Installation, Operation and Maintenance Instruction

Model ICB

ICB 100-english page 1

Revision 02

Article No 771076102

Issue 01/2010

TABLE of CONTENTS

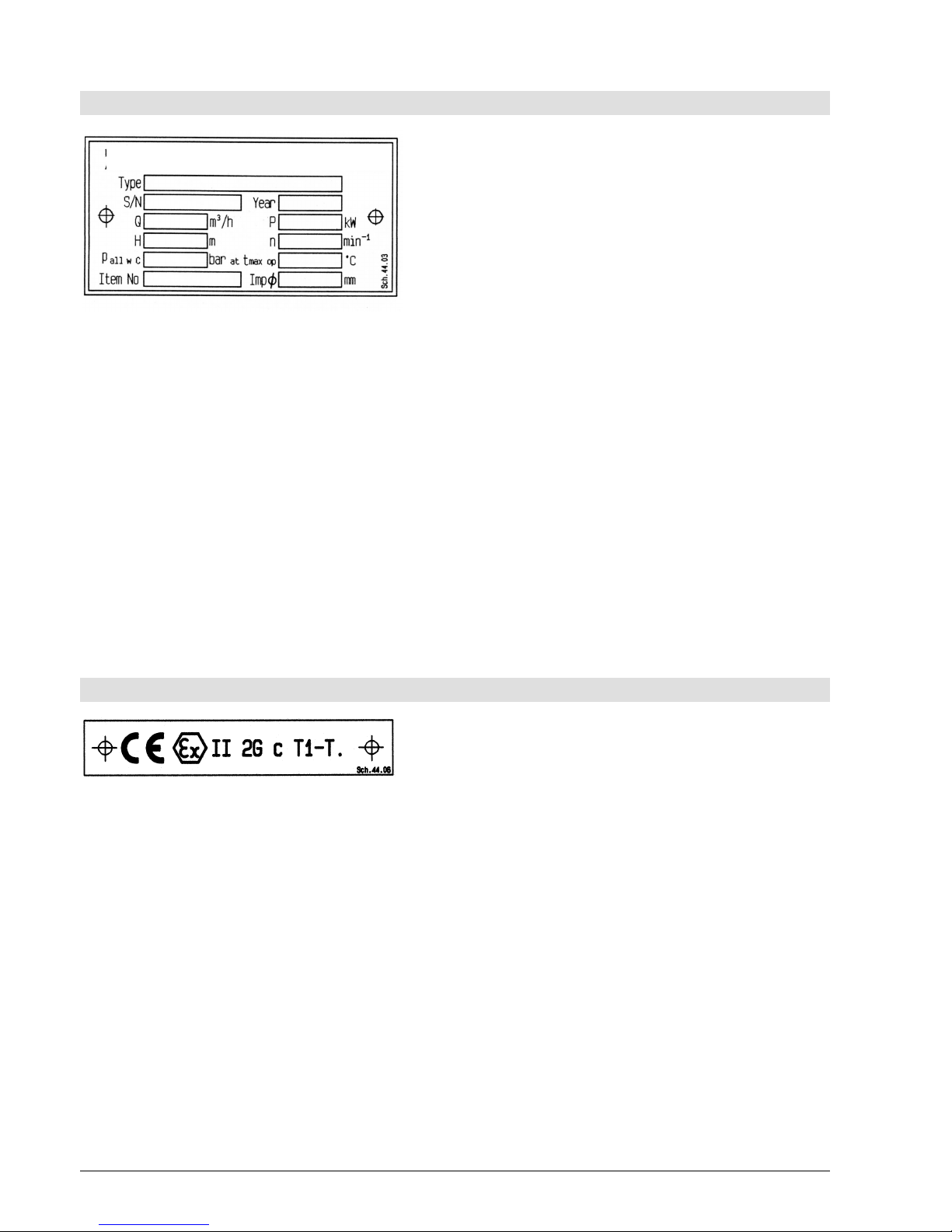

Pump Name Plate ..................................................... 2

ATEX-Label (only for pumps in compliance with

EC directive 94/9/EG)................................................ 2

1. General................................................................... 3

1.1 Guarantee ......................................................... 3

2. Safety Regulations ............................................... 3

2.1 Marking of References in the Operating

Instructions.............................................................. 3

2.2 Dangers of non-observance of the Safety

Instructions.............................................................. 4

2.3 Safety Instructions for the Operator / Worker ... 4

2.4 Safety Instructions for Maintenance, Inspections

and Mounting Work ................................................. 4

2.5 Unauthorized Alteration and Spare Parts

Production ............................................................... 4

2.6 Undue Operation............................................... 4

2.7 Explosion Protection.......................................... 4

2.8 Use acc. to Regulations .................................... 6

3. Description ............................................................ 6

3.1 Design ............................................................... 6

3.1.1 Design Coding System................................... 6

3.2 Shaft Sealing ..................................................... 7

3.3 Bearing .............................................................. 7

3.4 Approximate Value for Sound Pressure Level .. 7

3.5 Permitted Nozzle Loads and Torques at the

Pump Nozzles ... ..................................................... 7

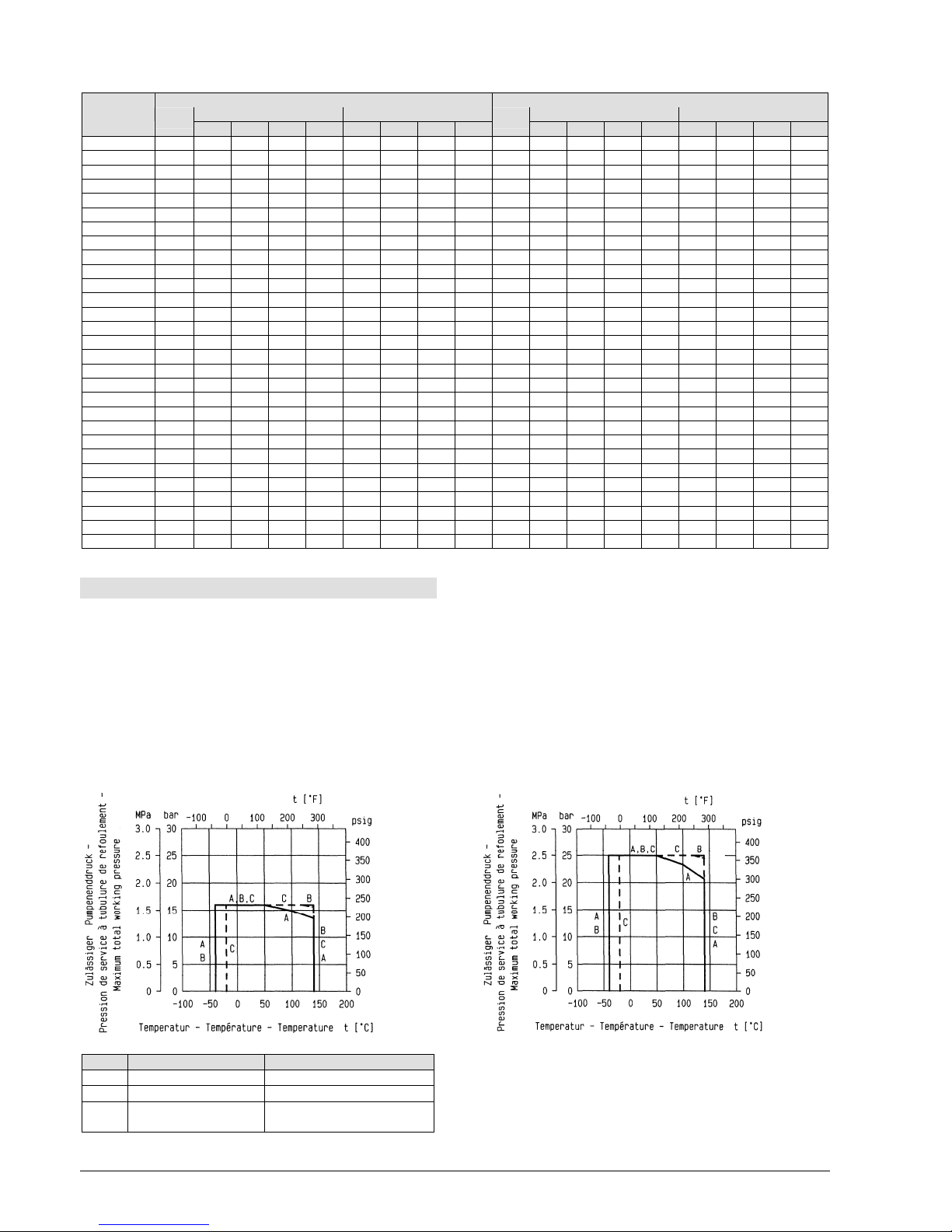

3.6 Permitted pressures and temperatures............. 8

3.7 Condensate ....................................................... 9

4. Transport, Handling, Storage .............................. 9

4.1 Transport, Handling........................................... 9

4.2 Storage / Conservation...................................... 9

5. Mounting / Installation ......................................... 9

5.1 Mounting of Pump / Unit.................................... 9

5.2 Connection of Pipings to the Pump................. 10

5.3 Drive................................................................ 10

5.4 Electric Connection ......................................... 10

5.5 Final Control .................................................... 11

6. Start-up, Operation, Shut down ........................ 11

