2

KGT 6 60 P20 – assembly guide

Contents

Symbols, safety .......................................................................................................................................................................................................2

General safety information ...................................................................................................................................................................................3

Correct use ...............................................................................................................................................................................................................3

Improper use.............................................................................................................................................................................................................4

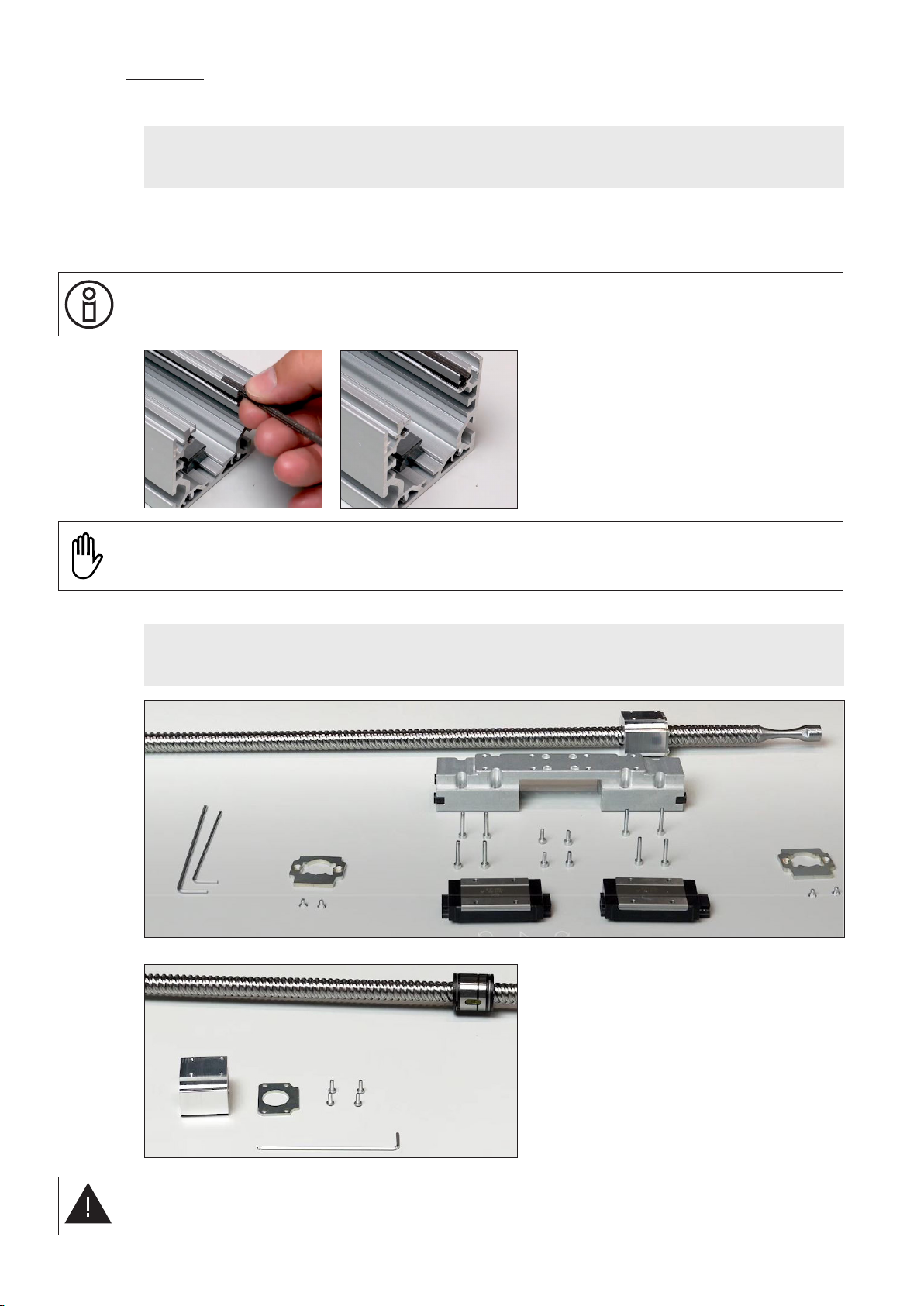

Product description.................................................................................................................................................................................................4

Technical data .........................................................................................................................................................................................................5

Preparing for assembly ..........................................................................................................................................................................................6

