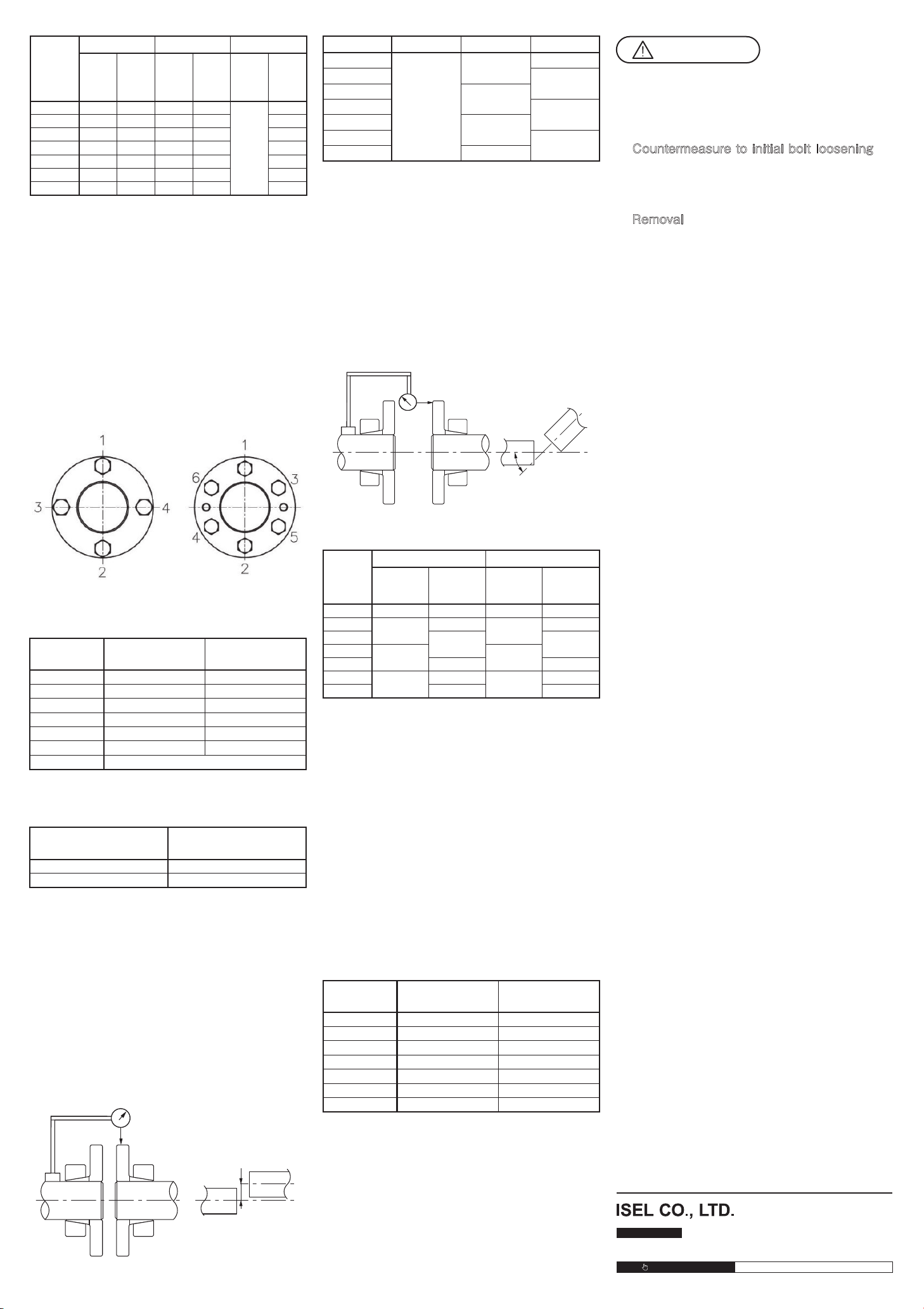

●Structuraldrawings

●Installation

(1)Usepaintthinnerorothermeanstowipeoffany

corrosion,dirt,orothersubstancefromthesurfaceof

theshaft,thenapplyalightcoatofoil.

(2)Applyalightcoatofoiltothecouplinginnerdiameter

parts,taperedparts,andthethreadsandheadseatsof

thelockbolts.

(2)Removetheclampboltsfromthediscpartofthe

provisionallyinstalledcoupling,andseparatethebody

anddisc.Onlythenecessarynumbersofwashers,bolts,

andotherpartsareprovided.Becarefulnottoloseany

ofthem.

(3)Setthedistancebetweenflangesurfaces(Table1)

accordingtothemodel.(Figure2)

◇Usingtheproductafterunpackagingwithoutapplyingoil

toitmaycauseadecreaseinallowabletorque.

(3)Machinethemotormountpartaccuratelysothatthe

misalignmentbetweenthe2shaftsisatorbelowthe

tolerancevalue.

CouplingInstructionManual

ASeries(AS,AT,AD,AL)

Forsafeuseoftheproduct

ThankyouforyourpurchaseofanISELproduct.

Inordertousetheproductsafelyandobtainthe

designatedfullperformance,pleasebesuretoreadthe

followingitems.

◎Readthisinstructionmanualcarefullyandunderstand

thecontentsbeforeusingtheproduct,andbesureto

observeallinstructionsinthemanualandusethe

productcorrectly.

◎Besurethatyoufullyunderstandtheinformationrelated

tothedeviceandsafetybeforeusingtheproduct.

◎Afterreading,besuretostorethismanualcarefullyso

thatitcanbereferredtoatanytimewhenneeded

duringuse.

Thismanualclassifiesimportantprecautionsintotwo

categories:DANGERandWARNING.

