T

he

reference

in

sandblasTing

T

he

reference

in

sandblasTing

1514

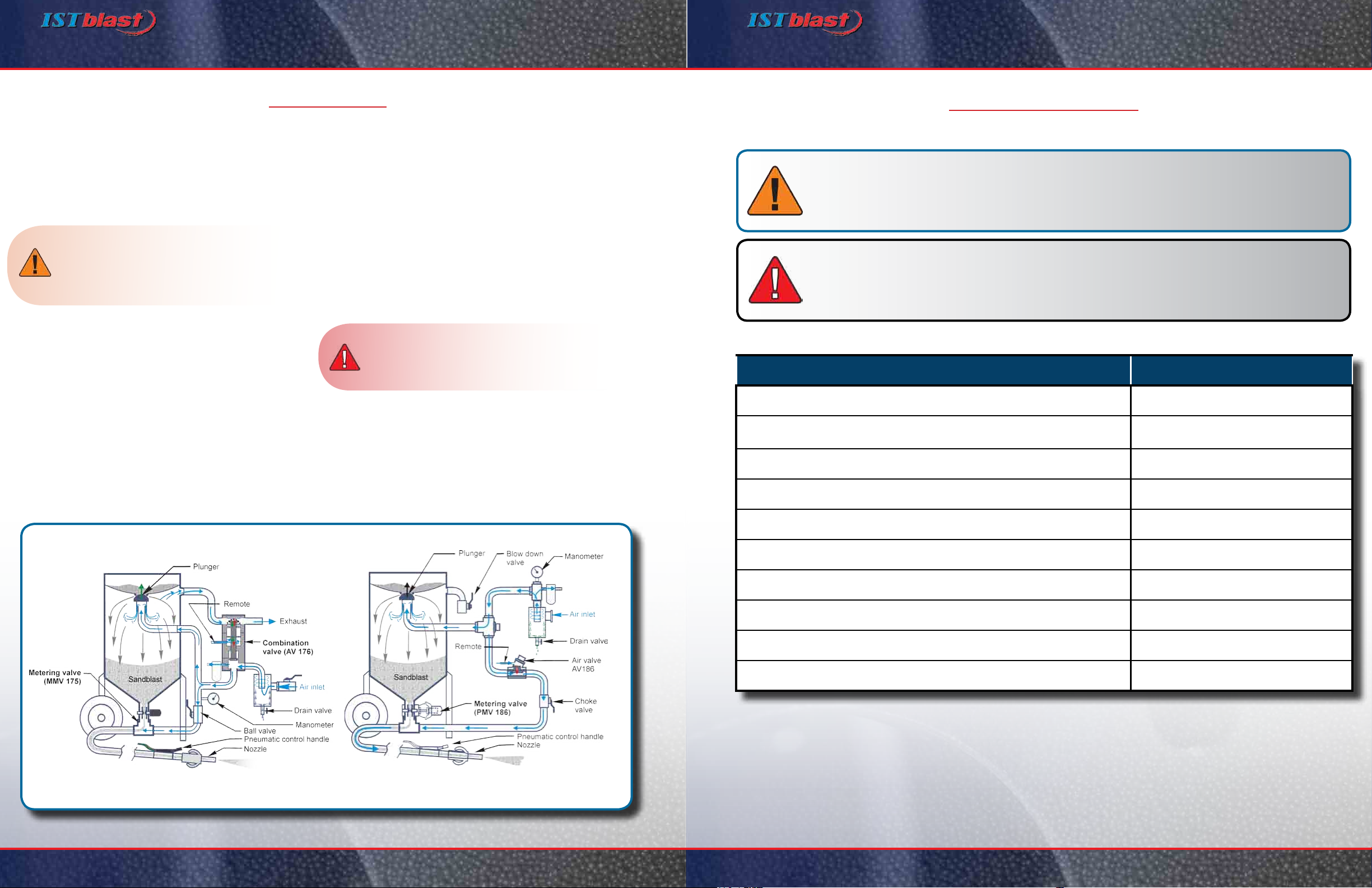

1046 Pressure Blaster - Instruction Manual & Parts 1046 Pressure Blaster - Instruction Manual & Parts

MAINTENANCE PROCEDURES TROUBLESHOOTING

ABRASIVE NOT FLOWING DURING BLASTING (AIR

ONLY)

Possible Causes :

1. The Abrasive Blaster is empty.

The abrasive cut-o function (if equipped) is engaged

and is preventing the abrasive from owing.

2. The MeteringValve is closed or not properly adjus-

ted.

