No Setup

Self conguring test set-up allows for arbitrary loading of the Device

Under Test (DUT). The DUT’s polarity, function, and orientation is auto-

matically detected. There’s no need to nd the right pin to access before

testing.

Accessible Results

Pass or fail LEDs indicators quickly shows testing result status. A backlit

LCD display shows observed measurements: parameter data, device type,

device classication, and the function or polarity of each pin.

Detects Current Leaks

Sensitive current measurement detects damaged or degraded devices with

leakage problems.

Versatile Operation

Multiple test sockets and test slot adaptor provides support for most types

of through-hole and SMD component testing.

Constant Current Sink or Current Bias

Switches between a constant current sink for regulator output loading or

current bias for measuring Diode or Zener Diode voltage.

Fingertip Test Activation

3-point probing device with ngertip test activation button makes in-cir-

cuit PCB testing fast and easy.

Programmable Voltage Source

Programmable voltage source up to 1,099 volts for breakdown voltage

and leakage current testing.

Includes 22 Types of Testing Routines.

• Bipolar Transistors (Iceo, Ices, Icbo, BVceo, BVces, BVcbo)

• MOSFETs (Idss, Igss, BVdss)

• Diodes (Ir, BVr, Vf)

• Zener Diodes (Vz, Iz)

• Thyristor (Idrm, BVdrm)

• J-FET (Idss, Igss)

• Optoisolator (Iceo)

• Regulator (+/- Vo, +/- I load)

• I leakage*

* - Measures the voltage and current across any two terminals up to

1,099V for voltage and down to the “nA” range for current. Used for

testing the clamping voltage (Vbr) of Transient Voltage Suppressors,

measuring the input impedance of a device (by OHM’s law R=V/I), or

detecting leakage current between two points (I leak).

FEATURES AND ADVANTAGES

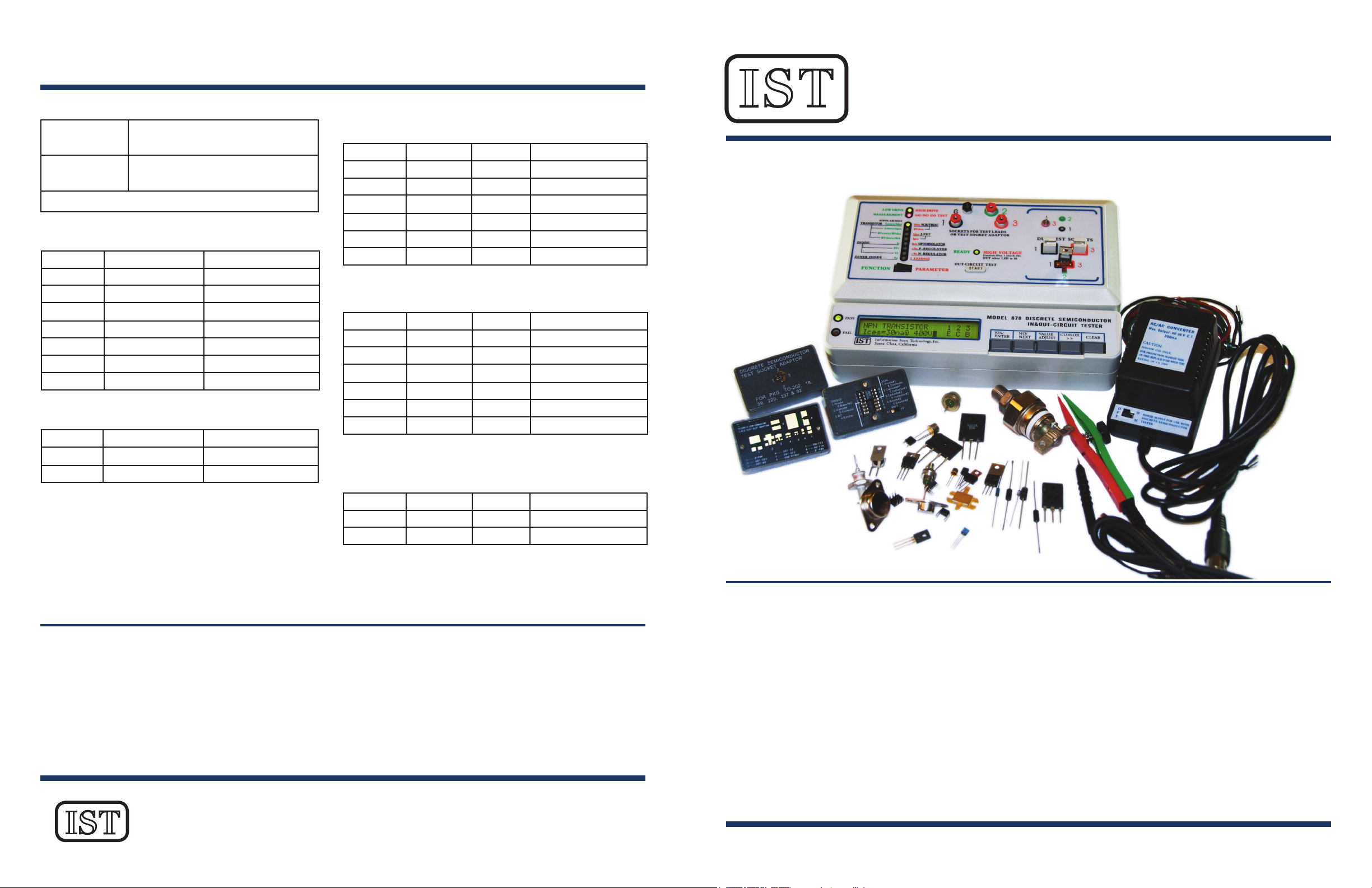

INTRODUCING THE IST MODEL 878

PROGRAMMABLE PARAMETRIC TESTER

FOR SEMICONDUCTOR DEVICES

Parameter / Function Switch – Selects

between a detailed parametric test or a self-

conguring function and leakage current test

Device and Parameter Indicators – LEDs show

test settings with parameter indicated with a

green light and test type with a red light.

Measurement / Testing Mode – Indicates

current mode as measurement or Go / No

Go testing mode.

Low/High Drive – Indicates that the DUT

requires low or higher driving current in order

to pass function tests. Higher driving current

indicates DUT has poor current gain or some

degree of malfunction.

Test Adaptor Sockets – Sockets for test leads with miniature banana

plugs or test adaptors for SMD and Optoisolator testing.

Ready / High Voltage Indicator – LED turns

green when all test conditions are entered and

red to indicate when a test is in progress and

high voltage is being applied to the DUT.

Start Button – When the green “Ready” LED is

lit, this button initializes an out-circuit test.

DUT Test Sockets – The Device Under Test (DUT)

can be loaded into one of the three test sockets

in any direction without regard to the function

or polarity of each pin. Function and polarity of

corresponding pins are detected automatically

during testing and are shown on the LCD display

once the test is completed.

LCD Display and Status Indicator – The 2x24

LCD display shows user prompts, test results,

and other operating information. The Pass or Fail

LED shows the test result of a functional test or

Parametric Go/No Go Test.

Function Key Switches – Keys to select and

setup testing procedure desired. Use to choose

device type, parameters, and test condition

values. Also used to clear test settings or to

interrupt a test in progress.