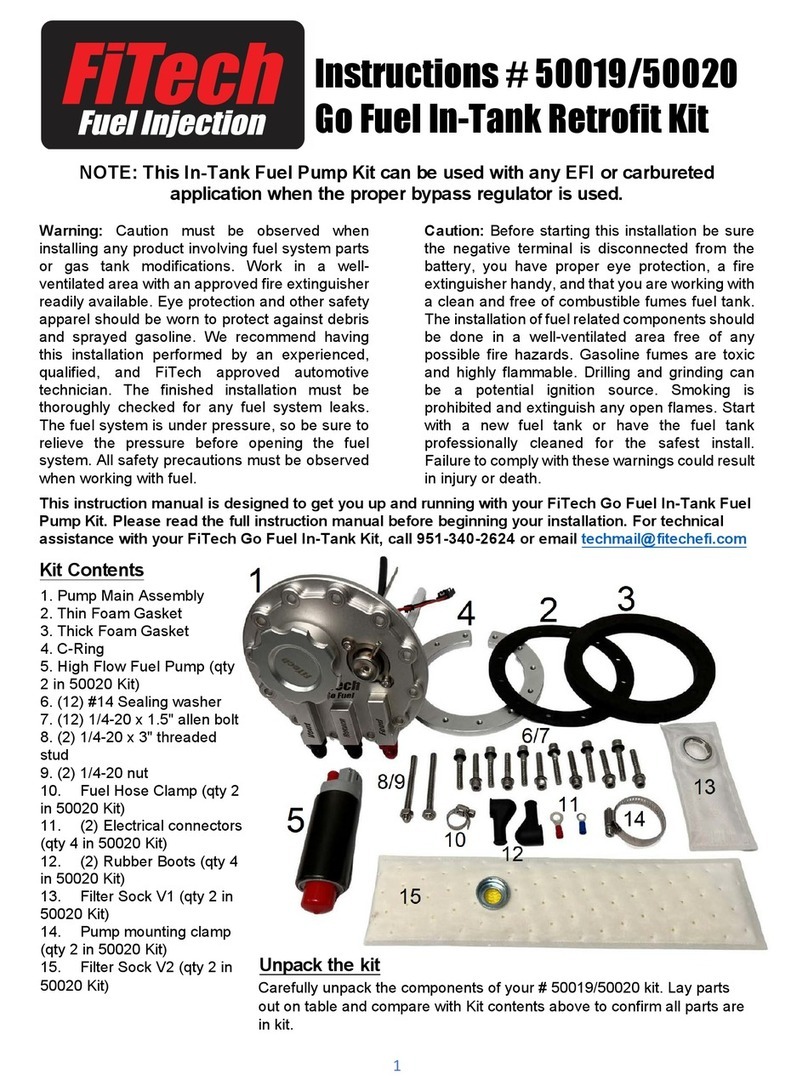

2Installation...........................................................................................................................................5