◇Checkthattheproductistheoneyouorderedandthat

thereisnodamagetoit.Iftheproductisnottheone

youorderedorisdamaged,thereistheriskofinjuryto

operators,damagetoequipment,andotherdamage.

◇Neverusemolybdenumoiloroilwhichcontainsan

extreme-pressureadditive.Doingsomaycausealarge

decreaseinallowabletorque,resultinginslipping.

◇Iftheshaftincludesakeygroove,itcanbeusedas

longasthegroovewidthisasprescribedintheJIS

standard.Howeverthemaximumallowabletorqueis

reducedby15%-20%.Removeanyburrsonthekey

TheASandATSeriesareflexible-typecouplingsthat

permitadeflectionanglebetweenthe2shafts,while

theADandALSeriesareflexible-typecouplingsthat

permitbothcenterdeviationandadeflectionangle

betweenthe2shafts.Theshafttolerances,surface

roughness,centeringaccuracy,andcorrecttighteningof

thelockboltsareveryimportantfactorsinorderto

obtainfullperformancefromeachseries.Ifyouhave

anyquestions,pleasecontactadealerorourcompany.

DANGER

WARNING

WARNING

Incorrectuseorhandling

willproducedangerous

conditionsthatmayresult

indeathorseriousinjury.

Incorrectuseorhandling

willproducedangerous

conditionsthatmayresult

ininjury.

Thereisalsotheriskof

propertydamage.

DANGER WARNING

◆Whenusingthisproduct,besurethatthenecessary

mechanisms(covers,enclosures,etc.)forensuringthe

safetyoflifeandhealthareinstalledontheequipment.

◆Wearclothingandprotectivegearthatissuitableforthe

work.

◆Keeptheworkareacleanandorderly,andworksafely

inordertopreventsecondaryaccidents.

◆Intheenvironmentwheretheproductoperates,install

safetymechanismsontoallpartswhichmaybea

dangertotheoperator.

◆Whenperformingmaintenanceorinspections,turnOFF

themotorpower(powersupply)andcheckthatthe

machinehasfullystoppedbeforebeginningwork.

◆Beforeusingliftequipment,installsafetymeasureson

theequipmenttopreventfalling.Thereistheriskof

deathorinjury,aswellasdamagetotheequipment,if

theliftpartfalls.

◆Iftheproductisusedfortransportingpersons,installthe

necessaryequipmentforsafety.

◆Donottouchtheproductwhileitisoperating.Doingso

mayresultininjury,damagetotheproduct,orother

damage.

◆Donotusetheproductforanypurposeotherthanthe

designatedpurpose,anddonotmodifytheproduct.

Thereistheriskthatthedesignatedaccuracyand

performancewillnotbepossible.

◆Ifabnormalnoiseorvibrationoccursduringwork,

immediatelydiscontinueoperationandinspectthe

equipmentandthisproduct.Ifuseiscontinuedwithout

inspecting,thereistheriskofinjurytooperators,

damagetoequipment,andotherdamage.

groovebeforeusing.

◇Iftheproductisreused,checkthatthereisno

deformation,damage,orotherproblemwiththeproduct

oranyofitscomponentsbeforeuse.Ifthereisdamage,

deformation,orotherproblem,replacewithanew

product.

◇Whentighteninglockbolts,besuretouseatorque

wrenchthatincludesatorqueadjustmentscale,and

tightenatthedesignatedtighteningtorque.Useofa

plate-typetorquewrenchmaycauseslipping,

deformation,andothertroublebecauseitisdifficultto

checkthedesignatedtorque.

◇Neveruseanyboltotherthanthedesignatedbolt.There

istheriskofdamagetothebolt,resultinginan

accident.

◇Inordertoensurethedesignatedperformance,an

oppositeshaftwithtolerancegradeh7andsurface

roughnessofRa1.6orlessisrecommended.

◇Inthecaseofahollowshaft(pipe),dependingonthe

thicknessitmaynotbepossibletoobtainsufficient

surfacepressure.Pleasecontactourcompany.

◇Installwithinthetolerancevaluesforcenterdeviation,

deflectionangle,andendplay.Thereistheriskof

damagetotheproduct.Inparticular,centeringaccuracy

hasaneffectonvibrationandthelifetimeofthe

coupling.

◇Itisrecommendedthattheproductbeusedwithin1/2

orlessofthedisplacementtolerancevalues.

◇Iftheproducthasspecialspecifications,itmaydifferin

partsfromthecontentsofthisinstructionmanual.

Pleasecontactadealerorourcompany.

◇Iftheboltsaretightenedwhenthecouplingisnot

connectedtoanything,thecouplingmaybecome

deformedandberenderedunusable.Thereforecheck

thattheshaftisfullyinsertedintothecouplingwhen

tighteningthebolts.

◇Duetothecouplingstructure,thereistheriskofinjuryif

theusergraspsthecornersordiscpart.Therefore

exercisesufficientcautionwhenhandling.

LL

48756 3 1 2

6 5 4 3 1 7 2

ASSeries

ALSeries

6 2 3 75 41A 1B

ATSeries

4

6 5 3 7 8 4 1 2

ADSeries

1.Body 4.Washer

1A.BodyA5.Clampingscrew

1B.BodyB6.Lockingscrew

2.Sidering 7.Unut

3.Disk 8.Spacer

●Installationprocedure

(1)Checkoutputmotorshaftcenteringaccuracy.

Confirmcenteringaccuracybymeasuringtheoutput

motorshaftbeforeinstallingthecoupling.

Setthegaugeasshowninordertomeasuremotor

shaftoff-centering(Figure.1).

Precautions:Themotorshaftoff-centeringamountis

establishedbyeachmanufacturerbutmay

alreadyhaveoccurredatthisstage.

(Figure1)

(Figure2)

Motor