4. CAUTION FOR USE

4-1 Caution for safety

1) In case of emergency, please pull off the power plug. Basically, circuit protection fuses

are installed to cut off any irregular electricity shock. Nevertheless, if there is any

emergency including a breaking out of a fire on the Teflon tape, pull off the power plug.

2) The user must use just the electricity power stipulated at this manual.

3) In case of exchanging any part of the machine, the power plug must be pulled off. And, to

prevent any malfunction or accident, it is prohibited to use of part against the specification

stipulated by the manufacturer.

4) It is prohibited that the buyer by himself rebuilds the machine.

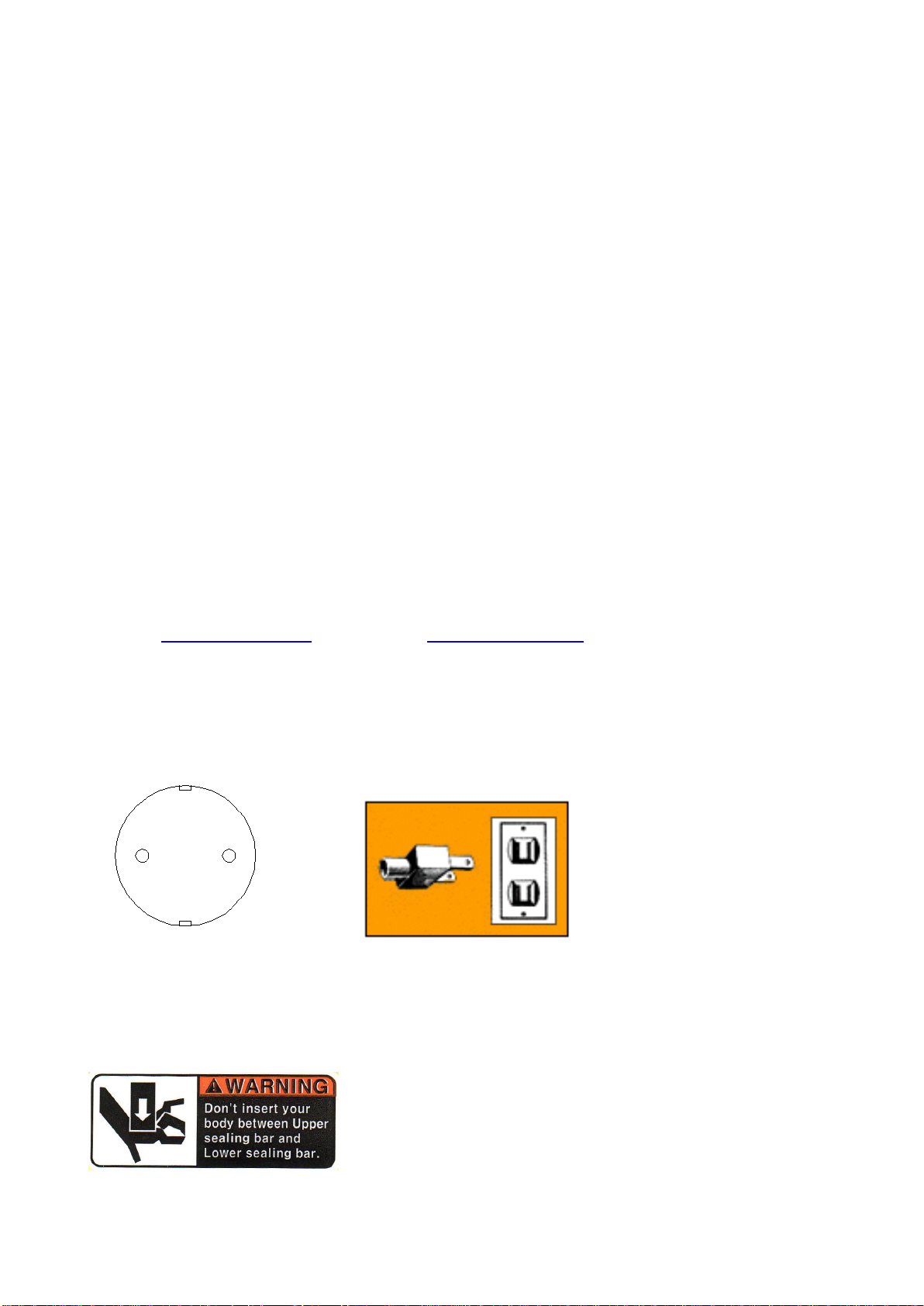

5) Electricity flows on the heat wire. Please do not insert any metal product between sealing

bars not to receive electricity shock.

6) If N.F.B automatically turns off, the user must find out the reason and take necessary

measures before the user turns on N.F.B. ( Please refer to 20-10. If N.F.B (NO FUSE

BREAKER ) turns off )

7) Please avoid installing the machine in the place where it is full of dust, or high temperature

and high humidity. Especially, the temperature of work place suitable for this machine is

0~50 ℃.

8) Please do not insert the hand between the sealing bars.

(1) A long time use of the machine accumulates heat around heat wire, and there is a

danger of burn.

(2) There is a chance that the power of the upper sealing bar’s going down hurts fingers.

( Regarding this, this machine has safety sensors so that sealing bar returns

immediately to the original state when finger, alien substance or packed object get

caught in. )

9) Before mass operation, please find out proper sealing time and cooling time through a full

sealing test.

10) Please check up whether there is any damage on Teflon sheet, Teflon tape, sealing rubber.

11) If the packing is wrongly operated, please push the STOP button. Then, the packing is

instantly suspended and the nozzle moves back and the upper sealing bar go up.

12) To reduce the risk of electric shock, disconnect power cord set before cleaning

13) You must lock up the gas cock of external gas line to cut off gas inflow to the machine in

the follow cases ;

(1) When the user does not use machine

(2) When the user does not use gas function of machine

(3) When there is any gas leakage on the gas line

14) You must NOT use any explosive gas for gas flushing packing.