Page 3

Avoidance of Back Flow

Careshouldbetakentoavoidthebackowofgasesintotheroomfromtheopenueofgasor

otheropenreappliances.

Safety of Children

Thisfanisnotintendedforusebyyoungchildrenorinrmpersonswithoutsupervision.

Replacement of supply cord

Ifthesupplycordisdamaged,itmustbereplacedbyaserviceagentorsuitablyqualiedperson

inordertoavoidahazard.

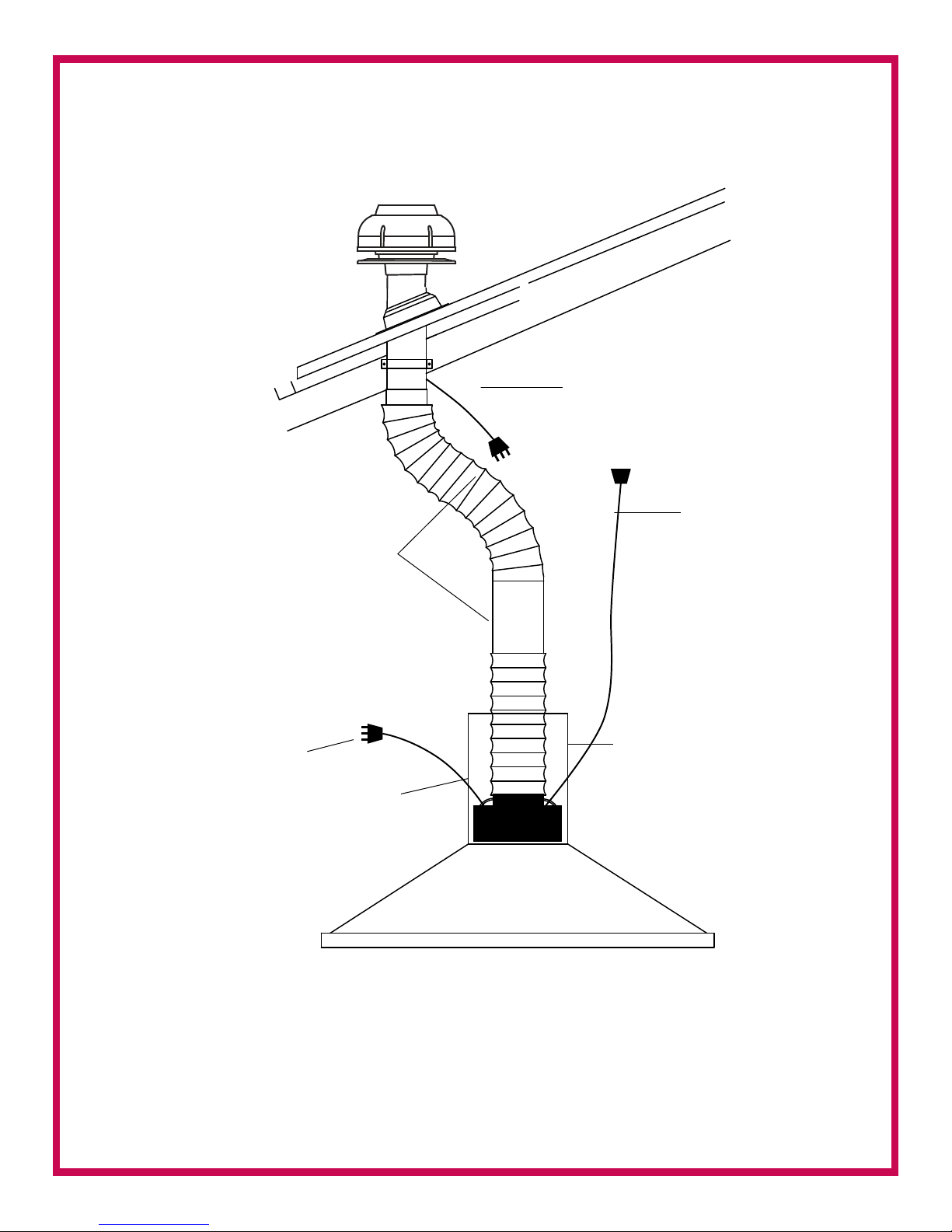

Why Flexi-duct

Someinternetsitesstronglyrecommendtheuseofrigidductingoverfullyexibleducting.This

maywellbethecasewithconventionalrangehoodswithinhoodfans.

