USC 2024-BB 3” UNIFORM SEMI-AUTOMATIC CASE SEALER Table of Contents

i

Table of Contents

Chapter Title Page

1GENERAL INFORMATION....................................................................................................1-1

1.1 Revision Control....................................................................................................................... 1-1

1.2 Technical Support.................................................................................................................... 1-1

1.3 Replacement Parts .................................................................................................................. 1-1

1.4Field Service Assistance.......................................................................................................... 1-2

1.5 Warranty .................................................................................................................................. 1-2

1.6 Description of USC 2024-BB 3" Uniform Semi-Automatic Case Sealer.................................. 1-4

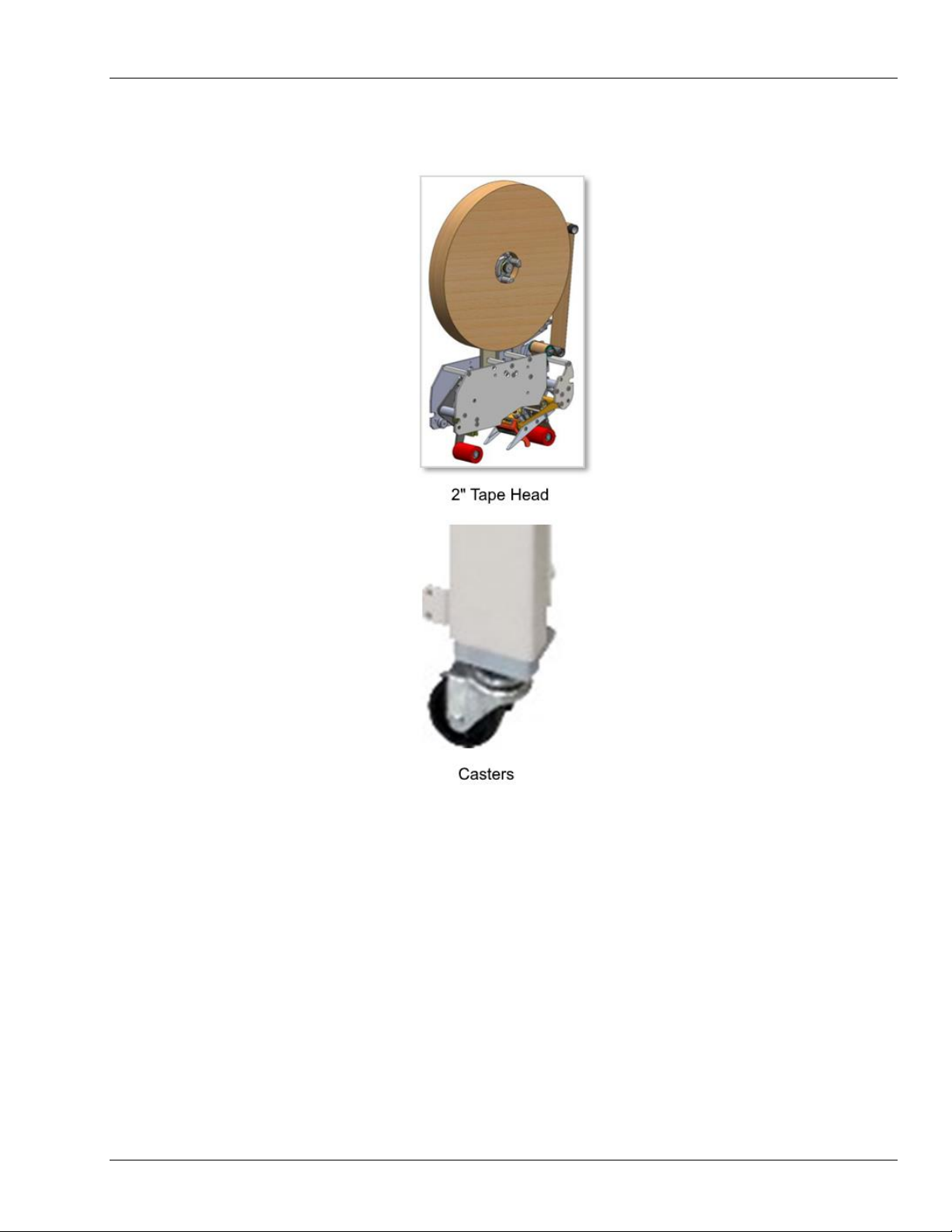

1.7 Optional Equipment ................................................................................................................. 1-5

2 IMPORTANT SAFEGUARDS.................................................................................... 2-1

2.1 Safety Labels .......................................................................................................................... 2-1

2.2 Safety Label Placement.......................................................................................................... 2-2

2.3 Safety Label Descriptions....................................................................................................... 2-3

2.4 Explanation of Signal Word Consequences ........................................................................... 2-5

2.5 Operator Skill Level Descriptions............................................................................................ 2-6

2.5.1 Skill “A” Machine Operator .................................................................................................. 2-6

2.5.2 Skill “B” Mechanical Maintenance Technician..................................................................... 2-6

2.5.3 Skill “C” Electrical Maintenance Technician ........................................................................ 2-6

2.5.4 Skill “D” Manufacturer’s Technician..................................................................................... 2-6

3SPECIFICATIONS..................................................................................................... 3-1

3.1 Machine Dimensions .............................................................................................................. 3-1

3.2 Machine Components............................................................................................................. 3-2

3.3 Machine Operating Conditions ............................................................................................... 3-3

3.3.1 Power Requirements........................................................................................................... 3-3

3.3.2 Operating Speed ................................................................................................................. 3-3

3.3.3 Tape Specifications ............................................................................................................. 3-3

3.3.4 Case Specifications............................................................................................................. 3-3

3.3.5 Case Processing Stability.................................................................................................... 3-4

4SET-UP PROCEDURES........................................................................................... 4-1

4.1 Receiving and Handling.......................................................................................................... 4-1

4.2 Caster Installation (If Purchased) .......................................................................................... 4-2

4.3 Machine Height Adjustment.................................................................................................... 4-3

4.4 Installation of Interpack Brand In-Feed and Roller Tables (If Purchased) ............................. 4-4

4.5 Installation of External In-Feed and Exit Conveyors............................................................... 4-5