TABLE OF CONTENTS

1.0 INSPECTION....................................................................................................................1

2.0 IMPORTANT SAFETY INSTRUCTIONS..........................................................................1

3.0 IMPORTANT SAFETY INSTRUCTIONS FOR THE RECOVERY OF TOXIC OR

NUISANCE DUST.......................................................................................................................3

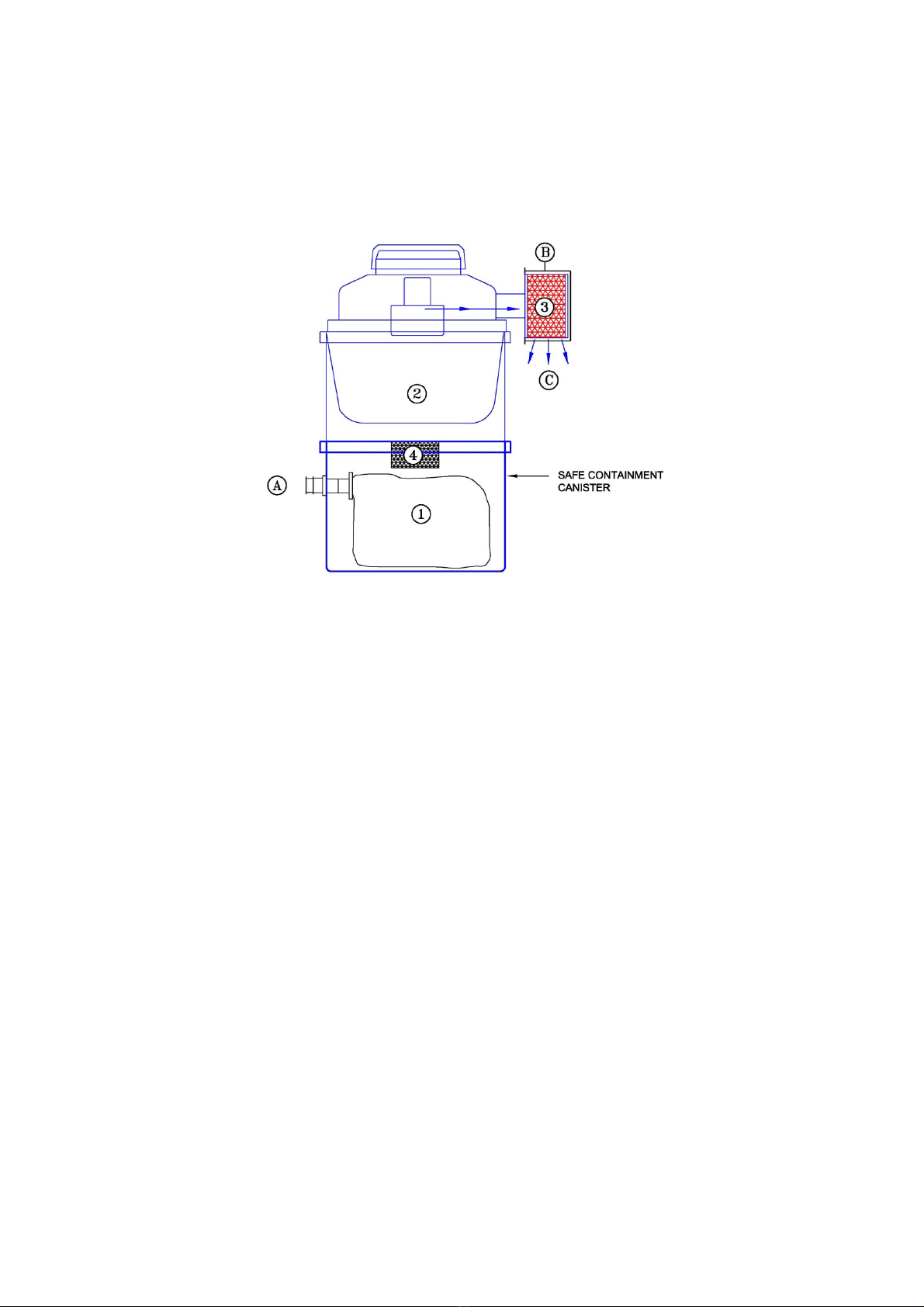

4.0 FILTRATION SYSTEM.....................................................................................................4

5.0 OPERATING PROCEDURE.............................................................................................6

6.0 MAINTENANCE ...............................................................................................................8

6.1. CLEANUP PROCEDURE OF PHARMA CLOTH FILTER ............................................8

6.2. CLEANUP PROCEDURE OF PHARMA WITH STAINLESS STEEL AISI 316

RECOVERY TANK AFTER USE ............................................................................................8

6.3. SAFE CONTAINMENT CANISTER DISPOSAL AND REPLACEMENT.......................9

6.3.1. DISPOSAL OF PHARMA SAFE CONTAINMENT CANISTER ............................... 10

6.3.2. REPLACEMENT OF PHARMA SAFE CONTAINMENT CANISTER.......................11

6.4. STORAGE ..................................................................................................................11

6.5. ULPA FILTER REPLACEMENT................................................................................. 12

6.6. SERVICING OF DOUBLE-INSULATED APPLIANCES .............................................13

7.0 EU DECLARATION OF CONFORMITY .........................................................................14