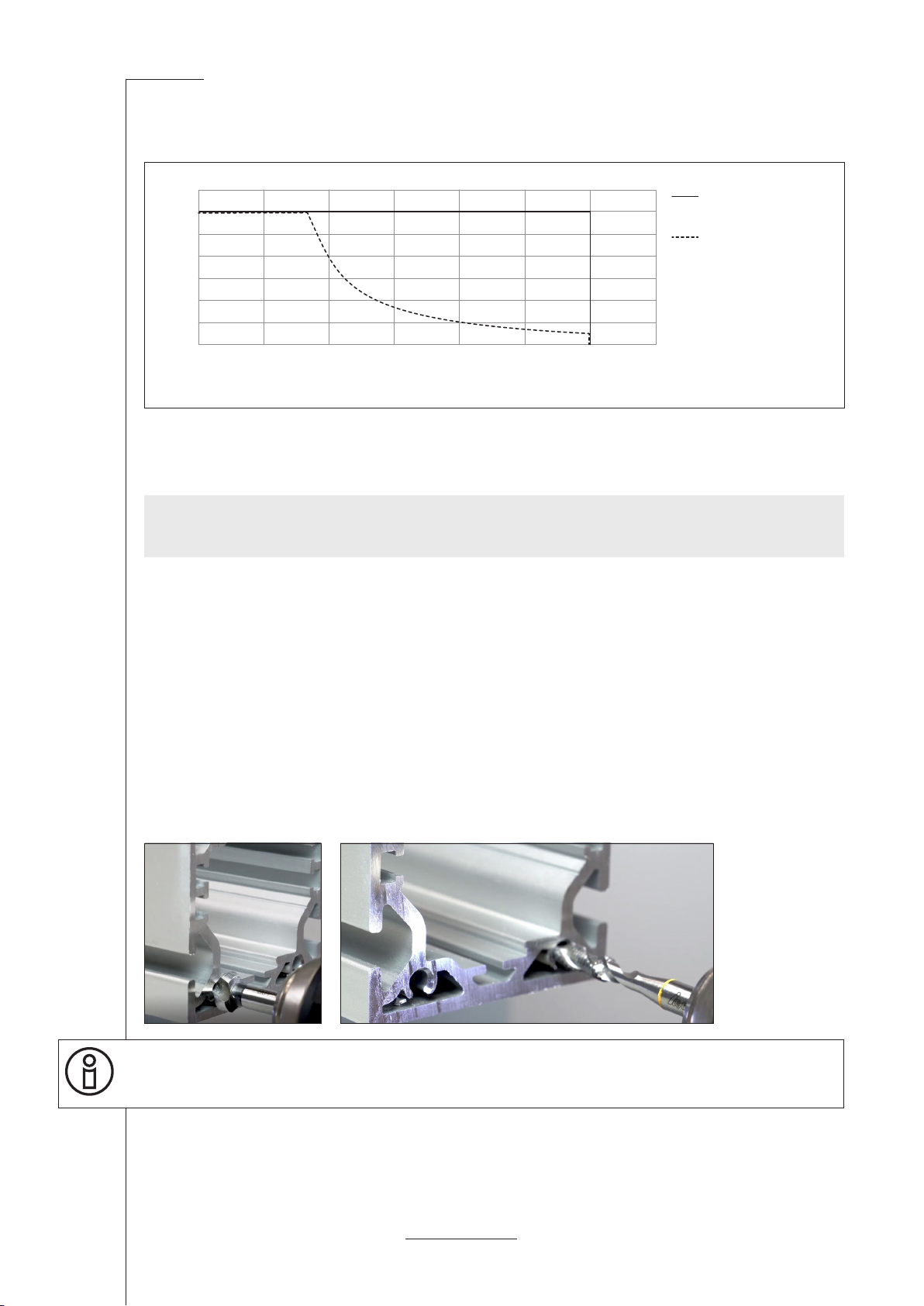

Fitting the spindle support stops..........................................................................................................................................................................7

