3

MAN0094/2

GENERAL PURPOSES Description.............................................................................................. 5

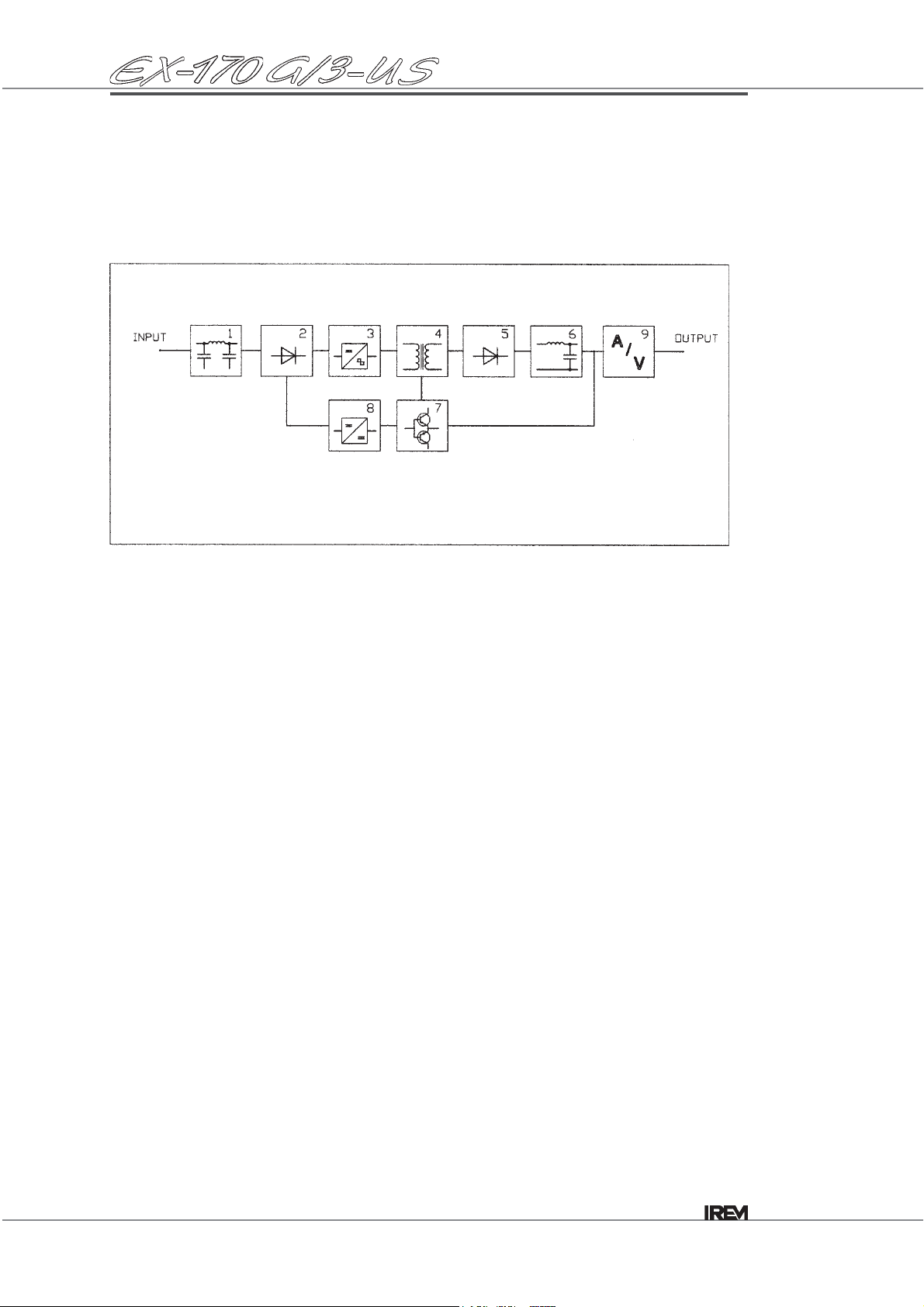

Block diagram ......................................................................................... 6

TECHNICAL SPECIFICATIONS

Technical specifications* ........................................................................

