diameter holes (slightly over-lapping) through the select-

ed switch mounting surface per the attached template.

Ensure the template is oriented correctly because it is

not symmetrical. Also, drill four appropriate sized holes

for the fasteners selected to secure the switch panel to its

mounting surface.

WASTE PUMP SERVICE

The Jabsco Quiet-Flush Toilet does not require routine

maintenance other than occasional cleaning to maintain a

hygienic sanitary condition. Clean toilet with mild non-abra-

sive cleaners without strong aromatics. Cleaners having

high concentrations of aromatics such as pine scented

concentrated cleaners and strongly scented degreaser

concentrates can cause the pump’s seal to swell and may

contribute to a premature seal leak. The toilet has no wear-

ing parts that need periodic replacement other than the

shaft seal which, under normal conditions, should provide

several years of service before needing replacement. The

seal only requires replacement if signs of leakage are

noticed around the base and rear of the toilet china bowl.

NOTICE: Before performing any service, turn off the

electrical power to the toilet and rinse water pump. Take

precaution to ensure it is not turned on until the service

is complete. Also, pump all water from the toilet bowl

and if connected to an overboard discharge, close the

discharge seacock.

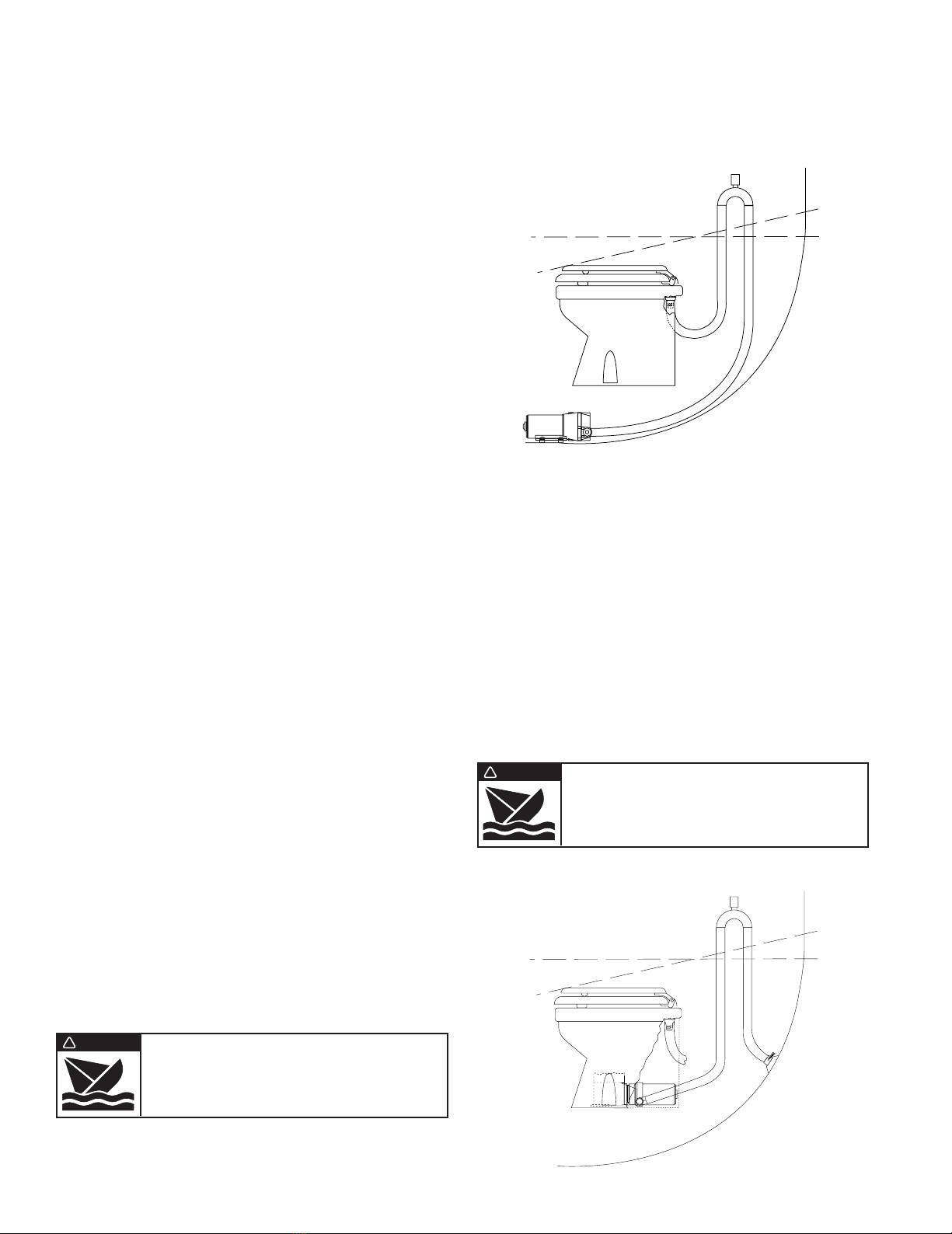

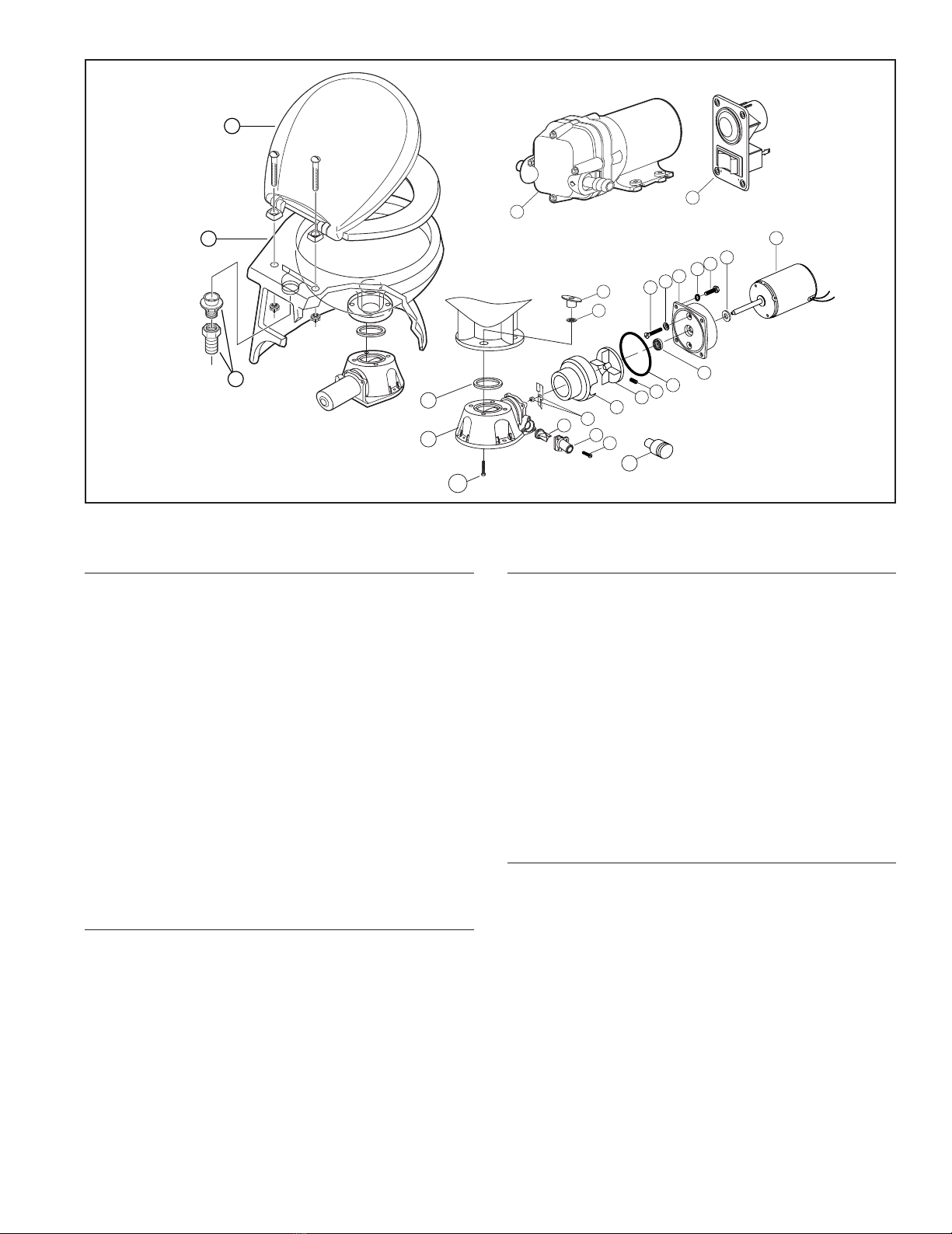

To replace the shaft seal, remove the two toilet hold-

down screw caps and remove the hold-down screw nuts.

Carefully lift the toilet up and away from the bulkhead at

it’s rear. Remove the pump assembly by removing the

four screws with lock washers that secure it to the plas-

tic toilet base. Carefully slide the pump assembly from

the base ensuring the macerator housing also slides out

of the base with the pump. The pump chopper will

engage the macerator housing and it may be necessary

to gently tap the chopper against the macerator housing

to free it from the base.

