Catalogue

Catalogue ..........................................................................................4

1. About this manual .................................................................................5

1.1 Using this manual ........................................................................... 5

1.2 Applicable areas .............................................................................5

1.3 Applicable group .............................................................................5

1.4 Illustration .................................................................................. 5

1.5 How to use this manual .......................................................................5

1.6 General Introduction ......................................................................... 5

1.7 Abbreviations and terms ...................................................................... 6

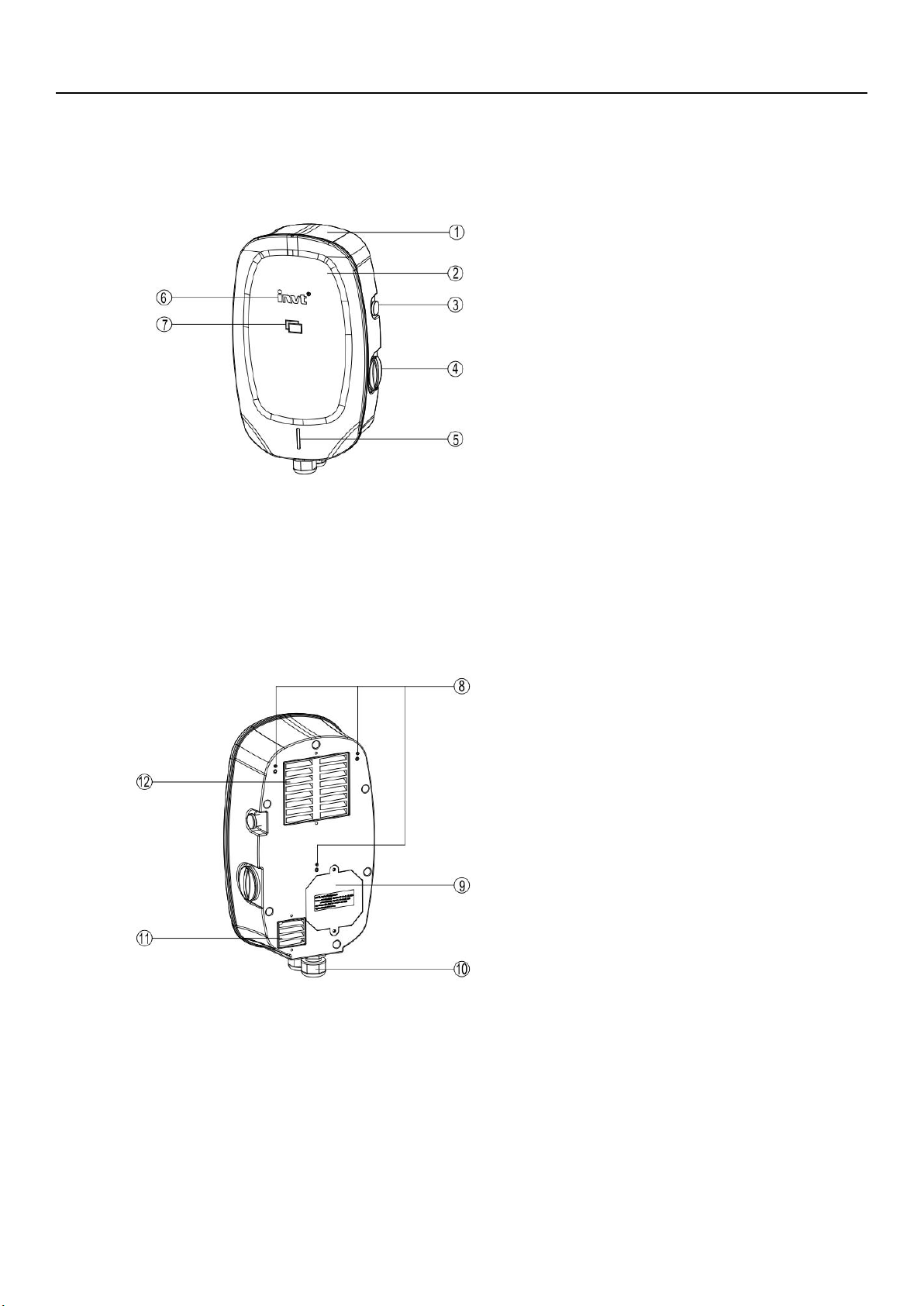

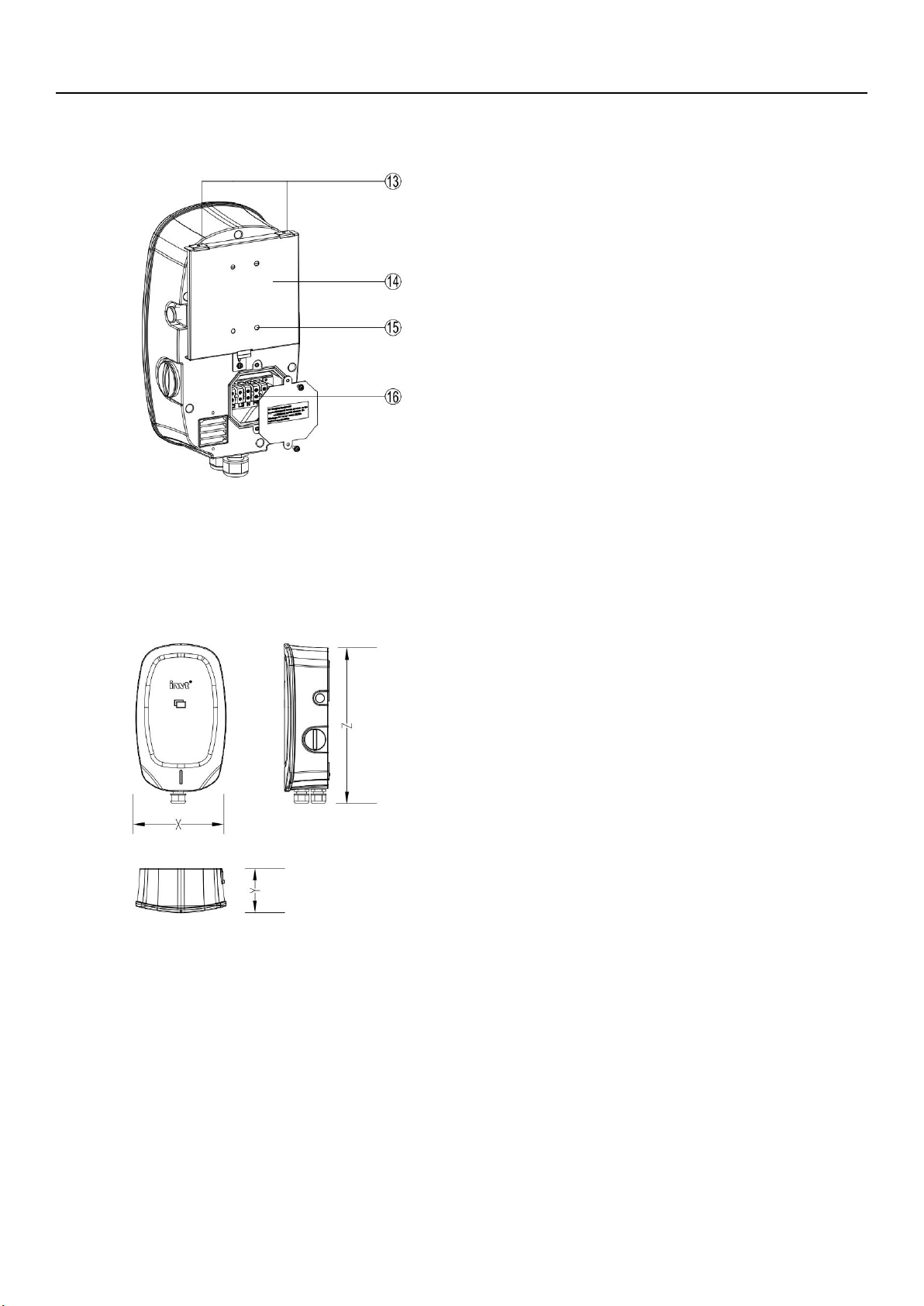

1.8 Product Overview ............................................................................7

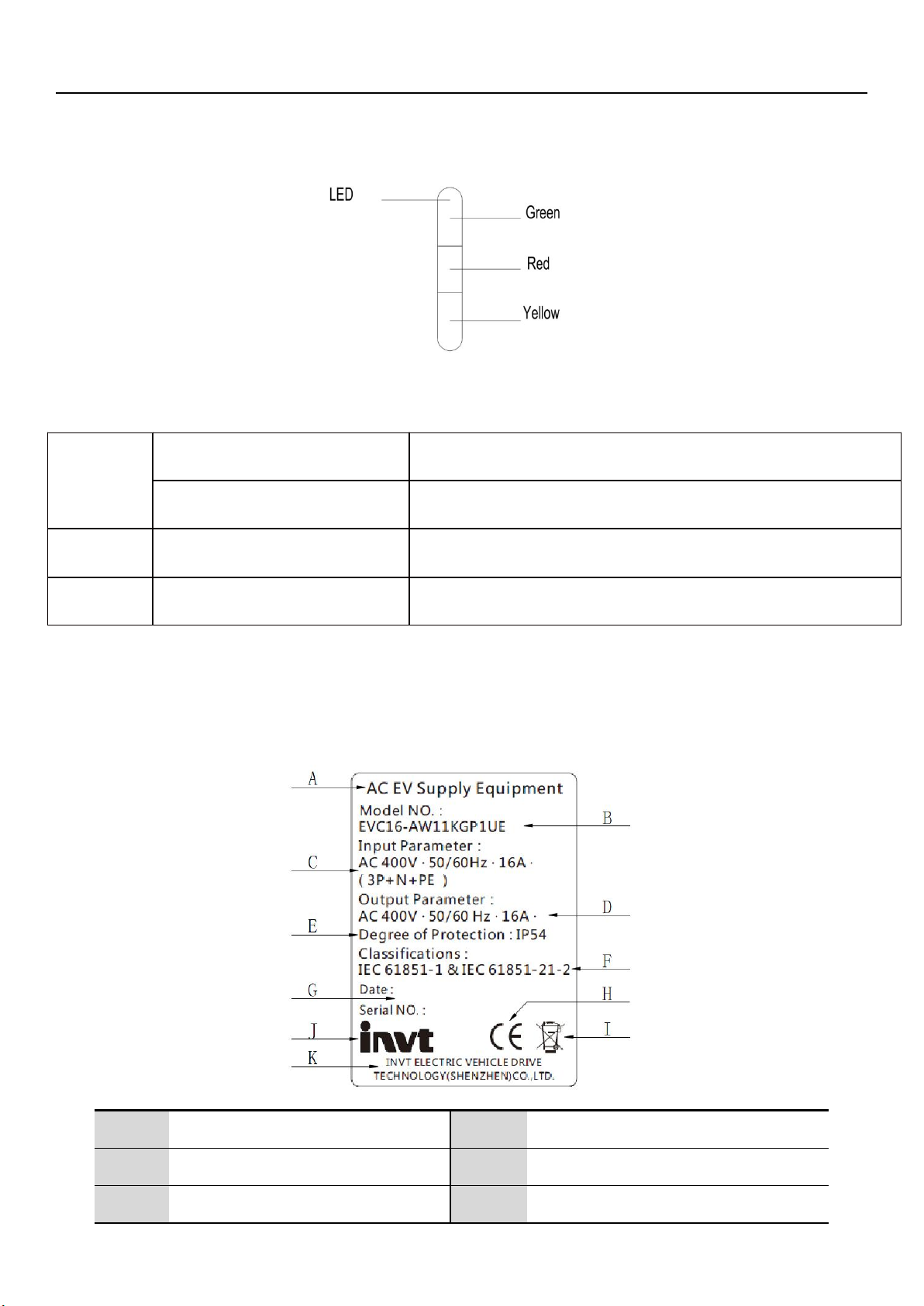

1.9 LED indicators .............................................................................. 9

2. Specifications .................................................................................... 9

