in the O-ring groove on the top of the base and place the

china bowl on the base in the desired orientation relative to

the pump assembly. Place one plastic washer (to protect

the china), then one stainles steel washer on each machine

screw and attach the remaining hex nuts to secure the

bowl to the base. Cap each machine screw and nut with a

white decorative nut cap.

Position the toilet assembly in its intended installed position.

When locating the toilet, ensure there is adequate

clearance above and to the rear of the bowl so the seat

and lid assembly can rotate slightly past vertical and will

remain up when lifted. Once the exact position for the toilet

has been determined, mark the location of the three base

attachment holes on the toilet mounting surface.

Determine the best toilet attachment method using 1/4"

(6mm) fasteners (either machine screws for through

bolting or lag screws for topside atttachment) and drill the

appropriate size holes for the fasteners being used. If

securing the toilet with lag screws into a plywood

underlayment below fiberglass, be sure to drill a hole

through just the fiberglass layer large enough to allow

clearance for the screw threads and shank to avoid

cracking the fiberglass.

To make the water connection, shut off the water system

pump and open one of the systems faucets or fixtures to

drain the pressure from the system. Select an appropriate

tee type fitting that can be installed in the existing

pressurized water system and will provide a 1/2" (13mm)

hose barb to feed water to the toilet. Install the tee fitting at

a location on the pressurized water system that provides

convenient connection to the toilet’s solenoid valve/siphon

breaker assembly. If the toilet is being connected to the

vessel’s fresh water system and the vessel may be

connected to an unregulated city water supply, it is

recommended that a valve be installed in the toilet water

supply line ahead of the solenoid valve/siphon breaker to

regulate the flow rate of incoming pressurized city water.

The solenoid valve/siphon breaker should be positioned a

minimum of six inches above the hose connection at the

back of the toilet bowl (at all angles of heel and trim) and

located as close to the toilet as possible. It should be located

where an occasional drop or two of water from the siphon

breaker will not adversely affect nearby equipment or

supplies. It must be installed in a vertical position with the

hose barb connections pointing down. The solenoid

valve/siphon breaker bracket should be secured to a solid

mounting surface with four screws. If the valve assembly is

attached to a wood surface, 3/8" (10mm) long screws are

generally adequate to support the weight of the valve

assembly. If desired, the valve assembly may be installed

inside a cabinet or locker to conceal it from view of the

vessel’s occupants.To provide a clean sanitary appearance

inside the head area, a six foot section of smooth white

hose is provided with the toilet to connect the toilet bowl

spud fitting to the siphon breaker outlet hose barb.

The solenoid valve inlet hose barb is then connected with

1/2" (13mm) reinforced vinyl hose suitable for pressurized

water to the tee fitting installed in the water system line.All

pressurized water system connections should be secured

with stainless steel band type hose clamps. The 3/4"

hose connecting the siphon breaker to the bowl should be

secured with a band clamp at the siphon breaker to prevent

it from being accidentally dislodged but generally does not

need a hose clamp to secure it to the bowl spud fitting

unless desired for added security.

The discharge port includes a 1" (25mm) hose barb and

should be plumbed with 1" (25mm) hose to an on board

holding tank or, if appropriate, to an overboard discharge

through hull. A 1" (25mm) to 1-1/2" (38mm) barbed hose

adaptor is provided to adapt a 1" (25mm) discharge hose

to 1-1/2" (38mm) hose, if desired. The discharge plumbing

should be kept as short as possible and bends in the

discharge hose should be kept to a minimum. To retain

water in the bowl, the discharge hose should be looped

upward about eight to ten inches above the base of the

toilet and as near to the toilet as can be practically

accomplished without creating an unsightly plumbing

situation.