6.1 Initial start-up................................................... 11

6.2 Switch on drive................................................ 11

6.3 Restarting ........................................................11

6.4 Limits of Operation ..........................................11

6.5 Lubrication .......................................................12

6.6 Monitoring ........................................................12

6.7 Shutting down ..................................................12

6.8 Storage / longer periods of non-operation .......12

7. Servicing, Maintenance ......................................13

7.1 General remarks..............................................13

7.2 Mechanical seals .............................................13

7.3 Motor bearings.................................................13

7.4 Cleaning of pump ............................................13

8. Dismantling and repair of pump ........................13

8.1 General remarks..............................................13

8.2 General............................................................13

8.3 Removal and Installation of screen in the motor

lantern....................................................................13

8.4 Removal of the Back Pull Out Assembly .........14

8.5 Removal of Impeller.........................................14

8.6 Removal of Shaft Sealing ................................14

8.7 Removal of Stub Shaft.....................................14

8.8 Reconditioning .................................................15

8.9 Mounting ..........................................................15

9. Spare parts, Spare pumps..................................16

9.1 Spare parts ......................................................16

9.2 Stand-by pumps...............................................16

10. Faults - Causes and Solutions.........................17

11. Motor Operating Instructions ..........................18

Installation Manual - Single mech. seal without shaft

sleeve (Design code S1..2) .......................................20

Installation Manual - Single mech. seal with quench

without shaft sleeve (Design code S4..2) ………...... 22

Sectional drawing pump unit (Design code S1..2),

Impeller with back vanes.......................................... 25

Sectional drawing pump unit (Design code S1..2),

Impeller with balancing holes ................................... 26

Sectional drawing pump unit (Design code S4..2),

Impeller with back vanes.......................................... 27

Sectional drawing pump unit (Design code S4..2),

Impeller with balancing holes ................................... 28

Connections ............................................................. 29

Dimensional drawing................................................ 30