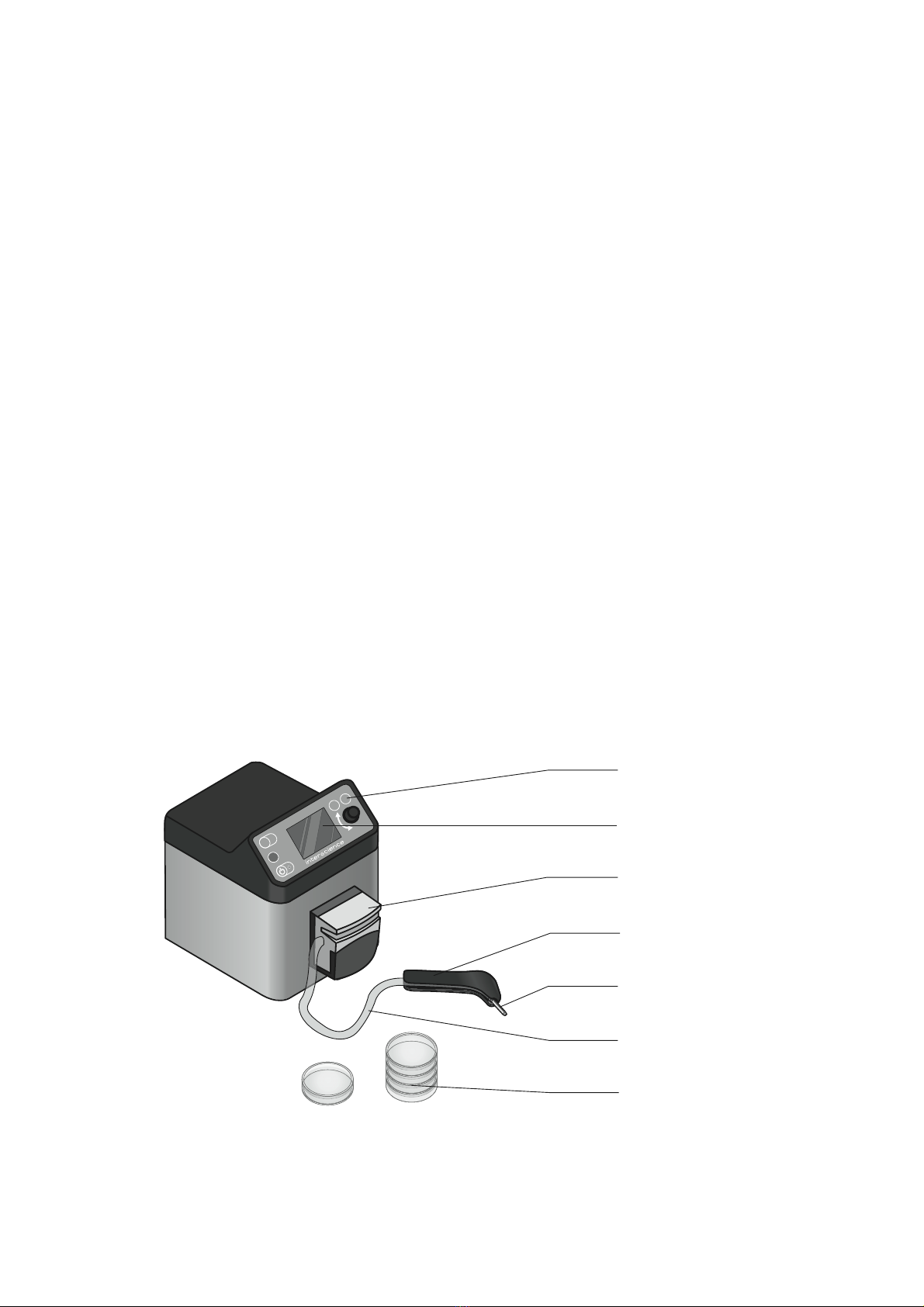

2.1Description of equipment.............................................................................................................5

2.2Installation ...................................................................................................................................9

3First steps..........................................................................................................................................10

3.1Principles of use........................................................................................................................10

3.2Principle of operations...............................................................................................................10

