SERVICE MANUAL ODE-3 FRAME SIZE 3

Page 2of 23

Contents Page no:

Service Request Form ..........................................................................................................3

Multimeter checks:................................................................................................................3

Control terminal checks:..................................................................................................................3

Input Terminal Checks: ...................................................................................................................4

Output Terminal checks:.................................................................................................................5

IGBT tests (480V).................................................................................................................6

IGBT tests (240V).................................................................................................................7

Brake chopper test 240V & 480V..................................................................................................8

Main components on an ODE-3............................................................................................9

Control PCB......................................................................................................................................9

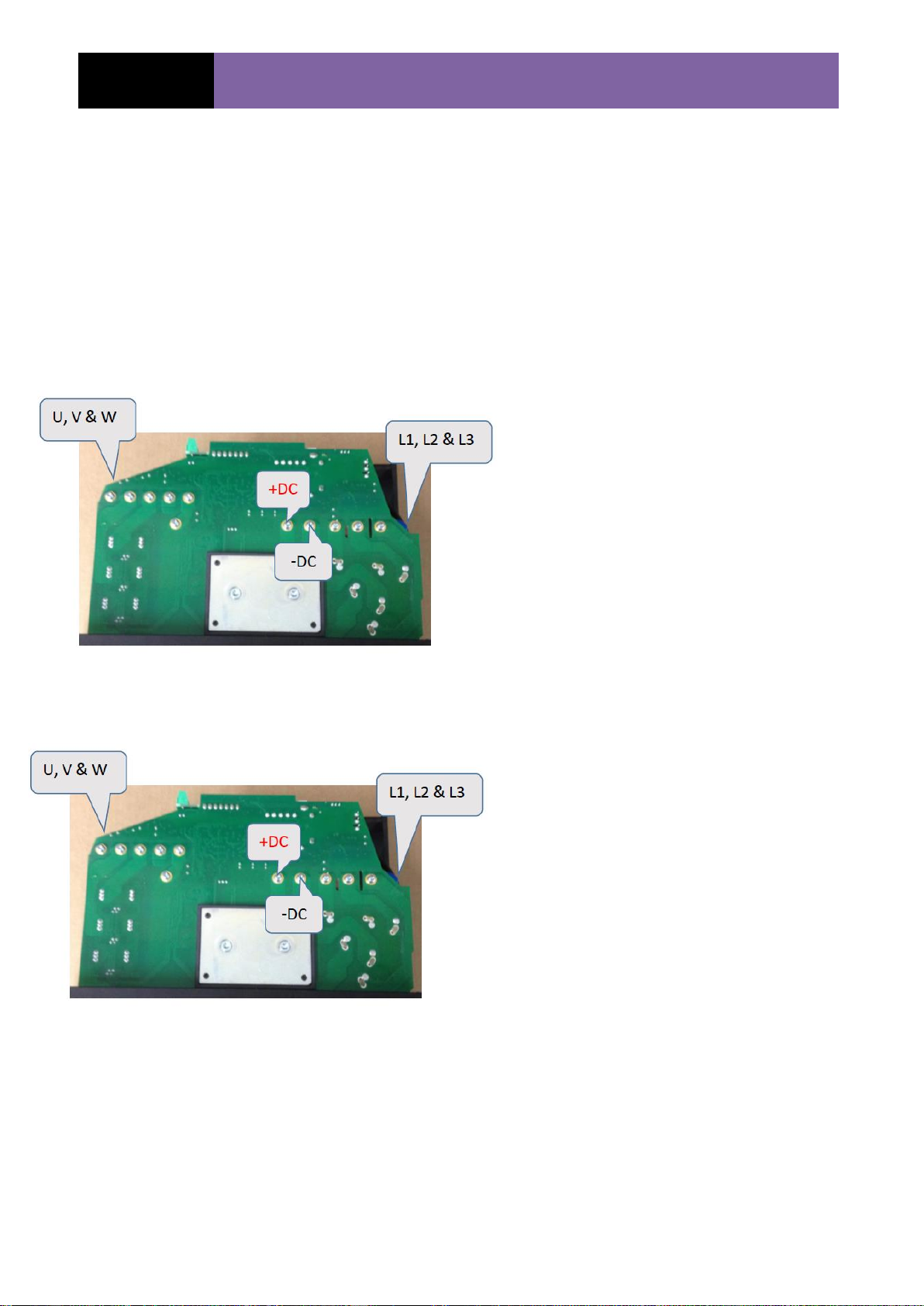

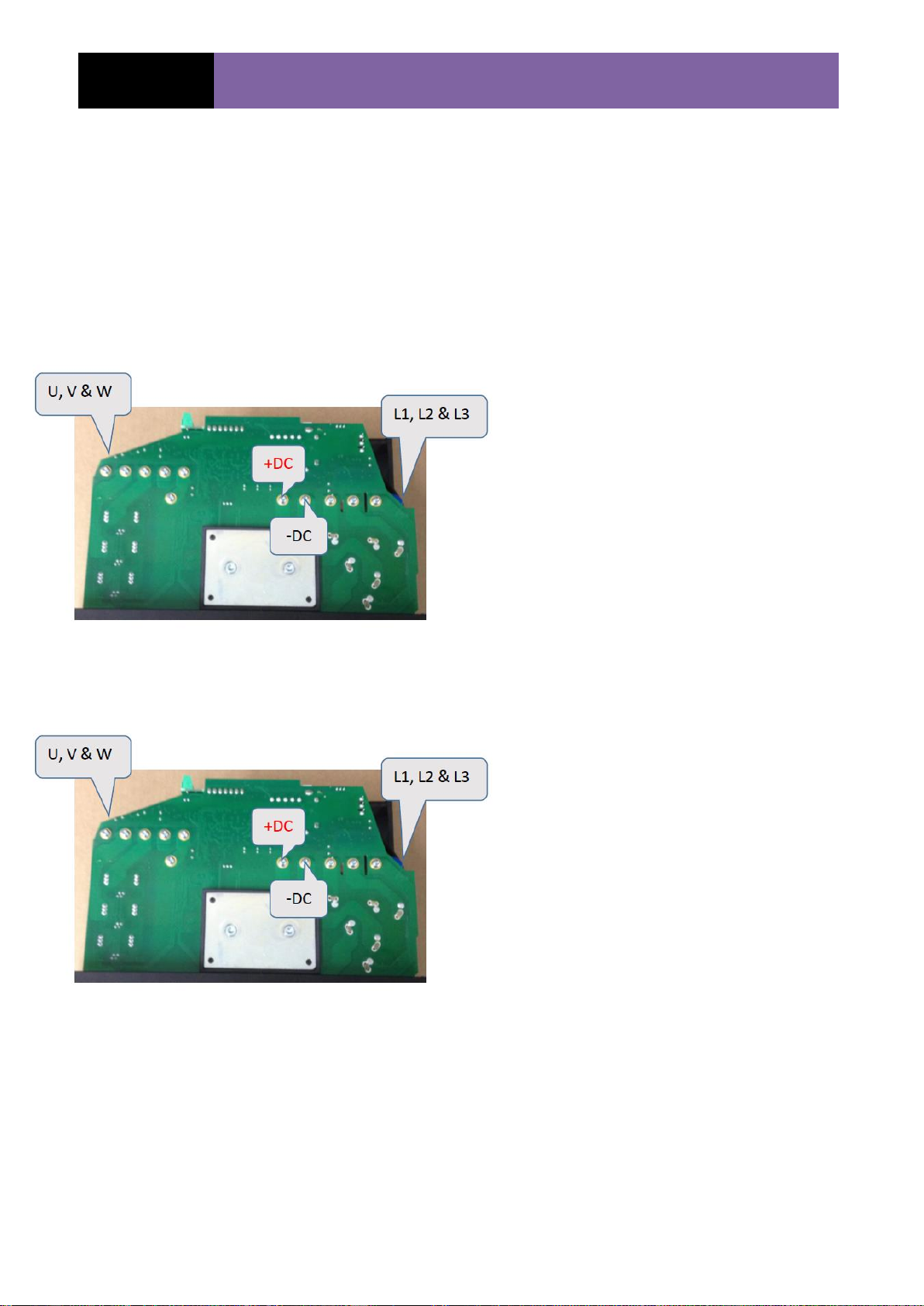

Power board PCB 240 & 480V.....................................................................................................10

Inrush circuit test (480V & 240V).........................................................................................12

IGBT pin outs......................................................................................................................13

4.0kW, 240V, 5.5 -7.5kW, 480V...................................................................................................13

5.5kW, 220V, 11.0kW, 480V ........................................................................................................13

DC Bus check.....................................................................................................................14

Power board (supply rails)...................................................................................................15

Power board Pin outs..........................................................................................................16

PCB pin outs...................................................................................................................................16

Control board PCB pin outs..........................................................................................................17

Control board (Supply rails).................................................................................................18

Control board (Digital inputs/outputs, Comms & display).....................................................19

Parameter group 0..............................................................................................................20

Fault codes.........................................................................................................................21

Drive test procedure (240 - 480V).......................................................................................22