If you suspect that a AR7+A6 Metering Valve is not

opening, conduct the following test : Shut o the Me-

tering Valve completely by turning the knob clockwise

until it stops. Next, turn it counterclockwise about 9

full turns. Then, depress the Control Handle and check

if the knob is dicult to turn or does not turn at all If so,

the Metering Valve is opening properly.

3. There is a blockage in the Metering Valve.

To free the blockage from a AR7+A6 Metering

Valve, begin by turning the knob on the Metering

Valve clockwise until it stops. Then, turn the knob

counterclockwise 9 full turns so it is fully open. Depress

the Control Handle and have a second qualied person

close the choke valve for 2 seconds and then re-open

it immediately. Minor obstructions, such as paint chips,

a bit of wet abrasive or a piece of paper, will be forced

through the Metering Valve and out the Nozzle. Turn

the Metering Valve back to the required blast setting

and check if the obstruction has been removed.

If there is still a blockage, depressurize the Abrasive

Blaster, remove the Pusher Line and the Metering Valve

and check if there is a steady stream of abrasive. If so,

allow the Abrasive Blaster to empty, and then reinstall the

Metering Valve.

If you nd a large obstruction, you will have to remove it

from inside the Pressure Vessel. To do so, start by making

sure that the Abrasive Blaster is depressurized. Next,

remove the Handway Assembly, scoop or vacuum all the

abrasive out of the Pressure Vessel, and then remove the

obstruction. You can then reinstall the Handway Assembly

and the Metering Valve. Be sure to tighten them securely.

Once this is done, you can rell the Abrasive Blaster.

It is advisable to use a screen to keep foreign objects

from getting inside the Abrasive Blaster and causing

a blockage.

4. There is wet abrasive in the Abrasive Blaster.

The wet abrasive must be removed. To do so,

depressurize the Abrasive Blaster, remove the Handway

Assembly and scoop or vacuum out the wet abrasive.

The Abrasive Blaster must always be used with dry

abrasive and supplied with clean, cool, dry air to keep

the abrasive dry. For outdoor operations, using a lid

is recommended to prevent water from getting inside

the Abrasive Blaster.

ABRASIVE STREAM TOO HEAVY OR THROBBING

DURING BLASTING

Possible Causes :

Note : When RC-176 systems rst start up, they may throb

for a while if there is an accumulation of abrasive in the

blast hose from a previous operation. This is normal, and

no corrective action is needed.

1. The Choke Valve is partially closed.

The Abrasive Blaster should be operated ONLY with the

Choke Valve fully open. Doing otherwise will cause

2. The Metering Valve needs adjusting.

Refer to the instructions on page 10 on how to adjust

Metering Valves.

DANGER: TheAbrasive Blaster must NEVER beopened while itis pressurized.Extreme

caution is required when troubleshooting involves pressurizing the Abrasive Blaster.

Only experienced, qualied persons should perform troubleshooting procedures.

1. Inspect Personal Protective Equipment (PPE)

Inspect all PPE to make sure that it ts and that it is in good working condition. Replace or repair PPE, or

have it tted, as needed.

2. Inspect Remote Control Handles and Control Hose/Cord

Pneumatic Remote Control Systems :

Inspect the Control Handle to be sure the Safety Flap/Lever Lock/Button is in good working condition. Check for

damages, and replace or repair components as needed. Inspect the twin-line hoses and replace them if there are

leaks, abrasions or soft spots.

Electric Remote Control Systems :

Inspect the Control Handle and make sure the Safety Flap/Lever Lock/Button is in good working condition. Check

for damages, and replace or repair components as needed. Inspect the control cord and replace it if there are