7

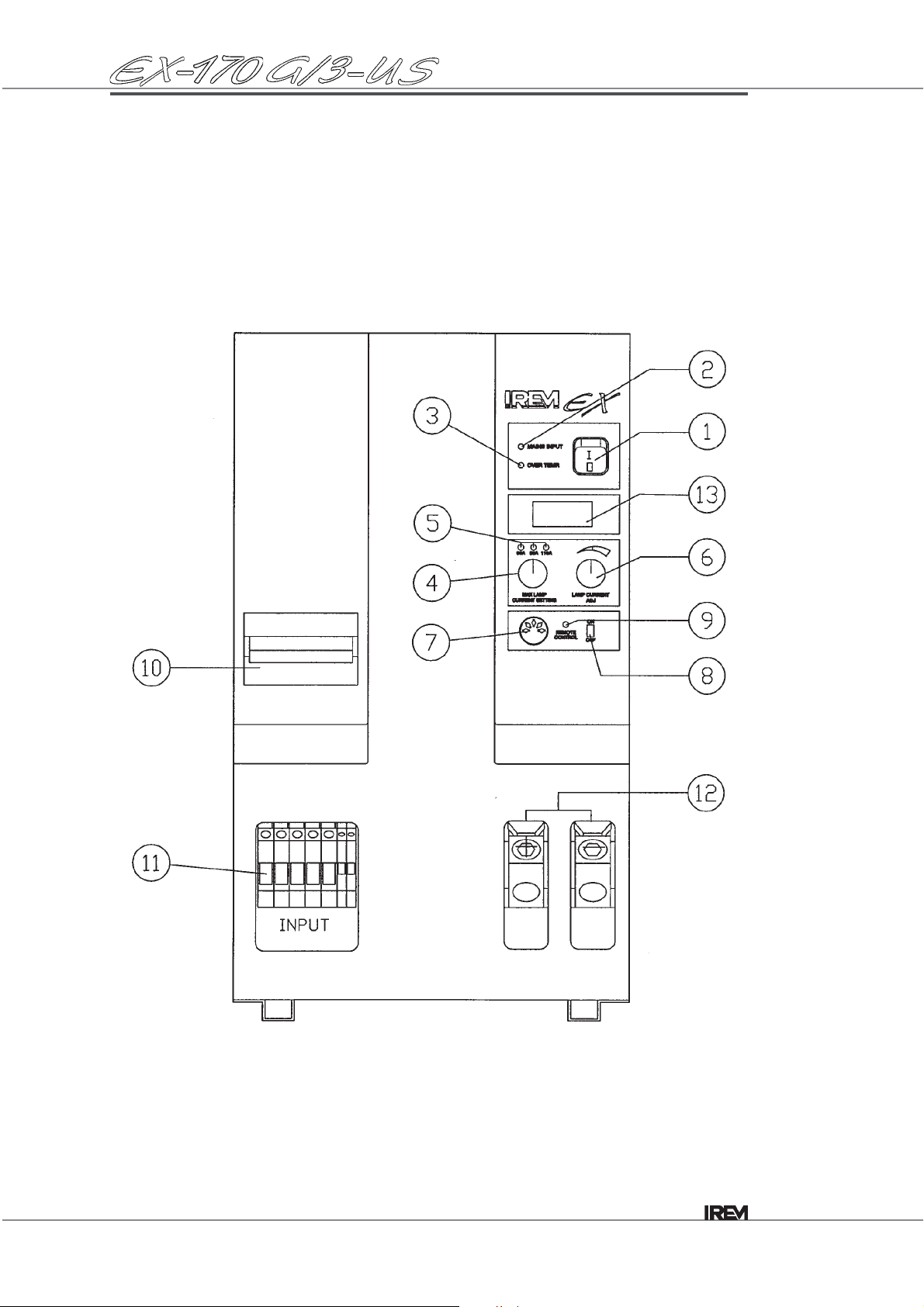

FUNCTIONS AND CONTROLS Control devices ....................................................................................... 8

CONNECTION AND OPERATING INFORMATION

Receiving the unit ................................................................................... 10

Delivery arrangement ............................................................................. 10

Storage ................................................................................................... 10

Removing of package and handling ....................................................... 10

Installantion - environment...................................................................... 10

Warnings................................................................................................. 11

Feet mounting displacement................................................................... 11

Preliminary checks.................................................................................. 12

Preparing the cables for remote control operation.................................. 12

Connecting the input-output cables ........................................................ 13

Connecting the cable for remote control operation................................. 13

DIRECTIONS FOR USE Local operation through the front panel controls .................................... 14

Switching on ........................................................................................... 14

Changing the lamp current ..................................................................... 14

Switching off ........................................................................................... 15

Remote operation ................................................................................... 16

Switching on ........................................................................................... 16

Setting the lamp current.......................................................................... 17

Changing the lamp current ..................................................................... 18

Switching off ........................................................................................... 18

Overheating protection and alarms......................................................... 19

Fan replacement..................................................................................... 20

TROUBLESHOOTING Possible failures...................................................................................... 21

TECHNICAL DATA Suggested wiring diagram ...................................................................... 24

Overall dimensions*................................................................................

25

* these sections have been modified with respect to the previous issue.

Table of contents