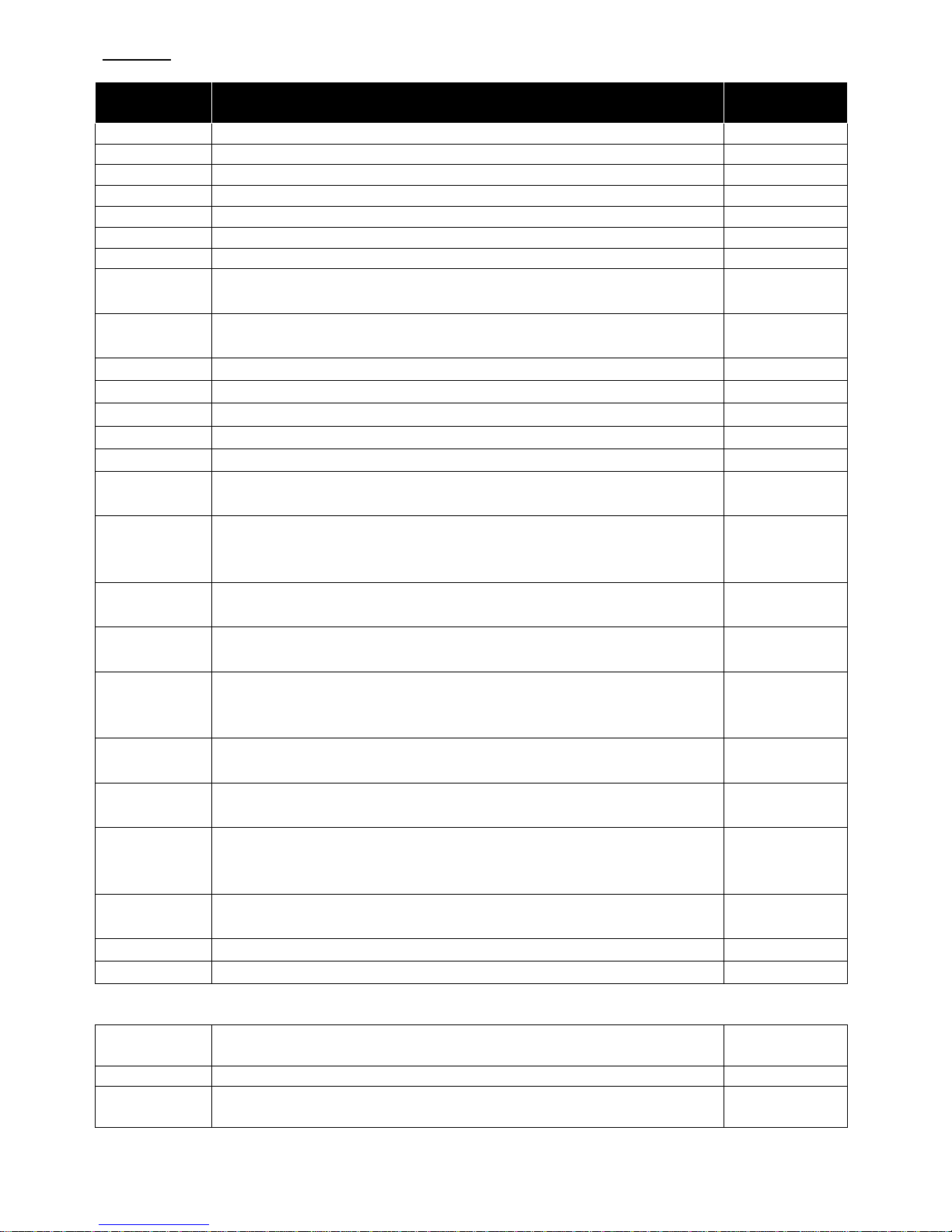

9

Function

Terminal Function Note

V+ DC +12V output

SEN- Connect to shield cable of sensor of RTX Black

SEN+ Connect to +cable of sensor of RTX Red

TX CLK Output of sensor’s transmitting signals in pulse form Option

RTH Connect to outer temperature sensor

VIN External Input[FOLW SWITCH]

RTN External input GND

TX When using RS232C interface, connection to RS232C's transmitter.

When using RS485, connection to Y.

RX When using RS232C interface, connection to RS232C's receiver.

When using RS485, connection to Z.

GND Digital communication GND

IOUT Current output (+): Output of 4 mA ~ 20 mA in proportion to flow rate Max. 600Ω

IRTN Current output (-)

PULSE OC Pulse output (+): at the set intervals

PULSE RTN Pulse output (-)

A1_NO ALARM_1 NO contact point.

On operation of ALARM_1, disconnection from A1_COM

A1_COM ALARM_1 COM contact point.

On operation of ALARM_1, disconnection from A1_NO & on its stop,

disconnection from A1_NC

A1_NC ALARM_1 NC contact point.

When ALARM_1 is not in operation, disconnection from A1_COM

A2_NO ALARM_2 NO contact point.

On operation of ALARM_2, disconnection from A2_COM

A2_COM ALARM_2 COM contact point.

On operation of ALARM_2, disconnection from A2_COM & on its stop,

disconnection from A2_NC

A2_NC ALARM_2 NC contact point.

When ALARM_2 is not in operation, disconnection from A2_COM

ER_NO ERROR_NO contact point.

On operation in ERROR situation, disconnection from ER_COM

ER_COM ERROR_COM contact point.

On operation in ERROR situation, disconnection from ER_NO & on its stop,

disconnection from ER_NC

ER_NC ERROR_NC contact point.

When not operated even in ERROR situation, disconnection from ER_COM

L AC power connection

N AC power connection

* The below points are useful when test the Sondar5000 in field.

THR Output of standard voltage that determines the volume of the ultrasonic

signal. Users can check the most suitable installation location.

Test Point

DET Output voltage of the detected ultrasonic signal Test Point

TVG Output of amplified voltage of the ultrasonic signal. Trigger source of DET

signal

Test Point