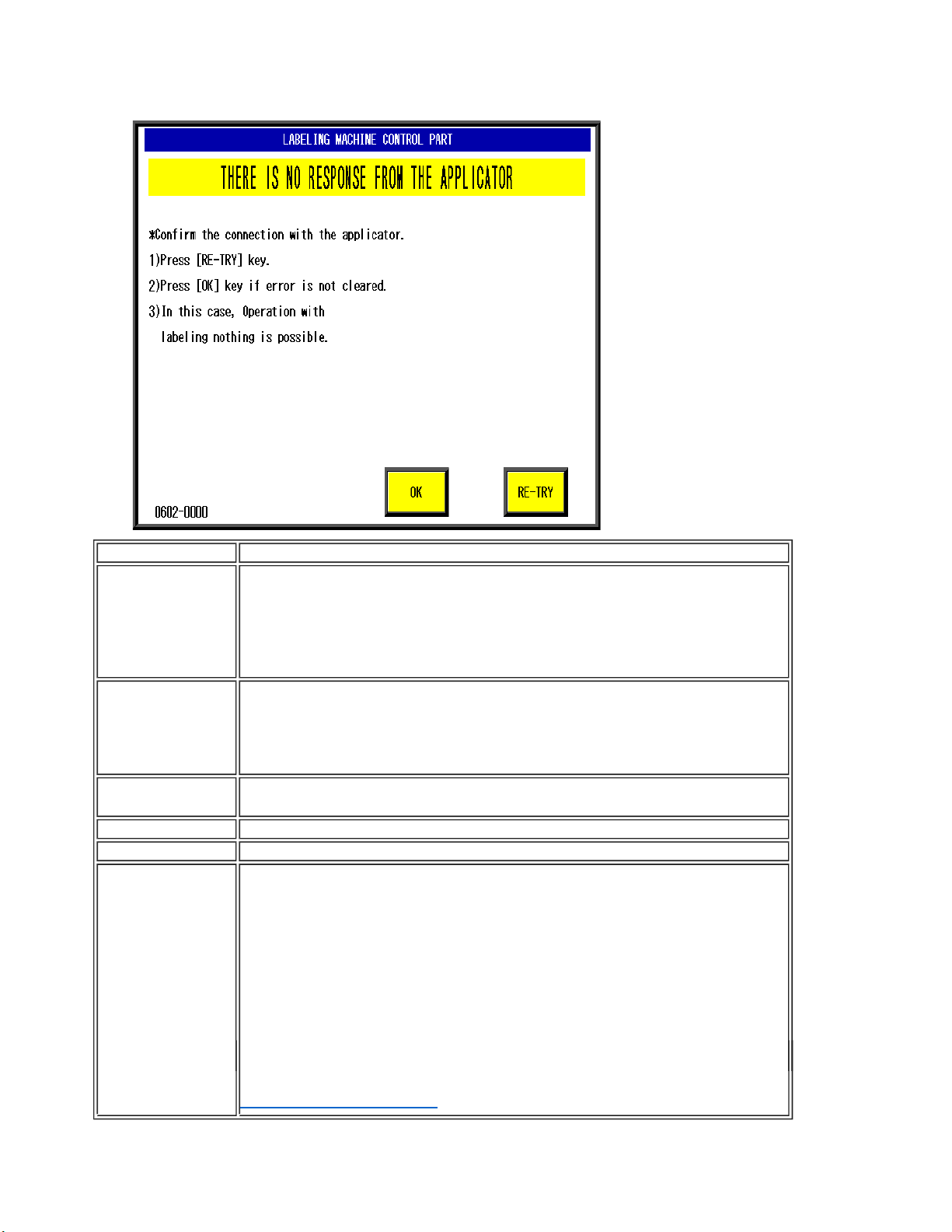

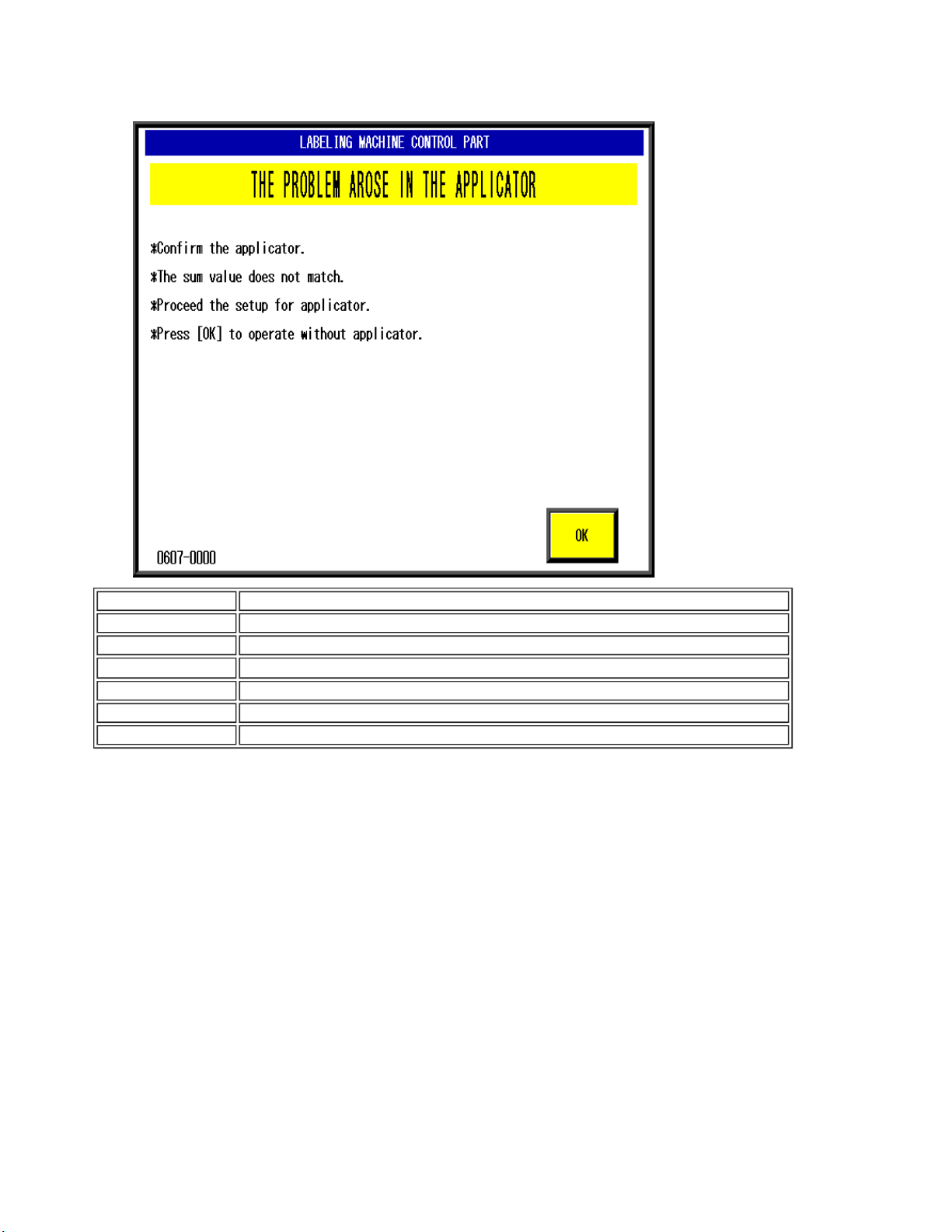

[Error content] The applicator is not connected.

[Detail]

・Communication wasn't achieved between the console and the

applicator.

・Communication phase number is in the sub-error.

・Communication errors after power ON result in this error.

[Solution]

[OK] : Cut communication with the applicator. Operate without the

applicator.

[Re-try] : Check connection with the applicator. The error is cleared if

connection is confirmed.

[Remarks] Operation without the applicator is possible after pressing the [OK]

button.

[Cause] Communication is not possible between boards P-910 -> P-918 ->

P-916.

[Response] Press the [Re-try] key to re-attempt communication. If the same

error occurs, consider the following causes:

1)Unplugged connector

2)Harness short

3)P-910 board malfunction

4)P-918 board malfunction

5)P-916 platform malfunction

• This error may occur if there is a short in the P-915, P-920

RS-485 line. Check if this is not fixed by 1-5.

0601

• Search for a shorted board by connecting P-915, P-916, and

P-920 one by one.

Confirm with a schematic

Ishida WM-4000 Error Codes and Solutions (600-2099)