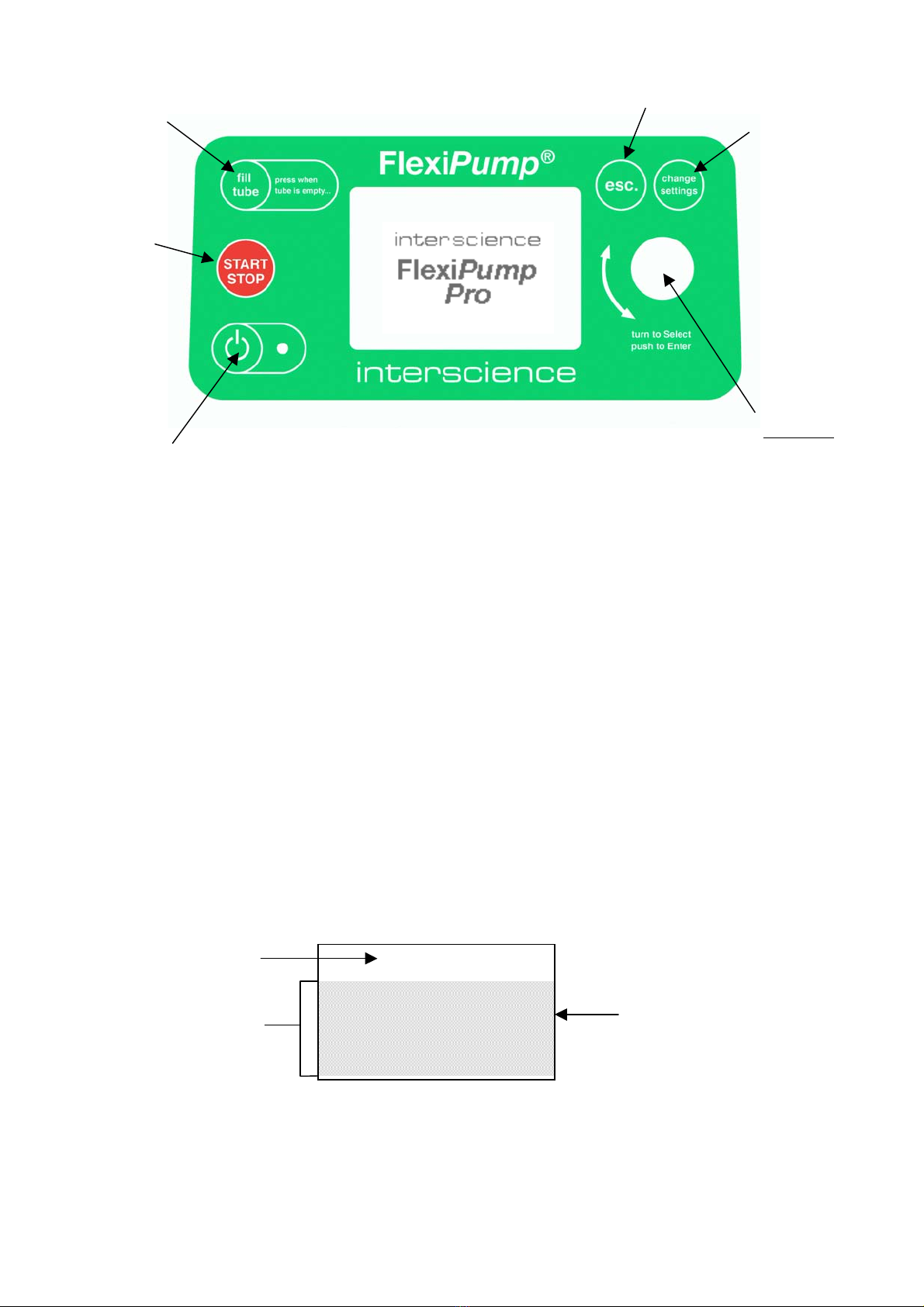

3.3Display and control buttons.......................................................................................................10

3.4Menu .........................................................................................................................................11

3.5Concept of program...................................................................................................................12