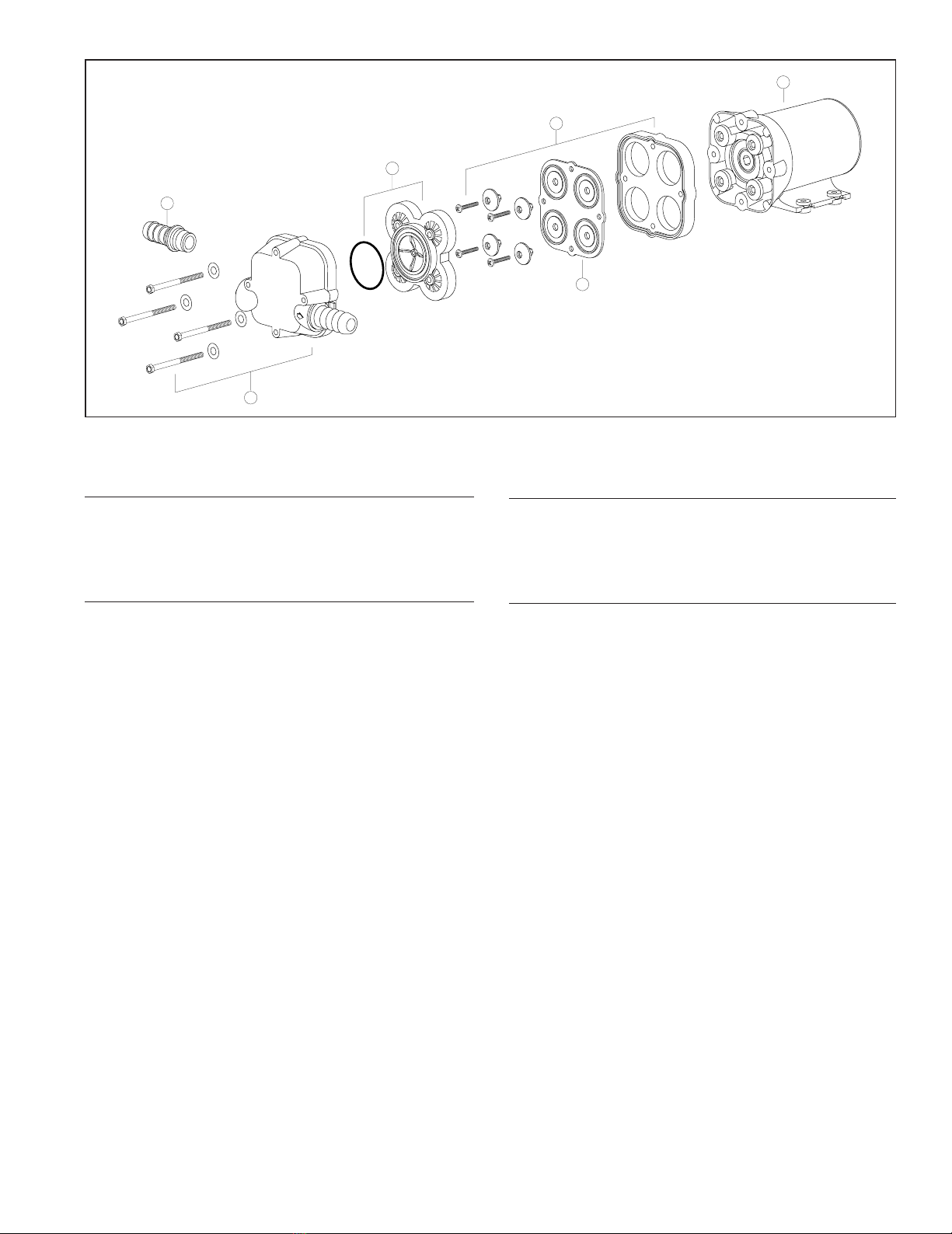

Prevent the motor shaft from turning by inserting a

screwdriver in the shaft slot at the rear of the motor and

remove the self locking nut. Remove the chopper and

macerator housing from the motor shaft. Remove the

O-ring from the O-ring groove around the outer diameter

of the seal housing. With an allen wrench, loosen the

centrifugal impeller set screw and slide the impeller off

the shaft. Remove the two screws that secure the seal

housing to the motor and slide the housing off the motor

shaft. Remove the two seal washers from under the

head of each of the two seal housing retainer screws.

With a pair of needle nose pliers, grasp the shaft seal

and pull it from the seal housing. Clean all parts and

inspect for damage.

Lubricate the OD of the new seal with a small amount of

water and press it into the seal bore with the seal’s lip fac-

ing the threaded end of the shaft. Do not use the stain-

less steel star retaining washer supplied with the seal.

Lubricate the ID of the seal and the motor shaft with a

small amount of water resistant grease. Ensure the

slinger is properly positioned on the motor shaft next to

the motor and slide the seal housing onto the motor shaft

until it is against the motor end bell. Position a new plas-

tic seal washer under the head of each of the flat head

seal housing retainer screws and secure the seal hous-

ing to the motor. Slide the centrifugal impeller on the

motor shaft positioning it about 1/32"(1 mm) from the

seal housing and secure it to the shaft with the set

screw. Rotate the impeller to ensure it does not rub on

the seal housing.

Slide the macerator housing over the motor shaft. Place

the chopper on the shaft with the tab on the flat of the

shaft. Install the self locking nut and tighten firmly while

holding the motor shaft at the rear of the motor. Position

a new O-ring in the seal housing O-ring groove (it may

be retained in the groove with a small amount of grease).

Slide the pump assembly into the toilet base ensuring

the macerator housing is properly positioned within the

base. The cut-out in the side of the macerator housing

must align with the discharge port in the base (the

macerator housing is keyed so it will only go in when

properly positioned). Ensuring the O-ring is still properly

positioned in the O-ring groove in the seal housing,

place the pump assembly against the base and secure it

in place with the four screws and lock washers.

Carefully lift the toilet and position over the two hold-

down screws using caution not to chip or break the china.

Secure the toilet down with the hold-down nuts and

washers ensuring the plastic washer is next to the china.

Do not overtighten hold-down nuts.