damaged plug ends or signs of abrasion, exposed wires or cracks

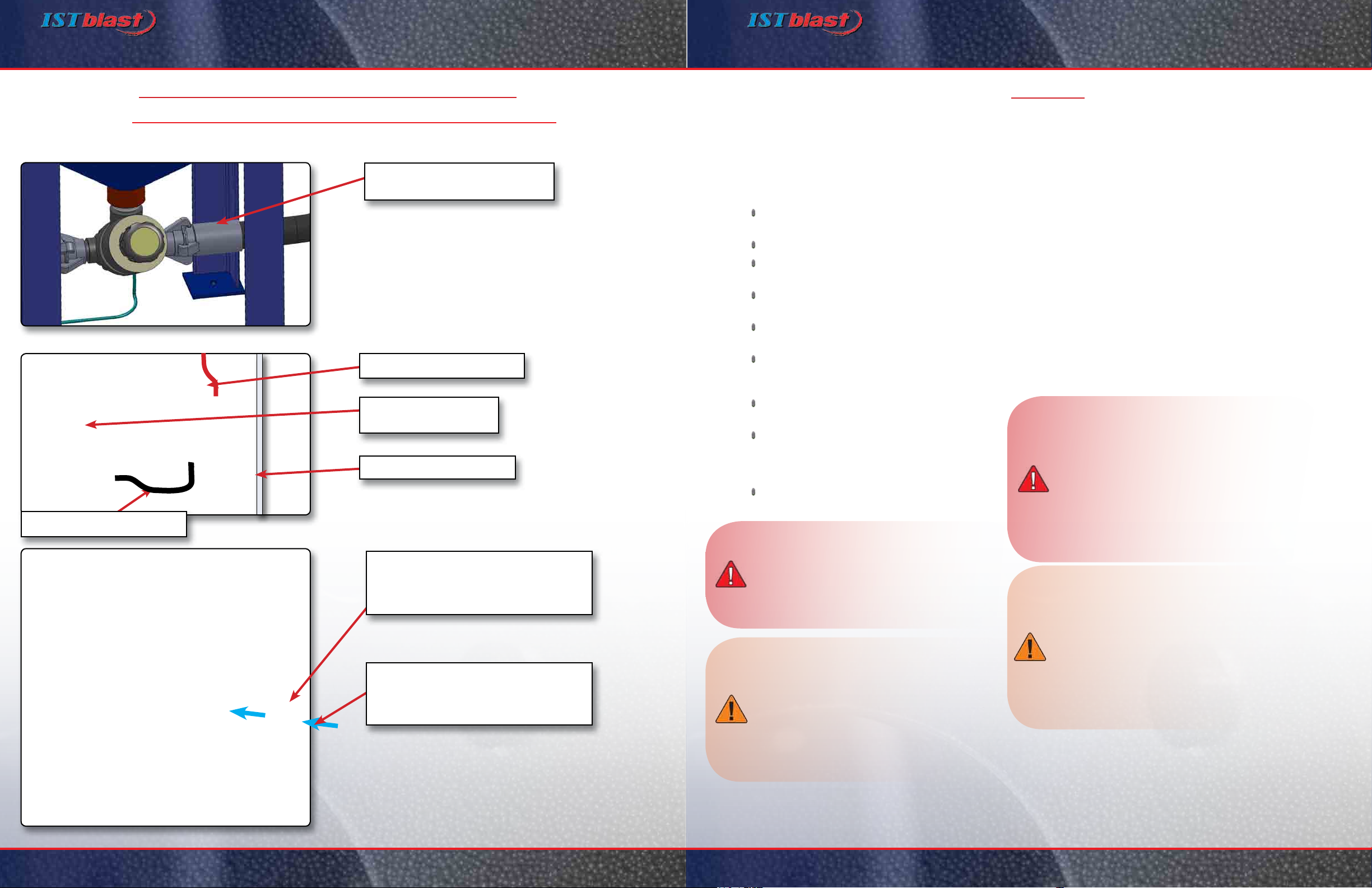

3. Inspect Blast Hose, Couplings & Gaskets

Check the Blast Hose for leaks, abrasions and soft spots. Inspect the couplings for damage, leaks and wear. Check

the coupling gaskets for leaks and wear. Replace all components as needed. Be sure safety clips and whip checks

(safety cables) are used to secure Blast Hose connections.

4. Inspect Blasting Nozzle

Check the Blasting Nozzle for wear, and measure the bore diameter. If the bore diameter is worn to the point of

being 1/16 in. larger than its original diameter, replace the Blasting Nozzle. For instance, a #5 Nozzle (5/16 in. bore)

needs to be replaced when the bore reaches 3/8 in.

5. Inspect Air Hose, Couplings & Gaskets

Check the Air Hose for leaks, abrasions and soft spots. Check the couplings for damage, leaks and wear. Check

the coupling gaskets for leaks and wear. Replace all components as needed. Be sure safety clips and whip checks

(safety cables) are used to secure Air Hose connections.

6. Inspect & Clean Blow-down Muffler

Remove the Blow-Down Muer and turn it upside down. Tap it on a hard surface to free any debris that may be

trapped inside. Replace the muer if it is blocked and the obstruction cannot be cleared

7. Inspect Blow-down Hose Assembly

Remove and inspect the Blow-Down Hose Assembly. Replace it if you nd leaks or soft spots.

8. Inspect Pop-Up & Pop-Up Gasket

Check the Pop-up and Pop-up Gasket for wear. Replace as needed

9. Service Metering Valve

Disassemble and clean the Metering Valve. Check for worn components and make sure it is working properly.

