International

Surface

Technologies

istsurface.com

L

eader

in

spray

booths

International

Surface

Technologies

istsurface.com

L

eader

in

spray

booths

2

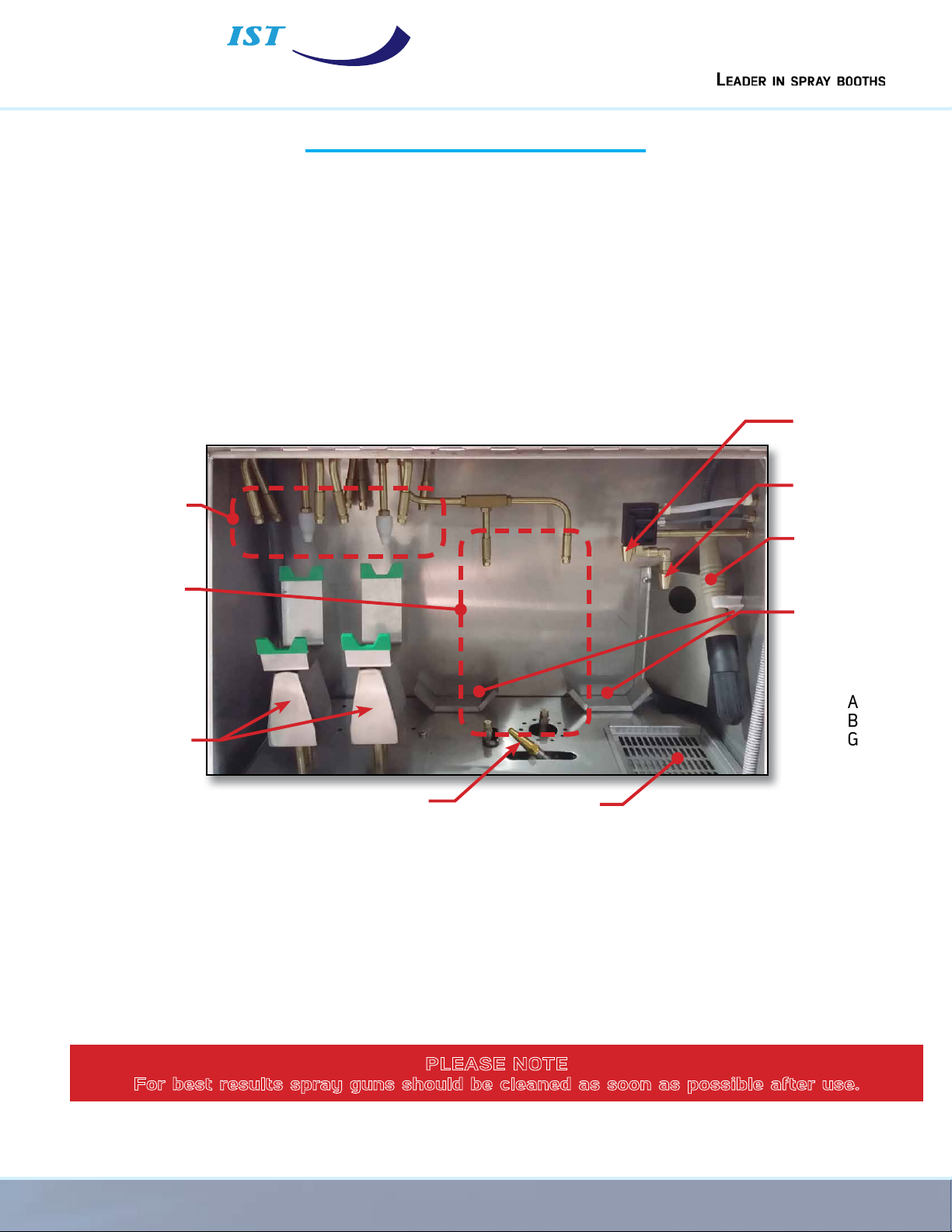

Spray gun cleaner Type GWMA 500

Page

TABLE OF CONTENTS

SETTING THE MACHINE UP...................................................................................................................................................... 3

MAINTENANCE SCHEDULE ..................................................................................................................................................... 3

INSTALLATION OF CONTAINERS ............................................................................................................................................ 4

EXHAUST INSTALLATION .......................................................................................................................................................... 5

AIR EXHAUST INSTALLATION .................................................................................................................................................. 5

AIR INLET CONNECTION ........................................................................................................................................................... 5

USING THE MACHINE : OPERATION...................................................................................................................................... 6

OPERATING THE CLEANER ....................................................................................................................................................... 7

