Page 2

INSTALLATION INSTRUCTIONS

CAUTION: Before installing, make certain the A.C. power is off and the IIS-35-HE unit

connector is disconnected.

1. MOUNTING THE IIS-35-HE

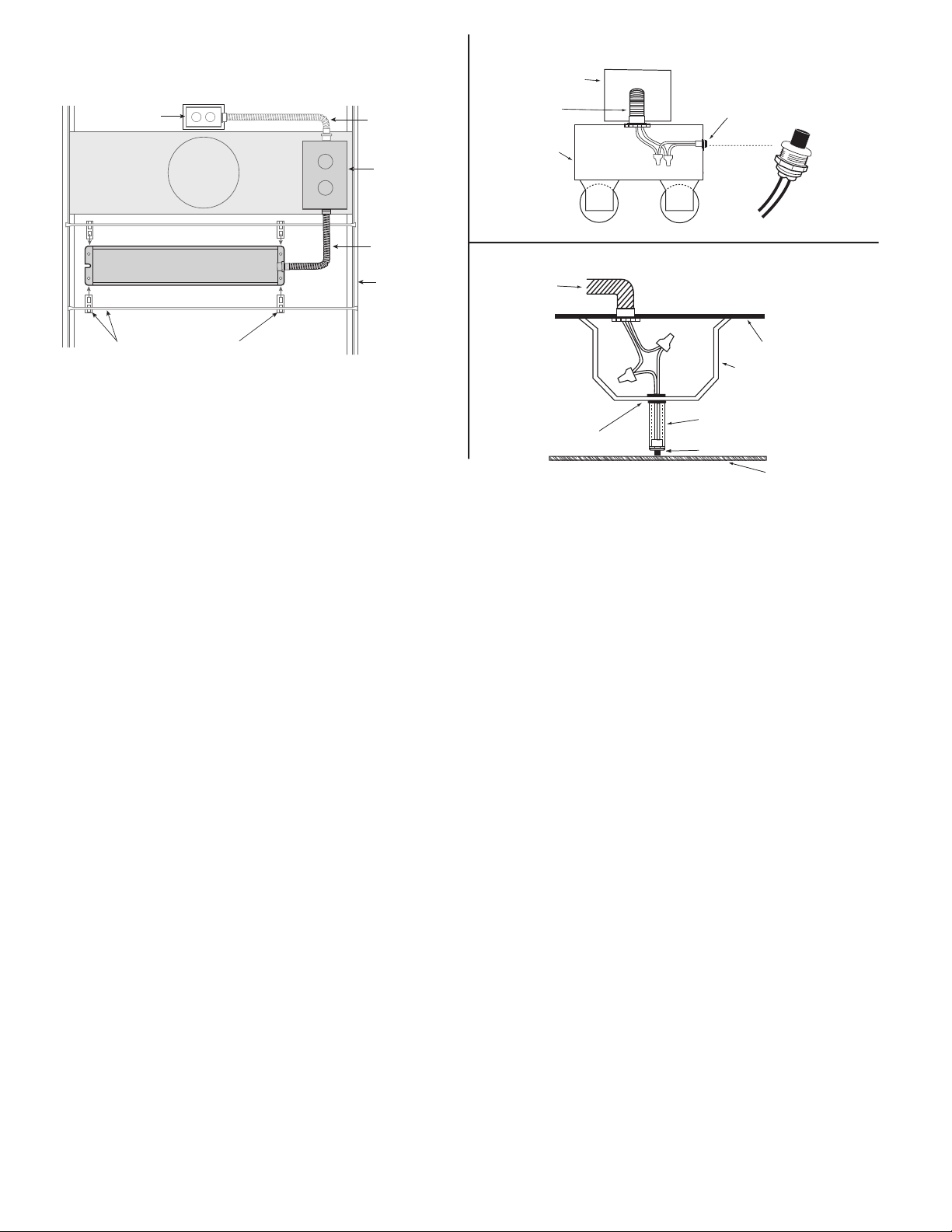

Mount the IIS-35-HE on or adjacent to the fixture in a position that does not interfere with the existing A.C. driver, ballast or

any other hardware. Extend the flex conduit to the junction box or wireway channel and punch a 7/8″hole. Feed the wires

and flex connector down through the hole in the fixture and secure in place with the flex connector nut. An optional T-bar

mounting kit is available to mount the IIS-35-HE above the ceiling tile adjacent to the fixture. Refer to Illustration 1. To order

the optional T-bar mounting kit (part number TBMK-160) contact Customer Service.

When remote mounting, maximum allowable distance between the inverter and fixture is 250 ft. Consult Customer

Service for additional information.

CAUTION: Properly secure the IIS-35-HE in the ceiling grid to insure compliance with local, state, and

federal guidelines regarding ceiling mounted equipment.

2. WIRING

A. CONNECTING THE INVERTER AC INPUT

This is the AC input that charges the inverter battery, therefore it requires an unswitched AC supply. Connect the AC line

wire to the ORG/BLK lead. Connect the WHITE to the AC Neutral. Refer to the Wiring Diagram on Page 4.

B. CONNECTING THE NORMAL AC SWITCHED / UNSWITCHED SUPPLY

This is the AC input that operates the fixture during normal operation. It may be switched or unswitched.

Connect the BLACK lead to the switched or unswitched AC supply. Refer to the Wiring Diagram on Page 4. For Emer-

gency Only (Normally Off) operation, the BLACK lead is not used and should be capped separately.

C. CONNECTING THE INVERTER TO THE AC FIXTURE

Connect the output leads of the IIS-35-HE to the AC fixture. Refer to the Wiring Diagram on Page 4. For additional

wiring diagrams consult Customer Service.

Wire the AC driver/ballast with the lamp(s) in accordance with the manufacturer’s installation instructions.

Note: only emergency fixtures should be present on the load side of the IIS-35-HE. Keep the output neutral isolated

from all other neutrals including the input neutral.

Install in accordance with the National Electrical Code and local regulations.

3. INSTALLING THE THREADED BODY TEST SWITCH (TBTS)

The TBTS test switch and charge indicator is to be installed either within the AC fixture or in a single gang switch

box (not provided) adjacent to the fixture.

Single Switch Box Installation - Cut a single gang switch box into the ceiling adjacent to the fixture. After mount-

ing the switch box, route test accessory leads from the junction box to the switch box via flexible conduit (not pro-

vided). Complete connections within the switch box, observing proper polarity. Refer to Illustration 1.

Integral Fixture Installation - Select a convenient location with proper clearance in the fixture where the test com-

ponents are visible and accessible after installation. Drill or punch a 1/2″hole. Push the TBTS housing into the 1/2″

hole until it is firmly locked in place. Connect the leads, observing the proper polarity. Refer to Illustration 2.

Recessed Troffer Fixture Installation - Select a convenient location with proper clearance in the ballast cover or

exposed wireway and drill or punch a 7/8″hole (1/2″knockout). Insert the 7/8″bushing into the hole. Push the plastic

tube through the bushing. Route the leads of the TBTS through the plastic tube. Connect the leads, observing the

proper polarity (Refer to the Wiring Diagram on Page 4). Push the entire assembly back into the tube until the lens

collar rests against the plastic tube. The plastic tube should be adjusted so that the TBTS is within ¼″of the fixture

lens. The TBTS must be visible after installation. Refer to Illustration 3.

4. COMPLETING INSTALLATION

INSURE WIRING IS IN ACCORDANCE WITH THE NATIONAL ELECTRICAL CODE AND LOCAL REGULATIONS.