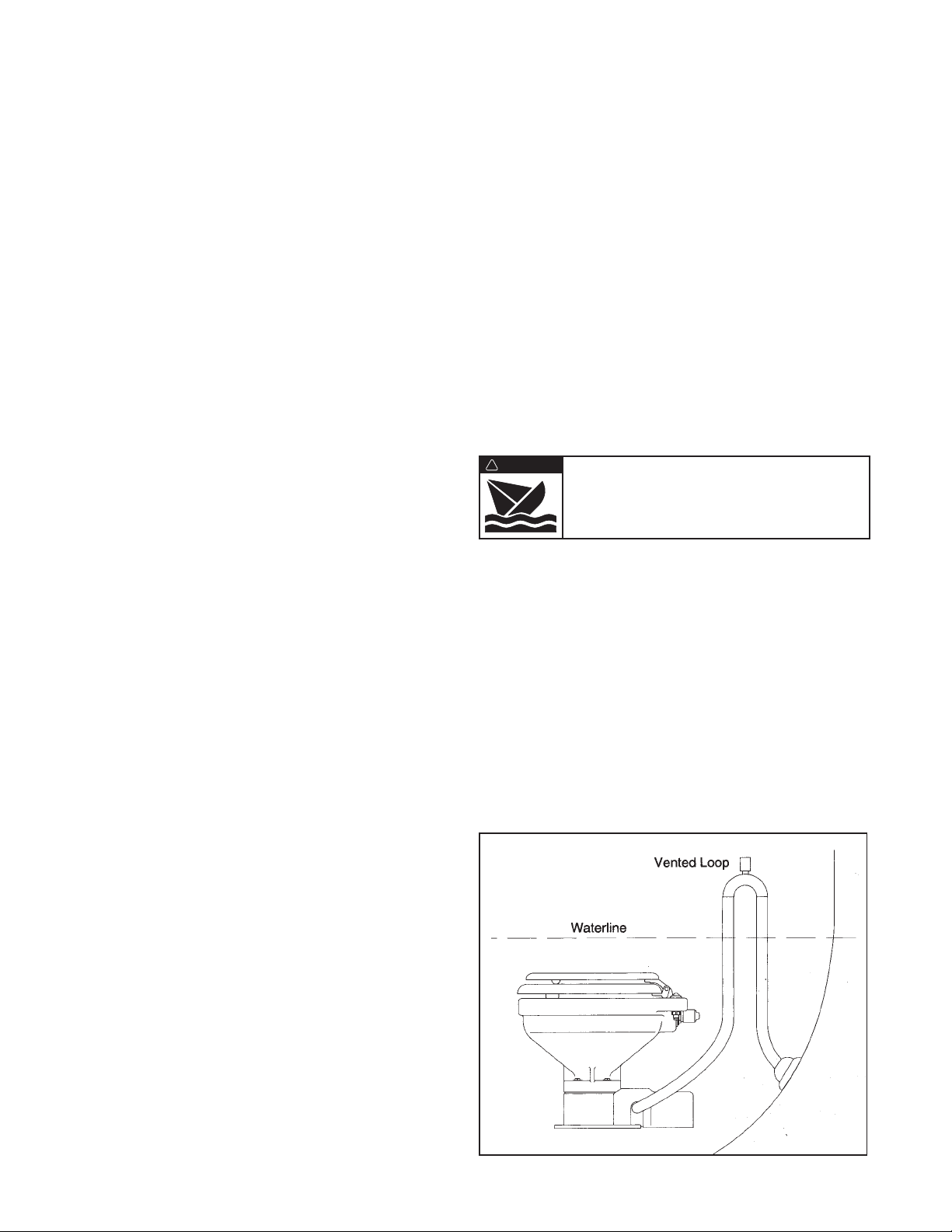

If the toilet is below the water line and is plumbed to an

overboard discharge through hull, the discharge plumbing

must include a vented loop positioned so it remains

above the water line at all angles of heel and trim. Total

discharge head should not exceed 4 feet (1.2M).

ELECTRICAL

The electrical wiring should be independent of all other

accessories. It should be made with marine grade copper

stranded wire of the gauge specified in the electrical

specifications chart. Make all wire connections with

mechanical locking type connectors (crimp type butt

connectors and terminals). Ensure the circuit is protected

by a proper sized fuse or circuit breaker determined from