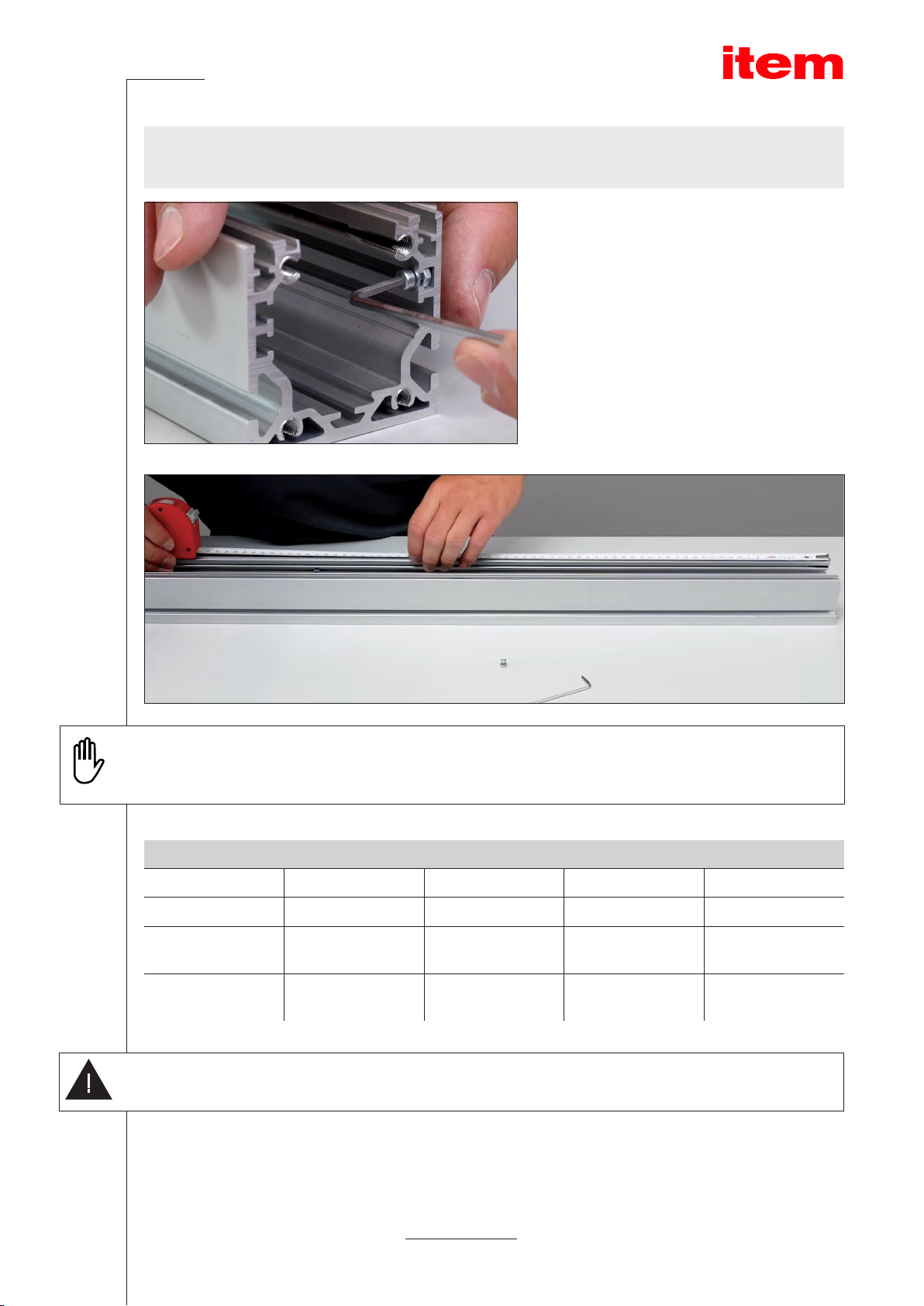

Fitting the linear guide rail.....................................................................................................................................................................................9

