8

3

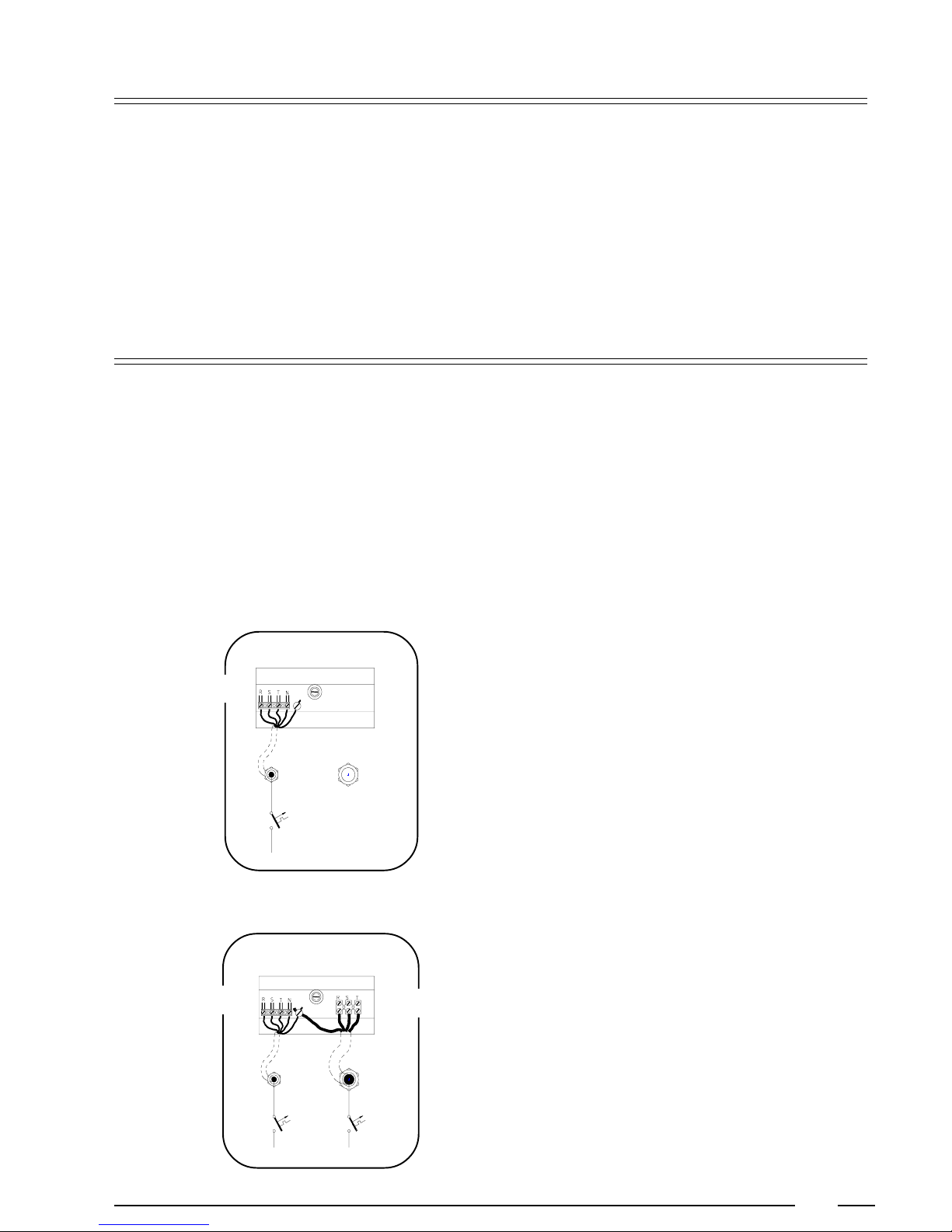

D

C

CG

D

B

A

F

E

D

C

A

B

E

The machine must be securely fi ed on a flat surface (metal base, concrete or solid

ground). The anchoring is to be done on the provided places (A) in the base. (See

Dimensions 2)

The machine must be placed entirely level. For easy maintenance it is recommen-

ded to keep a minimal distance of 600 mm between the wall and the back of the

machine.

If several machines are placed ne t to each another, there should be a minimal

distance of 30 mm between each machine.

