10

A

AA

A

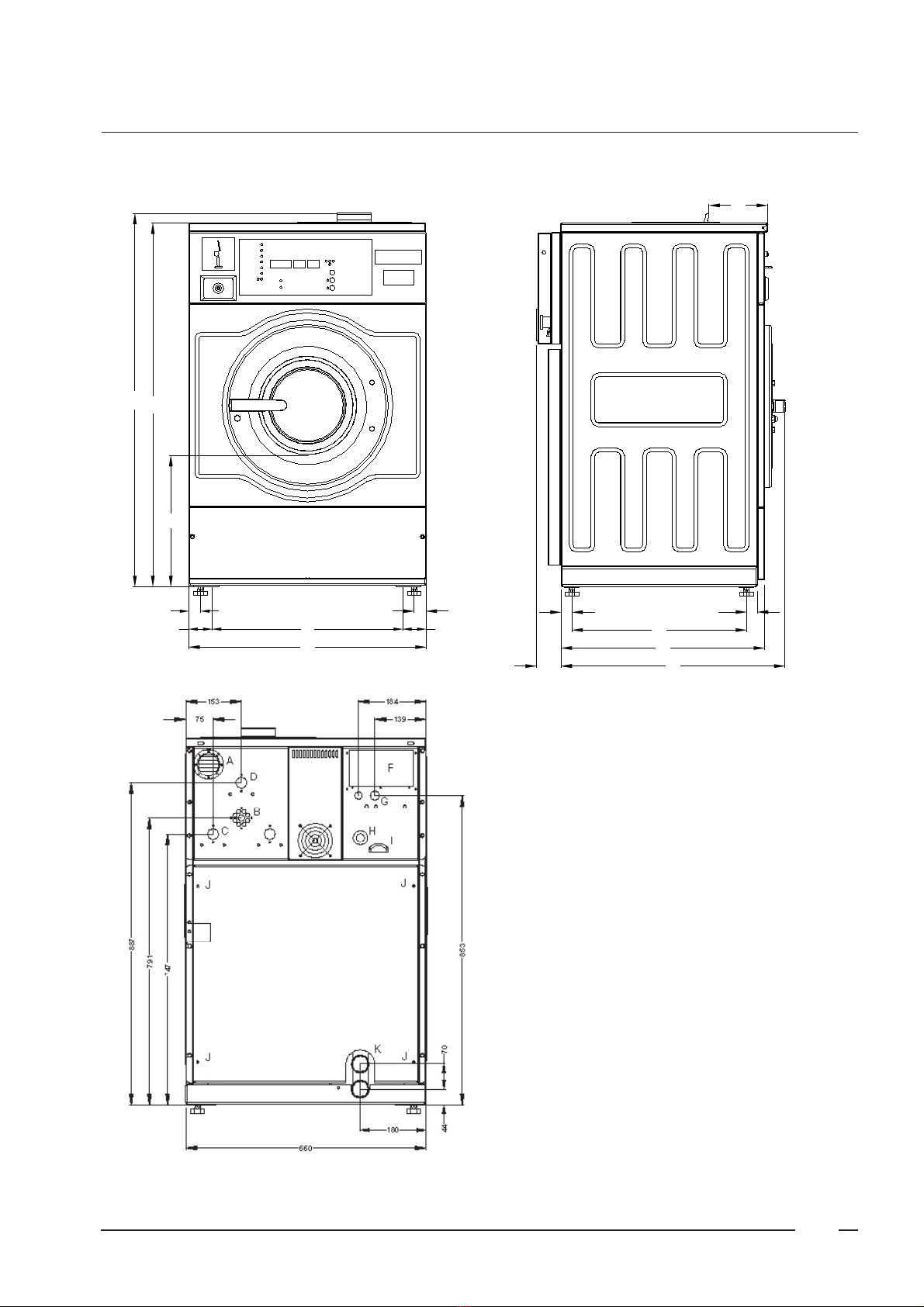

The machine (with rubber feet) must be placed on a flat, solid bottom (concrete

or fixed ground). When using a metal socle or with machines with steam heating,

the machine (without feet) must be anchored on the foreseeing points (A) in

the base (bolts M10). (see Dimensions 2).

The machine must be placed entirely level. For easy maintenance it is recom-

mended to keep a minimal distance of 600 mm between the wall and the back

of the machine.

If several machines are placed next to each another, there should be a minimal

distance of 30 mm between each machine.

To prevent damage during transportation, the machine has been

equipped with two red transport brackets (A) to eliminate every

possible movement of the tub.

After the machine has been placed level, take off the backpannel

and remove these transport brackets.

Important

The machine must never be activated before removing

these transport brackets.

Removal of the transport safety

The machine is delivered with hoses with 3/4" connections. These hoses fit the

water inlet valves of the machine and the main water inlet taps. To ensure the

optimal functioning of the water inlet valves, the water pressure on the inlet

should be between 0,5 and 10 kg/cm² (7 and 145 psi). If the pressure is too

low, the cycle time will increase considerably.

In case of boiler fed machines, a minimum of hot water of 90°C should

be available: HC60: 46l. HC65: 55 l. HC75: 65 l. HC100: 80l.

HC135: 100l. H165: 120l.

Water connection

Water drain The machine is equipped with a drain valve with 6/4" outer diameter (50 mm).

This drain valve should be connected to the drain by means of the drain elbow

which is delivered with the machine.

The diameter of the main drain should be adapted to the water flow and the

number of machines. It should be sufficient to handle at least 80L/min. per

machine.

It is necessary to connect the main drain at least on one side to an open air-

brake to allow ventilation.

Important

The bolt pattern for the fixation of the HC60 machine is foreseen in the

back panel of the cabinet. Put this panel on the floor and indicate the

holes (see page 7).

Installation and connection

3

Ground