2.1 Product name plate .......................................................................... 9

2.2 Product technical parameters ................................................................. 10

3. Preparation for Charger installation ................................................................. 12

3.1 General requirements ........................................................................ 12

3.2. Environment and tool requirements ............................................................12

3.3 Unpack the Charger ......................................................................... 12

4. Electrical installation of the Charger ................................................................. 12

4.1 General Specification ........................................................................ 12

4.2 Electrical installation procedure ................................................................ 14

5. Mechanical installation of the Charger ............................................................... 16

5.1 Installation procedure of power distribution module (Optional) ..................................... 16

(1) Cable hole pre-treatment ..................................................................16

(2) Power distribution module cable connection ................................................. 16

5.2 General Specification ........................................................................ 17

5.3 Support rear plate mounting ...................................................................18

5.4 Hanging ear installation ...................................................................... 19

5.5 Installation of the whole Charger ............................................................... 19

5.6 End and check .............................................................................. 19

6. Charger power supply operation .................................................................... 20

6.1 Power on operation .......................................................................... 20

6.2 Close the Charger power switch ............................................................... 20

6.3 Power-off operation .......................................................................... 21

7. Daily maintenance and fault diagnosis ............................................................... 21

7.1 Daily maintenance ........................................................................... 21

7.2 Fault diagnosis .............................................................................. 21