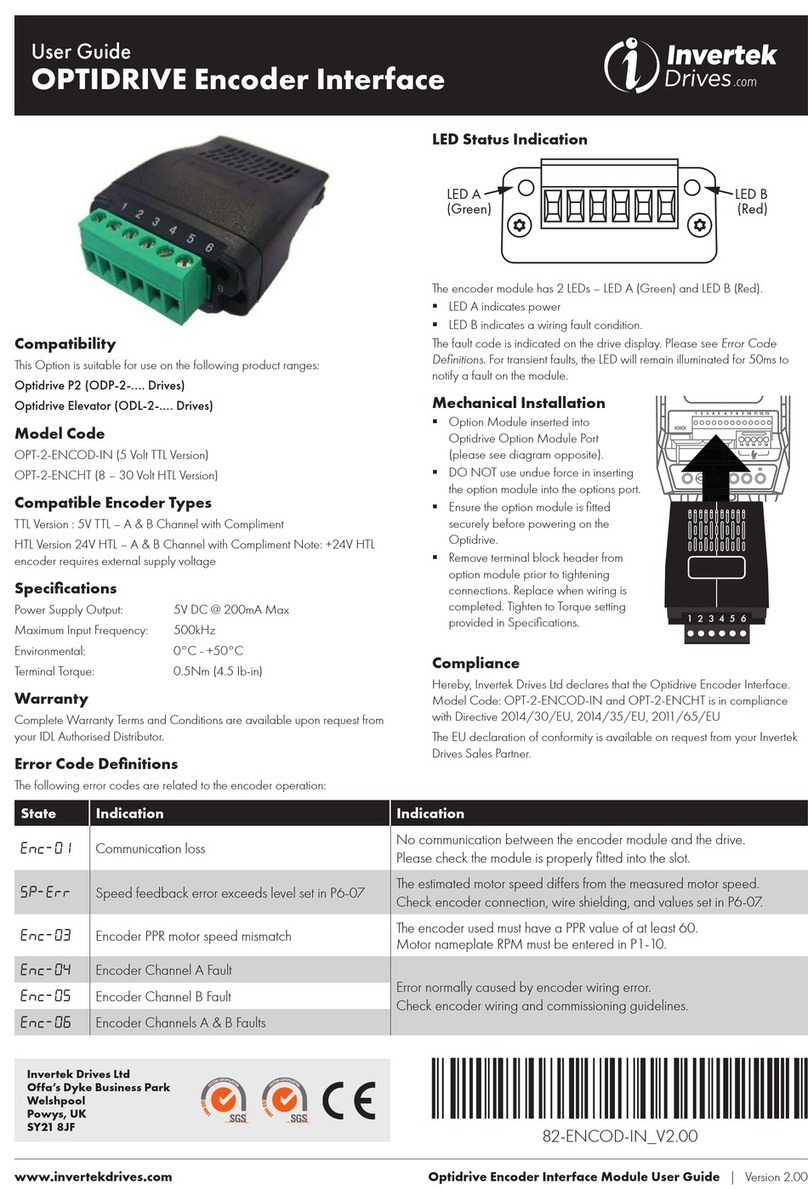

1) Option Module inserted into Optidrive

Option Module Port

2) DO NOT use undue force in inserting

the option module into the options port.

3) Ensure the option module is fitted

securely before powering on the

Optidrive.

4) Remove terminal block header from

option module prior to tightening

connections. Replace when wiring is

completed. Tighten to Torque setting

provided in Specifications.

OPERATION

Parameter Settings

When operating with an encoder, the following parameter settings are required

as a minimum:

P1-09: Motor rated frequency (found on the motor nameplate).

P1-10: Motor rated speed (found on the motor nameplate).

P6-06: Encoder PPR value (enter value for the connected encoder).

Closed Loop Vector speed provides full torque holding capability at zero speed

and enhanced operation at frequencies below 1Hz. The drive, encoder module

and encoder should be connected according to the voltage rating of the encoder

as shown in the wiring diagrams.

Note: Encoder Vector Torque Control and Encoder V/F speed control operation

is detailed in the Optidrive P2 Encoder Speed control application guide.

The encoder cable should be an overall shielded type, with the shield bonded to

earth at both ends.

COMMISSIONING

When commissioning, the Optidrive should firstly be commissioned in

Encoderless Vector Speed Control (P6-05 = 0), and a speed / polarity check

should then be made to ensure that the sign of the feedback signal matches that

of the speed reference in the drive. The steps below show the suggested

commissioning sequence, assuming the encoder is correctly connected to the

Optidrive.

1) Enter the following parameters from the motor nameplate:-

P1-07 –Motor Rated Voltage

P1-08 –Motor Rated Current

P1-09 –Motor Rated Frequency

P1-10 –Motor Rated Speed

2) To enable access to the advanced parameters required, set P1-14 = 201

3) Select Vector Speed Control Mode by setting P4-01 = 0

4) Carry out an Auto-tune by setting P4-02 = 1

5) Once the Auto-tune is completed, the Optidrive should be run in the forward

direction with a low speed reference (e.g. 2 –5Hz). Ensure the motor operates

correctly and smoothly.

6) Check the Encoder Feedback value in P0-58. With the Optidrive running in

the forward direction, the value should be positive, and stable with variation of +

/ - 5% maximum. If the value in this parameter is positive, the encoder wiring is

correct. If the value is negative, the speed feedback is inverted. To correct this,

reverse the A and B signal channels from the encoder.

7) Varying the drive output speed should then result in the value of P0-58

changing to reflect the change of the actual motor speed. If this is not the case,

check the wiring of the whole system.

8) If the above check is passed, the feedback control function can be enabled by

setting P6-05 to 1.

An application note, detailing full use of the Encoder interface module, is

available from your local Invertek distributor.