Schweigen’suniqueIsodrivesystemworksintheoppositewaytoconventionalrangehoods,

pullingairthroughthehoodandacousticallymatchedductingproducingalmostsilenthigh

volumeow.Theuseofacompleterigidorsemi-rigidductingsystemwillallowanorganpiping

effecttooccur;likeadidgeridoowhereanoiseisproducedatoneendofahollowrigidpipe

andthenoiseisampliedouttheother.

TheIsodrivesystemputsthenoiseoutsidethehouseanditneedstobekeptthere.

Installationwithouttheuseofatleasttheminimumrecommendedlengthof

acousticallymatchedexi-ductinginthesystemwillvoidperformanceexpectations.Any

installationproblemmustbereportedtoSchweigen.Calloutsrelatingtoincorrectinstallation

willresultinaservicefeedirecttothecustomer.Schweigentakesnoresponsibilityforproblems

causedbyfaultyinstallation.Faultyinstallationmayvoidwarranty.Apreferredinstallerlistcanbe

obtainedfromSchweigenwebsiteorcall1300 881 693.

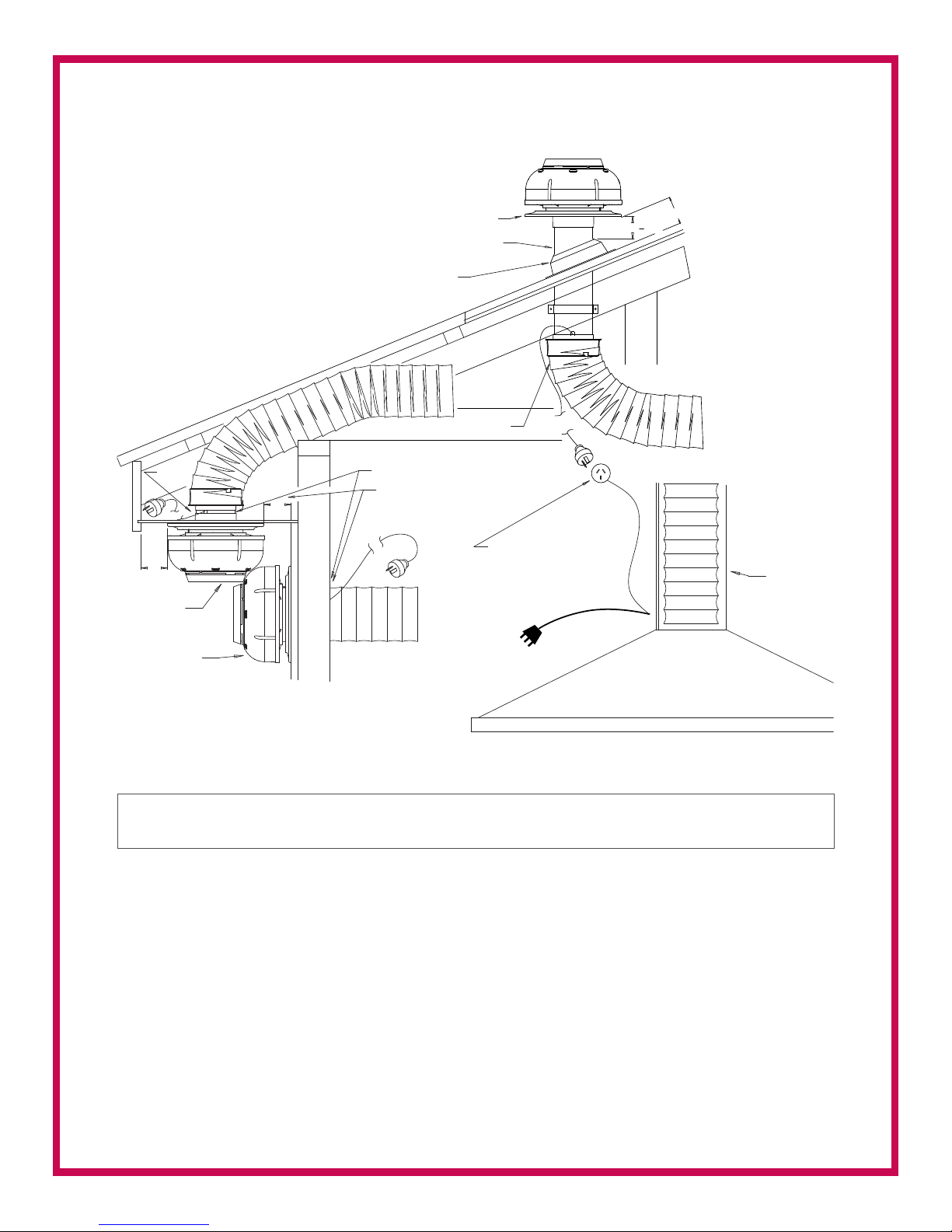

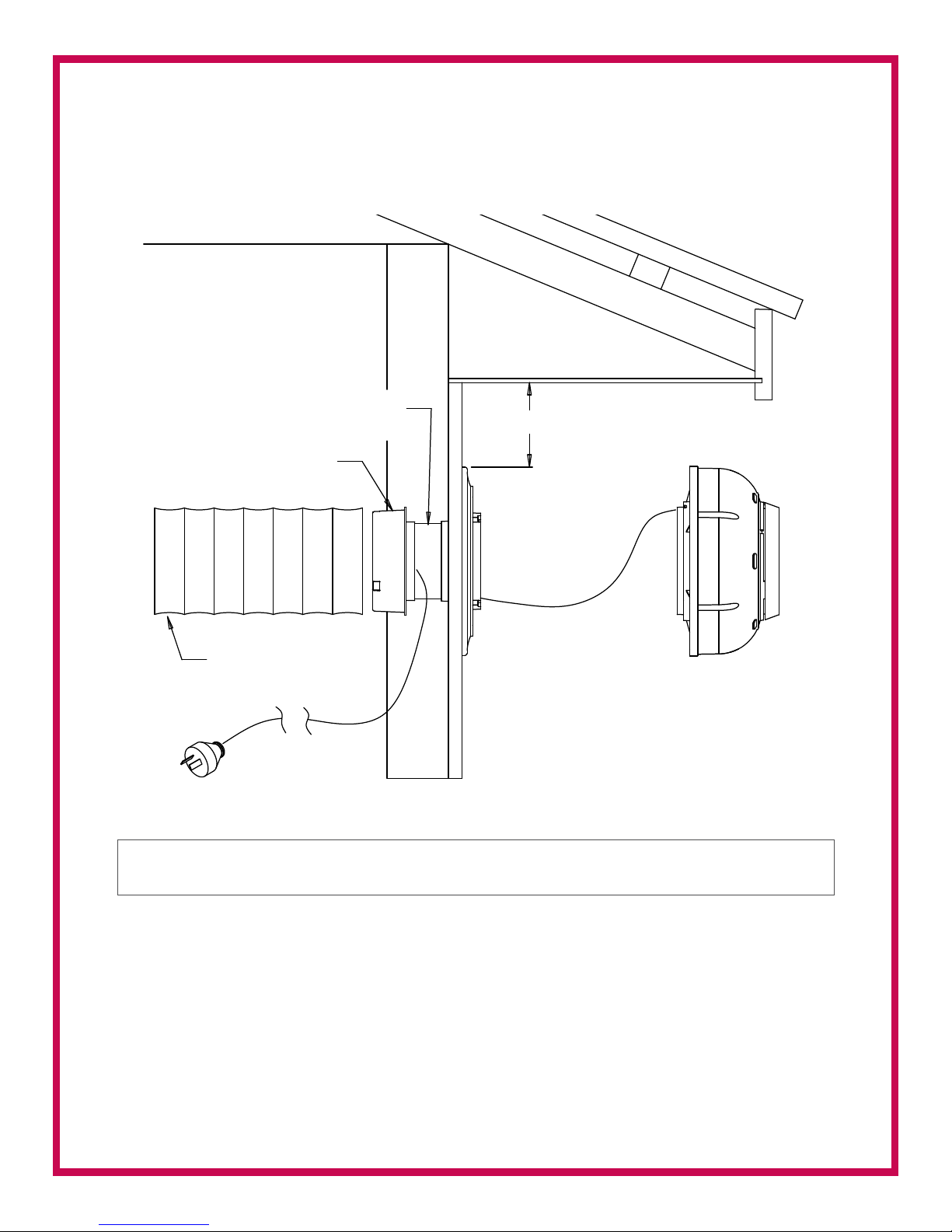

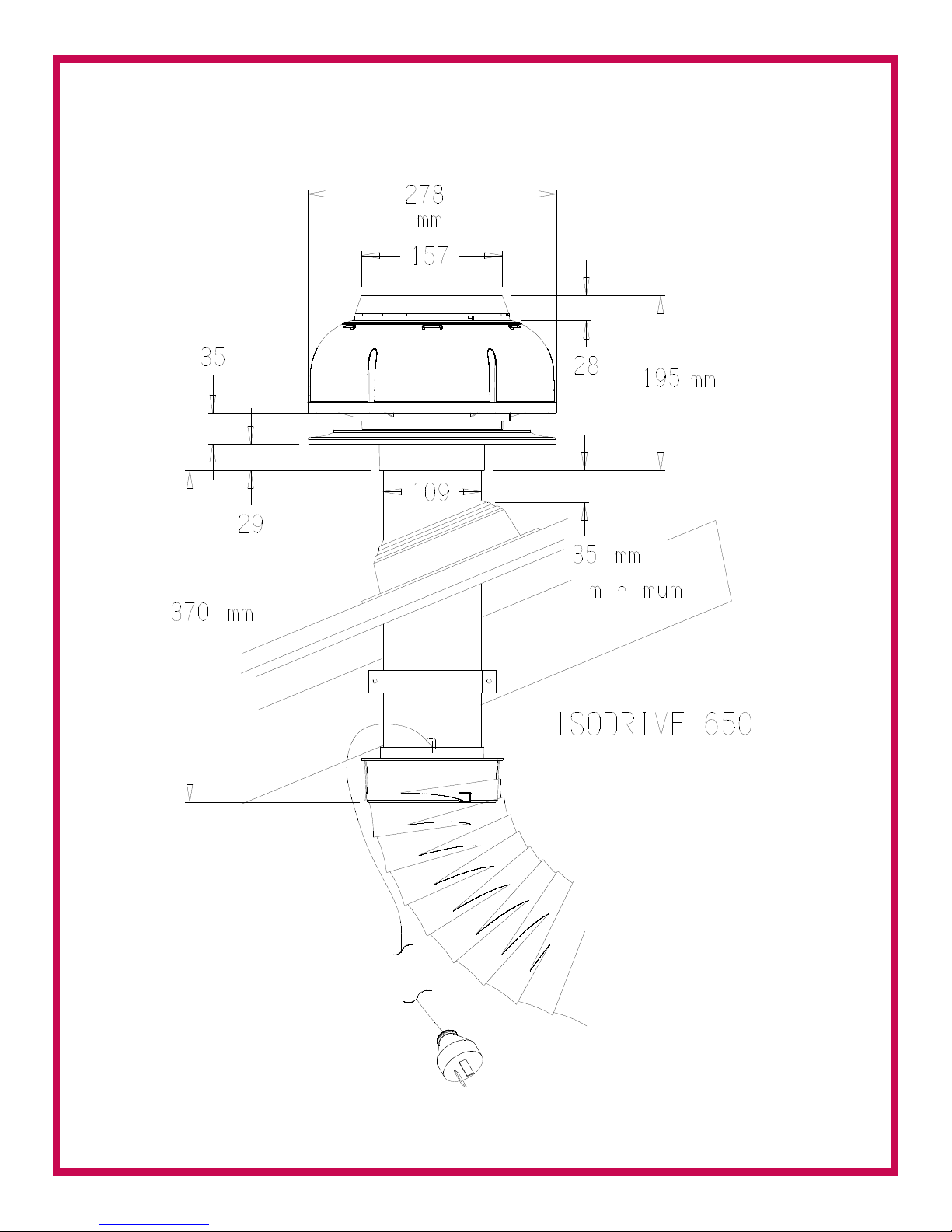

Roof Installation (Recommendedductlength:650motor-3m)

Mountthe100mmrigidPVCpipesecurelytothebeams,trussesorotherappropriatestructures,

refergure1.

Thepipeshouldbemountedeitherverticalorperpendiculartotheroofcladdingwiththeroof

penetrationbeingsealedusingaDektiteorothersealingdevice.

Ensurethatthepipeprotrudesatleast80mmpastthetopoftheDektite,checkingthatthe

mountingangeclearstheroofcladdingatupperedgeasshowningure1.

Maximumrecommendedprotrusionis500mm.Fitmountingange,refergure1,topipeusing

siliconsealant,thentapeinpositionuntilsealanthasset.

Passpowercordandplugthroughmountingangeandpipe,thenouttheslottedPVCpipefor

connectiontothefemaleplugcomingfromthecanopy/rangehoodorauthorizedswitching

mechanisminbathroomapplication.

Fitfanmoduletomountingangebyplacinginposition,rotatingclockwisetoengagebayonet

ngersthensecurebyscrewinginlockingscrew(whileholdingfanmodulermlyinthefully

clockwiseposition).