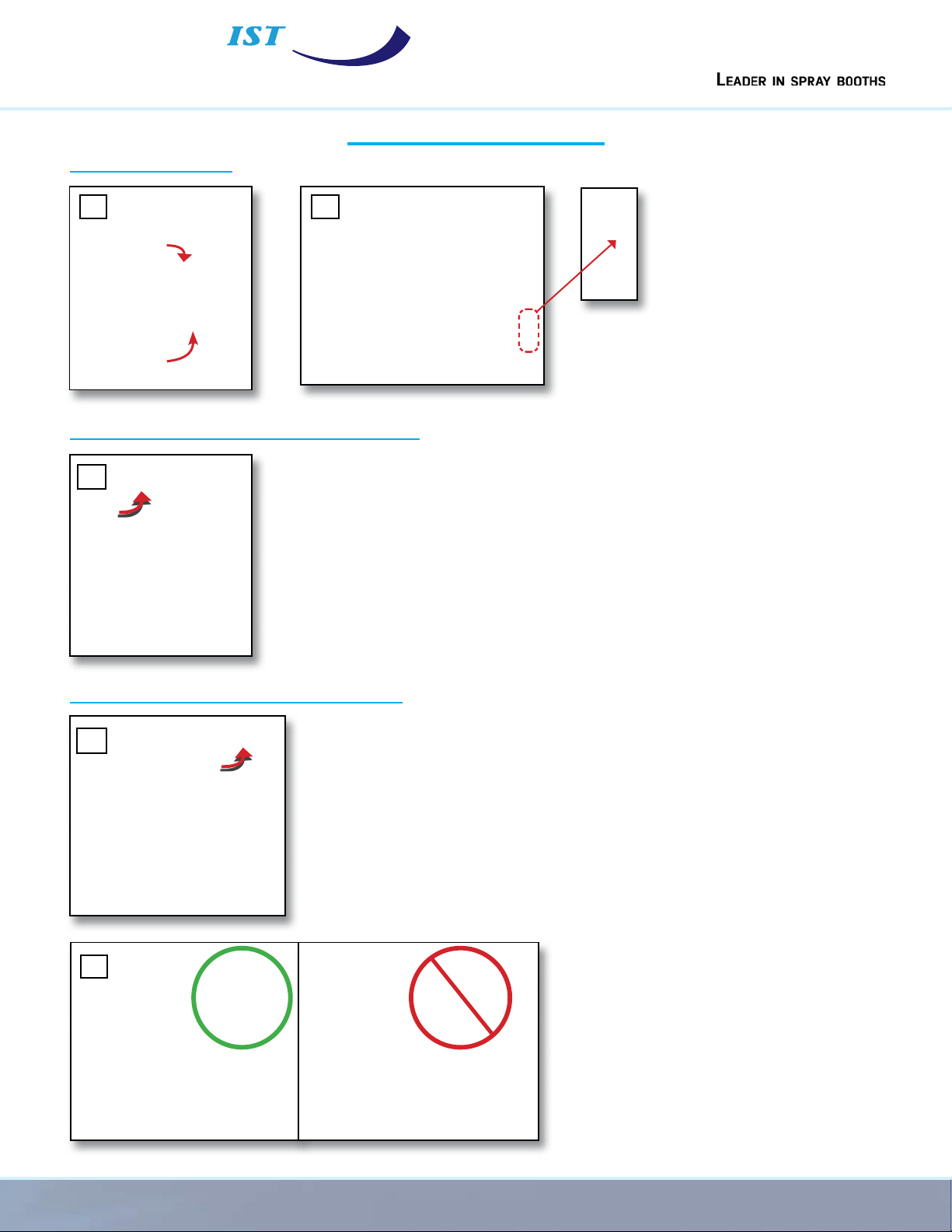

AUTOMATIC WASH..................................................................................................................................................................... 7

MANUAL WASH USED SOLVENT/WATER........................................................................................................................ 7

RINSING WITH CLEAN SOLVENT/WATER............................................................................................................................. 7

AUTO WASH GRAVITY SPRAY GUN .................................................................................................................................... 8

AUTO WASH SUCTION SPRAY GUN.................................................................................................................................... 9

MANUAL WASH .......................................................................................................................................................................... 10

BLUE FILTER ................................................................................................................................................................................... 11

HEALTH & SAFETY DATA SHEET ............................................................................................................................................ 12

AIR PIPING CIRCUIT .................................................................................................................................................................... 13

TECHNICAL SPECIFICATIONS ................................................................................................................................................. 13

EXPLODED VIEW & PARTS LIST............................................................................................................................................. 14

LIMITED WARRANTY.................................................................................................................................................................. 15

WARRANTY REGISTRATION .................................................................................................................................................... 16