28/06/2013 7CH4Q107_E_4

6

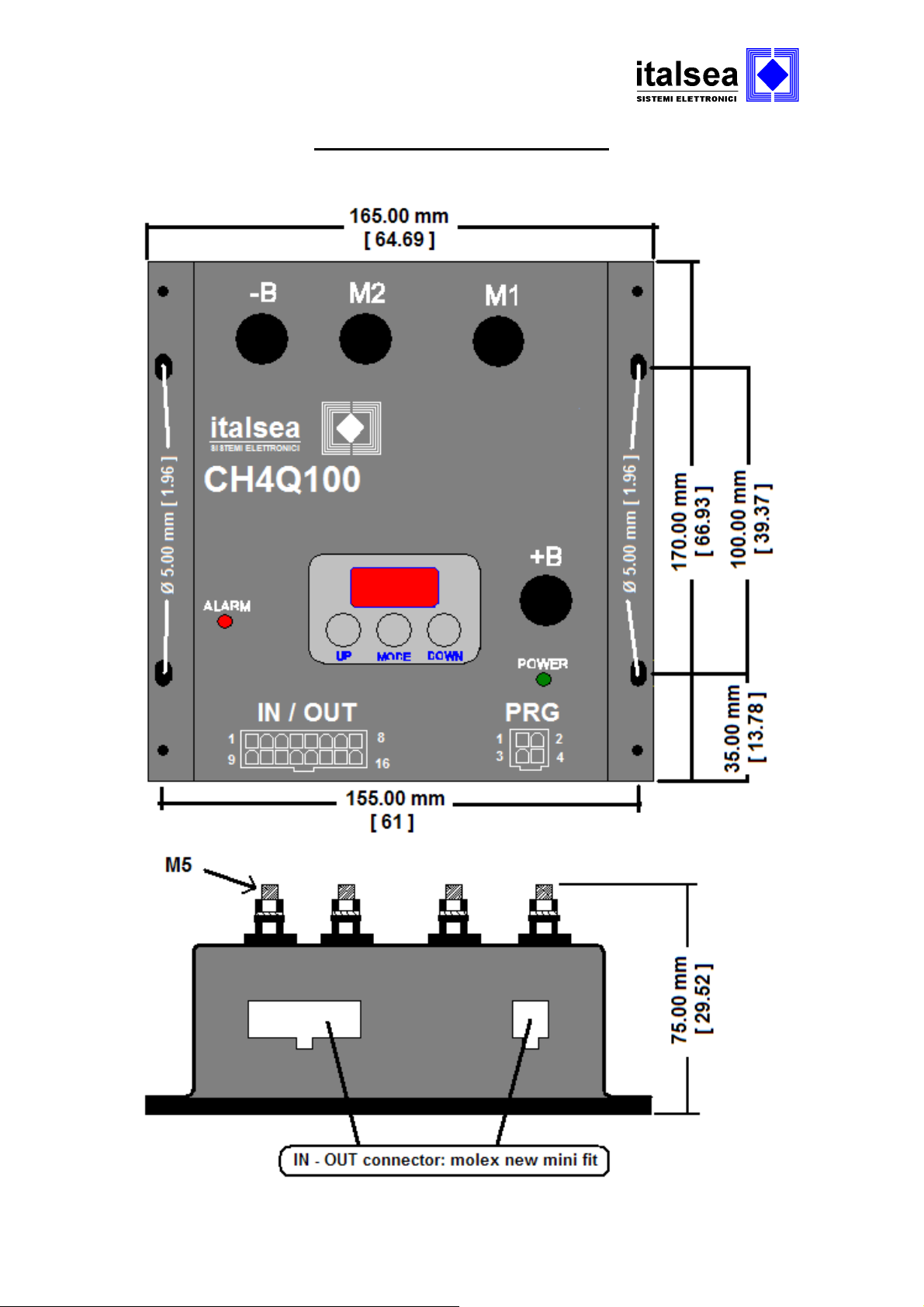

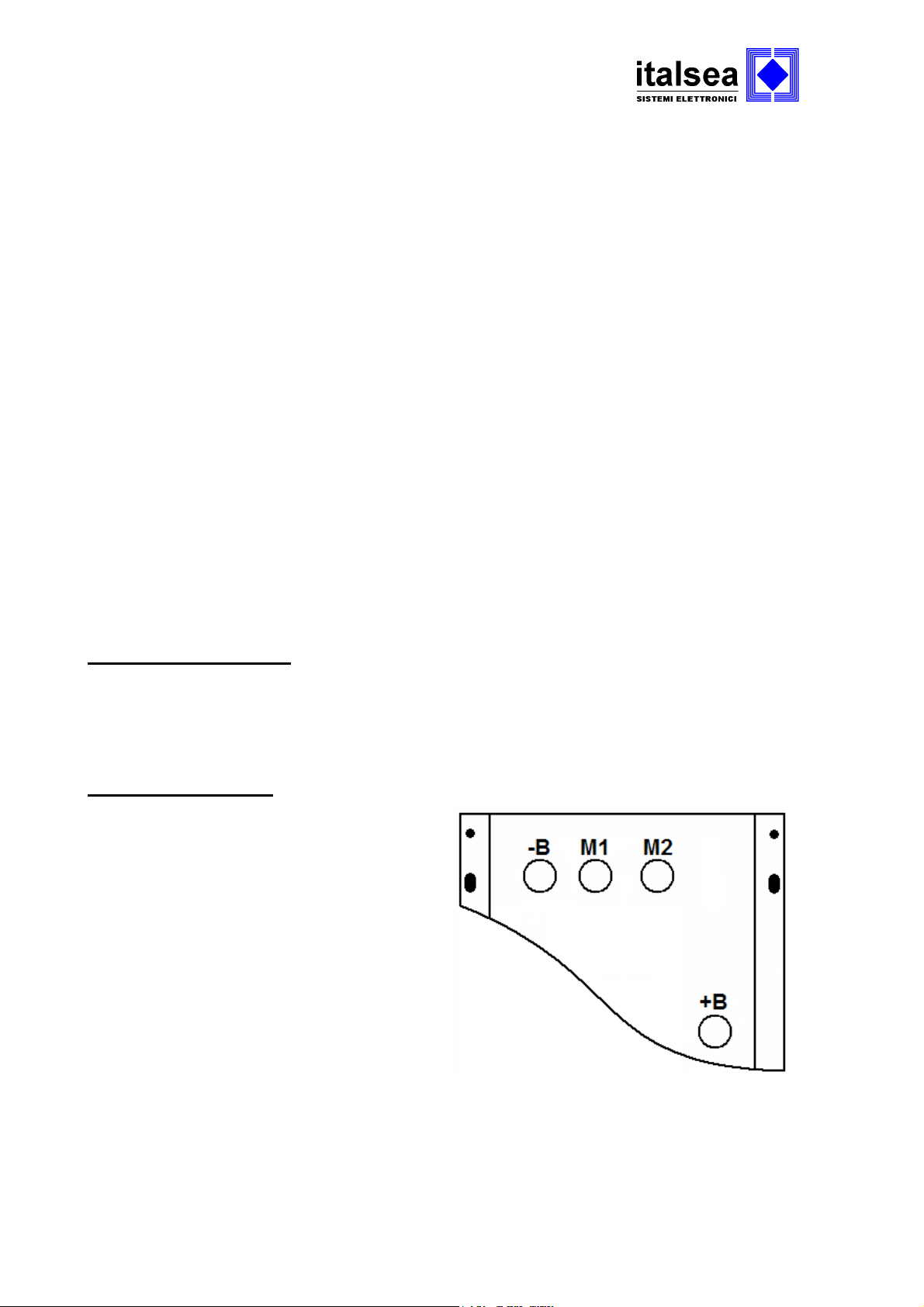

I/O CONNECTOR

16v Molex connector

(Molex p/n.39012160, contacts p/n.39000038)