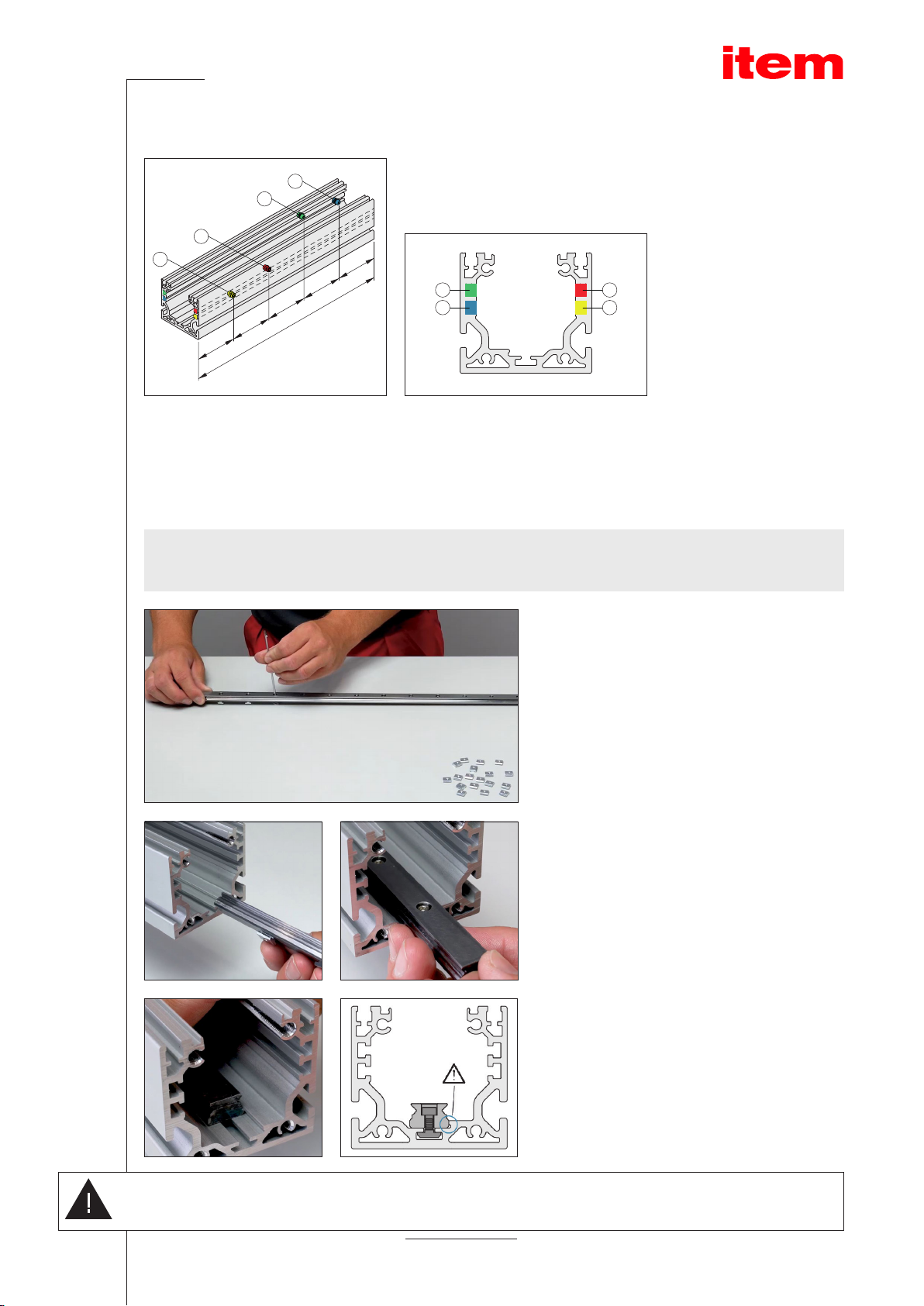

Fitting the magnetic strips.................................................................................................................................................................................. 10

Fitting the carriage ............................................................................................................................................................................................... 10

Number and positioning of spindle supports................................................................................................................................................. 12

Fitting the xed and oating bearings.............................................................................................................................................................. 14

Fitting the steel strip............................................................................................................................................................................................. 15

Fitting Cover Prole LE 6 .................................................................................................................................................................................... 17

Motor connection with Drive Set KGT 6 60.................................................................................................................................................... 18

Motor connection with Parallel Drive Set 6 60..............................................................................................................................................20

Precongured variants ....................................................................................................................................................................................... 21

KGT 6 60 P20 accessories ................................................................................................................................................................................22

Proximity Switch KLE 6........................................................................................................................................................................22

Cover Prole 6 LE .................................................................................................................................................................................22

Dealer conguration and spare parts list........................................................................................................................................................23

Checklist .................................................................................................................................................................................................................26

Repair and maintenance .... ...............................................................................................................................................................................26

Care and cleaning.................................................................................................................................................................................................26

Disposal .................................................................................................................................................................................................................27

Product development and documentation .................................................................................................................................................... 27

Symbols, safety

Important information

Observe directions for disposal

Observe directions for disposal

Maintenance

Note! Failure to observe this safety instruction can result in material damage

Warning! Failure to observe this safety instruction can result in material damage, serious injury or death

Caution! Failure to observe this safety instruction can result in material damage, serious injury or death

Caution! Failure to observe this safety instruction can result in material damage or injury