Operating environment

The product must not be directly exposed to moisture or water. The system (the machine/system in

which the product is installed) is only suitable for use in dry indoor areas.

When moving the product from a cold to warm conditions, allow the product to adjust to the change in

temperature for a few hours before operation, to avoid possible damage from condensation.

Do not install the product near devices which generate powerful magnetic fields. This could disturb its

functions.

Avoid environments exposed to direct solar radiation, considerable heat, cold, humidity or moisture.

Power supply (only applies to products with stepper motors, brushed DC/brushless DC or AC

servo motors and a suitable motor output stage/controller)

Only connect the mains adapter of the stepper motor/servo motor output stage IMD10/IMD20, the link

to the servo motor output stage IMD40 (terminals L, N, PE) or the single-axle controller iMC1-10/iMC1-

20 or multi-axle controller iMC-M/iMC-P (stepper) or iMC-V/iMC-VP (servo) to an earthed mains socket

with a mains voltage of 230 V AC/50…60 Hz (1-phase AC power supply).

You are advised to use the original mains adapter recommended by isel Germany AG (primary switch-

ing power supply: 230 V AC, secondary: 48 V DC) for the stepper motor or servo motor output stage

IMD10/IMD20. Using a different, inappropriate mains adapter renders the warranty null and void. In

addition, using an inappropriate mains adapter entails risks caused by electric current, such as electric

shock, fire or short circuits.

If you notice faults, activate the EMERGENCY STOP button on the (single axle) controller, the CNC

operating panel/CNC console, the control panel/control cabinet or a handheld device. Activating the

EMERGENCY STOP button interrupts the power supply to the motor output stage. If the mains adapt-

er used is damaged you must not operate it. Have a qualified technician check and if necessary repair

the product.

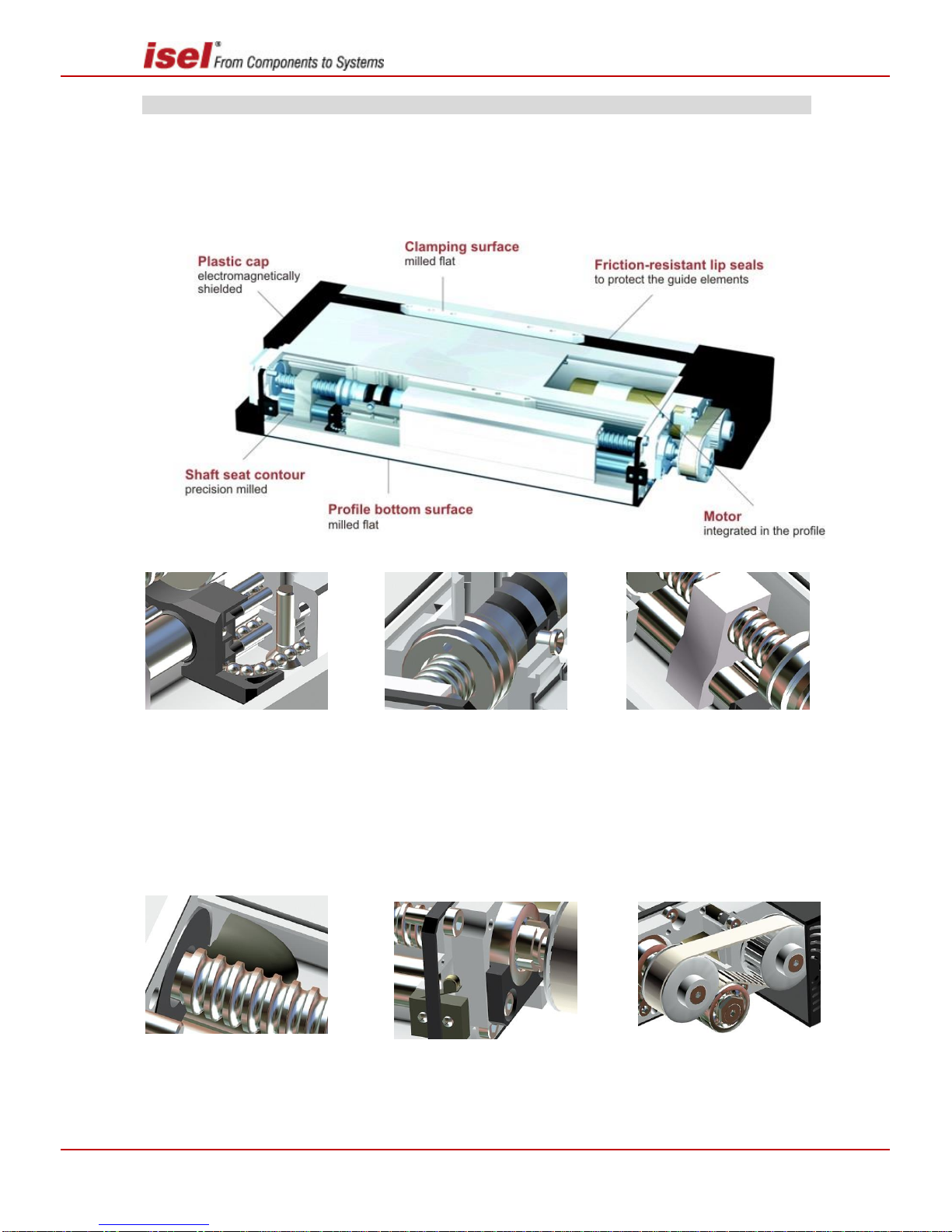

The linear unit

For safety reasons you must not convert and/or modify the linear unit on your own.

When in operation, the linear unit must not be covered by supply lines (electric or pneumatic), objects

(e.g. tools) or canvas covers, packaging materials or cloth etc. (e.g. clothing), which could cause me-

chanical damage or a build-up of heat, and a possible fire.

If using a single-axle/multi-axle controller to control a linear unit (equipped with an AC, brushed DC

(BDC) or brushless DC (BLDC) servo motor), you need to ensure that the controller or motor output

stage used (in a control cabinet or on a mounting rack) is placed in a well ventilated environment.