Installation and connection

Surface

Anchoring

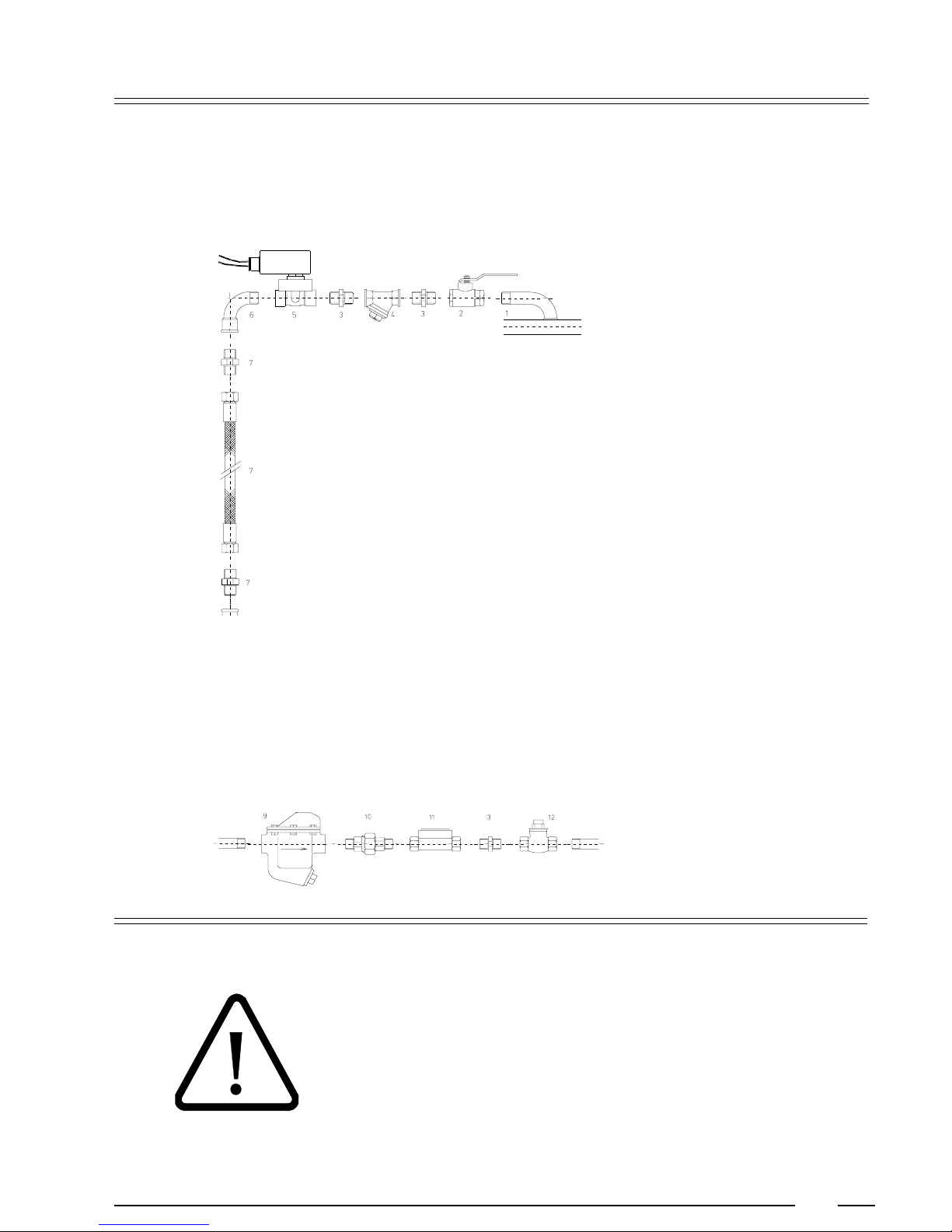

The machine is delivered with hoses with 3/4" connections. These hoses fit the

water inlet valves of the machine and the main water inlet taps. To ensure the

optimal functioning of the water inlet valves, the water pressure on the inlet should

be between 0,5 and 10 kg/cm² (7 and 145 psi). If the pressure is too low, the cycle

time will increase considerably.

In case of boiler fed machines, a minimum of hot water of 90°C should be available:

For the WE55: 50 l. WE 110: 90l.

For the WE73: 65 l. W E132: 120l.

For the WE95: 80 l. W E165: 140l.

Water connection

The machine must be anchored directly on a concrete base.

Directly on the ground

The machines must be fi ed on a metal base which is securely anchored on a

concrete base.

A: Bolt M12 (WE55/73/95), M16 (WE110/132/165)

B: Concrete base (WE55/73: 20cm, WE95/110: 30cm, WE132/165: 40cm)

C: Washer 40 17 4

D: Nut M12 (WE55/73/95), M16 (WE110/132/165)

E: Base of the machine

F: Metal base

On a metal base

A: Bolt M12 (WE55/73/95), M16 (WE110/132/165)

B: Concrete base (WE55/73: 20cm, WE95/110: 30cm, WE132/165: 40cm)

C: Washer 40 17 4

D: Nut M12 (WE55/73/95), M16 (WE110/132/165)

E: Base of the machine