1.1.0

WARNING NOTES

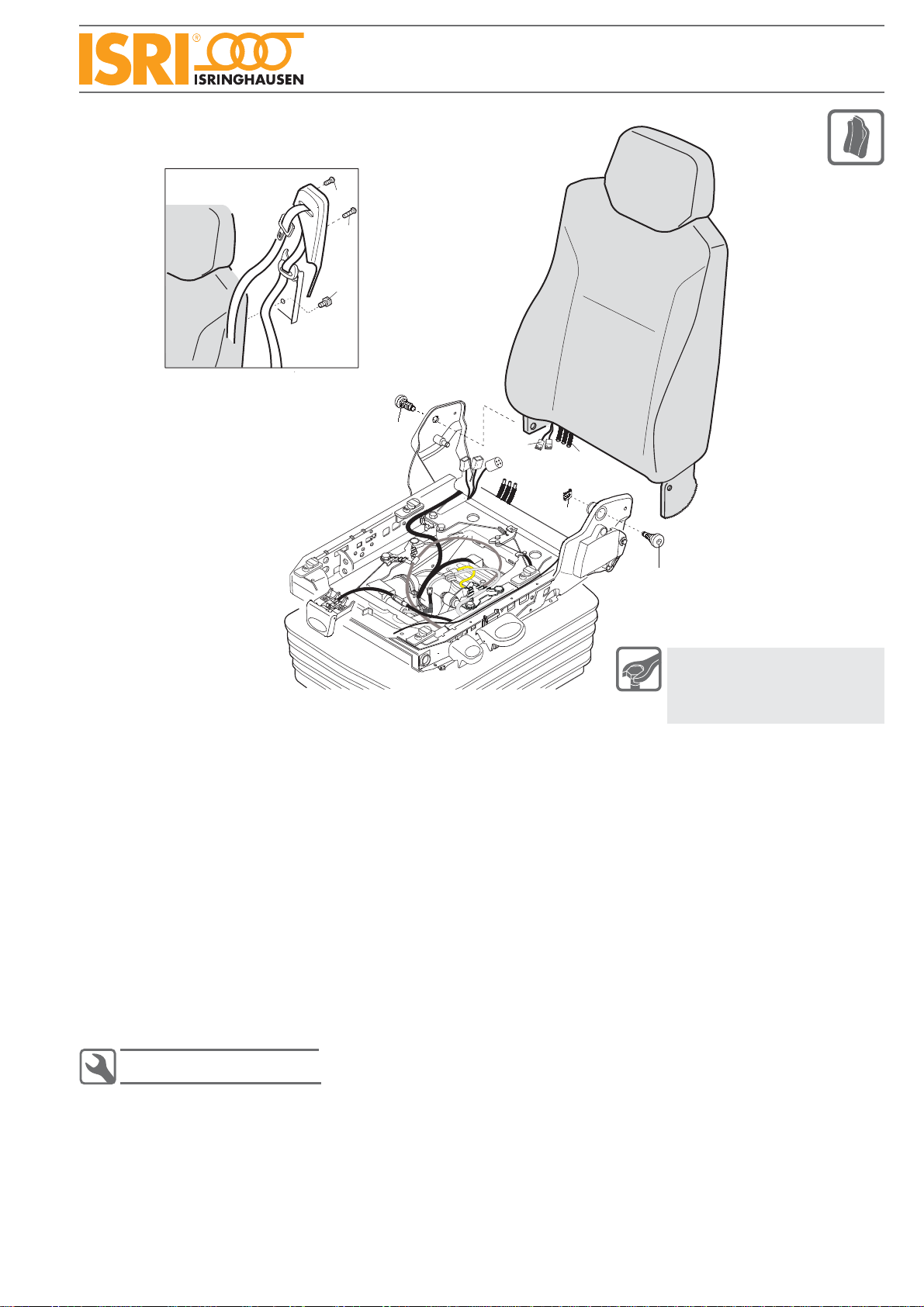

The seat has to be installed or repaired only by workshop specialists.• In doing so the regulations of the relevant countries have to be observed.

When the seat will be mounted and connected in the vehicle, the guidlines of the vehicle manufaturer• have to be considered.

Don‘t use a damaged or faulty seat.•

Defective parts have to be repaired or exchanged immediately.•

After a vehicle accident the seat must be exchanged completely.•

Changings on the seat are inadmissible.•

Only original spare parts have to be used.•

Seat anchorages and locking mechanisms have to be checked frequently.•

It is not allowed to weld broken steel parts.•

If you don`t consider the following instruction, the liability, warranty and possibly the

general operating permit will be lost.

Breaking these rules could cause serious or fatal injury to yourself and others:

Before repair, read the warning notes in chapter 1.