Replace any worn components. Lubricate the MMV-175 and AR7+A6 valves with an anti-seize compound before

reassembly.

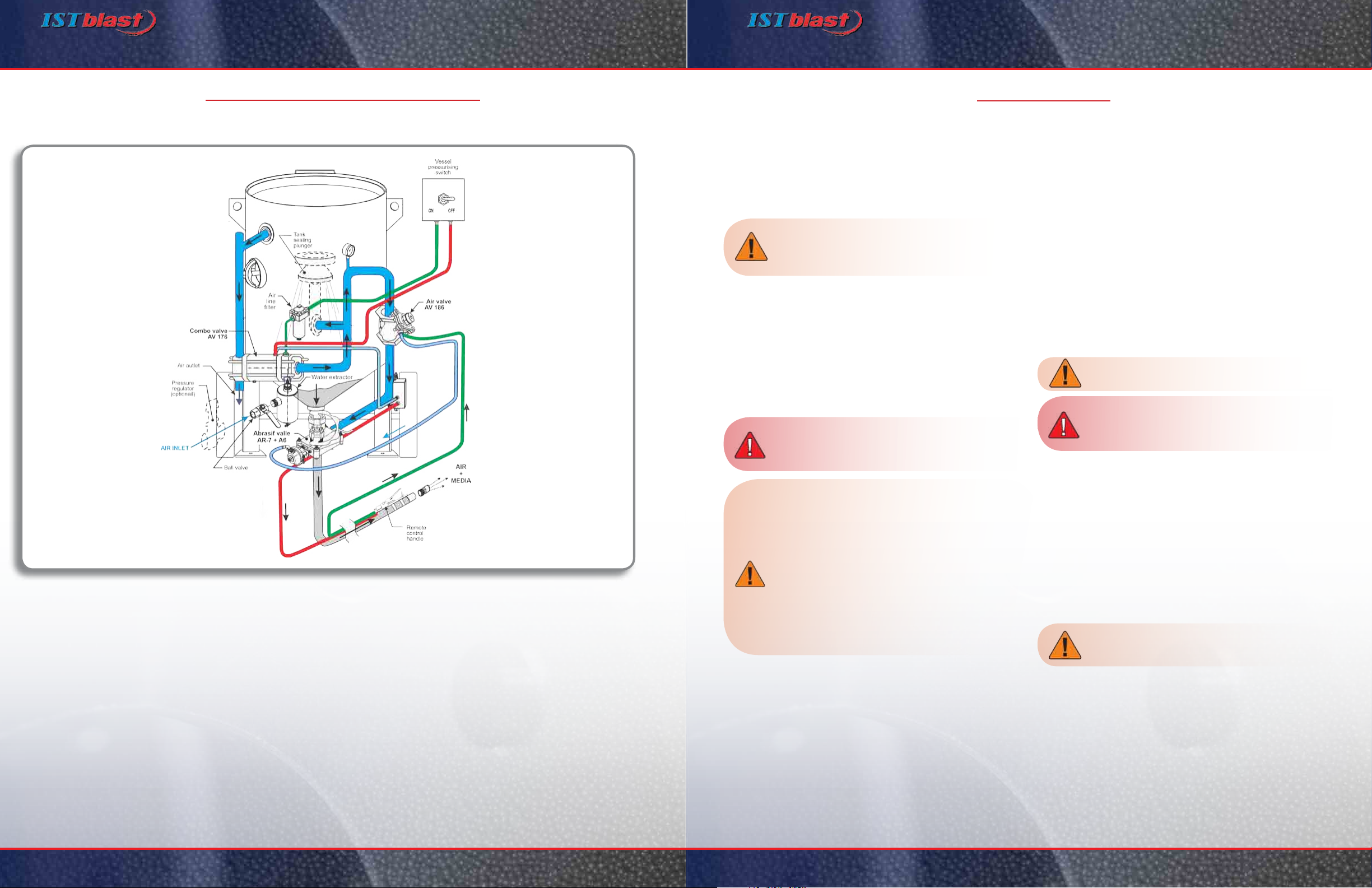

10. Service Air Valve AV-186

Disassemble and clean the valve. Check for worn components and make sure it is working properly.

Replace any worn components. Lubricate with an anti-seize compound before reassembly.

11. Service Combination Valve AV-176

Disassemble and clean the valve. Check for worn components and make sure it is working properly.

Replace any worn components. Lubricate with an anti-seize compound before reassembly.

12. Service Control Valve(s)

Disassemble and clean the valve(s). Check for worn components and make sure everything is working

properly. Replace any worn components. Lubricate with an anti-seize compound before reassembly