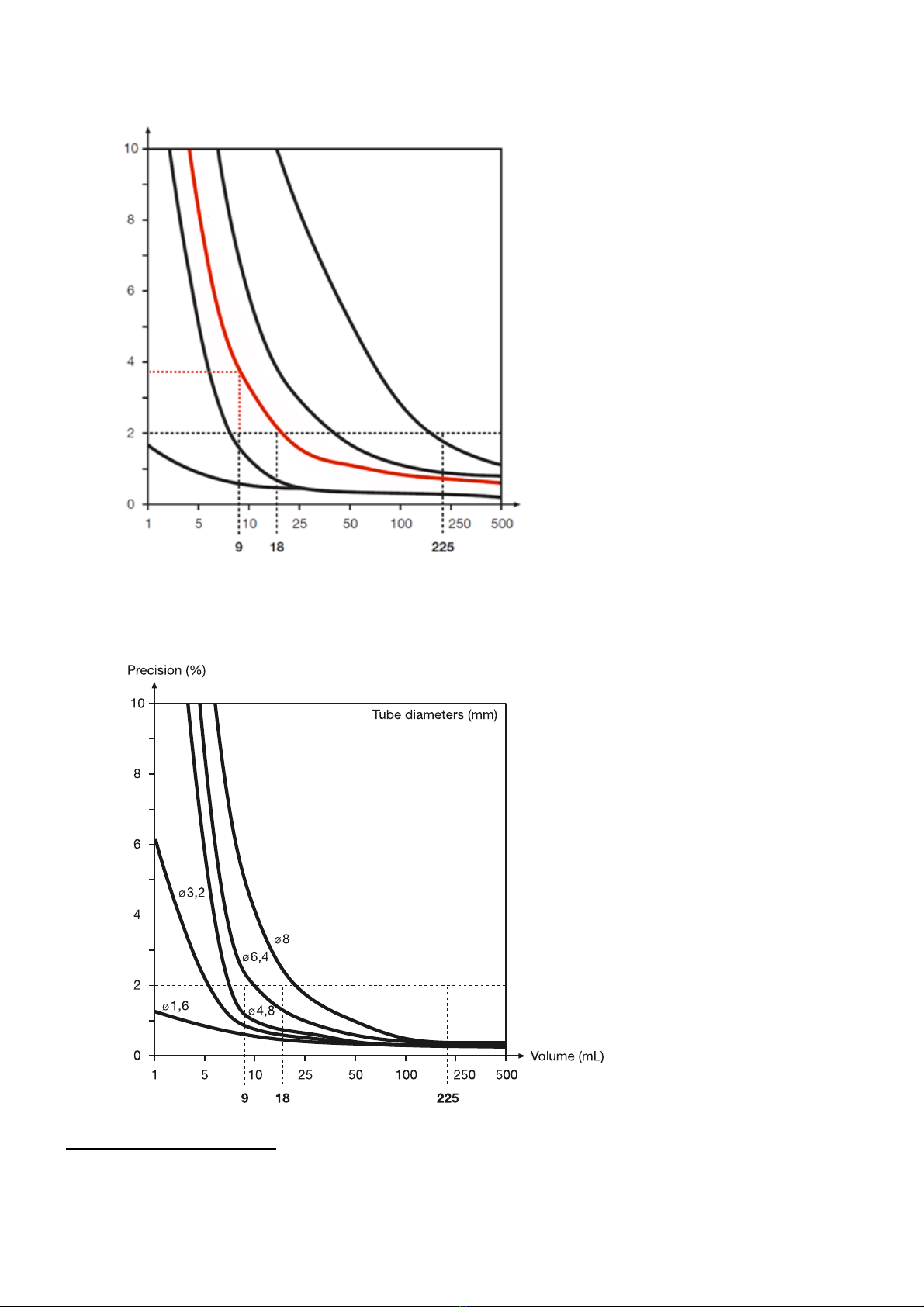

3.5.1Programs and tubings..................................................................................................................... 12

Advice for the choice of a tubing ......................................................................................................... 12

3.5.2Programs and calibration ................................................................................................................ 14

3.5.3Programs : user manual.................................................................................................................. 14

3.6General settings ........................................................................................................................14

3.6.1Flow direction of the pump .............................................................................................................. 15

3.6.2Anti-drop system ............................................................................................................................. 15

3.6.3Sound.............................................................................................................................................. 15

3.6.4Contrast........................................................................................................................................... 15

3.6.5Date/time......................................................................................................................................... 15

3.6.6Language ........................................................................................................................................ 15

3.6.7Specific configurations of FlexiPump®Pro...................................................................................... 16

Name of the user................................................................................................................................. 16

How to enter a name for the first time: ................................................................................................ 16

How to change the name:.................................................................................................................... 16

Language............................................................................................................................................. 16

Printing formats ................................................................................................................................... 16

