NOTE:

Sunlight shines on the panels will generate voltage, high voltage in series

may cause danger to life. Therefore, before connecting the DC input line,

the solar panel needs to be blocked by the opaque material and ensure that

the DC switch is 'OFF', otherwise, the high voltage of the inverter may lead

to life-threatening conditions.

Do not close the DC switch after the DC terminal is connected. Connect the AC terminal

to the AC side of the inverter, the AC side is equipped with three-phase AC terminals that

can be conveniently connected. Flexible cords are recommended for easy installation. The

specifications are as shown in sheet 5.2

1. Matching socket 2.Sleeve 3.Sealing core 4.Sealing nut

Pic 5.7 AC connector structure

The AC output connector is divided into three parts: matching socket, sleeve and sealing

sleeve, as shown in Picture 5.7, the steps are as follows:

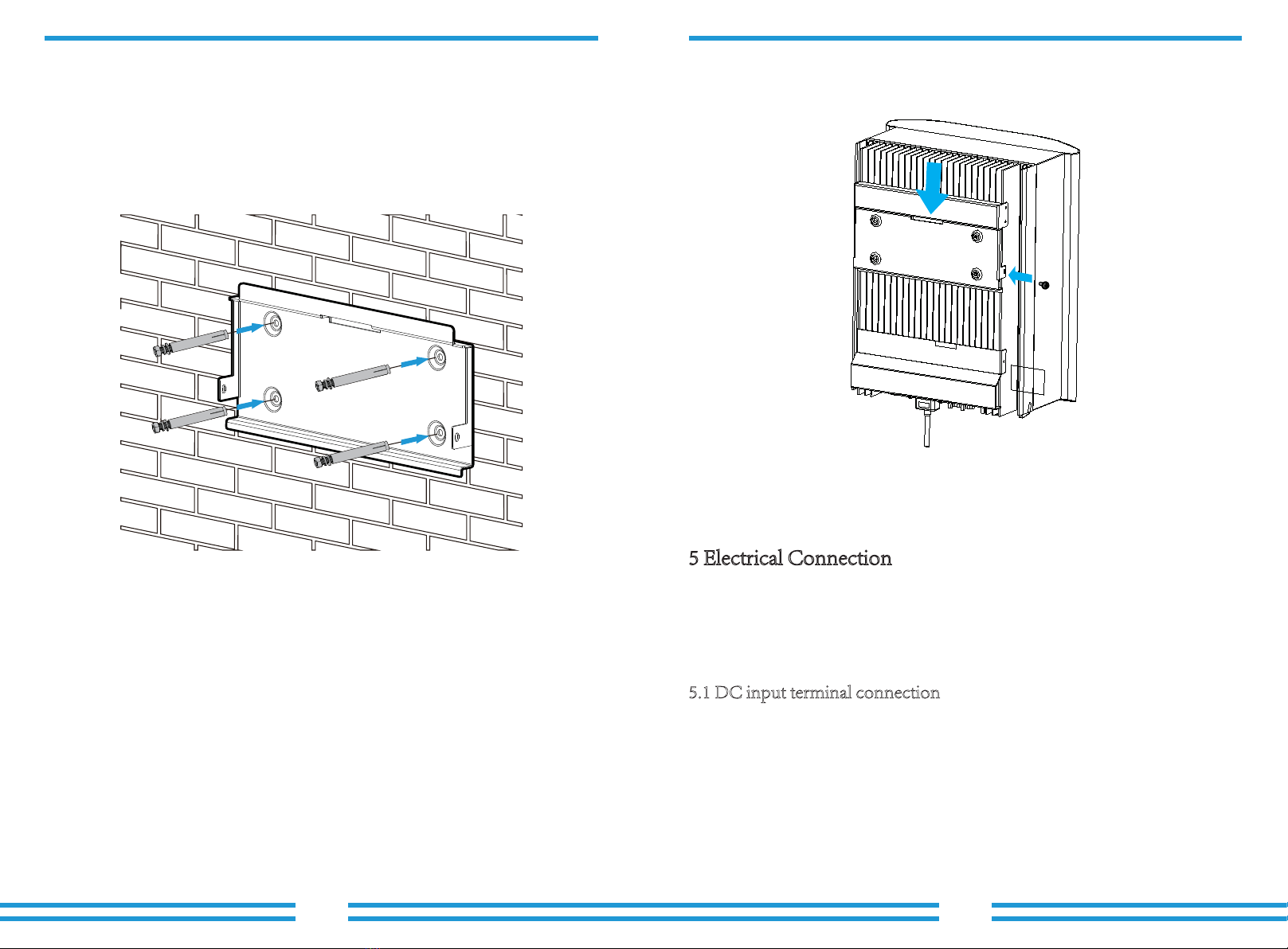

Step 1 Remove the cable sealing ring and sleeve in sequence from the AC connector.

Step 2 Use strippers to strip the protective sheet and insulation layer of the AC cable

to the right length, as shown in Picture 5.8.

Step 3: Insert the cable (L1, L2, L3, PE) into the sealing sleeve and sleeve.

Step 4 Use the hexagon screwdriver, loosen the bolts of the socket in turn, and insert

each cable core into the corresponding jack, and set each screw. The connection hole

of AC connection terminal labeling is shown in Picture 5.9.

Warning:

Prohibit using a single circuit breaker for multiple inverters , prohibit the

connection of load between inverter circuit breakers.

Table 5.2 Cable information

Warning:

Be careful to distinguish the L1, L2,L3 and PE of the AC cables.

Outside cable(3+PE)20m Outside cable(3+PE)20m

5.2 DC input terminal connection

Specification

Model NITROX-12,15KW-3Ph-5G

30A/400V

NITROX-20KW/25KW-3Ph-5G

40A/400V

DiaCable item Cable

CSA

Cable

outer

dia

15~18mm2.5mm 6mm

AWG Dia Cable

CSA

10mm10 2.5mm

Cable

outer

dia

AWG

15~18mm 8

2 2

Breaker

Max cable

length

1

2

34

Pic 5.8 Strip AC cable

8~15mm

40mm

- 15 - - 16 -