Installation Hotline • 866.EZINPRO

Inprocorp.com • 800.222.5556 • 262.679.9010

World Headquarters S80 W18766 Apollo Drive, Muskego, WI 53150 USA

Installation Instructions

2000/2000W/G2-2000 Handrail

Please read all instructions before installing

handrail.

LEFT RETURN

(3 15

/16" [99mm] ALLOWANCE)

RETAINER

BUTT JOINT

HANDRAIL

SPLICE

RIGHT RETURN

(3 15

/

16" [99mm] ALLOWANCE)

INSIDE/OUTSIDE CORNER, 90º

(5 3/8" [136mm] ALLOWANCE FOR INSIDE C

(1/4" [6mm] ALLOWANCE FOR OUTSIDE CORNER)

CORNER, 135º

(2 3/8" [62mm] ALLOWANCE FOR INSIDE CORNER)

1/4" [6mm] ALLOWANCE FOR OUTSIDE CORNER)

BOTTOM

PLATE

(Included with left return)

BOTTOM PLATE

(Included with right return)

CONTINUOUS

ALUMINUM RETAINER

.080" [2mm]

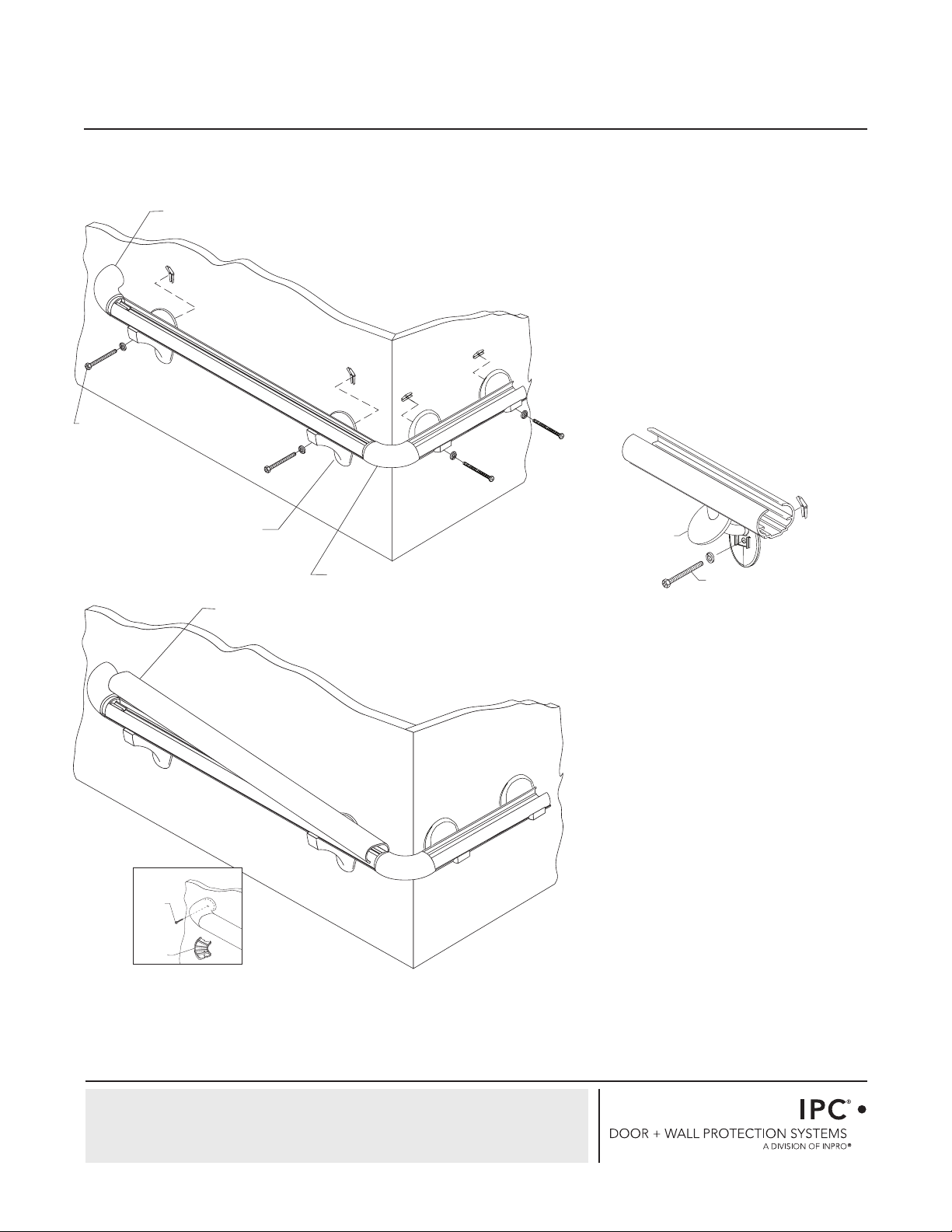

FIG. 1

FIG. 2

2. Drill holes in centerline of aluminum retainer

for brackets, returns and corners using 1/4"

(6mm) drill bit. Attach returns, inside corners

and outside corners to retainer leaving a 1/16"

(1.5mm)gap between returns/corners and

retainer to allow for adjustment. See Figure 2.

a. Plastic Brackets - Attach brackets to retainer.

See Figure 2a.

b. Stainless Steel Brackets - Slip stainless steel

cover over post. Insert post through retainer

hole and attach. See Figure 2b.

DRILL 4" [102mm] FROM EACH END

FOR BRACKETS

SPACE HOLES

A MAXIMUM OF

EVERY 32" [812mm]

FOR BRACKETS

DRILL 1/2" [13mm]

FROM

EACH END

FOR RETURNS

AND CORNERS

TURN

INSIDE/OUTSIDE

CORNER

11/8" SLOTTED

PAN HEAD

BOLY ASSEMBLY

11/8"SLOTTED

PAN HEAD BOLT

ASSEMBLY

MOUNTING

BRACKET

1

/

4

” SERRATED

FLANGE

HEX NUT

STAINLESS STEEL

CKET ASSEMBLY

1/4” SERRATED

FLANGE

HEX NUT

FIG. 2A

FIG. 2b

1. Cut aluminum retainer to desired length,

leaving allowance for returns, outside corners

and inside corners. See Figure 1.