Please read accessorily the operating instruction of the seat, to become fami-

liar with its technical features.

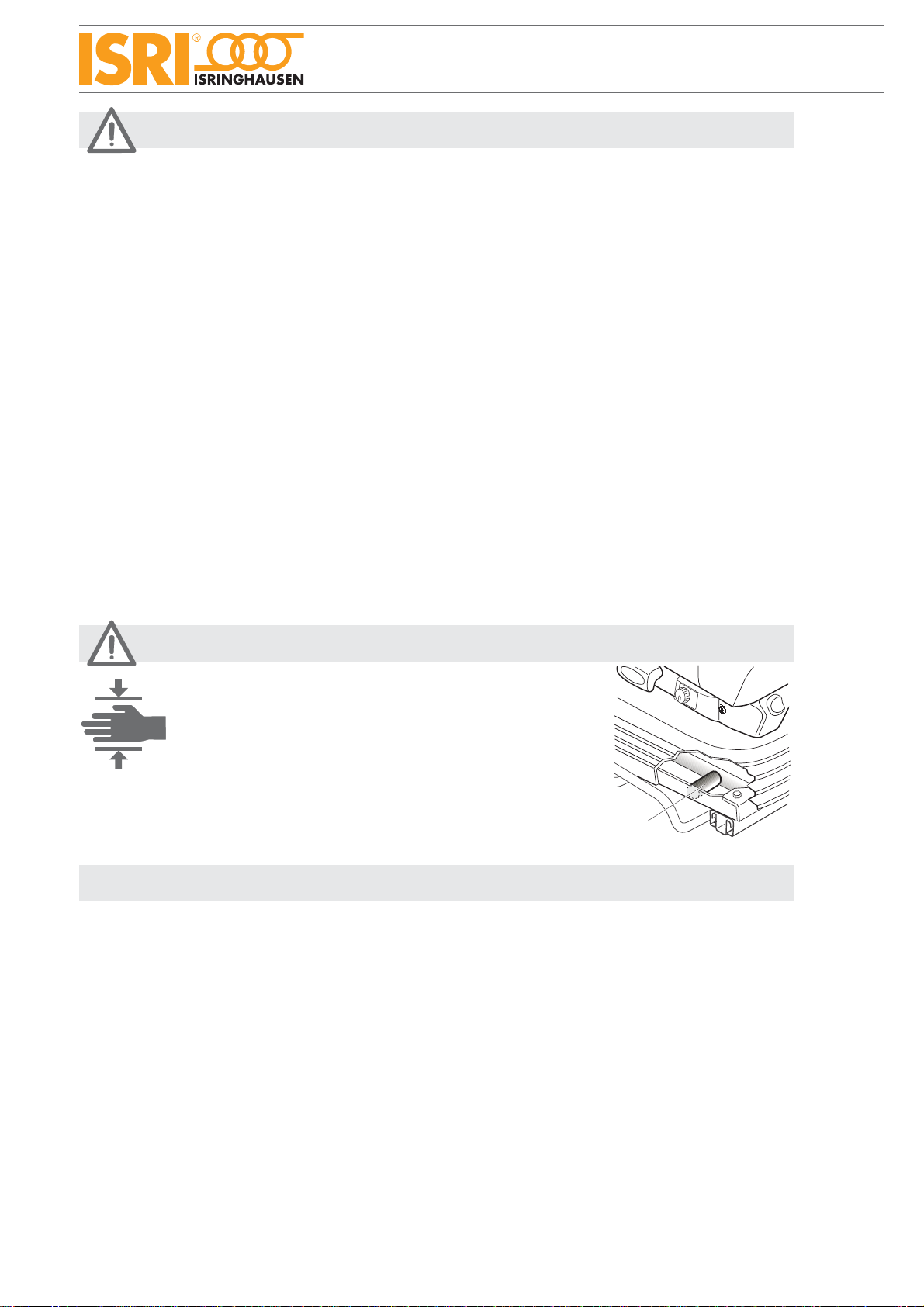

WARNING

CAUTION

For cleaning the seat, use only an slightly dampened cloth without strong solvents.•

The upholstery cover shall not be soaked.•

The seat is suitable for the operator‘s weight of maximum 150 kg.•

• The seat shall not be used as ascent help.•

The seat may not be blocked by objects in the vehicle, otherwise the seat can be damaged.•

Do not place anything on the seat and don`t cover the seat.•

Inappropriate handling of seat heating, respectively wrong connection, can lead to overheating.•

When driving without passenger, take care that the seat heating of the passenger seat are switched• off.

The fuse protection of the seat heating/ active ventilation may be maximally 10A.•

The electrical connection of the seat has to be installed by the vehicle ignition.•

The active ventilation system doesn‘t switch off automatically. The operating happens in self-respon-• sibility of the user.