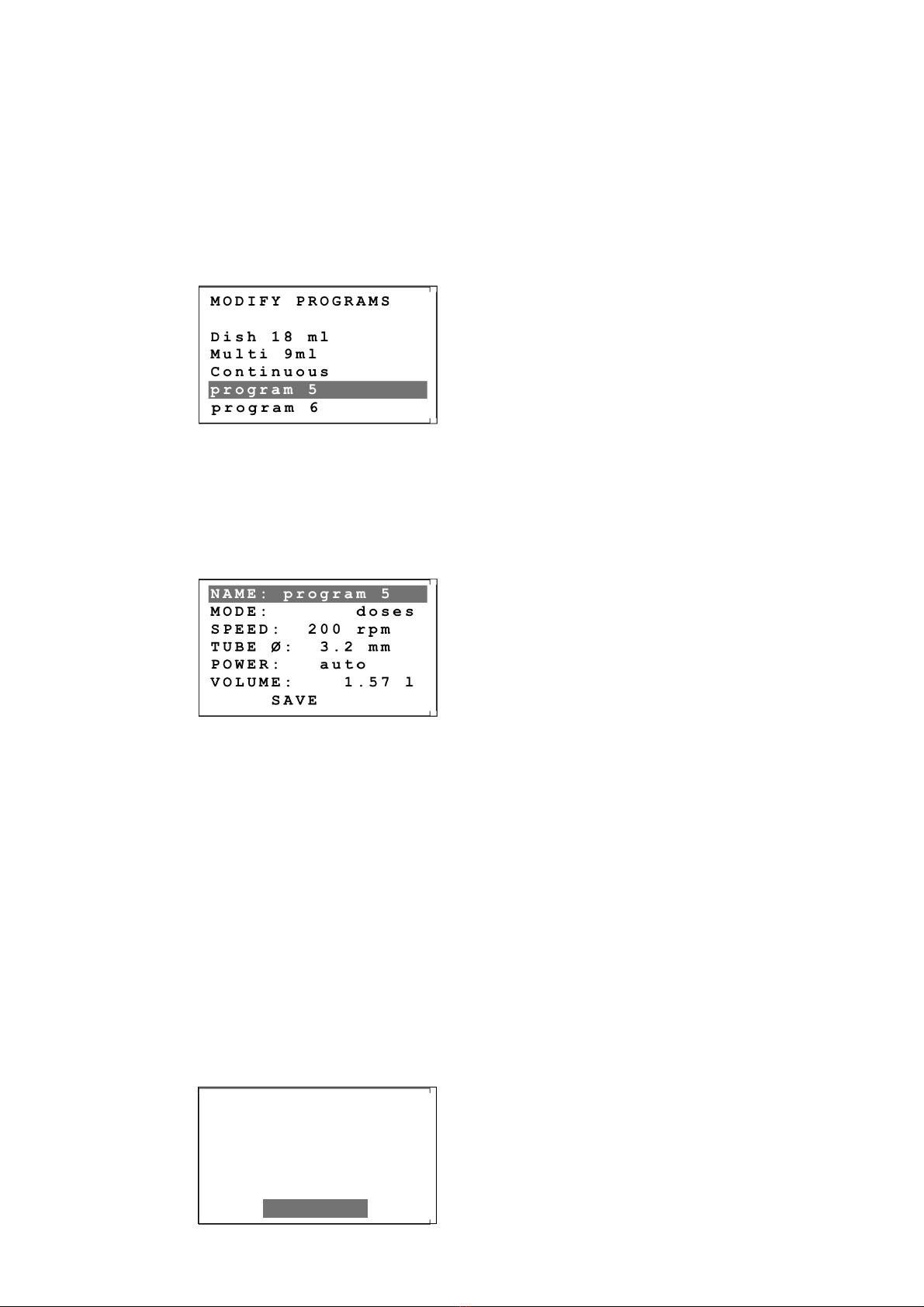

3.7Programs...................................................................................................................................17

3.7.1Create a program............................................................................................................................ 17

3.7.2Modify a program ............................................................................................................................ 17

Rename a program.............................................................................................................................. 18

Distribution mode................................................................................................................................. 18

Pump speed ........................................................................................................................................ 19

Inner diameter of the tubing................................................................................................................. 19

Power of the pump motor.................................................................................................................... 19

Volume of a dose................................................................................................................................. 19

Number of doses................................................................................................................................. 19

Delay between each dose................................................................................................................... 19

3.7.3Calibration....................................................................................................................................... 20

When ?................................................................................................................................................ 20

Necessity of a calibration..................................................................................................................... 20

Principle of operations......................................................................................................................... 20

Procedure............................................................................................................................................ 20

Test...................................................................................................................................................... 21

Calculation of accuracy ....................................................................................................................... 21

3.7.4Use a program................................................................................................................................. 21

Immediate launching ........................................................................................................................... 22

Start after verifications......................................................................................................................... 22

Suspend an operation ......................................................................................................................... 22

Cancel an operation ............................................................................................................................ 22

Change the speed during dispensing.................................................................................................. 22

Dispensing in « dose » mode.............................................................................................................. 23

Dispensing in « multi-doses » mode.................................................................................................... 23

Dispensing in continuous mode........................................................................................................... 24

3.8Basic pumping...........................................................................................................................24

3.9Use with diluent broth bags.......................................................................................................24

3.9.1How to install a diluent broth bag .................................................................................................... 24

3.9.2Using the FlexiPump® to fill in Dry-bags from Oxoid(Thermo Fisher Scientific).............................. 25

3.10

Using the handy gun (ref. 561 001).........................................................................................25

How to install the handy gun ....................................................................................................................... 25

3.11

Advanced features (FlexiPump® Pro)......................................................................................25

3.11.1

Printed report................................................................................................................................. 26

3.11.2

Data export to computer................................................................................................................ 26