3

Battery Safety 0

WARNING: A battery can present a risk of electrical shock or burn from large

amounts of short-circuit current, fire, or explosion from vented gases. Observe

proper precautions.

WARNING: Risk of Explosion. Proper disposal of batteries is required. Do not

dispose of batteries in fire. Refer to local regulations or codes for requirements.

CAUTION: When replacing batteries, use properly specified number, sizes,

types, and ratings based on application and system design.

CAUTION: Do not open or mutilate batteries. Released electrolyte is harmful

to skin, and may be toxic.

● Servicing of batteries should be performed, or supervised, by personnel

knowledgeable about batteries, and the proper safety precautions.

● Be very careful when working with large lead-acid batteries. Wear eye protection

and have fresh water available in case there is contact with the battery acid.

● Remove watches, rings, jewelry and other metal objects before working with

batteries.

● Wear rubber gloves and boots.

● Use tools with insulated handles and avoid placing tools or metal objects on top of

batteries.

● Disconnect charging source prior to connecting or disconnecting battery terminals.

● Determine if battery is inadvertently grounded. If so, remove the source of contact

with ground. Contact with any part of a grounded battery can result in electrical

shock. The likelihood of such a shock can be reduced if battery grounds are

removed during installation and maintenance (applicable to equipment and remote

battery supplies not having a grounded supply circuit).

● Carefully read the battery manufacturer's instructions before installing / connecting

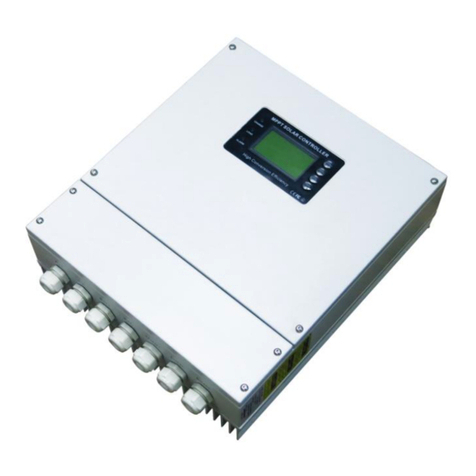

to, or removing batteries from, the MPPT.

● Be very careful not to short circuit the cables connected to the battery.

● Have someone nearby to assist in case of an accident.

● Explosive battery gases can be present during charging. Be certain there is

enough ventilation to release the gases.

● Never smoke in the battery area.

● If battery acid comes into contact with the skin, wash with soap and water. If the

acid contacts the eye, flood with fresh water and get medical attention.

● Be sure the battery electrolyte level is correct before starting charging. Do not

attempt to charge a frozen battery.

● Recycle the battery when it is replaced.