fig.4

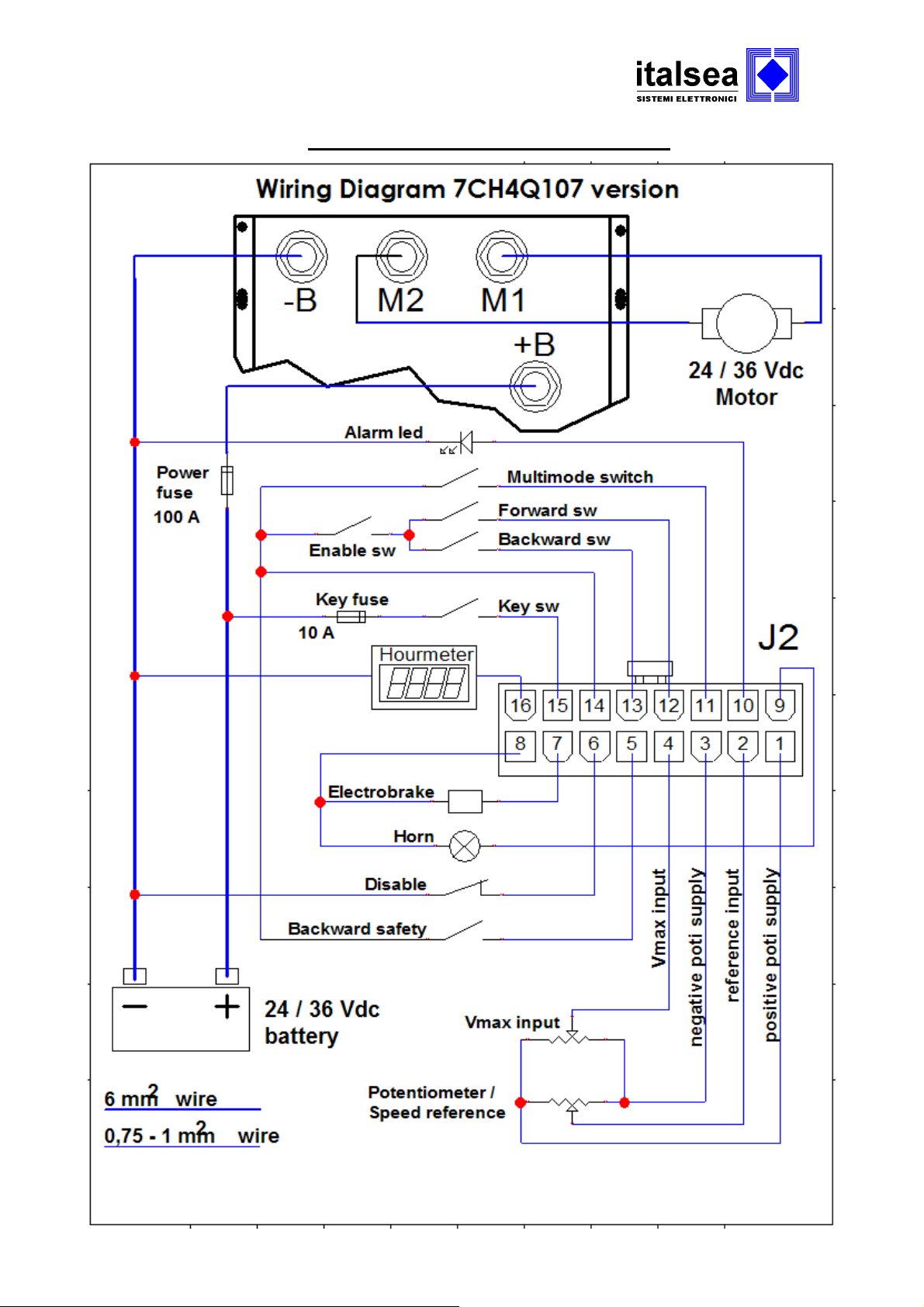

Pin 1: HI –POT. INPUT

Positive Potentiometer Supply

Pin 2: C-POT.INPUT

Central Potentiometer, or Voltage (0,5-4,5Vdc) Speed Reference Input

Pin 3: LO-POT.INPUT

Negative Potentiometer Supply, or Gnd Voltage Speed Reference Input

Pin 4: Pin 2:V_MAX (OPTIONAL)

Max speed input potentiometer (>100 KΩ).

Pin 5: PUSH

Default N.O. input contact ( +V_Batt/Pin14) for Backward safety. This input is

active when close.

Pin 6: DISABLE

Default N.C. input contact. When the contact is open the controller will decelerate

(Neutral Ramp) , will check if the motor voltage is near zero (motor stopped) and

after the electro-brake delay will inhibit the motor : appear the alarm A12 (to reset

switch-off and on again the key). If the contact will be close before the motor stop,

the machine will restart at the desired speed.

Pin 7: ELECTROBRAKE COIL ( - )

Output active low 2 Amps max (short circuit protected) and internal diode.

Pin 8: ELECTROBRAKE / HORN COIL (+)

Common +V battery for electro-brake and horn coils.

Pin 9: HORN ( - )

Output active low ( close to –Battery) for the horn or light backward direction

(2 Amps max, short circuit protected, and internal diode).