Kwik-Way

SVS II Deluxe Valve Refacer

Copyright © 2018 by Irontite Products Inc.

All Rights Reserved. Rev. 180802

pg. 7

SAFETY GUIDE FOR VALVE GRINDER WHEELS

(Read before installing the Grinding Wheels)

IMPORTANCE OF PROPER MACHINE MAINTENANCE

The most common cause of wheel breakage is due to improper mounting and abusive and/or careless

operation. Only through proper use, regular machine maintenance, service, and inspection procedures

can wheel breakage be prevented.

It is the responsibility of the user to inspect, at regular intervals, to be certain that mounting flanges are

in usable condition, are of proper size and shape and that no damage has occurred to the wheel or the

machine.

The following DO’S and DON’TS should be used as a guide to safer grinding.

WARNING: IMPROPER USE MAY CAUSE BREAKAGE AND SERIOUS INJURY.

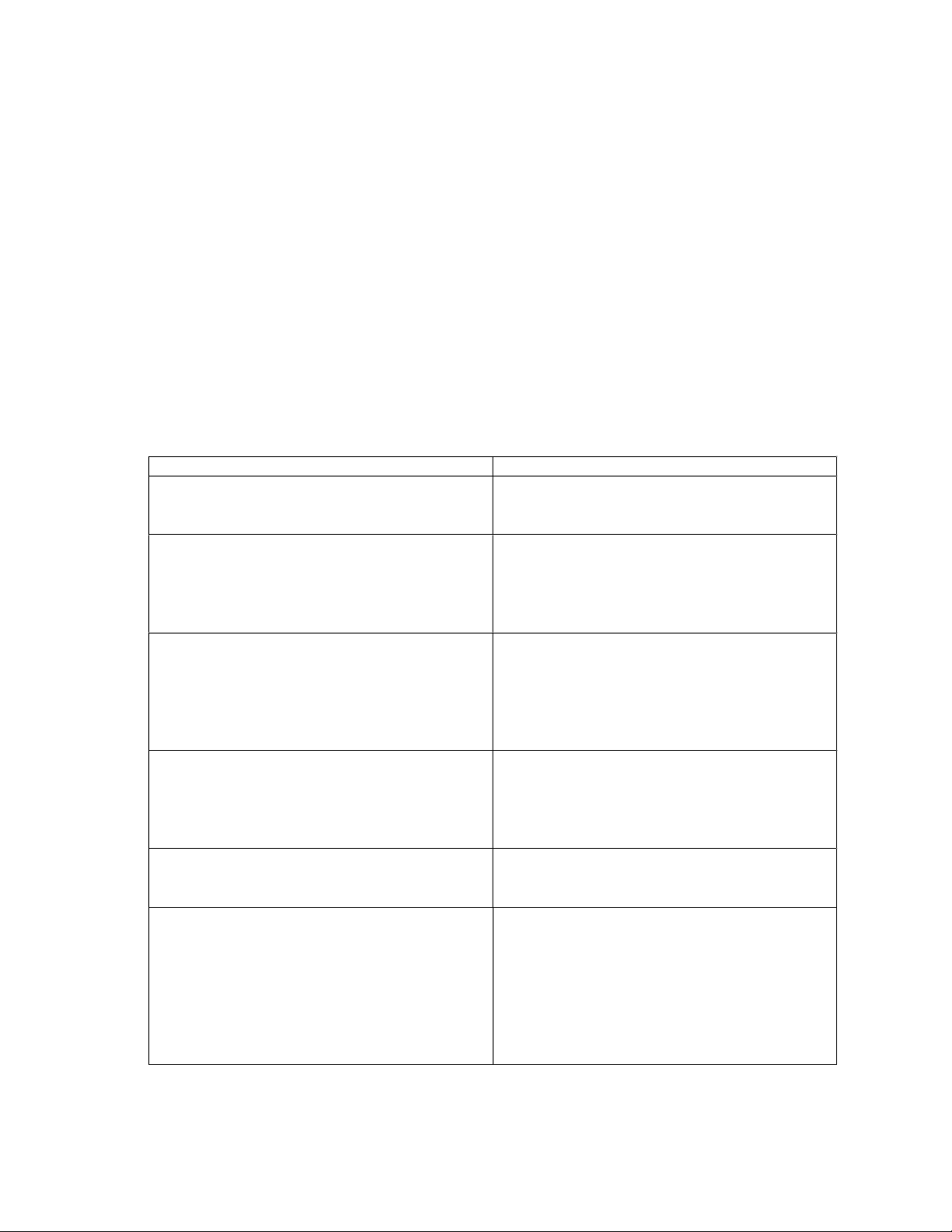

DO: CHECK all wheels for CRACKS or

other DAMAGE before mounting.

DON’T: USE wheels WHICH HAVE BEEN

DROPPED or otherwise damaged.

DO: USE MOUNTING BLOTTERS. Most

modern wheels are supplied with blotters

attached. If not, it is your responsibility to

use appropriate mounting blotters.

DON’T: USE EXCESSIVE PRESSURE

WHEN MOUNTING the wheel between

flanges. Tighten the nut only enough to

hold the wheel firmly.

DO: be sure the WHEEL HOLE, threaded

or unthreaded, FITS the machine arbor

PROPERLY and that flanges are clean,

flat, and of the proper type for the wheel

you are mounting.

DON’T: USE HEAVY GRINDING

PRESSURE.

DO: always RUN THE WHEEL WITH THE

GUARD IN PLACE at least one minute

before grinding with it.

DON’T: USE THE MACHINE FOR ANY

PURPOSE OTHER THAN GRINDING

VALVES, VALVE STEMS OR ROCKER

ARMS.

DO: USE THE WHEEL GUARD furnished

with the machine.

DON’T: Operate the machine while

wearing any baggy or loose clothing.

DO: always WEAR PROTECTIVE

SAFETY GLASSES or FACE SHIELD.

DON’T: Use any cleaning chemicals that

can leave a film or any residue as this will

affect the performance of your chuck. The

Collar and Balls area of the Chuck should

only be lubricated with Automatic

Transmission Fluid and NOTHING ELSE.

And only clean the chuck with Alcohol.